Professional Documents

Culture Documents

WMS For Pile Load Test - Draft

Uploaded by

Hemant YesajiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WMS For Pile Load Test - Draft

Uploaded by

Hemant YesajiCopyright:

Available Formats

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

NAME OF WORK: “DESIGN AND CONSTRUCTION OF ELEVATED VIADUCT OF LENGTH 8.027 Km

(CH: -0.675 Km to -0.050 Km & CH: 11.137 Km to 18.350 Km) INCLUDING RAMPS AND

FORMATION IN EMBANKMENTS /CUTTINGS INCLUDING BLANKETING, MAJOR BRIDGES,

MINOR BRIDGES, RUB, ROB, ROR, RETAINING WALL, SACRIFICIAL RETAINING WALL AND

DRAINS, UTILITY DIVERSIONS OF AT-GRADE SECTION OF LENGTH 17.551 Km (CH: -0.964 Km to

CH:-0.675 Km, CH: -0.050 Km to CH: 11.137 Km & CH: 18.350 Km to 24.425 Km) AND OTHER

RELATED INFRASTRUCTURAL WORKS FROM BENNIGANAHALLI TO CHIKKABANAVARA,

EXCLUDING STATION BUILDINGS, OF CORRIDOR - 2 OF BENGALURU SUBURBAN RAILWAY

PROJECT (BSRP)”

CONSTRUCTION WORK METHOD STATEMENT

FOR

PILE LOAD TESTS

|1 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

REVISION RECORD SHEET

Rev.

Date Description of Change

No.

02/11/202

R0 New preparation

3

Prepared by Reviewed and Approved by

QMS Co-Ordinator (Project) Project In charge

Name:

Date:

Signature:

|2 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

TABLE OF CONTENTS

Sl.No Page no Description

1 1

2 2

3 3

4 4

5 4

6 4

7 5

8 5

9 8

10 9

11 10

12 11

13 11

14 12

15 14

16 16

17 18

18 18

19 19

20 20

21 20

22 21-28

23 29-39

24 40-42

25 43-51

|3 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

INTRODUCTION:

The Bangalore suburban rail project is the first Suburban network planned to be

constructed in Karnataka. The BSRP corridor 2 Project line connects Benniganahalli to

Chikkabanavara, Elevated Viaduct of length 8.027Km (CH: -0.675 Km to -0.050 Km & CH:

11.137 km to 18.350 Km) including ramps and formation in Embankments /Cuttings

including Blanketing, Major Bridges, Minor Bridges, RUB, ROB, ROR, Retaining Wall,

Sacrificial Retaining Wall and Drains, Utility Diversions of At-Grade section of length

17.551 Km (CH: -0.964 Km to Ch: -0.675 Km, CH: -0.050 Km to CH: 11.137 Km & CH:

18.350 Km to 24.425 Km)

Corridor 2 Package of BSRP project is awarded to L&T Construction it starts from Ch. -

0.964 km at Vadodara to Ch. 24.425 km. The alignment of the BSRP Corridor 2 package is

shown in the below figures.

|4 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

Fig.2 BSRP Corridor-2 Alignment plan

2. SCOPE

The scope of this method statement includes the detailed procedure for conducting the

different types of pile load tests, testing frequency and EHS Risk Assessment.

3. REFERENCES

a. Clause No. 8.7 of Section 8B, Technical Specifications of Employer’s Requirement.

b. IS 2911 (Part 4)

4. ACTIVITY STEP WISE.

Geotechnical Investigation & Analysis of results

Type of pile load test to be done shall be decided

Details of equipment to be used shall be decided

Preparation of test setup, pile testing scheme along with detailed design, drawings

Mobilization of all necessary equipment, machinery etc. at site

Test Bore and Installation of test piles (for initial load test)

Pile load test to be done as per section 97 of this WMS, based on the type of test

selected

Preparation & Submission of Test Results

Analysis of Test Results

Pile approved (if results are found in order), Remedial/Corrective Actions to be taken (if test

resultstest results are unsatisfactory)

5. Activity Organisation

Section in-charge

Piling-charge QA&QC Engineer EHS Engineer P&M Engineer

Site – Engineer Surveyor Approved testing Agency

|5 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

6. Staff Responsibilities:

6.1 Section-In-Charge:

• Reports to Project Manager

• Plan’s resources in his area and make them available at site

• Responsible for monitoring the implementation of adopted safe practices, quality assurance

processes and quality control measures.

• Responsible to achieve work productivity by proper planning of finalising testing locations.

• Responsible for time cycle & achievement for the day for activities

• Responsible to have latest revisions of approved drawings at site

• Responsible to submit, take approval and implement work procedures

• Initiates and applies all safety norms and work practices

• Interacts with Customer for approvals.

• Corresponds with Customer complaints in time, quality, safety and cost of Construction

within 07 (seven) days or their receipt

• Suggest and implement, improvements to product quality

6.2 PILING In-charge:

Reports to the Section In-charge, Project Manager for day to day activities.

Site Engineer

Plans the test movement sequence according to the week programme.

Involves in preparation of plan of test along with Approved testing agency and with

Client’s representative.

Interfacing with internal departments like Planning, Quality, Plant & Machinery,

Safety and Stores for operation of activities.

Ensures to implement safety and Quality requirements.

Responsible for resources.

Prepares his work schedule based on Project schedule.

Monitors to achieve the set program.

6.3 Site Engineers:

Reports to Piling In-charge

Responsible for executing the work by adopting safe practices, housekeeping, quality

assurance processes and achieve required degree of quality control.

Responsible for arranging and attending all internal and Customer’s inspections against

RFIs.

Executes the shift related activities

Follow latest approved drawings

Responsible to cross check the pile location

Imparts in Safety and Quality Pep talks.

|6 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

Interacts with Approved agency for testing, Surveyor, QA/QC team and EHS team for

better implementation of activities in his/her area of work

6.4 Surveyor:

Report to Shift-In-Charge

Responsible for executing the work by adopting safe practices, housekeeping, quality

assurance processes and achieve required degree of quality control in surveying.

Ensures only calibrated survey instruments are used in construction

Responsible for marking levels and fixing coordinates of the structure

Responsible for marking of centreline lines of piles, pile-caps and piers.

6.5 QA/QC Engineer:

Reports to QA/QC-In-Charge

Coordinate/Supervise with Site team.

Co-ordinate with the testing agency for tests conforming to specified frequency

Identify and raises non-conformances, in case of works/activities not meeting the

specification requirements

6.6 P&M Engineer:

Reports to P&M-In-Charge

Responsible for plant operation, availing the required fuel, oils and mechanical for smooth

running of plant.

