Professional Documents

Culture Documents

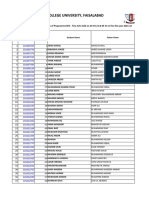

Eastern Garments GA 37 API212452

Eastern Garments GA 37 API212452

Uploaded by

Zain Khan0 ratings0% found this document useful (0 votes)

9 views8 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views8 pagesEastern Garments GA 37 API212452

Eastern Garments GA 37 API212452

Uploaded by

Zain KhanCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

Scanned with CamScanner

Compressor type

Prossure variant

Voltage

LP Element PN

HP Element PN

Canopy

10 dryer

1D dryer + DD fiter

Regulating system

Energy recovery

Serial number

Product number

Water cooled

Frequency

Serial number

Serial number

Modulating contro!

Har

osp

Wintersation kit

Marine version

AP 21S,

289149922

Vir cota

60

PP RIE >

oR

Scanned with CamScanner

Condition ofthe erat on artval LK ] Not OK:

Unpacking considered easy o Yes 1 No .

Were all loose parts included Les IT No

Condition ofthe loose parts Sox £2 not ox

Were all documents included res No

I Notox

Were all documents in good shape

+ Bodywork

‘Any transport damage

‘Any signs of corrosion

= 7 Any loose bolts: io

Any damage to the bodywork R/No

‘ay presence of water S/o

Inside canopy

Any transport damage

Any signs of corrosion

‘Transport locking bolls easy lo remove

Any loose bolts/connections

‘Any signs of ol spillage or leakage

Was the ug clean inside

Scanned with CamScanner

tectric/Elektronikon equipment

‘ny signs of corrosion

wring in accordance with clagram

‘any ose olectrcal connections

Check torque of moin motor cable's

inside cubicle

Main motor, overload corecty set

Solin indicated correctly on

sone diogram

Fan motors), everlad correctly set

Selting(s) indicated correctly on

service diagram

Transformer wire taps correclly sat

Eleccic diagram clear and legible

ii Yos

fies

Eo Yes

ROK

Ves

Wes

res

“Yes

Ares

Ses

Scanned with CamScanner

—-w

Compressed air application

Transport locking boks removed

Installation carried out by

Environmental condtion Zien EJ ously FF Very duty

Connection to the air net IF Rigid coupling ID Flexible coupling

Electical connection carried out by, * BA’Customer:

Foundation ok

Compressor room properly ventilated

Air intake quality ok

Air neader ok

‘Any other eompressor(s) in the seme

Inlet and/or outlet ducting used iy f :

Receiver installed

Doiyor instaed

Loryer bypass installed

iors) installed

oD

60+ Po

“| DD+PD+QD

Bllen is Cecile

No

Scanned with CamScanner

J

seers cine opety connected Tax) No

Ww Ves “) No

Drain waler goes to sewer

Maximum pressure(e), loaded ho | bar

2.0

Normal working pressure(e) at full rated lar | esi

ceapacily «

Minimum working pressure) ata Re} bar [lest i

rated copacity

Maximum permissible pressure drop

‘over air intake fiter

Maximum permissible ambient

lemperature

Maximum permissible cooling water

pressure(e)

Cooling water inlet temperature, *

‘rormalmaximum

Cooling water outlet temperature,

snormalimaximum

‘Normal temperature of he air outlet

above the ambient temperature at

continuous operation and nominal

working pressure

Maximum permissible air outlet

tomperature

Loadluntoad settings:

: Unloading at

Loading at

Currenviimit ol pressure setting

Currenviimit oll temperature setting

Currentiimit air or airfoil temperature *

setting low pressure element outlet

Currenttimil air or airfoil temperature

setting

‘capacity (approx.)

a Us gal

i /—] us gal

"Ys

jal

Scanned with CamScanner

/

cord iter change interval (Geers | hs

recommenda ts Cepee serves | Careser ‘ws

inspection interval

Selocted oil

ype of rolrigerant

Amount of refrigerant i fko

Lowest air temperature

Make

Type

Serial number

Voltage

Rated current

Speed

Mains fuse capacity

Greasing interval

Quantity of grease par bearing

‘Ae path cleaning interval

Selected groaso

Scanned with CamScanner

te (egae- Bor 22Gd- 13

Sova! number CBSEVIY

Service Diagram number

Contol volage

Frequency

Supply votoge

Rated current

Suitch on volage/Push reset and check

if all LED's and displays light up SOK

Direction rotation main motor ox

Direction rotation fan moter oil cooler OK

Direstion rotation fan rotor 1 dryer

Cheek foro leakage ax

Check the grive shaft seal r

Check for air leakage

Not OK

Not OK

Not OK

Not OK

TJ Not ok

Not OK

Not OK

Scanned with CamScanner

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Direct and Inverse Iterative Design Method For Centrifugal Pump ImpellersDocument13 pagesDirect and Inverse Iterative Design Method For Centrifugal Pump ImpellersZain KhanNo ratings yet

