Professional Documents

Culture Documents

Column 1

Uploaded by

LUIZ CALROS0 ratings0% found this document useful (0 votes)

8 views2 pagesOriginal Title

Column1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views2 pagesColumn 1

Uploaded by

LUIZ CALROSCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

UD

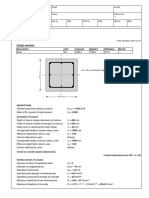

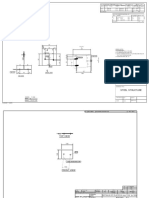

Member C1

1.1 Design Code

AISC 360-16-ASD

1.2 Member Properties

The required Compressive Strength

𝑃𝑎 = 1000 𝑘𝑁

Length

Length Value Unit

Lx 4 m

Kx 1

Ly 4 m

Ky 1

Lz 4 m

Kz 1

1.3 Cross Section Properties - HE 160 A

Cross-Section Property Symbol Value Unit

Gross area Ag 3877.14 mm2

Moment of inertia about major principal axis Ix 16729.77 x103 mm4

Moment of inertia about minor principal axis Iy 6155.73 x103 mm4

Radius of gyration about major principal axis rx 65.69 mm

Radius of gyration about minor principal axis ry 39.85 mm

Torsional constant J 121.08 x103 mm4

Warping constant Cw 31.41 x109 mm6

1.4 Material Properties - A992

Material Property Symbol Value Unit

Modulus of elasticity E 200000 N/mm2

Shear modulus G 77000 N/mm2

Yield strength Fy 235 N/mm2

1.5 Classification of Cross-Section

Compression – Table B4.1a

Flange

Case 1: Flanges of rolled I-shaped sections

𝑏 = 80 𝑚𝑚

𝑡 = 9 𝑚𝑚