Attends incidental breakdowns immediately

Ensures lock-out and tag-out system while attending breakdown and/or maintenance

Suggest and implement, improvements to product quality

6.7 EHS Engineer:

Reports to EHS-In-Charge

Involves in regular pep-talks and periodical demonstrations of safety practices at plant area

as well as site

Helps to provide necessary safety materials at the work location as per requirements

Implement EHS system at plant & site

Coordinate and arrange flagmen at entry-exits of construction vehicles

Ensures the site is illuminated sufficiently, in case of night work is carried out

Identified/supervise safety lapses before the start of work and ensure the same are

corrected

Coordinate with site administration, first-aid, Doctor and hospitals during emergency

7. Man Power

|7 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

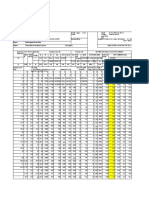

Sl.No Description Nos Per shift

1 Section in-charge 1

2 Piling in-charge 1

3 Site Engineer 1

4 Supervisor 1

5 Surveyor 1

6 Survey helpers 1

7 EHS Engineer 1

8 Safety steward 1

9 P&M Engineer 1

15 P&M Helpers 2

16 QA&QC Engineer 1

19 Helpers – site activity 4

20 Traffic marshal / flag men 2

8. Plant, Equipment, Tools and Tackles

Sl.

Description Capacity/Purpose

No.

Circular Steel Plate (>50mm

1 To protect pile cap from being crushed

thickness)

2 Datum Bars with dial gauges For settlement measurement

3 Kentledge (As per design req.) To apply required load

4 Anchor piles/rock anchors To obtain reaction load

5 Stopwatch For measuring time interval

Impact Hammer (as per design

6 For applying impact energy

requirement)

7 Hydraulic Jacks and pumps As required

8 Measurement device with sensors To accurately form signals up to 10 kHz

Mild steel Access Ducts (50mm,

9 To provide access for probes

150mm dia.)

|8 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

Refer Section 7.9.1 of this WMS for equipment required in Cross-Hole Sonic

10

Logging Test

Refer Section 7.9.2 of this WMS for equipment required in Low Strain Pile

11

Integrity Test

9. Procedure (Test on Piles).

9.1 Load Test on Piles

The hydraulic jack, pump, hoses, pipes, couplings and other apparatus to be operated

under hydraulic pressure shall be capable of withstanding a test pressure of one and a

half times the maximum working pressure without leaking.

The weight of kentledge shall be greater than the maximum test load and if the

weight is estimated from the density and volume of the constituent materials, an

adequate factor of safety shall be considered.

All the equipment and instruments shall be properly calibrated both at the

commencement and immediately after completion of tests, so that they represent true

values.

The complete jacking system including the hydraulic jack, hydraulic pump and

pressure gauge shall be calibrated as a single unit over its complete range of travel

for increasing and decreasing loads same as that of test loads. The calibration

certificate shall be submitted to the Engineer.

The reaction load for the test shall be at least 25% greater than the maximum jacking

force. The reaction system shall be designed for the total reaction load.

The vertical displacement of pile shall be measured using dial gauges having a least

count of 0.01 mm.

Load Test shall be conducted at the pile Cut-off-Level (COL). If the water table is

above the COL, the test pit shall be kept dry throughout the test period by

dewatering in an apt manner. In such cases, anchor piles and rock anchors may be

used for testing purposes. The COL might also be raised above the water table, if

permitted by the Engineer.

|9 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

9.2 Test Pile Installation

Test Pile Shall be installed as per Method Statement for Bored Cast in-situ Pile Construction.

9.3 Types of Tests

1. Initial vertical (compression) load test: The test shall be carried out on test piles to

assess the Ultimate Bearing Capacity of Pile before the commencement of the

installation of working piles. The test piles shall have the same design details as of

the working piles and be adopted in the predominant soil profile in that area. The test

shall be performed as per cyclic method as per IS2911-2013 (Part 4)

2. Routine vertical (compression) load test: The test shall be conducted to verify the

load carrying capacity of the working piles. The test can be conducted as per static or

dynamic method as per the codal guidelines.

3. Horizontal load test / Lateral Load Test: The test shall be conducted to verify the

horizontal load carrying capacity of the working/test piles.

4. Pile Integrity Test by Cross Hole Sonic Logging: The test shall be carried out on

25% of total piles.

5. Pile Integrity test by Low strain pile integrity test: Low Strain Pile Integrity Test (see

Section 7.9 of this WMS) to verify the structural integrity, shape and continuity of

pile.

6. Sonic Coring: In case of piles founded on rock, Sonic coring shall be conducted prior

to initial vertical (compression) load test to ascertain the soundness of the

concrete/rock interface. Core drilling of 50 mm diameter shall be carried below the

concrete/rock interface, in the 100 mm sonic tube fixed in the pile.

Each core taken from a pile shall be examined as follows –

(i) The concrete cores shall not show any evidence of honeycombing or segregation

of individual constituent materials.

(ii) Rock core shall conform with the required rock material specified in the

geotechnical report.

(iii) The cores shall be examined to confirm the adequacy of the interface between

concrete and rock.

|10 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

9.4 Frequency of Tests

At every one KM initial load tests both vertical and horizontal is to be performed for

initial tests pile, or as specified and directed by engineer to follow IS 2911 (Part 4):

2013. “Testing of piles should be as per IS 2911 (Part 4): 2013

Routine load test shall be carried out at 0.5% of the total number of piles as directed

by Engineer or One test at every 100 pile.

9.5 Testing-Piles

The testing-piles for routine load test shall be identified by the engineer,

Testing-pile head shall be prepared for testing purposes only one week after casting

the pile

Testing pile shall be cut off at the proper level to get the sound concrete uniformly

and provided with a proper cap with the higher grade of concrete, to provide a plane

bearing surface for the test plate and for proper arrangements for seating of the jack

and dial gauges.

If any initial pile load test gets abandoned and is not successfully completed, then

another test pile shall be installed and initial test repeated after making corrections.

|11 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

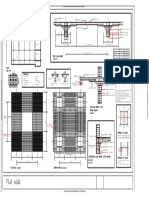

9.6 Static Vertical Load Test

The tests shall conform to IS: 2911-Part-4 and it shall be conducted by Cyclic

Method as per Annex A, clause.no 7.3..

Equipment and Test Setup –

(1) A steel plate of adequate thickness shall be centered on the pile cap to prevent

it from getting crushed under applied load. The size of the circular test plate

shall not be less than the pile size nor less than the area covered by the base of

the hydraulic jack(s).

(2) The datum bars shall be supported on immovable supports of concrete

pedestals or steel sections, placed sufficiently far away from the test pile. The

distance shall not be less than 3 times the diameter of testing-pile and in no

case less than 2 meters from the edge of the testing- pile. These supports shall

be placed at an adequate depth below ground to be unaffected by ground

movements.

