Professional Documents

Culture Documents

Chemical Dosing Pump Checklist Site Acceptance Test Report

Uploaded by

Deshan Sing100%(1)100% found this document useful (1 vote)

57 views2 pagesOriginal Title

Dosing Pumps Checklist-Elec_r1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

57 views2 pagesChemical Dosing Pump Checklist Site Acceptance Test Report

Uploaded by

Deshan SingCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

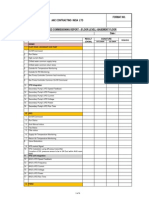

Site Acceptance Test Report

Chemical Dosing Pumps Checklist - EICA

Rev 1

(Pre-Commissioning & Commissioning)

CONTRACTOR: ACE WATER DATE: 17/01/2023

LOCATION: TSDP-CHEMICAL BUILDING EQUIPMENT TAG NO.: 57- P-003

EQUIPMENT DESCRIPTION: Diaphragm Process EQUIPMENT NO.: 2022012505

Metering Pumps for Sodium Silico Fluoride EQUIPMENT MODEL NO.: TZMBD041400PCT1100R0040

Purpose / Pump shall be checked for correct installation (Pre-Commissioning) and functional test

Scope (Commissioning).

Pass/Fail The inspection and verification of these tests must meet all system requirements and design

Criteria specifications without defects or deficiencies.

S/N Task / Description (Pre-Commissioning & Commissioning) Result Remark

Pass / Fail

MCC Mode Checking

1. Make sure emergency is released for LCS and MCC

2. Check Stop indication LCS, MCC, SCADA

3 Press start push button and check pump running

4 Check run indication on MCC, LCS & SCADA

5 Press Stop push button and check the pump stop after ramp down check the stop

indicator light

6 Start again the pump with start push button, press emergency switch and check

the pump stop

7 After press emergency, press start and make sure pump doesn’t start

8 Release the emergency button

9 Simulate fault in VFD and check trip indicator light in MCC, LCS and SCADA, &

check the alarms in the SCADA

LCS Mode Checking

1 Put the selector switch in LCS mode

2 Make sure emergency is released for LCS and MCC

3 Check Stop indication LCS, MCC, SCADA

4 Press starts push button and check pump running

5 Check run indication on MCC, LCS & SCADA

6 Press Stop push button and check the pump stop after ramp down check the stop

indicator light

7 Start again the pump with start push button, press emergency switch

8 After press emergency, press start and make sure pump doesn’t start

9 Release the emergency button

SCADA Mode Checking

1 Put the selector switch in PCS mode

2 Click start from SCADA of pump and run

3 Press stop and check the pump stop after ramp down

4 Change the speed of pump from SCADA and check on site as well as on SCADA

feedback

25%

50%

75%

100%

5 Change the stroke length and check on site as well as on SCADA feedback

25%

50%

75%

100%

6 Set the minimum and maximum speed of the pump (min. 20 Hz (TBC) and max 50

Hz)

7 Set the minimum and maximum stroke of the pump (min. 20 % (TBC) and max

100%)

Auto Mode from SCADA

1 The duty standby logic has been changed to LEAD, LAG 1 AND LAG 2. (From 2

pumps to 3 pumps)

Page 1 of 2

Site Acceptance Test Report

Chemical Dosing Pumps Checklist - EICA

Rev 1

(Pre-Commissioning & Commissioning)

2 Put the pump in SCADA Auto Mode and set the lead/lag by Priority to LEAD for

this pump – as only 1 pump will be requested to run as per existing logic (no

change in the requirement or permission to run this Sod. Silico pump from exiting

logic)

3 Check the pump runs as per existing sequence

4 Check the speed and stroke length as per existing sequence

5 Simulate the trip for this pump (57-p-003) and check the other available pump

kicks in. only 1 pump can run at a time

Make the LEAD and lag 1 both pumps UNAVAILABE and check the Lag 2 pump

kicks in.

Conclusion:

Remarks:

PREPARED BY ACE WATER CHECKED BY ACEWATER WITNESS / ACCEPTED BY PUB

SIGNATURE SIGNATURE SIGNATURE

NAME NAME NAME

DATE DATE DATE

Page 2 of 2

You might also like

- Safe Work Method Statement: (Installation of Wet Sprinkler System)Document10 pagesSafe Work Method Statement: (Installation of Wet Sprinkler System)balaji100% (1)

- Installation Method of Flow SwitchDocument1 pageInstallation Method of Flow SwitchBento BoxNo ratings yet

- Functional Design Specification - Automation SystemDocument52 pagesFunctional Design Specification - Automation SystemHari Prashanna83% (6)