\𝑙𝑎𝑚𝑏𝑑𝑎 =\𝑠𝑓𝑟𝑎𝑐{𝑏}{𝑡} =\𝑓𝑟𝑎𝑐{80}{9} = 8.89

\𝑙𝑎𝑚𝑏𝑑𝑎𝑟 = 0.56\𝑠𝑞𝑟𝑡 {\𝑓𝑟𝑎𝑐{𝐸}{𝐹𝑦 }} = 0.56\𝑠𝑞𝑟𝑡{\𝑓𝑟𝑎𝑐{200000}{235}} = 16.34

\𝑙𝑎𝑚𝑏𝑑𝑎\𝑙𝑒\𝑙𝑎𝑚𝑏𝑑𝑎𝑟 \𝑟𝑖𝑔ℎ𝑡𝑎𝑟𝑟𝑜𝑤 𝑛𝑜𝑛𝑠𝑙𝑒𝑛𝑑𝑒𝑟

Web

Case 5: Webs of doubly symmetric rolled and built-up I-shaped sections

ℎ = 104 𝑚𝑚

𝑡𝑤 = 6 𝑚𝑚

\𝑙𝑎𝑚𝑏𝑑𝑎 =\𝑠𝑓𝑟𝑎𝑐{ℎ}{𝑡𝑤 } =\𝑓𝑟𝑎𝑐{104}{6} = 17.33

Ultimate Design 2021 UltimateDesignMA@gmail.com

1

UD

\𝑙𝑎𝑚𝑏𝑑𝑎𝑟 = 1.49\𝑠𝑞𝑟𝑡 {\𝑓𝑟𝑎𝑐{𝐸}{𝐹𝑦 }} = 1.49\𝑠𝑞𝑟𝑡{\𝑓𝑟𝑎𝑐{200000}{235}} = 43.47

\𝑙𝑎𝑚𝑏𝑑𝑎\𝑙𝑒\𝑙𝑎𝑚𝑏𝑑𝑎𝑟 \𝑟𝑖𝑔ℎ𝑡𝑎𝑟𝑟𝑜𝑤 𝑛𝑜𝑛𝑠𝑙𝑒𝑛𝑑𝑒𝑟

1.6 Design for Compression

Elastic Flexural Buckling Stress

\𝑓𝑟𝑎𝑐{𝐾𝑥𝐿𝑥 }{𝑟𝑥 } =\𝑓𝑟𝑎𝑐{1\𝑡𝑖𝑚𝑒𝑠4\𝑡𝑖𝑚𝑒𝑠1000}{65.69} = 60.893\𝑙𝑒200\𝑐𝑑𝑜𝑡𝑠 𝑜𝑘

\𝑓𝑟𝑎𝑐 {𝐾𝑦𝐿𝑦 } {𝑟𝑦 } =\𝑓𝑟𝑎𝑐{1\𝑡𝑖𝑚𝑒𝑠4\𝑡𝑖𝑚𝑒𝑠1000}{39.85} = 100.387\𝑙𝑒200\𝑐𝑑𝑜𝑡𝑠 𝑜𝑘

the y-y axis will govern

2

𝐹𝑒 =\𝑓𝑟𝑎𝑐{\𝑚𝑎𝑡ℎ𝑏𝑖𝑡{\𝑝𝑖}2𝐸 } {\𝑙𝑒𝑓𝑡(\𝑓𝑟𝑎𝑐{𝐿{𝑐𝑦} }{𝑟𝑦 }\𝑟𝑖𝑔ℎ𝑡) } (from Spec. Eq. E3-4)

𝑁

=\𝑓𝑟𝑎𝑐{\𝑚𝑎𝑡ℎ𝑏𝑖𝑡{\𝑝𝑖}2\𝑙𝑒𝑓𝑡(200000\𝑟𝑖𝑔ℎ𝑡) }{\𝑙𝑒𝑓𝑡(100.39\𝑟𝑖𝑔ℎ𝑡)2 } = 195.87

{\𝑟𝑚 𝑚𝑚}2

Elastic Critical Torsional Buckling Stress

2

𝐹𝑒 =\𝑙𝑒𝑓𝑡 (\𝑓𝑟𝑎𝑐{\𝑚𝑎𝑡ℎ𝑏𝑖𝑡{\𝑝𝑖}2𝐸𝐶

𝑤 } {{𝐿{𝑐𝑧} } } + 𝐺𝐽\𝑟𝑖𝑔ℎ𝑡) \𝑓𝑟𝑎𝑐{1}{𝐼𝑥 + 𝐼𝑦 } (Spec. Eq. E4-2)

2\𝑙𝑒𝑓𝑡(200000\𝑟𝑖𝑔ℎ𝑡)\𝑙𝑒𝑓𝑡(31.41\𝑡𝑖𝑚𝑒𝑠{10}9\𝑟𝑖𝑔ℎ𝑡 )

=\𝑙𝑒𝑓𝑡 (\𝑓𝑟𝑎𝑐 {\𝑚𝑎𝑡ℎ𝑏𝑖𝑡{\𝑝𝑖} } {\𝑙𝑒𝑓𝑡(4000

\𝑟𝑖𝑔ℎ𝑡)2 } +\𝑙𝑒𝑓𝑡(77000\𝑟𝑖𝑔ℎ𝑡)\𝑙𝑒𝑓𝑡(121.08\𝑡𝑖𝑚𝑒𝑠{10}3\𝑟𝑖𝑔ℎ𝑡 )\𝑟𝑖𝑔ℎ𝑡)

\𝑓𝑟𝑎𝑐{1}{\𝑙𝑒𝑓𝑡(16729.77 + 6155.73\𝑟𝑖𝑔ℎ𝑡)\𝑡𝑖𝑚𝑒𝑠{10}3 }

𝑁

= 576.72

{\𝑟𝑚 𝑚𝑚}2

The flexural buckling limit state controls.