• Loading System – The test load shall be applied in one of the following ways,

(1) By means of hydraulic jack(s) which obtain reaction from kentledge heavier than

the required test load. Care shall be taken to ensure that the center of gravity of

kentledge is on the axis of the pile. The load applied by the jack(s) should also be

coaxial with the pile. The nearest edge of crib supporting the kentledge stack shall

be at a distance of at least 3 times the testing-pile shaft diameter from the center of

the testing-pile and in no case less than 1.5 meters to the edge of the testing-pile.

(2) By means of hydraulic jack(s) which obtain reaction from anchor piles and/or

suitable loading frame. While using this method all anchor piles shall be at a

center-to-center distance of 3 times the testing-pile shaft diameter from the testing-

pile and in no case less than 2 meters. It must be ensured that the datum bar

supports are not affected by heaving up of soil.

|12 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

(3) By means of hydraulic jack(s) which obtain reaction from suitable rock anchors.

When this method is adopted, the anchor transferring the load to the ground shall

not be closer than 3 times the pile-shaft diameter from the center of the testing pile

and in no case less than 1.5 m from the edge of the testing-pile.

Photograph – 1

Photograph – 2

|13 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

9.6.1 Kentledge Test Procedure –

Load test shall be carried out by loading the pile as per cyclic methoddirect

loading method by applying a series of vertical downward incremental load in

5 cycles. Each increment shall be about 20% of the rated capacity of the pile.

The first loading shall be 20% and then unloading to be done, each loading to

be maintained as per (9.6.1.d) and unloading to be maintained for 15min and

elastic rebound to be measured before next increment cycle.

The total test load is 2.5 times the estimated safe load carrying capacity of the

pile for initial vertical test load and 1.5 times for routine vertical test and shall

be carried out by applying a series of vertical downward incremental load.

The step-by-step procedure for load application and measurement of deflection

is given below:

a) The initial dial gauge readings shall be noted down.

b) First load increment i.e. 20% of the rated capacity of pile shall be

applied.

c) Dial gauge readings shall be recorded immediately after application of

load and at an interval of 15 and 30 minutes and thereafter at half-hourly

intervals until application of next load increment.

d) Each stage of loading shall be maintained till the rate of settlement of the

pile top is not more than 0.2mm per hour or until 2 hours have elapsed

and after unloading the next increment to be given after 15min interval.,

whichever is earlier.

e) The rate of movement of pile shall not be permitted to be extrapolated

from period of test less than one hour.

|14 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

f) The load shall be increased by 20% of rated pile load capacity and dial

gauge readings shall be recorded for each increment.

g) Loading on piles shall be continued till one of the following takes place:

1. In case of Iinitial load test, applied load reaches 2.5 times the safe

vertical load carrying capacity or maximum settlement of pile

exceeds a value of l.0% of pile diameter. (Kindly include the criteria

of IS 2911 – 2013 (Part 4) given in cl.no 7.1.5

2. In case of routine load test, applied load reaches one and half times

the safe vertical load carrying capacity or the maximum settlement of

test loading in position attains 182mm.

h) Where yielding of soil / rock does not occur, full test load shall be

maintained on the pile head for a minimum period of 24 hours, after the

last increment of load has been applied. Settlement values shall be

recorded at every 6 hours interval during this period.

i) Unloading shall be carried out as per cyclic method in the same steps as

loading. A minimum period of 30 minutes shall be allowed to elapse

between two successive stages of load decrement.

j) Final rebound shall be recorded 6 hours after the entire test load has been

removed.

k) Load and settlement shall be calculated and tabulated.

l) Following curves shall be drawn and recorded:

Load vs Settlement

Time vs Settlement [for each increment of load)

Interpretation of results:

The safe vertical load carrying capacity of single pile from the initial and routine vertical

load tests shall be as follows, Kindly include the criteria of IS 2911 – 2013 (Part 4) for

Initial and Routine load tests

|15 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

Two thirds of final load, at which total settlement attains a value of 182mm.

|16 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

9.6.2 Dynamic Vertical Load Test

The purpose of the test is to obtain general information of the vertical ultimate bearing

capacity of a single pile under impact loading.

(1) Equipment & Test Setup –

a) The impact device consists of a hammer for imparting impact force to the pile

head of the test pile and a pile driver for operating it.

b) The planned maximum impact energy shall be given to the pile body with

adequate displacement to exert ground resistance which satisfies the purpose of

the test.

c) Since the energy transferred to the pile may be smaller than expected due to

characteristics of the driving device and the use of the pile, the driving device shall

be capable of giving greater impact energy than planned maximum energy.

(2) The driving device shall align the axis with the test pile so that locally excessive stress

will not occur and the pile head will not be damaged

a) Good quality products shall be used for cushion for protecting the head surface of

the pile, so that excessive impact to the pile head does not cause easy buckling

and breakage of the pile body.

b) For capturing stress waves propagating at high speed, measurement devices that

can accurately form input signals up to 10 kHz shall be used.

(3) The sensor shall be installed at a position more than 1.5 times the pile diameter from

the pile head, taking into consideration the disturbance of the stress state of the pile

body just below the striking position. The sensor shall be installed at two axially

symmetrical positions, as it can check the influence of unbalanced driving and use the

average value to offset the influence.

|17 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

(4) Method of Loading and Measurements –

a. The planned maximum impact energy shall be large enough to produce a

sufficient pile displacement so that the soil resistance is mobilized for achieving

the test purpose

b. Driving shall be done multiple times to confirm the reproducibility and stability of

the supposed waveform.

c. In the re-driving tests, signals of the first driving shall be measured carefully, as

succeeding multiple drives may result in reduction of soil resistance.

|18 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

Items to be Measured –

(a) Axial strains along the pile.

(b) Accelerations along the pile.

(c) Displacements along the pile.

(d) Others, if required.

Measurement duration and sampling intervals –

a) Signal measurement for each driving shall be continued until the full stop of

the pile movement. Generally, the measurement duration will be 2 to 3 times

the time necessary for the wave to travel back and forth along the pile.

b) The sampling interval shall be less than 0.1 m.

Record of the Test Conditions – During the test, the following items shall be

recorded

(a) Number of blows

(b) Total nos. of tests

(c) Rebound and penetration per blow

(d) Others, if required.

Commencement, interruption and completion of test-

a) The test shall be commenced after ensuring the conditions surrounding the

site, preparations of all equipment and the suitability of the weather condition.

b) If any abnormal conditions are noticed during the test, the test shall be

interrupted promptly and shall only be resumed when the cause of the

abnormal condition has been detected and rectified.

c) The test shall be completed when the objectives of the test shall have been

achieved or when it is judged that abnormal conditions make it impossible to

continue the test.

