Professional Documents

Culture Documents

Pump Motor Test

Uploaded by

JHON CHRISTOPHER CENTINO0 ratings0% found this document useful (0 votes)

3 views1 pageOriginal Title

PUMP MOTOR TEST

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views1 pagePump Motor Test

Uploaded by

JHON CHRISTOPHER CENTINOCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 1

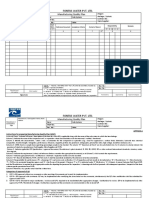

Date Conducted :

Control No. :

MOTORS / PUMP TESTING FORM

PROJECT :

LOCATION :

Trade:

Mechanical ✘ Fire Protection Electrical Plumbing / Sanitary

Attachment:

Plan Diagram Product Data Methodology Calibration Certificate Mill Certificate

Bldg. # / Loc. : Brand / Contractor :

Equipment No. : Model/Serial No. :

Type/ Rating :

DATA DESIGN / SPECS ACTUAL PASS FAIL REMARKS

1. Model number/brand see Product Data same

2. Serial number see Product Data same

3. Capacity (lps) see Product Data same

4. TDH (mm h20) see Product Data same

5. Motor drive

5.1 Power (kw) see Product Data to be tested Note: if Failed - Testing must be Retested

5.2 Volts see Product Data to be tested

L1 - L2 see Product Data to be tested Subcontractor / Supplier must conduct initial or

L2 - L3 see Product Data to be tested internal testing first before notice for final test

L3 - L1 see Product Data to be tested

5.3 Ampere (FLA/Starting/Running)

L1 see Product Data to be tested

L2 see Product Data to be tested

L3 see Product Data to be tested

5.4 Phase see Product Data same

6.5 Cycle see Product Data same

6. Pump RPM see Product Data same

7. Operational set points

7.1 Suction pressure (psi) see Product Data to be tested

7.2 Discharge pressure (psi) see Product Data to be tested

7.3 Diff pressure (psi) see Product Data to be tested

8. Pump type see Product Data same

9. Impeller diameter (mm) see Product Data same

10. Overload rating see Product Data same

11. Functional Test of Motor see Product Data to be tested

CONDUCTED BY: WITNESSED BY: APPROVED BY: NOTED BY:

(Supplier & Contractor Representative) ( MEPF / Client) (QA / QC) ( PIC / PM / MEPF HEAD)

DISTRIBUTION : Subcon Document Control Client

You might also like

- Process Flow Fmea Control PlanDocument5 pagesProcess Flow Fmea Control Plansudeep_singh1No ratings yet

- VDA PPF Report FormDocument8 pagesVDA PPF Report FormMohamed KhalifaNo ratings yet

- Appendix 11F: Operational ChecklistsDocument15 pagesAppendix 11F: Operational Checklists许爱文No ratings yet

- VDA Volume 2 - Annex 5 / Cover Sheet: Sender Recipient Submission LevelDocument1 pageVDA Volume 2 - Annex 5 / Cover Sheet: Sender Recipient Submission LevelJuliaNo ratings yet

- Cooper Industries PPAP Forms KitDocument25 pagesCooper Industries PPAP Forms KitAshutosh SinghNo ratings yet

- PG Test Report Rev 01-SignedDocument84 pagesPG Test Report Rev 01-SignedK R Kumar RanjanNo ratings yet

- PS - Copy of Supplier PSODocument11 pagesPS - Copy of Supplier PSODesmond MahadeoNo ratings yet

- Control Plan-General SampleDocument7 pagesControl Plan-General SampleMartin PetricNo ratings yet

- Cover Sheet: Attachements / Items For Inspection Product / ProcessDocument6 pagesCover Sheet: Attachements / Items For Inspection Product / ProcessSeval GünaltayNo ratings yet

- PLUMBING FIXTURES FORMS Rev. 2Document1 pagePLUMBING FIXTURES FORMS Rev. 2JHON CHRISTOPHER CENTINONo ratings yet

- RO-RG80-00031 - Rev H, JPPAP Templates (Jabil Production Part Approval Process)Document38 pagesRO-RG80-00031 - Rev H, JPPAP Templates (Jabil Production Part Approval Process)KM MuiNo ratings yet