𝑁

\𝑡ℎ𝑒𝑟𝑒𝑓𝑜𝑟𝑒 𝐹𝑒 = 195.87

{\𝑟𝑚 𝑚𝑚}2

Flexural Buckling Stress

\𝑓𝑟𝑎𝑐{𝐹𝑦 }{𝐹𝑒 } =\𝑓𝑟𝑎𝑐{235}{195.87} = 1.2

\𝑏𝑒𝑐𝑎𝑢𝑠𝑒\𝑓𝑟𝑎𝑐{𝐹𝑦 }{𝐹𝑒 } < 2.25

\𝐿𝑜𝑛𝑔𝑟𝑖𝑔ℎ𝑡𝑎𝑟𝑟𝑜𝑤 𝐹{𝑐𝑟} =\𝑙𝑒𝑓𝑡({0.658}\𝑓𝑟𝑎𝑐{𝐹𝑦 }{𝐹𝑒 }\𝑟𝑖𝑔ℎ𝑡 )𝐹𝑦 (Spec. Eq. E3-2)

𝑁

=\𝑙𝑒𝑓𝑡({0.658}{1.2}\𝑟𝑖𝑔ℎ𝑡 )\𝑙𝑒𝑓𝑡(235\𝑟𝑖𝑔ℎ𝑡) = 142.23

{\𝑟𝑚 𝑚𝑚}2

Effective Area

Flange

Because the flanges are not slender, there is no reduction in effective area due to local buckling of the flanges.

Web

Because the Web is not slender, there is no reduction in effective area due to local buckling of the Web.

Available Compressive Strength

𝑃𝑛 = 𝐹{𝑐𝑟}𝐴𝑔 (Spec. Eq. E3-1)

=\𝑠𝑓𝑟𝑎𝑐{\𝑙𝑒𝑓𝑡(142.23\𝑟𝑖𝑔ℎ𝑡)\𝑙𝑒𝑓𝑡(3877.14\𝑟𝑖𝑔ℎ𝑡)}{1000} = 551.44 𝑘𝑁

\𝑚𝑎𝑡ℎ𝑟𝑚{\𝑂𝑚𝑒𝑔𝑎}𝑐 = 1.67

\𝑓𝑟𝑎𝑐{𝑃𝑛 }{\𝑚𝑎𝑡ℎ𝑟𝑚{\𝑂𝑚𝑒𝑔𝑎}𝑐 } =\𝑓𝑟𝑎𝑐{551.44}{1.67} = 330.2

Design Ratio

𝐷

𝑟𝑎𝑡𝑖𝑜\𝑐𝑜𝑙𝑜𝑛3.028 > 1\𝑐𝑑𝑜𝑡𝑠 𝑛𝑜𝑡 𝑜𝑘

𝐶

Ultimate Design 2021 UltimateDesignMA@gmail.com

2

You might also like

- Column 2Document3 pagesColumn 2LUIZ CALROSNo ratings yet

- RC Beam1Document15 pagesRC Beam1LUIZ CALROSNo ratings yet

- Beam Columns Design According To AISC 360-16-LRFDDocument18 pagesBeam Columns Design According To AISC 360-16-LRFDsever2000No ratings yet

- Steel BeamsDocument21 pagesSteel BeamsAli HassenNo ratings yet

- Simulation and ModelingDocument23 pagesSimulation and ModelingVincent Lasconia Jr.No ratings yet

- CE0039-M6 (Design of Composite Members) PDFDocument42 pagesCE0039-M6 (Design of Composite Members) PDFJude BayranNo ratings yet

- Module 2Document44 pagesModule 2Vishwa VardhanNo ratings yet

- Example 2 To Start ExplainationDocument8 pagesExample 2 To Start ExplainationsamehNo ratings yet

- CE250 HW2 NCJajurieDocument7 pagesCE250 HW2 NCJajurieRanji JajurieNo ratings yet

- Example On Design of Biaxial Column With Design EccecntricitiessDocument10 pagesExample On Design of Biaxial Column With Design EccecntricitiessweynNo ratings yet

- Chapter 8Document19 pagesChapter 8Elmer Leyson BaldesansoNo ratings yet

- Design of Cold-Formed Steel Built-Up Post Members - TSNDocument12 pagesDesign of Cold-Formed Steel Built-Up Post Members - TSNNuno PedrinhoNo ratings yet