- MME501 Tutorial Topic1 v1.2Document49 pagesMME501 Tutorial Topic1 v1.2Zain KhanNo ratings yet

- Case Study - Centrifugal Compressor Failure Analysis - BIC MagazineDocument1 pageCase Study - Centrifugal Compressor Failure Analysis - BIC MagazineZain KhanNo ratings yet

- What Is Blade Loading and How Is It Specified - by ADT - MediumDocument1 pageWhat Is Blade Loading and How Is It Specified - by ADT - MediumZain KhanNo ratings yet

- MME501 Tutorial Topic5 v1.5Document61 pagesMME501 Tutorial Topic5 v1.5Zain KhanNo ratings yet

- ZT55-90 AslDocument192 pagesZT55-90 AslZain Khan100% (1)

- In Uence of Blade Wrap Angle On Centrifugal Pump Performance by Numerical and Experimental StudyDocument9 pagesIn Uence of Blade Wrap Angle On Centrifugal Pump Performance by Numerical and Experimental StudyZain KhanNo ratings yet

- Al Abbas Fabrics InspectionDocument7 pagesAl Abbas Fabrics InspectionZain KhanNo ratings yet

- Al Abbas Fabrics InspectionDocument7 pagesAl Abbas Fabrics InspectionZain KhanNo ratings yet

- MME501 Tutorial Topic4 v1.3Document42 pagesMME501 Tutorial Topic4 v1.3Zain KhanNo ratings yet

- Elko Organizarion (PVT) LTD (FX12 (E10) ITJ039599) SQ-19009Document4 pagesElko Organizarion (PVT) LTD (FX12 (E10) ITJ039599) SQ-19009Zain KhanNo ratings yet

- Revised Quotation - Bearings SKFDocument1 pageRevised Quotation - Bearings SKFZain KhanNo ratings yet

- Service PortfolioDocument3 pagesService PortfolioZain KhanNo ratings yet

- 563 Units Rs. 15,337.29: Abdul Rehman DhananiDocument2 pages563 Units Rs. 15,337.29: Abdul Rehman DhananiZain KhanNo ratings yet

- 30120701-Part 2Document24 pages30120701-Part 2Zain KhanNo ratings yet

- Payment Advice Record (Cts - Services)Document4 pagesPayment Advice Record (Cts - Services)Zain KhanNo ratings yet

- C - Users - DK-17 - Downloads - Chepter 4B (F Test, T Test) (1) .B01Document18 pagesC - Users - DK-17 - Downloads - Chepter 4B (F Test, T Test) (1) .B01Zain KhanNo ratings yet

- Zain Rnac Final ChartsDocument1 pageZain Rnac Final ChartsZain KhanNo ratings yet

- Bachelor TranscriptDocument2 pagesBachelor TranscriptZain KhanNo ratings yet

- Genuine Student Assessment FormDocument5 pagesGenuine Student Assessment FormZain KhanNo ratings yet

- Elements and Principles of Design: Example IllustrationDocument1 pageElements and Principles of Design: Example IllustrationZain KhanNo ratings yet

- Al Karam Towel Commission GA55Document8 pagesAl Karam Towel Commission GA55Zain KhanNo ratings yet

- Government College University, FaisalabadDocument20 pagesGovernment College University, FaisalabadZain KhanNo ratings yet

- 4990 - Habibullah Associates For HVAC Works at Dolmen Mall, KarachiDocument7 pages4990 - Habibullah Associates For HVAC Works at Dolmen Mall, KarachiZain KhanNo ratings yet

- Scheme of Studies of Graphic Design 5th & 7thDocument14 pagesScheme of Studies of Graphic Design 5th & 7thZain KhanNo ratings yet

- Abstract.: Figure: Connecting RodDocument6 pagesAbstract.: Figure: Connecting RodZain KhanNo ratings yet

- Combined Final Drive. (Bulldozer) : Project ProposalDocument3 pagesCombined Final Drive. (Bulldozer) : Project ProposalZain KhanNo ratings yet