Professional Documents

Culture Documents

Inspection & Test Plans

Inspection & Test Plans

Uploaded by

คุณพ่อน้อง บิ๊กบอสOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection & Test Plans

Inspection & Test Plans

Uploaded by

คุณพ่อน้อง บิ๊กบอสCopyright:

Available Formats

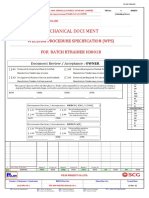

EP-CM-F-0004-003

CLIENT NAME : THAI PLASTIC AND CHEMICALS PUBLIC COMPANY LIMITED TOTAL: 3 SHEETS

PROJECT NAME : TPR Productivity improvement PG680,740 130 MTPD ( Including Cover )

PROJECT NO. : C-22-1092

LOCATION : RAYONG THAILAND

MECHANICAL DOCUMENT

INSPECTION & TEST PLANS

FOR BATCH RTRAINER H3001B

DISTRIBUTION

Master File

Client

Maintenance

Procurement

ENG. DESIGN

EM

PR

PIP

IE

MSE

MRE

EE

CVE

IC

] IA

CONSTRUCTION

PM

CM

CVE

ME

PIP

IE

EE

A IFR = Issue for Review Khanis Y. 12-Nov-22 Khanis Y. 12-Nov-22 Khanis Y. 12-Nov-22

REV. PURPOSE PRED. DATE CHKD. DATE APPD. DATE EM DATE PM DATE

PILIN PROJECT CO.,LTD.

Vendor / Fabricator / Contractor REPCO Doc. No. Client Doc. No. Issued Date

6518-ITP-00-A TPC-000-MSE-ITP-H3001B-00-A - 12-Nov-22

IFS = Issue for Squadcheck IFR = Issue for Review IFE = Issue for Enquiry IFD = Issue for Design IFC = Issue for Construction

IFI = Issue for Information IFP = Issue for Purchase IFF = Issue for Final

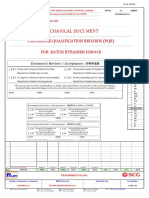

EP-CM-F-0004-003

PILIN PROJECT CO.,LTD.

REPCO Doc. No. Rev. Sheet No.

REVISION LIST

TPC-000-MSE-ITP-H3001B-00-A A 2 OF 3

REV. DATE ITEM No. REFERENCE DOCUMENT DESCRIPTION

A 12-Nov-22 - - IFR = Issue for Review

0 22-Jan-18 - - IFC = Issue for Construction

Page 1 of 1

INSPECTION & TEST PLANS

Pilin Project Co.,Ltd. FOR BATCH RTRAINER H3001B

Project Name : TPR Productivity improvement PG680,740 130 MTPD Doc. No. : 6518-ITP-00-A

Owner : THAI PLASTIC AND CHEMICALS PUBLIC COMPANY LIMITED Revision No. : A

Vendor Name : PILIN PROJECT CO.,LTD. Date : 12/11/2022

DESCRIPTION QUALITY CONTROL/ REFERENCE/CODES QUALITY SURVEILLANCE

ITEM Pilin SCG REMARK

ACTIVITY/PROCESS MANUFACTURING ACTIVITY STANDARDS/DRAWINGS

CODE SIGN CODE SING

1 DOCUMENT SUBMITTAL

- WPS.&PQR. Verify Code compliance, Clear detail of Fabrication ASME Sect. IX QR R

- Welder Test and WPQ Client requirement or welder transference ASME Sect. IX QR R

- Work procedure and specification Client requirement Client requirement QR R

- AFC Drawing and calculation orientation & dimension Fabrication Drawing QR R

2 MATERAIL INCOMING

- Procurement Review Puchase Oder ASME Sec. II Part A,B,C,D, Drawing I/QR R

- Receving Inspection Check, marking, dimension check NDE.if req'd.,quantity No Damage I/QR W

- Material Mill Certificate Verify P.O. & Code compliance ASME Sec. II Part A,B,C,D QR R

- PMI for stainless steel material Inspection by Third party ASME Sec. II Part A,B,C,D,Procedure QR SW/R