5 ) Processing of test results – The following relationships shall be graphed based on the

collected data – (i) Axial force-time relationship (ii) Velocity-time relationship (iii) Others, if

required.

|19 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

(6) Analysis of test results – Based on the purpose of the test, the characteristics of the

vertical bearing capacity of the pile shall be evaluated by clearly separating the frictional

and end bearing capacities as per test results..

9.7 LATERAL PILE LOAD TEST:

Test Set-up:

The lateral load shall be applied to the test pile by using hydraulic jack and a

reaction shall be taken from the adjacent compression pile.

A 1l .2m bore shall be done adjacent to the test pile up to scour level for

allowing pile to deflect in other direction.

A blocking beam of sufficient strength shall be used between the reaction

system and the hydraulic jack to transfer the applied lateral reaction without

distortion.

The lateral load applied by hydraulic jack shall be measured by a calibrated

pressure gauge.

The lateral displacement of the test pile shall be measured by dial gauges or

LVDTs (Linear Variable Differential Transducers) having at least l 00mm of

travel. The read out unit shall have a minimum display of 3 ½ digits, capable of

monitoring output at least l O DC/PC type LVDTs.

After completion of the lateral pile load test 1l .2 dia bore shall be backfilled by

using crushed sand. At first we shall fill crushed sand up to 1l m depth and

water ponding will be done for proper consolidation of crushed sand. We

should fill the remaining position of the bore in a similar manner by filling

crushed sand and ponding with water.

|20 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

Load Testing:

The pile shall be tested at the cut-off level. The test shall be conducted by

applying a series of loads on the test pile. The load shall be applied by means

of a hydraulic jack reacting against the reaction pile. For the pile to be tested

the surface on the sides shall be prepared smooth and flat to receive the load

from the jacks.

The loading shall be applied in increments of 20% of the rated capacity of pile.

The load shall be increased after the rate of displacement is nearer to 0.1mm

per 30 minutes.

Lateral displacement readings shall be observed immediately before and after

application of loads, and immediately before and after release of loads.

If the cut-off level is approachable, one dial gauge of 0.01mm sensitivity placed

diametrically opposite to the jack shall be used to directly measure the

displacement. In case the cut-off level is not approachable, 2 dial gauges

spaced at 30cm and kept horizontally one above the other on the test pile

shall be used and the displacement shall be interpolated at cut-off level from

similar triangles.

Following curves shall be drawn and recorded:

Load vs Displacement

Time vs Displacement [for each increment of load)

Interpretation of test data

The safe lateral load on the pile shall be taken as the least of the following:

o 50% of the final load at which the total displacement increases to 12 30 mm.

o Final load at which the total displacement corresponds to 5 12 mm.

|21 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

9.8 Pile Integrity Test on Working Piles

Pile Integrity Test shall be carried out by Cross Hole Sonic Logging test as per

ASTM D 6760 on each pile founded on rock.

25 % o0f piles shall be tested by Cross Hole Sonic Logging test and every pile

shall be tested by Low Strain Integrity Test as per ASTM D 5882, however all

piles shall have provision of tubes for sonic logging test.

This test is meant to verify the structural integrity, shape and continuity of

pile.

9.8.1 Cross Hole Sonic Logging Testing

Scope-

The test measures the propagation time and relative energy of an ultrasonic pulse

between parallel access ducts installed in the deep foundation element (pile).

Principle of the Test Method-

This test is based on the speed of travel of the P (Pressure) waves through the

pile concrete, when a soundwave of ultrasonic frequency (>20,000 Hz) is

generated.

In good quality concrete the speed of the P-wave would typically range

between 3600 to 4400 m/s.

By measuring the transit time of an ultrasonic P-wave signal between an

ultrasonic transmitter and receiver in two water filled access ducts cast into

the concrete during construction and spaced at a known distance apart,

defects such as soil inclusion, gravel, water, drilling mud, bentonite, voids,

contaminated concrete, or excessive segregation may be detected.

Apparatus-

|22 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

Access ducts made of mild steel – dia. 50 mm and 150/100 mm (to provide

access for the probes), installed during pile installation.

Weighted (plumb bob) measuring tape to act as a dummy probe to determine

the unobstructed lane of each access duct

Magnetic Compass accurate to within 10 degrees to document the access duct

designations compared with the site layout plan.

Probes (capable of sinking under their own weights in the access ducts) with a

probe housing waterproof to at least 1.5 times the maximum depth of testing

– to allow a generated or detected pulse within 125 mm of the bottom of the

access duct.

There shall be a transmitter probe, a receiver probe, a probe centralizer, signal

transmission cables and probe depth measuring device.

Computerized Apparatus for recording, processing, and displaying data in the

form of an ultrasonic profile.

Recording Apparatus to store raw digitized ultrasonic pulses and the processed

data from each ultrasonic profile for each pair of access ducts.

Digital Computer or Microprocessor capable of analyzing all data to identify at

least the first arrival and energy of the transmitted ultrasonic pulse at the

receiver probe for each depth interval.

Apparatus for Display of Measured Data capable of displaying the raw receiver

ultrasonic pulses to confirm data quality during acquisition.

|23 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

Photograph – 4

Access Ducts-

The access ducts shall be installed during construction of the pile foundation

to be tested.

The tubes shall have an internal diameter of 50 mm, except for one tube in

each pile, where it shall be of internal diameter 100 mm minimum to allow for

coring of the concrete at the base of the pile.

The access tubes shall be straight and free from internal obstructions. The

exterior tube surface shall be free from contamination.

The access tubes shall be close ended at the bottom and fitted with removable

end caps at the top to prevent entry of concrete or foreign objects which could

block the tubes prior to testing operation.

If extension of access tubes is necessary due to long tube lengths, access tube

couplings shall be used which prevent slurry or grout ingress during

|24 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

construction. For coupling - plastic tubes, threaded or glued plastic couplings

shall be used.

Access Tube Installation-

All piles shall be provided with sonic logging tube cast in to it. The tubes shall

be manufactured from mild steel and shall extend 0.5 m above the pile head

and 0.5m above the pile toe.

The access tubes shall have a minimum concrete cover of one tube diameter.

Access tubes shall be secured to the inside of the main axial reinforcement of

the steel cage at frequent and regular intervals along their length to maintain

the tube alignment during cage lifting, lowering and subsequent pile

concreting.

The access tubes shall be installed parallel to each other to the maximum

extent possible.

After installation of the reinforcement cage into the pile, the top end caps

shall be temporarily removed, and the tubes shall be inspected to verify that

they are clear of obstructions.

The access tubes shall be filled to the top with clean water prior to, or within

one hour of, concrete placement to ensure good bonding of the concrete to

the tube, once the concrete cools.

Test Procedure-

The test equipment shall be properly maintained and calibrated and checked

for proper functioning.

The test shall be performed no sooner 7 days after casting, depending on the

concrete strength and the shaft diameter.

|25 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

The tests shall be repeated for each pair of tubes, i.e. three runs for a pile

with three tubes and six runs for a pile with four tubes.