- Example Assignment 1Document6 pagesExample Assignment 1aur.lai.kaNo ratings yet

- Reinforced Concrete Section PropertiesDocument10 pagesReinforced Concrete Section PropertiesJose MLNo ratings yet

- Design of Plate Girder: Faculty of Engineering Technology and ResearchDocument15 pagesDesign of Plate Girder: Faculty of Engineering Technology and ResearchDhruv ShahNo ratings yet

- CE71 Module 3b 2ND SEM 2022Document16 pagesCE71 Module 3b 2ND SEM 2022Orland Son FactorNo ratings yet

- Biaxial BendingDocument4 pagesBiaxial BendingOdiit StephenNo ratings yet

- Design of Footing BY Eng. Kaid Ahmd Ali Kaid TEL:733843999Document9 pagesDesign of Footing BY Eng. Kaid Ahmd Ali Kaid TEL:733843999AwadNo ratings yet

- 4.3 Eg. Box Girder DesignDocument24 pages4.3 Eg. Box Girder Designananiya dawitNo ratings yet

- Design of BearingDocument56 pagesDesign of BearingPawan BhattaraiNo ratings yet

- Design of Compression MembersDocument18 pagesDesign of Compression MembersWilfharry billyNo ratings yet

- Detailed Calculation SheetDocument32 pagesDetailed Calculation SheetAwa SigeNo ratings yet

- Lasac. Assignment 3. Ce43s4Document9 pagesLasac. Assignment 3. Ce43s4Karyme MendezNo ratings yet

- Continous One Way Slabs With MathCadDocument18 pagesContinous One Way Slabs With MathCadGiomar OzaitaNo ratings yet

- Timber Column Design To Bs5268-2:2002: Project Job RefDocument2 pagesTimber Column Design To Bs5268-2:2002: Project Job RefZayyan RomjonNo ratings yet

- Punching Shear Calculations: Aci - 318 Adapt-PtDocument32 pagesPunching Shear Calculations: Aci - 318 Adapt-PtMahmoud Mohsen HassanNo ratings yet

- f13 Ce470ch4ftb CompDocument10 pagesf13 Ce470ch4ftb CompAulia Rahma AzisNo ratings yet

- Cylindrical Member DesignDocument5 pagesCylindrical Member DesignolomuNo ratings yet

- Composite BeamsDocument16 pagesComposite BeamsNoureddine SemaraNo ratings yet

- Foundation Engg Module 3 Square Footing With Axial Load OnlyDocument8 pagesFoundation Engg Module 3 Square Footing With Axial Load Onlyjc gelacioNo ratings yet

- 5 - Helical GearsDocument4 pages5 - Helical GearsAnil YildizNo ratings yet

- Solved Problem On BeamDocument11 pagesSolved Problem On BeamBeki WalkerNo ratings yet

- Design Guide As Per Eurocode Midas GenDocument96 pagesDesign Guide As Per Eurocode Midas Gentim_lim12100% (1)

- TN 192 Punching Shear Calculation in BuilderDocument24 pagesTN 192 Punching Shear Calculation in BuilderHieu100% (1)

- Connections 1 - Ch.6 Bolted Shear Connections - Exercise Solutions (2 of 2) (233-248)Document14 pagesConnections 1 - Ch.6 Bolted Shear Connections - Exercise Solutions (2 of 2) (233-248)travis8zimmermannNo ratings yet

- Column Steel DesignDocument37 pagesColumn Steel DesignIlya Joohari100% (1)

- Calculation Deflection in Accordance To EC-2: 1.1 Design DataDocument15 pagesCalculation Deflection in Accordance To EC-2: 1.1 Design DataMisgun SamuelNo ratings yet

- A Theoretical and Numerical Evaluation On The Ductility of Reinforced Concrete Flexural Members Due To The Effects of Varying Structural ParametersDocument16 pagesA Theoretical and Numerical Evaluation On The Ductility of Reinforced Concrete Flexural Members Due To The Effects of Varying Structural ParametersWai FaiNo ratings yet

