Professional Documents

Culture Documents

Checklist For Inprocess Inspection

Uploaded by

Salman Tamboli0 ratings0% found this document useful (0 votes)

16 views1 pageThe document is a checklist for inspecting a pump, containing 18 checkpoints to verify aspects like the pump identification numbers, inspecting for defects, drilling and tapping, packing assembly, direction of rotation, hydrotesting, stripping, rotation, matching of split case pump components, cleanliness, rust protection, impeller balancing, performance testing, rotor balancing, primer paint, and intact accessories. The checklist is used to inspect the physical condition and performance of the pump and its components.

Original Description:

Original Title

Checklist for Inprocess Inspection

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document is a checklist for inspecting a pump, containing 18 checkpoints to verify aspects like the pump identification numbers, inspecting for defects, drilling and tapping, packing assembly, direction of rotation, hydrotesting, stripping, rotation, matching of split case pump components, cleanliness, rust protection, impeller balancing, performance testing, rotor balancing, primer paint, and intact accessories. The checklist is used to inspect the physical condition and performance of the pump and its components.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views1 pageChecklist For Inprocess Inspection

Uploaded by

Salman TamboliThe document is a checklist for inspecting a pump, containing 18 checkpoints to verify aspects like the pump identification numbers, inspecting for defects, drilling and tapping, packing assembly, direction of rotation, hydrotesting, stripping, rotation, matching of split case pump components, cleanliness, rust protection, impeller balancing, performance testing, rotor balancing, primer paint, and intact accessories. The checklist is used to inspect the physical condition and performance of the pump and its components.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

Sr

No Checkpoint Remark

1 Verification of OA and Pump Sr No.

Visual inspection for casting defects on pump casing, impeller, casing cover

2

and bearing housing, Inserts etc

Visual inspection for machining/casting defects on machining parts of pump

3

casing, impeller,casing cover and bearing housing, inserts etc

4 Verification of Drilling and Tapping

5 Verification of Mechanical or Gland Packing Assembly

Fitment of Sealing pipe, Grease Nipple,Plugs sealing connections, Lifting Eye

6

Bolt

7 Direction of Rotation of Pump

8 Hydrotest of Pump

9 Strip Test

10 Rotation of Pump

11 Top and Bottom matching in case of Split case Pump

12 Cleanliness of component

13 Rust oil application on machined parts

14 Impeller balancing stamp verification on impeller during CVT /spare inspection

15 Performance Test of Pump

16 Rotor Balancing

17 Verify Primer paint inside casing/Volute and on external surface of Pump

18 Verify Pump Accessories are Intact

You might also like

- Excavator Student ManualDocument25 pagesExcavator Student ManualSamuel Woldemichael Yohannes83% (6)

- Liebherr Crane Inspection SheetDocument9 pagesLiebherr Crane Inspection SheetDon Stortts0% (1)

- TA1 Visual Inspection Form Master - Wheel LoaderDocument12 pagesTA1 Visual Inspection Form Master - Wheel LoaderCarlosNo ratings yet

- Centrifugal Pumps Pre-Commissioining ChecklistDocument2 pagesCentrifugal Pumps Pre-Commissioining ChecklistMuhammad TalhaNo ratings yet

- V28 Rebuild GuidelinesDocument26 pagesV28 Rebuild Guidelinesacere18100% (1)

- 1) Limestone Crushing, Storage and Extraction System: Pre-Commissioning Check List For Clinkerization CircuitDocument1 page1) Limestone Crushing, Storage and Extraction System: Pre-Commissioning Check List For Clinkerization CircuitSSAC PVT.LTD.No ratings yet

- Centrifugal Pumps Commissioning Checklist Parco MCR Revamp Project Package-IIDocument2 pagesCentrifugal Pumps Commissioning Checklist Parco MCR Revamp Project Package-IIMuhammad Talha100% (1)

- Check ListDocument3 pagesCheck ListSalman TamboliNo ratings yet

- PML 087a - PMS - EngineDocument70 pagesPML 087a - PMS - EngineFidriNo ratings yet

- 07 IOT - Form - Inspection Generator Set 1Document2 pages07 IOT - Form - Inspection Generator Set 1Oneesa Chandra0% (1)

- Checklist For Centrifugal PumpsDocument1 pageChecklist For Centrifugal PumpsAnoopNo ratings yet

- TA1 English ExcavatorDocument13 pagesTA1 English ExcavatorJoel RodríguezNo ratings yet

- 22E Backhoe Loader HBEDocument29 pages22E Backhoe Loader HBEhebert trujilloNo ratings yet

- Liebherr Crane Inspection SheetDocument10 pagesLiebherr Crane Inspection SheetDon StorttsNo ratings yet

- TA2 424D Backhoe Loader RXADocument34 pagesTA2 424D Backhoe Loader RXAahmad adelNo ratings yet

- MM y ServicioDocument82 pagesMM y Serviciojesus francoNo ratings yet

- Signaling MaintenanceDocument1 pageSignaling MaintenancePraveen Varma VNo ratings yet