The access ducts shall be exposed, and the protective top caps removed.

The access ducts shall be filled to the top with clean water.

To get a good acoustic coupling between the probes and the water in the

access ducts, the probes shall be clean and free from all contaminants.

A systematic reference label shall be assigned to each access duct and a

reference sketch of the access duct layout shall be prepared.

The access ducts being tested shall be documented and the probe cable

pulley guides shall be placed into the access ducts.

The transmitter and receiver probes shall be inserted into the access ducts

such that the cables are engaged over the respective cable pulley guides

fixed at the access duct tops.

If the access duct tops are not level, the probes are to be held at the level of

the lower access duct top.

The depth measuring device shall be zeroed, if required by the recording

apparatus.

The probes shall be carefully lowered to the bottom of the access ducts,

always keeping them at approximately the same level, until one probe

reaches the bottom of the duct or encounters an obstruction. The depth

location shall be set to the bottom of the tubes, if necessary.

The probes shall be raised from the tube bottom to a portion of the pile with

good quality concrete.

The relative level of the probes shall be adjusted to ensure that the distance

between the probes is minimized, until the time of arrival of the first signal is

minimized.

The cables must be secured temporarily at that level with the cables

remaining in equal tension.

|26 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

The apparatus shall be so adjusted so that an ultrasonic pulse with good

amplitude is consistently obtained in a portion of the pile of good quality.

The probes must be returned to the access duct bottoms.

Recording of the ultrasonic pulses shall be commenced as the probes are

raised.

Both the probes shall be lifted by steadily pulling the probe cables

simultaneously at a speed of ascent slow enough to capture one ultrasonic

pulse for each depth interval specified.

If the ultrasonic pulse is not obtained for any depth interval, then the probes

shall be lowered past that depth and the test shall be repeated until all

depth intervals have an associated ultrasonic pulse.

After Completion of the tests tubes shall be grouted with non shrinkage

compound in the cement slurry.

Analysis of Test Results-

A report shall be prepared for each pile tested.

The photographic record of the oscilloscope shall be analyzed in detail.

Any deviation in results from what would be in adherence to the results

excepted from a pile constructed with sound concrete and without defect shall be

recorded.

The report shall indicate the nature, location and severity of the defect and

recommendations shall be made for further testing.

The implication of the existence of the defect on the performance of the pile shall be

evaluated.

Submission of Test Results-

Immediately after testing a signed copy of all the raw data of a pile shall be given to

the Engineer.

A test report shall be submitted to the Engineer within 3 days after testing.

Note: Pile cap will be casted after approval of report by Engineer.

|27 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

Sonic Coring –

For piles founded in rock, proof coring shall be done for all the piles as per

Section 9.3 of this Work Method Statement.

At least 7 days after the pile has been cast, but before carrying out any sonic

logging test, a core of concrete and rock from the founding materials shall be

taken.

The core shall be taken from the base of the 100 mm diameter sonic logging

tube using a triple tube core barrel and shall have a minimum diameter of 50

mm.

The scanning of the pile toe for its integrity by measuring the propagation time

of transmitted waves between the vertical tubes and the pile toe/founding

strata shall also be carried out.

Acceptance Criteria:

Pile classification FAT increase relative to Energy reduction Relative

good Concrete to good Concrete

Satisfactory/Good 0-10% <6Db

Minor Defect 11-20% <9Db

Poor/Flaw 21-30% 9Db to 12Db

Poor/Defect >31% >12 Db

Anomalous Sonic Logging Test Results-

The piles with anomalous sonic logging results shall be rejected at the Engineer discretion unless

the Contractor is able to demonstrate that the pile integrity is acceptable through proof coring

results. In case of piles founded on rock, if the results of sonic logging test and/or proof coring

(and/or pile load test) confirm or indicate the existence of void, sludge or the like between the

|28 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

pile toe and rock, the Engineer shall reject such piles or pile group, or alternatively, as per

geotechnical expert’s advice, shall require the Contractor to clean and grout between the pile toe

and rock. The Engineer’s decision shall be final and binding on the Contractor without any extra

payment.

Grouting of pile after testing-

Upon completion of sonic logging test, the access tubes and sonic coring holes,

if any, shall be grouted using an approved grout mix or approved concrete mix.

2 Low Strain Integrity Test

Scope-

This test method is used for determining the integrity of individual vertical or

inclined piles by measuring and analyzing the velocity (required) and force

(optional) response of the pile induced by an (handheld hammer or other similar

type) impact device applied axially to the pile normally at the pile head.

Pulse Echo Method (PEM) shall be used wherein the pile head motion is measured

as a function of time and the time domain record is then evaluated for pile integrity.

Apparatus-

Handheld Hammer (with a very hard plastic tip) – shall produce an input force pulse

of generally less than 1 mt.s duration and not cause any local pile damage owing to

the impact.

Accelerometers (linear to at least 50 g) – for velocity measurement. The

accelerometers should be placed at (or near) the pile head and shall have their

sensitive axis parallel with the pile axis. If A/C devices are used, the time constant

shall be greater than 0.5 s and the resonant frequency shall be at least 30 000 Hz. If

D/C devices are used, they shall have frequency response up to 5 000 Hz with less

than −3 dB reduction of content.

Velocity or Displacement Transducers (accuracy of 5% throughout the applicable

measurement range) – As an alternative to accelerometers. The motion sensor shall

|29 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

be placed at or near the pile head using a suitable, or temporary, bonding material

such as wax or Vaseline to ensure that it correctly measures the axial pile motion

(transducer axis of sensitivity aligned with the pile axis). The motion sensor shall be

placed near the center of the pile. Additional locations shall be considered for piles

with diameters greater than 500 mm. The low strain impact shall be applied to the

pile head within a distance of 300 mm from the motion sensor. If the pile head is not

accessible, as when already integral with the structure, the sensor(s) may be

attached to the side of the pile shaft.

Low noise shielded cable – for signal transmission from the sensors to the apparatus

for recording, reducing and displaying the data.

Apparatus for Recording, Reducing and Displaying Data - The apparatus shall

include a graphic display of velocity and a data storage capability for retrieving

records for further analysis. The apparatus shall be capable of averaging data of

several blows to reinforce the repetitive information from soil and pile effects while

reducing random noise effects. The apparatus shall be able to apply increasing

intensity amplification of the motion signal with time after the impact to enhance the

interpretation of the measured motions that are reduced by soil and pile material

damping. The apparatus shall have filtering capability with variable frequency limits

for eliminating high frequency, or low frequency signal components, or both. The

apparatus shall be capable of transferring all data to a permanent storage medium.