- E21-C Motor Operated ValveDocument2 pagesE21-C Motor Operated Valveyskushwah16No ratings yet

- GDC QF 003 - Allegion PPAP Workbook: Instructions: Fill Out Requested Information in TheDocument31 pagesGDC QF 003 - Allegion PPAP Workbook: Instructions: Fill Out Requested Information in TheAbhijit shindeNo ratings yet

- Deckblatt - : First Sample Test Report VDADocument9 pagesDeckblatt - : First Sample Test Report VDAJuliaNo ratings yet

- SWT Lab4Document37 pagesSWT Lab4Manh Hieu NguyenNo ratings yet

- Level 2 m200 Pahu Qa-Qc ChecksDocument10 pagesLevel 2 m200 Pahu Qa-Qc ChecksAnurag KumbhareNo ratings yet

- Engineering Change / Process Change Request Form: MDT ApprovalDocument4 pagesEngineering Change / Process Change Request Form: MDT ApprovalRaja Durai100% (2)

- Control PlanDocument11 pagesControl PlanRadhika GuptaNo ratings yet

- 28 - Uninterrupted Power Supply (Ups)Document8 pages28 - Uninterrupted Power Supply (Ups)jigyeshNo ratings yet

- Be-Pdp-Fr-07-E Papso Form Roanoke To Waybo120809Document21 pagesBe-Pdp-Fr-07-E Papso Form Roanoke To Waybo120809Ricardo Frank CordeiroNo ratings yet

- Project Handover Check List: Page 1 of 5Document5 pagesProject Handover Check List: Page 1 of 5Mohammed Al DissoukyNo ratings yet

- PPAP Workbook TemplateDocument18 pagesPPAP Workbook TemplateRaju.PalNo ratings yet

- Bps Product Certification Scheme Surveillance Audit Form: Company ProfileDocument1 pageBps Product Certification Scheme Surveillance Audit Form: Company ProfileLenin Rey PolonNo ratings yet

- Sample PPAP Level-3Document36 pagesSample PPAP Level-3Mr. Mafia BhargavNo ratings yet

- TER Elevated Water TankDocument1 pageTER Elevated Water TankBenjie AlfelorNo ratings yet

- 4M Change - FormatDocument1 page4M Change - Formatmurali4095No ratings yet

- E10-002 Dry Transformer InspectionDocument8 pagesE10-002 Dry Transformer InspectionAtika SekarNo ratings yet

- Mixing Devices Mixers Agitators Etc Supply Verification ITPDocument8 pagesMixing Devices Mixers Agitators Etc Supply Verification ITPVarun Malhotra100% (1)

- Manufacturing Quality Plan (MQP)Document2 pagesManufacturing Quality Plan (MQP)Ranjit Singh100% (3)

- Manufacturing Quality Plan (MQP)Document2 pagesManufacturing Quality Plan (MQP)Ranjit SinghNo ratings yet

- Manufacturing Quality Plan (MQP)Document2 pagesManufacturing Quality Plan (MQP)Ranjit SinghNo ratings yet

- Package Name Factory Acceptance Test Check Sheet Shutdown Valve, Blow Down Valve Inspection & Installation Instrument I-010 Rev 0Document1 pagePackage Name Factory Acceptance Test Check Sheet Shutdown Valve, Blow Down Valve Inspection & Installation Instrument I-010 Rev 0Musab ShabbirNo ratings yet

- Production Analysis and Work Flow For GLDocument20 pagesProduction Analysis and Work Flow For GLkwonilNo ratings yet

- MFG Process Audit ReportDocument1 pageMFG Process Audit ReportBASAVA ENGINEERINGNo ratings yet

- User Guide-ProdDiag For Sucker Rod Pump PDFDocument25 pagesUser Guide-ProdDiag For Sucker Rod Pump PDFViorica SîrghiiNo ratings yet

- Inspection and Test Plan For Shell and Tube Heat Exchanger - Sample01Document3 pagesInspection and Test Plan For Shell and Tube Heat Exchanger - Sample01Mohamed AtefNo ratings yet