- Placing Boom Inspection ReportDocument3 pagesPlacing Boom Inspection ReportBishoo ShenoudaNo ratings yet

- K017 - OHSE Tower Crane ChecklistDocument2 pagesK017 - OHSE Tower Crane ChecklistRajib MondalNo ratings yet

- Unloader Check ListDocument1 pageUnloader Check ListAnonymous ahdhFMaNo ratings yet

- Sample Copy: Daily Site Vehicle/Plant Inspection ScheduleDocument1 pageSample Copy: Daily Site Vehicle/Plant Inspection ScheduleAVENON MardocheeNo ratings yet

- Enumerate The Procedures in Dismantling Oil PumpDocument3 pagesEnumerate The Procedures in Dismantling Oil PumpJaysie FernandezNo ratings yet

- Test Specifications and Task Lists: Automobile Service Technology Area TestsDocument23 pagesTest Specifications and Task Lists: Automobile Service Technology Area TestsAbdo JondiNo ratings yet

- Technical Service Manual: Heavy-Duty Bracket Mounted Pumps Series 124 Models J, K, KK, L, LQ, LL and LMDocument16 pagesTechnical Service Manual: Heavy-Duty Bracket Mounted Pumps Series 124 Models J, K, KK, L, LQ, LL and LMryanNo ratings yet

- 4 130111099314896972Document3 pages4 130111099314896972ishaqNo ratings yet

- TA1 Visual Inspection Form Master - Track-Type TractorDocument11 pagesTA1 Visual Inspection Form Master - Track-Type TractorCarlosNo ratings yet

- Maintenance Schedules For BG Coaches of Icf DesignDocument6 pagesMaintenance Schedules For BG Coaches of Icf DesignParthaprotim NathNo ratings yet

- SOP of Maintenance For Ball Mill Including PolycomDocument3 pagesSOP of Maintenance For Ball Mill Including PolycomsantoshNo ratings yet

- Engine Repair (A1) : M01 - HALD2866 - 03 - SE - ANS1.indd 1 05/01/19 10:09 AMDocument48 pagesEngine Repair (A1) : M01 - HALD2866 - 03 - SE - ANS1.indd 1 05/01/19 10:09 AMGait CorporationNo ratings yet

- Conveyor Check ListDocument2 pagesConveyor Check Listh1549697100% (1)

- Mud Pump - High Pressure Lines PDFDocument7 pagesMud Pump - High Pressure Lines PDFKaleem UllahNo ratings yet

- High Pressure Lines PDFDocument3 pagesHigh Pressure Lines PDFKaleem UllahNo ratings yet

- Field Inspection ReportDocument14 pagesField Inspection ReportRanjit SinghNo ratings yet

- PRE - Delivery Inspection OF EX200 Super: /TTC-KGP/SOP/2)Document10 pagesPRE - Delivery Inspection OF EX200 Super: /TTC-KGP/SOP/2)Habibur RahamanNo ratings yet

- RTX Piston Running GuideDocument32 pagesRTX Piston Running GuideDaniel TsvetilovNo ratings yet

- Fortnightly - Checklist - Kobelco CranesDocument3 pagesFortnightly - Checklist - Kobelco Cranesdevansh ranaNo ratings yet

- Annual Inspection Checklist PDF 2Document14 pagesAnnual Inspection Checklist PDF 2Tarek ElghazzalyNo ratings yet

- Preventive Maintenance Introduction: For Centrifugal Pump SystemsDocument13 pagesPreventive Maintenance Introduction: For Centrifugal Pump SystemsZaenal AripinNo ratings yet

- Presentation On VibrationDocument24 pagesPresentation On VibrationSethuRamalingamNo ratings yet

- Pauta de Mantencion RWE 120Document2 pagesPauta de Mantencion RWE 120Fran PobleteNo ratings yet

- 05 Turbine Operation MaintenanceDocument9 pages05 Turbine Operation Maintenancesakera 88No ratings yet

- Start Up Form MPDocument5 pagesStart Up Form MPBUDAPESNo ratings yet

- HGDocument6 pagesHGlaxman JoshiNo ratings yet

- Testing and Commissioning of Water Booster Pump Set Method Statement PDFDocument3 pagesTesting and Commissioning of Water Booster Pump Set Method Statement PDFHumaid Shaikh100% (1)

- Testing and Commissioning of Water Booster Pump Set Method Statement PDFDocument3 pagesTesting and Commissioning of Water Booster Pump Set Method Statement PDFHumaid ShaikhNo ratings yet

- Quality Check in G-9Document1 pageQuality Check in G-9mukeshhNo ratings yet

- Inspection Checklist For Excavator MachineDocument1 pageInspection Checklist For Excavator Machineabhishek narayan singhNo ratings yet

- Lab Module 01 Maintenance & Troubleshoot Centrifugal PumpDocument12 pagesLab Module 01 Maintenance & Troubleshoot Centrifugal Pumpazroy06No ratings yet