The apparatus shall allow for a permanent graphical output of the records.

|30 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

Photograph - 5

Photograph – 6

Procedure-

Integrity testing is to be carried out no sooner than 7 days after casting or after

concrete strength has achieved at least 75 % of its design strength, whichever occurs

earlier.

|31 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

The pile head surface shall be accessible, above water, and clean of loose

concrete, soil or other foreign materials resulting from construction.

A smooth surface shall be prepared for motion sensor attachment and impact.

The motion sensor shall be firmly attached with appropriate material at selected

locations away from the edge of the pile head.

For piles with diameters larger than 500 mm, the accelerometers shall be attached at

a minimum of three locations so that an integrity evaluation near the pile head may

be made for each localized section of pile.

The apparatus shall be positioned for applying the impact force so that the impact is

applied axially with the pile and at a distance no larger than 300 mm from the

accelerometer.

Apparatus for recording, reducing, and displaying data shall be set up so that it is

operational, and the velocity signals are zeroed.

The following information shall be recorded in the field notes –

(i) Pile identification, nominal and actual pile head diameter and length.

(ii) Date and method of concrete placement.

(iii) As-built geometry that is, total concrete volume, nominal or actual diameter

versus length, permanent or temporary casing, steel reinforcement, etc.

(iv) Soil stratigraphy.

(v) Any specific observation related to each pile tested that affects the pile

construction, excavation, integrity, etc.

(vi) Location of transducers at pile head and corresponding measurements.

(vii) Date of pile is tested.

Several impacts shall be applied and each individual impact or the average, if

required, or both, shall be recorded.

If only the individual impacts are recorded, the apparatus for recording, reducing,

and displaying data shall be capable of averaging up to 10 individual records.

The number of impacts for a specific averaged record shall be recorded.

|32 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

A series of velocity measurements shall be taken, recorded and displayed.

For confirmation of data quality, the velocity from several impact events shall be

monitored for consistency.

Evaluation of Results-

Results of Low Strain Integrity tests shall be evaluated together with other

information, including pile installation procedures and observations, soil

information, loading requirements etc. to assess the pile’s acceptance.

The report shall indicate the severity of defect and recommendations for further

tests, repair or replacement.

A test report shall be submitted to the Engineer within 3 days after testing.

Note – The test setup, pile testing scheme along with detailed design, drawings shall be

submitted separately to the Engineer, before planning to carry out the tests.

10. Environmental & Safety Precautions

All the safety norms and precautions shall be taken as per site safety plan

(HSE Plan) and clearance shall be taken before commencing.

Flagman shall be provided at all entry and exit points of the heavy vehicles.

Level staff shall be made of non-electricity conductive materials.

If work is carried out at night, the working area shall be sufficiently provided with

lighting.

Necessary safety signboards and precautionary boards, barricading (Type-III) shall

be placed near working locations.

Safety stewards shall conduct daily checking to ensure the working areas are safe.

Daily pep-talks shall be conducted to all workers at site to create awareness

and to follow safe working practices.

It shall be ensured that when the hydraulic jack and load measuring device

are mounted on the pile head, the whole system will be stable up to the

maximum load applied.

Necessary means shall be provided to enable dial gauges to be read from a

|33 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

Larsen & Toubro Limited, Construction

Transportation Infrastructure IC

Roads, Runways and Elevated Corridors

“ K-RIDE, CORRIDOR-2 PROJECT”

Work Method

Title

Construction work method statement for Pile Load Test

Work

procedure No.

RREC/KRIDE/WP/010 REV : R0

position clear of the kentledge stack or test frame in conditions where failure

in any part of the system due to overloading, buckling, loss of hydraulic

pressure and so on might constitute a hazard to personnel.

The maximum test load or test pressure expressed as a reading on the gauge

in use shall be displayed and all operators shall be made aware of this limit.

Where kentledge is used, the foundations for kentledge and any cribwork,

beams or other supporting structures shall be constructed in such a manner

that there will be no differential settlement, bending or deflection of an

amount that constitutes a hazard to safety or impairs the efficiency of the

operation.

All reaction loads shall be stable and balanced during all operations of testing.

During testing, stability of reaction system shall be ensured.

All operations in connection with pile load test shall be carried out in a safe

manner to prevent exposure of the people to hazard and also ensure the safety

of manpower and material.

The maximum test load or test pressure expressed as a reading on the gauge

in use shall be displayed and all operators shall be made aware of this limit.

|34 | P a g e RREC/KRIDE/WP/004 R0

Sensitivity: LNT Construction Internal Use

You might also like

- 7 Days Cube TestDocument6 pages7 Days Cube TestSurajit SahaNo ratings yet

- Pile Cap (04 Locs) Cube M-NDocument16 pagesPile Cap (04 Locs) Cube M-NMehdi HasanNo ratings yet

- Cement Testing Week No 37Document1 pageCement Testing Week No 37DNYANESHWAR PATILNo ratings yet

- Material Description For 60 Modules QTY THK WidthDocument25 pagesMaterial Description For 60 Modules QTY THK WidthUmamaheshwarrao VarmaNo ratings yet

- SW TSP C 001 Rev - 02 Topo PDFDocument10 pagesSW TSP C 001 Rev - 02 Topo PDFramesNo ratings yet

- Railway Track - 33 KV CableDocument1 pageRailway Track - 33 KV CableRajat MarvalNo ratings yet

- Vas Design and Infrastructure Consultants PVT LTD: Concrete Cores Test Result of HaryanaDocument2 pagesVas Design and Infrastructure Consultants PVT LTD: Concrete Cores Test Result of HaryanaPankaj SherwalNo ratings yet

- L&T Construction: Power Transmission & DistributionDocument6 pagesL&T Construction: Power Transmission & DistributionharishduttNo ratings yet

- 16.04.2022 - Description of CSSDocument2 pages16.04.2022 - Description of CSSYazhisai SelviNo ratings yet

- BRD 1455 181006 - Ch.7 - 008 - LHS 16 1 20 PDFDocument53 pagesBRD 1455 181006 - Ch.7 - 008 - LHS 16 1 20 PDFNilay GandhiNo ratings yet

- CCTV System - Technical SpecificationDocument8 pagesCCTV System - Technical SpecificationJitendra PathakNo ratings yet

- Dia of Pile M Bore Hole No. Length Cut-Off Level : (M) (M) (M) (M) T/M Deg Deg Deg T/M M T/M T/MDocument1 pageDia of Pile M Bore Hole No. Length Cut-Off Level : (M) (M) (M) (M) T/M Deg Deg Deg T/M M T/M T/MPankaj SherwalNo ratings yet

- ULB E 3 C6 CS 040 - Rev1Document63 pagesULB E 3 C6 CS 040 - Rev1Budi SetiawanNo ratings yet

- Plan View Isometric View: RPK-SE-942Document1 pagePlan View Isometric View: RPK-SE-942ajNo ratings yet