- CESTEEL Lecture 3 (Updated) PDF-Tension MembersDocument85 pagesCESTEEL Lecture 3 (Updated) PDF-Tension MembersAivi VelasquezNo ratings yet

- Timber Design: Bending StressDocument6 pagesTimber Design: Bending StressChris AbrenicaNo ratings yet

- B1Document48 pagesB1hendyNo ratings yet

- 10.1 Material Properties, Development, and Splice LengthsDocument12 pages10.1 Material Properties, Development, and Splice LengthsjoshuaNo ratings yet

- Kathmandu University Design of Column Section Designed By:: Er. Sudip ShresthaDocument9 pagesKathmandu University Design of Column Section Designed By:: Er. Sudip ShresthaSudip ShresthaNo ratings yet

- Calculation of Deflections Due To Shrinkage & CreepsDocument2 pagesCalculation of Deflections Due To Shrinkage & CreepsChuksbozmentNo ratings yet

- Composite Beam Simply Supported DesignDocument21 pagesComposite Beam Simply Supported DesignTharanga Pradeep100% (1)

- Mech Design B ReportDocument14 pagesMech Design B ReportanuNo ratings yet

- G.Curved BeamDocument7 pagesG.Curved BeamChimdi GadafaNo ratings yet

- Nonlinear GuideDocument17 pagesNonlinear Guidepiv0ter_betterNo ratings yet

- 10688-ABU ALI-RPT-0003 - RevAA - Class 2 - 6mW Double Swing GateDocument9 pages10688-ABU ALI-RPT-0003 - RevAA - Class 2 - 6mW Double Swing GateSehna SerajNo ratings yet

- Tedds RC Beam Design 2Document3 pagesTedds RC Beam Design 2Hor Ka WaiNo ratings yet

- Base ExcitationDocument51 pagesBase ExcitationPuneet BahriNo ratings yet

- 8 - Design For TorsionDocument34 pages8 - Design For TorsionACTION plusNo ratings yet

- Rivets Theory-MergedDocument35 pagesRivets Theory-MergedRabbani SadhikNo ratings yet

- Assignment 2 - SolutionDocument10 pagesAssignment 2 - SolutionDilum VRNo ratings yet

- Project Job Ref.: 8 No. 16 MM Diameter Longitudinal BarsDocument2 pagesProject Job Ref.: 8 No. 16 MM Diameter Longitudinal BarsErwin MaguideNo ratings yet

- Spur Gear Design by IIT MadrasDocument28 pagesSpur Gear Design by IIT MadrasC.S.ABHILASHNo ratings yet

- Design of FootingDocument67 pagesDesign of FootingHarlene Marie M. Ilagan100% (1)

- Steel Structure: SkylightDocument12 pagesSteel Structure: SkylightLUIZ CALROSNo ratings yet

- Steel Structure: SkylightDocument3 pagesSteel Structure: SkylightLUIZ CALROSNo ratings yet

- N1Document1 pageN1LUIZ CALROSNo ratings yet

- MTC TubeDocument1 pageMTC TubeLUIZ CALROSNo ratings yet

- RAHMAN CO كمياتDocument1 pageRAHMAN CO كمياتLUIZ CALROSNo ratings yet

- Type 2V Sheet#12 New RevDocument1 pageType 2V Sheet#12 New RevLUIZ CALROSNo ratings yet

- CoulumnDocument6 pagesCoulumnLUIZ CALROSNo ratings yet

- A TubeDocument10 pagesA TubeLUIZ CALROSNo ratings yet

- Flight Eticket A221224241250Document4 pagesFlight Eticket A221224241250LUIZ CALROSNo ratings yet

- Relation of Form To Structure (Repaired)Document13 pagesRelation of Form To Structure (Repaired)Ar Frank EpeNo ratings yet