3 FABRICATION

3.1 Shell & Head

- Material identify Verify transfer of original marking Material Mill Certificate,Drawing W/QR SW

- Lay-out & cutting Dimension check Cutting plan, Drawing I SW

- machine Dimension check Fabrication Drawing I SW

3.2 Nozzle machine

- Material identify Verify transfer of original marking Material Mill Certificate,Drawing W/QR SW

- Lay-out & cutting Dimension check Cutting plan, Drawing I SW

- machine Dimension check Fabrication Drawing I SW

3.3 Support & other accessories

- Material identify Verify transfer of original marking Material Mill Certificate,Drawing W/QR R

- Lay-out & cutting Dimension check Cutting plan, Drawing I SW

- Fit-up & weld Verfy WPS , welder, visual inspection WPS, WPQ,ASME Sect. IX, Drawing I/QR SW/R

4 Assembly

4.1 Shell to Head

- Orientation and position Check alignment, cleanliness, visual inspection of all tack welds ASME Vlll Div.1 , Procedure I/QR SW

- Fit-up & weld Verfy WPS , welder, visual inspection WPS, WPQ,ASME Sect. IX, Drawing I/QR R/SW

- Visual check for weld appearance Visual ASME Vlll Div.1 I/QR SW

- Spot RT: Butt Weld By Third party ASME Vlll Div.1 QR R

- Dimension check Check Straight Drawing I/QR SW/R

4.2 Nozzle

- Layout and opening on head Dimension check Drawing I SW

- Fit-up & weld Verfy WPS , welder, visual inspection,Dimension check ASME Vlll Div.1 I/QR SW/R

- Visual check for weld appearance Visual ASME Vlll Div.1 I/QR SW/R

- PT 100% nozzle By third party ASME Vlll Div.1 W/QR W

4.3 Other accessaries

- Orientation and position Visual/Dimension Drawing I/QR SW/R

- Fit-up & weld Verfy WPS , welder, visual inspection,Dimension check Drawing I/QR SW/R

- Visual check for weld appearance Visual ASME Vlll Div.1 I/QR SW/R

- PT 100% After weld and remove attachment NDT by Third party ASME Vlll Div.1 I/QR W

5 HYDROSTATIC TEST

- Final visual check for overall appearance (Welding Dimension, Orientation check Drawing

I/QR H/W

& Dimension) before hydrotest Check all weling seam for leak ASME Vlll Div.1

- Cleaning & drying Check for cleanliness, dryness ASME Vlll Div.1 I/QR H/W

6 NDE

- PMI for stainless steel material Inspection by Third party ASME Sec. II Part A,B,C,D,Procedure QR SW/R

- 100% PT for all weldment By Third party ASME Vlll Div.1 W/QR H/W

- 100% PT for removed all tack welds to pressure part By Third party ASME Vlll Div.1 W/QR H/W

- Spot RT or PAUT : Butt weld seam By Third party ASME Vlll Div.1 W/QR H/R

- PAUT at weld of Nozzle to shell and Head By Third party ASME Vlll Div.1 W/QR H/R

7 Internal buffing

- Internal buffing #250 (JAPANESE STANDARDS) Surface Roughness inspection (Ra ≤0.25 m) Procedure I/QR SW/R

8 Chemical cleaning

- Chemical cleaning Inside and outside tank shall be applied Chemical cleaning

Verify flux residues and weld spatter shall be removed CleaningProcedure I/QR SW/R

mechanically using stainless steel tools.

9 PACKING & DELIVERY

- Cleanliness (Inside and Outside) Visual check Packing Procedure I W

- Temporary Support Verify to suitable position Packing Procedure I W

- Nameplate Check Check wording Drawing I W

- Packing, Marking and Tagging Check Verify packing condition Packing Procedure I W

- Quantity Check Visual check Packing List I W

- N2 Purge at 0.5 kg/cm2 Visual check Shipping&Packing Procedure I W

- Final Ship Release Verify Shipping condition Shipping&Packing Procedure I W

10 MDR Record Final visual inspection, verify as-built dimension All shop inspection report I/QR H

REMARK I = INSPECTION W = FULL WITNESS

QR = QUALIFY REPORT SW = SPOT WITNESS

R = REVIEW & COMMENT H = HOLD POINT

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Alignment Inspection Report (Vertical Equipment) : - Sign / Date Sign / Date Owner Sign / DateDocument6 pagesAlignment Inspection Report (Vertical Equipment) : - Sign / Date Sign / Date Owner Sign / Dateคุณพ่อน้อง บิ๊กบอส100% (1)

