0% found this document useful (0 votes)

1K views6 pagesWelding Procedure Specification (WPS)

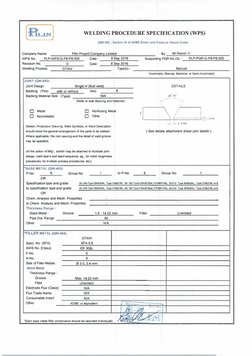

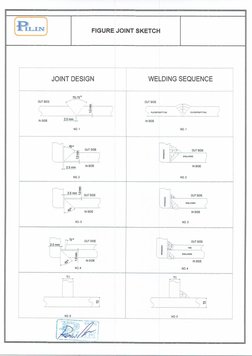

This document provides a welding procedure specification for welding stainless steel 304 to stainless steel 304 using gas tungsten arc welding. The joints will be single V butt welds, without backing, between 2-3mm thick plates. A sketch of the joint design is attached for details. This welding procedure specification was prepared according to Section IX of the ASME Boiler and Pressure Vessel Code.

Uploaded by

คุณพ่อน้อง บิ๊กบอสCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views6 pagesWelding Procedure Specification (WPS)

This document provides a welding procedure specification for welding stainless steel 304 to stainless steel 304 using gas tungsten arc welding. The joints will be single V butt welds, without backing, between 2-3mm thick plates. A sketch of the joint design is attached for details. This welding procedure specification was prepared according to Section IX of the ASME Boiler and Pressure Vessel Code.

Uploaded by

คุณพ่อน้อง บิ๊กบอสCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

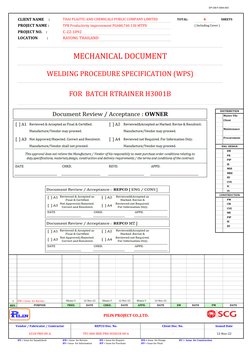

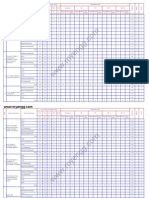

- Document Review / Acceptance: Contains approval and review details for the Welding Procedure Specification (WPS) for a specific batch product.

- Revision List: Outlines the revision history of the document including version numbers and dates.

- Welding Procedure Specification Overview: Provides a title page introducing the WPS for welding stainless steel 304 to 304.

- Welding Procedure Details: Lists detailed specifications for welding procedures including material, joint type, and preparation requirements.

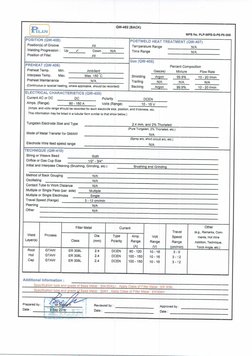

- Postweld Heat Treatment and Weld Characteristics: Describes postweld heat treatment requirements and weld characteristics necessary for quality control.

- Figure Joint Sketch: Illustrates the joint design and welding sequence with diagrams to guide visual understanding.