- Footing Slab ReportDocument2 pagesFooting Slab ReportkathrynzNo ratings yet

- MiTek Engineered Building ProductsDocument6 pagesMiTek Engineered Building ProductsNiko TassigiannakisNo ratings yet

- Underpinning: UnderpiningDocument50 pagesUnderpinning: Underpiningtejani yakshuNo ratings yet

- MasterbuilderDocument4 pagesMasterbuildermahakNo ratings yet

- Exit Gate Civil PartDocument30 pagesExit Gate Civil PartMATRIX ENGINEERSNo ratings yet

- Repair and Rehabiliation PDFDocument210 pagesRepair and Rehabiliation PDFSivaramakrishnaNalluri100% (1)

- Eurocode 6 - IntroductionDocument24 pagesEurocode 6 - IntroductionAyis ANo ratings yet

- Question Bank of DRCBMDocument11 pagesQuestion Bank of DRCBMrishinathnehruNo ratings yet

- Structural Analysis of Steel WorkDocument595 pagesStructural Analysis of Steel WorkKids Strola50% (2)

- St7016 Prefabricated Structures L T P c3 0 0 3Document1 pageSt7016 Prefabricated Structures L T P c3 0 0 3Dinesh AJNo ratings yet

- BUILDING & ITS PARTS (Compatibility Mode)Document36 pagesBUILDING & ITS PARTS (Compatibility Mode)BackupFilesNo ratings yet

- Cycle Test 1Document3 pagesCycle Test 1Santhi KaruppiahNo ratings yet

- Design of Bending MembersDocument21 pagesDesign of Bending MembersChico AlvesNo ratings yet

- CE530 Exercises 2021Document3 pagesCE530 Exercises 2021jonathan katongoNo ratings yet

- Development Length of Reinforcing Bars - Need To Revise Indian Code ProvisionsDocument8 pagesDevelopment Length of Reinforcing Bars - Need To Revise Indian Code ProvisionsAvijitNo ratings yet

- Design of Column Using Channel (Front)Document8 pagesDesign of Column Using Channel (Front)Nitesh SinghNo ratings yet

- Approach Form Camber Specifications With CautionDocument4 pagesApproach Form Camber Specifications With CautionDonald HamiltonNo ratings yet

- SegmentsDocument16 pagesSegmentsMetha NoosaloongNo ratings yet

- Work Site For ConstructionDocument38 pagesWork Site For ConstructionJackson LeonardNo ratings yet

- Ground Floor Plan: Fisheries Ndii Students' ProjecctDocument3 pagesGround Floor Plan: Fisheries Ndii Students' ProjecctDaḿilareNo ratings yet

- Analysis of G+10 Residential Building by Staad ProDocument6 pagesAnalysis of G+10 Residential Building by Staad ProAli MarkiswahNo ratings yet

- Basement Retaining Wall Structural Design OverviewDocument10 pagesBasement Retaining Wall Structural Design OverviewMathias OnosemuodeNo ratings yet

- Chapter 3 Example of Compression ColumnDocument9 pagesChapter 3 Example of Compression ColumnMesfin100% (2)

- Bailey Bridge: Comprehensive Training For DPWH Field Engineers April 22, 2013Document63 pagesBailey Bridge: Comprehensive Training For DPWH Field Engineers April 22, 2013Edhz AmbalesNo ratings yet

- Saic Q 1002Document1 pageSaic Q 1002Hussain Nasser Al- NowiesserNo ratings yet

- Petronas Towers PDFDocument22 pagesPetronas Towers PDFRuSsdy MubaraQhNo ratings yet

- Lab. Trial Report: ProjectDocument1 pageLab. Trial Report: Projectmahesh naikNo ratings yet

- Steel Roof Truss TutorialDocument6 pagesSteel Roof Truss TutorialrantoNo ratings yet

- Software Verification: EXAMPLE Eurocode 2-04 PT-SL-001Document7 pagesSoftware Verification: EXAMPLE Eurocode 2-04 PT-SL-001võ hoàng thái100% (1)