- Field Schedule Control ProcedureDocument37 pagesField Schedule Control Procedureคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Method Statement For Rotating Equipment InstallationDocument10 pagesMethod Statement For Rotating Equipment Installationคุณพ่อน้อง บิ๊กบอส100% (4)

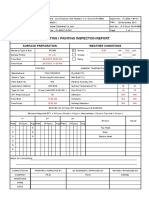

- BlastPainting Report R.1Document1 pageBlastPainting Report R.1คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Method Statement For Static Equipment InstallationDocument20 pagesMethod Statement For Static Equipment Installationคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Welding Procedure Specification (WPS)Document6 pagesWelding Procedure Specification (WPS)คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Method Statement For Piping InstallationDocument9 pagesMethod Statement For Piping Installationคุณพ่อน้อง บิ๊กบอส100% (12)

- Painting Procedure Rev.ADocument12 pagesPainting Procedure Rev.Aคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Hydrostatic Test ProcedureDocument11 pagesHydrostatic Test Procedureคุณพ่อน้อง บิ๊กบอสNo ratings yet

- 7) - Procedure FRP Tank InstallationDocument34 pages7) - Procedure FRP Tank Installationคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Slope CheckDocument2 pagesSlope Checkคุณพ่อน้อง บิ๊กบอสNo ratings yet

- ITP Equipment1Document9 pagesITP Equipment1คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Inspection Report TK3200Document100 pagesInspection Report TK3200คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Procedure Qualification Records (PQR)Document13 pagesProcedure Qualification Records (PQR)คุณพ่อน้อง บิ๊กบอสNo ratings yet

- CC F 01102557Document1 pageCC F 01102557คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Att-6 - 077QS0101 - B - INSPECTION INSTRUCTION TO VENDORSDocument22 pagesAtt-6 - 077QS0101 - B - INSPECTION INSTRUCTION TO VENDORSคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Shell DimensionDocument1 pageShell Dimensionคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Weld Location MapDocument1 pageWeld Location Mapคุณพ่อน้อง บิ๊กบอสNo ratings yet

- MDR lNDEXDocument35 pagesMDR lNDEXคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Hydrostatic Test 3D-3711Document3 pagesHydrostatic Test 3D-3711คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Cleaning Inspection ReportDocument2 pagesCleaning Inspection Reportคุณพ่อน้อง บิ๊กบอสNo ratings yet

- CAST - WP0 - Deliverable 0.3Document34 pagesCAST - WP0 - Deliverable 0.3คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Fabrication and Control ProcedureDocument19 pagesFabrication and Control Procedureคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Welder Qualification Records (WQT)Document17 pagesWelder Qualification Records (WQT)คุณพ่อน้อง บิ๊กบอสNo ratings yet

- S-A3-125f-01 - Specification For Painting Work - Rev.b - CDocument35 pagesS-A3-125f-01 - Specification For Painting Work - Rev.b - Cคุณพ่อน้อง บิ๊กบอสNo ratings yet

- PL 6507 Pul 01Document1 pagePL 6507 Pul 01คุณพ่อน้อง บิ๊กบอสNo ratings yet

- WPQ Ix - C - WPW 7.0.4 Form 2007 Rev. 0Document1 pageWPQ Ix - C - WPW 7.0.4 Form 2007 Rev. 0คุณพ่อน้อง บิ๊กบอส100% (1)

- Material Inspection Report 6426-1Document5 pagesMaterial Inspection Report 6426-1คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Polishing Procedure For PipesDocument4 pagesPolishing Procedure For Pipesคุณพ่อน้อง บิ๊กบอส0% (1)

- ISBL ISO Joint DB 14-9-16Document35 pagesISBL ISO Joint DB 14-9-16คุณพ่อน้อง บิ๊กบอสNo ratings yet