- Number: Weight (KG)Document2 pagesNumber: Weight (KG)secretNo ratings yet

- Level 2 M020 Pumps QA-QC ChecksDocument10 pagesLevel 2 M020 Pumps QA-QC ChecksAnurag KumbhareNo ratings yet

- Tech Spec For Centrifugal PumpDocument5 pagesTech Spec For Centrifugal PumpRoby Mirza100% (1)

- ANPQP Category 6 Product ConfirmationDocument7 pagesANPQP Category 6 Product Confirmationjefry sitorusNo ratings yet

- PM-CY-DLI-SOP-257 Cal TEOM Rev.1Document7 pagesPM-CY-DLI-SOP-257 Cal TEOM Rev.1Nayyar MahmoodNo ratings yet

- 4M Change ManagementDocument2 pages4M Change ManagementManoj KumarNo ratings yet

- Test Plan TemplateDocument17 pagesTest Plan TemplateDhiraj PatilNo ratings yet

- Insp. Test Plan - Rev01Document2 pagesInsp. Test Plan - Rev01kapsarcNo ratings yet

- Ipp 260 EcoDocument25 pagesIpp 260 EcoYoosu NguyenNo ratings yet

- Exhibit D3 Inspection and Test Plan (ITP)Document12 pagesExhibit D3 Inspection and Test Plan (ITP)Muhammad Ali AkbarNo ratings yet

- Inspection Report (IR) : Key Point(s)Document3 pagesInspection Report (IR) : Key Point(s)nathan pagotoNo ratings yet

- AIAGDocument29 pagesAIAGGunNandaTianPurnamaNo ratings yet

- TA1 Visual Inspection Form Master - Track-Type TractorDocument11 pagesTA1 Visual Inspection Form Master - Track-Type TractorCarlosNo ratings yet

- TA1 English - Generator SetDocument13 pagesTA1 English - Generator Setahmad adelNo ratings yet

- Supplier 8D FormDocument3 pagesSupplier 8D FormBen DesireNo ratings yet

- PPAP Fourth Edition 2006Document5 pagesPPAP Fourth Edition 2006Đại Hữu Tuấn MaiNo ratings yet

- Delivery Report Form BreakerDocument1 pageDelivery Report Form BreakerAkbarNo ratings yet

- Cpap 0124CDocument2 pagesCpap 0124CmaruthaiNo ratings yet

- Inspection and Test Plan: Fabrication / In-Process InspectionDocument17 pagesInspection and Test Plan: Fabrication / In-Process InspectionGLEDSON100% (1)

- Paddle Switch CombinedDocument10 pagesPaddle Switch CombinedPriyanshu GuptaNo ratings yet

- Boiler Control Systems Engineering, Second EditionFrom EverandBoiler Control Systems Engineering, Second EditionRating: 4.5 out of 5 stars4.5/5 (15)

- Handbook of Microwave Component Measurements: with Advanced VNA TechniquesFrom EverandHandbook of Microwave Component Measurements: with Advanced VNA TechniquesRating: 4 out of 5 stars4/5 (1)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Megger Test FormDocument1 pageMegger Test FormJHON CHRISTOPHER CENTINONo ratings yet

- PLUMBING FIXTURES FORMS Rev. 2Document1 pagePLUMBING FIXTURES FORMS Rev. 2JHON CHRISTOPHER CENTINONo ratings yet

- Smoke Leak Testing FormDocument1 pageSmoke Leak Testing FormJHON CHRISTOPHER CENTINONo ratings yet

- Traverse Reading Testing FormDocument1 pageTraverse Reading Testing FormJHON CHRISTOPHER CENTINONo ratings yet

- JVCVReport1215 PDFDocument1 pageJVCVReport1215 PDFUlises BadilloNo ratings yet

- Design and Fabrication of Mini Solar RefrigeratorDocument4 pagesDesign and Fabrication of Mini Solar RefrigeratorMr.Aung Kyaw SoeNo ratings yet

- Power Systems Analysis - Bee 21 & Bew 21Document3 pagesPower Systems Analysis - Bee 21 & Bew 21zy44cwfjjgNo ratings yet