- Haryana TestDocument1 pageHaryana TestPankaj SherwalNo ratings yet

- 13.11.2021 CSL Full ReportDocument22 pages13.11.2021 CSL Full ReportJulius GuingabNo ratings yet

- Module 18Document81 pagesModule 18Hemant YesajiNo ratings yet

- Sub-Regional Transport Enhancement Project: Atterrberg Limits TestDocument14 pagesSub-Regional Transport Enhancement Project: Atterrberg Limits Testsakar shresthaNo ratings yet

- Bored-Cast in Situ Pile DesignDocument2 pagesBored-Cast in Situ Pile Designnimish.aquamarineNo ratings yet

- LOT1 CONCRETE Mixes 27-03-2019 - REV 9.1Document7 pagesLOT1 CONCRETE Mixes 27-03-2019 - REV 9.1Soundar PachiappanNo ratings yet

- 1.summary of Concrete Mix DesignsDocument2 pages1.summary of Concrete Mix DesignsGanesh Kumar TulabandulaNo ratings yet

- Pile Capacity FINEL FINEL BY SIRDocument4 pagesPile Capacity FINEL FINEL BY SIREr Navneet JassiNo ratings yet

- Larsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreDocument1 pageLarsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreOuseppachan AmbookenNo ratings yet

- Sub-Regional Transport Enhancement Project: Modified Proctor Compaction TestDocument15 pagesSub-Regional Transport Enhancement Project: Modified Proctor Compaction Testsakar shresthaNo ratings yet

- Pavement Design IllustrationsDocument27 pagesPavement Design IllustrationsMadhavpokaleNo ratings yet

- BC-CALC-ANALYSIS - Jetty Modul Near Gantry Crane - Su 20, 0.5 M Thk. and 1.1 M THK For Travelling AreaDocument4 pagesBC-CALC-ANALYSIS - Jetty Modul Near Gantry Crane - Su 20, 0.5 M Thk. and 1.1 M THK For Travelling Areanoto.sugiartoNo ratings yet

- RCC Bridge A2 Nallah PDFDocument24 pagesRCC Bridge A2 Nallah PDFEr Arabinda Kumar Dhar100% (1)

- Is456 2000Document8 pagesIs456 2000gyanthNo ratings yet

- Sr-380 Gtifr Pc-04 38bhs Rev2Document608 pagesSr-380 Gtifr Pc-04 38bhs Rev2Amit RawatNo ratings yet

- Wind Load2Document1 pageWind Load2Waqar FaziNo ratings yet

- Mix Design PosterDocument1 pageMix Design PosterAbhilash KumarNo ratings yet

- Drain DesignDocument2 pagesDrain DesignghansaNo ratings yet

- Others (Protection)Document7 pagesOthers (Protection)Hoque joynulNo ratings yet

- Cube Strength & Cylinder StrengthDocument5 pagesCube Strength & Cylinder StrengthRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Sojitz-L&T Consortium: Safe Bearing Capacity CalculationDocument4 pagesSojitz-L&T Consortium: Safe Bearing Capacity Calculation906rahulNo ratings yet

- Cube TestDocument7 pagesCube TestMani PathakNo ratings yet

- Project: Rev. Drawing No. Client: Authority Engineer:: Roads & Buildings DepartmentDocument2 pagesProject: Rev. Drawing No. Client: Authority Engineer:: Roads & Buildings DepartmentNilay GandhiNo ratings yet

- General Shear Local ShearDocument1 pageGeneral Shear Local ShearPankaj SherwalNo ratings yet

- Abutment Design For CausewayDocument7 pagesAbutment Design For CausewayVinay ChandwaniNo ratings yet

- Pile Uplift AkDocument4 pagesPile Uplift AkAbhishek KumarNo ratings yet

- 16km ConcreteDocument108 pages16km ConcretekwameNo ratings yet

- BORLOG BH-01 JEMBATAN BAH UpDocument1 pageBORLOG BH-01 JEMBATAN BAH UpBiltsar BardaNo ratings yet

- Moisture Correction..02Document2 pagesMoisture Correction..02Er Dnyaneshwar PatilNo ratings yet

- Boq SummaryDocument1 pageBoq Summarynimish.aquamarine100% (1)

- Valtam DataDocument2 pagesValtam DataSantosh ZunjarNo ratings yet

- Data: BH.01 Pile Size: Dia. 30 CM: Calculation SheetDocument4 pagesData: BH.01 Pile Size: Dia. 30 CM: Calculation SheetRafaArdiSyahrezaNo ratings yet

- FRNT ColDocument96 pagesFRNT ColARUN RAWATNo ratings yet

- Highway Lab Report (Full) PDFDocument84 pagesHighway Lab Report (Full) PDFWai KiatNo ratings yet

- Cube Strength-1Document1 pageCube Strength-1Joe ArmandaNo ratings yet

- PropertiesDocument2 pagesPropertiesVikasNo ratings yet

- Shore Pile Pressure Calculation: 1.7m 12m 13.5m 20 kN/m2Document9 pagesShore Pile Pressure Calculation: 1.7m 12m 13.5m 20 kN/m2vishnumani3011No ratings yet

- Model Estimate For Hume Pipe Culvert Dia - 600 MMDocument6 pagesModel Estimate For Hume Pipe Culvert Dia - 600 MMRajkumar PalNo ratings yet

- PropertY Calculation 75CS40X10X1.2Document15 pagesPropertY Calculation 75CS40X10X1.2kingsuk1980No ratings yet

- Liquefaction CPTDocument19 pagesLiquefaction CPTaditya gairNo ratings yet

- Revision 3 Methodology & AP Design - Balaji - Ludhiana-MinDocument38 pagesRevision 3 Methodology & AP Design - Balaji - Ludhiana-MinHemant Yesaji100% (1)

- Concrete Mix Design M-40 (RCC) Grade: Name of Work Client Authority Engineer ContractorDocument34 pagesConcrete Mix Design M-40 (RCC) Grade: Name of Work Client Authority Engineer ContractorAshok amlapureNo ratings yet

- S. No. Signal Data Type 1 2 3 4 5 6 7 8 9Document1 pageS. No. Signal Data Type 1 2 3 4 5 6 7 8 9gohilnarendraNo ratings yet

- WMM PLANTCalDocument61 pagesWMM PLANTCalp. kiran kuamrNo ratings yet

- MS Format-Tata Projects HosurDocument19 pagesMS Format-Tata Projects HosurSukhdeb BiswakarmaNo ratings yet

- RWR Method Statement-R00Document18 pagesRWR Method Statement-R00Rahul Kumar PatelNo ratings yet

- 01 Report - 172+328Document14 pages01 Report - 172+328Hemant YesajiNo ratings yet

- Revision 3 Methodology & AP Design - Balaji - Ludhiana-MinDocument38 pagesRevision 3 Methodology & AP Design - Balaji - Ludhiana-MinHemant Yesaji100% (1)