- Daily PC1250 FormDocument1 pageDaily PC1250 FormlilikNo ratings yet

- Equipment Group:: Intermediate Inspection Criteria, Well Control EquipmentDocument2 pagesEquipment Group:: Intermediate Inspection Criteria, Well Control Equipmentkaleem ullah janNo ratings yet

- NO Spare Parts Service 10000 Hrs 20000 Hrs 30000 HrsDocument3 pagesNO Spare Parts Service 10000 Hrs 20000 Hrs 30000 HrsrandyNo ratings yet

- Checklist For NP CO2 Compressor Overhauling - Rev 0 PDFDocument6 pagesChecklist For NP CO2 Compressor Overhauling - Rev 0 PDFMohsin MurtazaNo ratings yet

- Check Sheet Equipment Pre CommDocument23 pagesCheck Sheet Equipment Pre CommHANIF AKBARNo ratings yet

- 1-Turbine Operation & MaintenanceDocument17 pages1-Turbine Operation & Maintenanceshobhan1984No ratings yet

- Maintenance Schedule For BOP - 5131086 - 01Document4 pagesMaintenance Schedule For BOP - 5131086 - 01franko guddiNo ratings yet

- TA-2 Visual & Technical Inspection For Wheel Loaders: SMCS - Job Code - 540 Component Code - 753TDocument22 pagesTA-2 Visual & Technical Inspection For Wheel Loaders: SMCS - Job Code - 540 Component Code - 753Tahmed el sayedNo ratings yet

- Weekly Check List RS-1Document12 pagesWeekly Check List RS-1Pinki SahayNo ratings yet

- 049b Pump ChecklistDocument13 pages049b Pump ChecklistRamy AdelNo ratings yet

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsFrom Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsRating: 1 out of 5 stars1/5 (1)

- VoucherlistDocument2 pagesVoucherlistSalman TamboliNo ratings yet

- Ajinkya Kurale ResumeDocument5 pagesAjinkya Kurale ResumeSalman TamboliNo ratings yet

- Training Evaluation Form - Inspection at KBLDocument1 pageTraining Evaluation Form - Inspection at KBLSalman TamboliNo ratings yet

- ICP Receipt - ICP 384036Document2 pagesICP Receipt - ICP 384036Salman TamboliNo ratings yet

- Training Evaluation Form - Inspection at KBLDocument1 pageTraining Evaluation Form - Inspection at KBLSalman TamboliNo ratings yet

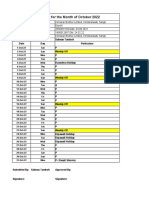

- Timesheet-KBL December 2022-SalmanDocument1 pageTimesheet-KBL December 2022-SalmanSalman TamboliNo ratings yet

- VoucherlistDocument2 pagesVoucherlistSalman TamboliNo ratings yet

- Timesheet-KBL September 2022-SalmanDocument1 pageTimesheet-KBL September 2022-SalmanSalman TamboliNo ratings yet

- VoucherlistDocument2 pagesVoucherlistSalman TamboliNo ratings yet

- Timesheet KBL July 2022 SalmanDocument29 pagesTimesheet KBL July 2022 SalmanSalman TamboliNo ratings yet

- Timesheet-KBL October 2022-SalmanDocument1 pageTimesheet-KBL October 2022-SalmanSalman TamboliNo ratings yet

- 57!34!13ca8cf098ac4682 - PR-In-GEN-HR-006-Leave and Attendance Policy - 01 Apr 2021Document6 pages57!34!13ca8cf098ac4682 - PR-In-GEN-HR-006-Leave and Attendance Policy - 01 Apr 2021Salman TamboliNo ratings yet

- VoucherlistDocument2 pagesVoucherlistSalman TamboliNo ratings yet

- In-Process-Weekly-June-2022 1Document13 pagesIn-Process-Weekly-June-2022 1Salman TamboliNo ratings yet

- Ma in I&e in 0Document6 pagesMa in I&e in 0Salman TamboliNo ratings yet

- 100 - Learner Transcript ReportDocument4 pages100 - Learner Transcript ReportSalman TamboliNo ratings yet

- AjebsDocument4 pagesAjebsSalman TamboliNo ratings yet

- 100 - Learner Transcript ReportDocument4 pages100 - Learner Transcript ReportSalman TamboliNo ratings yet

- API 619 5th EditionDocument1 pageAPI 619 5th EditionSalman TamboliNo ratings yet

- Section Wise PerformaceDocument2 pagesSection Wise PerformaceSalman TamboliNo ratings yet

- VoucherlistDocument2 pagesVoucherlistSalman TamboliNo ratings yet

- Vendor ReportDocument3 pagesVendor ReportSalman TamboliNo ratings yet

- FGH Claim Form OnlineDocument2 pagesFGH Claim Form OnlineSalman TamboliNo ratings yet

- ICP Receipt - ICP 370034Document2 pagesICP Receipt - ICP 370034Salman TamboliNo ratings yet