- E510 Startup Installation ManualDocument147 pagesE510 Startup Installation Manualpermitha sariNo ratings yet

- Exercise 04Document22 pagesExercise 04Shreyas SudhirNo ratings yet

- 02disconnector Catalogue 2015 CompressedDocument12 pages02disconnector Catalogue 2015 CompressedBachtiar RamadhanNo ratings yet

- Segura 2017 Seismic Performance Limitation of Slender Reinforced Concrete Structural WallsDocument268 pagesSegura 2017 Seismic Performance Limitation of Slender Reinforced Concrete Structural WallsDavid VallejoNo ratings yet

- Catalogue Iskra KNKDocument20 pagesCatalogue Iskra KNKSỹ TháiNo ratings yet

- 2 GasesDocument51 pages2 Gasesnirvanjain212007No ratings yet

- Milliohm Meter MODEL 16502Document4 pagesMilliohm Meter MODEL 16502hil96No ratings yet

- As 5100.6-2017 Steel and Composite ConstructionDocument337 pagesAs 5100.6-2017 Steel and Composite ConstructiontracyhopyNo ratings yet

- Tie-In List (Epcc-09) : DOC. NO.: IBCE-6373-471-PRS-IFD-000-0001Document3 pagesTie-In List (Epcc-09) : DOC. NO.: IBCE-6373-471-PRS-IFD-000-0001srini100% (1)

- PPF4 - Ultrasonic Phaser Pain Field Generator: Basic Device DescriptionDocument16 pagesPPF4 - Ultrasonic Phaser Pain Field Generator: Basic Device DescriptionAndreas KNo ratings yet

- Carnot's Theorem PDFDocument17 pagesCarnot's Theorem PDFAsif Mahmoud100% (1)

- UT Outline Training LV IIIDocument4 pagesUT Outline Training LV IIITrung Tinh HoNo ratings yet

- Tedom CHP UnitsDocument2 pagesTedom CHP UnitsMadhav RathourNo ratings yet

- FR601 - FR607: 6.0A Fast Recovery RectifierDocument3 pagesFR601 - FR607: 6.0A Fast Recovery RectifierWALTER DAVID TAPIA HERNÁNDEZNo ratings yet

- BTech Alloy Weld On Instructions WebDocument1 pageBTech Alloy Weld On Instructions Webwalid mahmoudNo ratings yet

- Solutions Manual Metal Forming MechanicsDocument5 pagesSolutions Manual Metal Forming MechanicsJoão Paulo100% (1)

- BOTIL Product CatalogueDocument176 pagesBOTIL Product CataloguenappyNo ratings yet

- Manual 2WBDocument4 pagesManual 2WBAlfredo Zambra Alarcón Alias MorroNo ratings yet

- Technical Data Sheet: Vacuum Pump V-100Document6 pagesTechnical Data Sheet: Vacuum Pump V-100Palak AgarwalNo ratings yet

- Artificial Neural Network Method For Solving The Navier-Stokes EquationsDocument9 pagesArtificial Neural Network Method For Solving The Navier-Stokes EquationsMuhammad Imran KhanNo ratings yet

- Lab 5B - P4-11Document1 pageLab 5B - P4-11Nacho BusinessNo ratings yet

- SandDocument2 pagesSandObaidurRahamanNo ratings yet

- Electrical Installation Level 2 Cl. 1 (June 2022) - InstructorDocument4 pagesElectrical Installation Level 2 Cl. 1 (June 2022) - InstructorGuyan GordonNo ratings yet

- Composite and Inverse FunctionsDocument24 pagesComposite and Inverse Functions52064No ratings yet

- Structural Design of A Water Intake Tower Located Inside A ReservoirDocument10 pagesStructural Design of A Water Intake Tower Located Inside A ReservoirArifullah WazirNo ratings yet

- LSI Bollard Series Spec Sheet 11-84Document2 pagesLSI Bollard Series Spec Sheet 11-84Alan MastersNo ratings yet

- 1.0 Fire CharacteristicDocument24 pages1.0 Fire CharacteristicYunxuan KwanNo ratings yet