- MTHL-PKG2-DS-TCN-A-00-027 Rev. 1Document10 pagesMTHL-PKG2-DS-TCN-A-00-027 Rev. 1Hemant YesajiNo ratings yet

- Design of Rigid Pavement For TunnelsDocument19 pagesDesign of Rigid Pavement For TunnelsHemant YesajiNo ratings yet

- MTHL PKG2 DS TCN A 00 028Document33 pagesMTHL PKG2 DS TCN A 00 028Hemant YesajiNo ratings yet

- FB Pier Annexure (BH-21 To BH-41)Document18 pagesFB Pier Annexure (BH-21 To BH-41)Hemant YesajiNo ratings yet

- Tunnel-2 Lining Geometry (Without Invert) Typical Tunnel-2 Lining Section (Without Invert)Document1 pageTunnel-2 Lining Geometry (Without Invert) Typical Tunnel-2 Lining Section (Without Invert)Hemant YesajiNo ratings yet

- Key Plan: Typ. Plan of Niche With Invert Without Invert Section 1-1 Section 1-1Document1 pageKey Plan: Typ. Plan of Niche With Invert Without Invert Section 1-1 Section 1-1Hemant YesajiNo ratings yet

- 7 Gir PDFDocument493 pages7 Gir PDFHemant Yesaji100% (1)

- IRC78-2014 B-3 Appendix-9 Bi-Axial Load Testing of Piles - Draft 27-10-2017 PDFDocument22 pagesIRC78-2014 B-3 Appendix-9 Bi-Axial Load Testing of Piles - Draft 27-10-2017 PDFHemant YesajiNo ratings yet

- ASTM D1763 00 Epoxy Resins PDFDocument4 pagesASTM D1763 00 Epoxy Resins PDFHemant YesajiNo ratings yet

- Module 18Document81 pagesModule 18Hemant YesajiNo ratings yet

- IRC:78-2014 Appendix-9 (Clause 709.2.5) : Bi-Directional Load Testing of PilesDocument22 pagesIRC:78-2014 Appendix-9 (Clause 709.2.5) : Bi-Directional Load Testing of PilesHemant YesajiNo ratings yet

- MTHL 3rd LotDocument12 pagesMTHL 3rd LotHemant YesajiNo ratings yet

- Additional Boreholes at Interchanges (F)Document1 pageAdditional Boreholes at Interchanges (F)Hemant YesajiNo ratings yet

- GT em Brochure en A4 DataDocument12 pagesGT em Brochure en A4 DataMarketing ChiarottotalNo ratings yet

- Types of ClinkerDocument3 pagesTypes of ClinkerJa Phe TiNo ratings yet

- 301-301LN Stainless SteelsDocument4 pages301-301LN Stainless SteelsTeka KamNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAli RazaNo ratings yet

- A63 May19 JCT PDFDocument12 pagesA63 May19 JCT PDFBojanĆirovićNo ratings yet

- SteelDocument24 pagesSteelsaranya rNo ratings yet

- Muhammad Arif SaeedDocument16 pagesMuhammad Arif SaeedsamNo ratings yet

- Multiprop MP PostidDocument22 pagesMultiprop MP PostidMahil PathiranaNo ratings yet

- BERGSTROM Manual Instalación InternationalDocument34 pagesBERGSTROM Manual Instalación InternationalCarlos AnticonaNo ratings yet

- Rti Searox S 337 Alu TapeDocument1 pageRti Searox S 337 Alu TapeAnh Le NgocNo ratings yet

- DIAGRID - Flat SlabDocument1 pageDIAGRID - Flat Slabsanthu maji100% (1)

- RC Cable Trench WallsDocument10 pagesRC Cable Trench WallsAnonymous UUw70xirblNo ratings yet

- Steam Tracing 101Document2 pagesSteam Tracing 101fawmer61100% (1)

- Heavy Machinery - Vocabulary: Verbs Occupations Materials Heavy Machinery Places Heavy Machinery PartsDocument1 pageHeavy Machinery - Vocabulary: Verbs Occupations Materials Heavy Machinery Places Heavy Machinery PartsKaren Dayana OCAMPO AYANo ratings yet

- HVAC Air Balance Report TemplateDocument5 pagesHVAC Air Balance Report TemplateJamie CheNo ratings yet

- Preformed Expansion Joint Filler For Concrete (Bituminous Type)Document2 pagesPreformed Expansion Joint Filler For Concrete (Bituminous Type)mjgutierrezperaltaNo ratings yet

- Astm A556 PDFDocument2 pagesAstm A556 PDFgaminNo ratings yet

- HFMW Cooling Tower QuestionsDocument3 pagesHFMW Cooling Tower QuestionsLucia RetanaNo ratings yet

- 992 AdzDocument2 pages992 AdzJavierRivasNeiraNo ratings yet

- Numerical Analysis of Deep ExcavationsDocument7 pagesNumerical Analysis of Deep ExcavationsChinnaswamy GounderNo ratings yet

- ASME Piping Block (UT+PAUT)Document1 pageASME Piping Block (UT+PAUT)Muhammed Abo-FandoodNo ratings yet

- Bostik UltraFinish Pro Premium Portland Cement Repair Patch Product Data 1848181Document4 pagesBostik UltraFinish Pro Premium Portland Cement Repair Patch Product Data 1848181Arturo Jr. TorresNo ratings yet

- Duct Design Calculation Sheet: Note:-Take the Value of α & β from above table use in the calculationDocument9 pagesDuct Design Calculation Sheet: Note:-Take the Value of α & β from above table use in the calculationchagar_harshNo ratings yet

- Cement - WikipediaDocument1 pageCement - WikipediafirosaahNo ratings yet

- CE 14 Syllabus 2nd Sem 2010-2011Document3 pagesCE 14 Syllabus 2nd Sem 2010-2011Tim AcostaNo ratings yet

- Material (Transformer) Lot-4Document2 pagesMaterial (Transformer) Lot-4John Nash TunNo ratings yet

- PIPE - : Prefunctional Test Checklist 03/02 15997-08-1 OF 6 D:/DOCS/DIV1/03-02/15997-08Document6 pagesPIPE - : Prefunctional Test Checklist 03/02 15997-08-1 OF 6 D:/DOCS/DIV1/03-02/15997-08rakeshamechNo ratings yet

- Hoa-4 1Document30 pagesHoa-4 1CarmsNo ratings yet

- NS128 Pole Installation and Removal Technical GuideDocument54 pagesNS128 Pole Installation and Removal Technical GuideseanNo ratings yet

- Bag Filters: Amerseal Cube Filters Dripak Dripak 2000Document4 pagesBag Filters: Amerseal Cube Filters Dripak Dripak 2000Bayu SamudraNo ratings yet