- Safe Work Method Statement For Testing & Commissioning of DX Split UnitsDocument5 pagesSafe Work Method Statement For Testing & Commissioning of DX Split Unitsvin ssNo ratings yet

- PUMP Testing SheetDocument3 pagesPUMP Testing SheetAlan Tan Y RNo ratings yet

- 4) Method Statement For HVAC Copper Piping & Drain PipingDocument16 pages4) Method Statement For HVAC Copper Piping & Drain PipingIzaaz AhamedNo ratings yet

- PR-1001b - Trip - Critical Alarm Setpoint ChangeDocument13 pagesPR-1001b - Trip - Critical Alarm Setpoint ChangerwerwerwNo ratings yet

- Pre-Commissioning Check List (SAMSUNG DVMS)Document3 pagesPre-Commissioning Check List (SAMSUNG DVMS)Uzair JavedNo ratings yet

- Precommissioning & Commissioning Method Statement For Fire Hose Racks & Fire Hose ReelDocument3 pagesPrecommissioning & Commissioning Method Statement For Fire Hose Racks & Fire Hose Reelvin ss0% (1)

- PPM CHECKLIST FOR AIR COOLED SPLIT UNITDocument2 pagesPPM CHECKLIST FOR AIR COOLED SPLIT UNITdonchakdeNo ratings yet

- T&C Check List For Centrifugal Exhaust FansDocument1 pageT&C Check List For Centrifugal Exhaust Fansbeho2000No ratings yet

- 2.FIT-UP & 3. Welding ReportDocument2 pages2.FIT-UP & 3. Welding Reportkhurshid alam Khan100% (1)

- CSIKSDocument52 pagesCSIKSGustavoSilvinoSilvinoNo ratings yet

- Checklist for Firefighting SystemsDocument1 pageChecklist for Firefighting SystemsTushar BabarNo ratings yet

- Pre Commiss. Check List Chilled Water PumpsDocument3 pagesPre Commiss. Check List Chilled Water PumpsARUL SANKARAN100% (1)

- Checklist For Smoke TestDocument1 pageChecklist For Smoke TestBelal AlrwadiehNo ratings yet

- Checklist For T&C of Chemical Fire Suppression SystemDocument2 pagesChecklist For T&C of Chemical Fire Suppression Systembeho2000No ratings yet

- T&C of Pressurization UnitDocument6 pagesT&C of Pressurization UnitMohamed YousufNo ratings yet

- Testing and Commissioning of Water Booster Pump Set Method Statement PDFDocument3 pagesTesting and Commissioning of Water Booster Pump Set Method Statement PDFHumaid Shaikh100% (1)

- INSPECTION & TEST PLAN FOR CLEANING/FLUSHING CHEMICAL DOSING SYSTEMDocument1 pageINSPECTION & TEST PLAN FOR CLEANING/FLUSHING CHEMICAL DOSING SYSTEMDong Vanra100% (1)

- BMT Check List - XLSXDocument6 pagesBMT Check List - XLSXNedunuri.Madhav MurthyNo ratings yet

- Testing and Commissioning of Water Booster Pump Set Method Statement PDFDocument3 pagesTesting and Commissioning of Water Booster Pump Set Method Statement PDFHumaid ShaikhNo ratings yet

- Chemical Dosing Pump SATRDocument2 pagesChemical Dosing Pump SATRDeshan Sing100% (1)

- Centrifugal Pump Commissioning ChecklistDocument2 pagesCentrifugal Pump Commissioning ChecklistMuhammad TalhaNo ratings yet

- Testing and Commissioning Split ACDocument2 pagesTesting and Commissioning Split ACNuratiqah SharifahNo ratings yet

- Fire hydrant system test formDocument1 pageFire hydrant system test formMahmoud HassanNo ratings yet

- 13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)Document7 pages13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)SANDEEP100% (1)

- Method Statement For Precommissioning & Commissioning of Close Control Units CCU'sDocument3 pagesMethod Statement For Precommissioning & Commissioning of Close Control Units CCU'svin ssNo ratings yet

- SAIC-A-2015 Rev 2Document9 pagesSAIC-A-2015 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- O&m Manual For Turbine Oil Purifier PDFDocument73 pagesO&m Manual For Turbine Oil Purifier PDFSHAILENDRA THAKURNo ratings yet

- EPRI CIM and 61850 Harmonization 061610Document29 pagesEPRI CIM and 61850 Harmonization 061610Jaime A. SánchezNo ratings yet

- Digital Technologies Transforming CGD Value Chain From Source To ConsuDocument24 pagesDigital Technologies Transforming CGD Value Chain From Source To ConsuTrichy srplshiftNo ratings yet

- Method Statement For Testing & Commissioning of AHUDocument4 pagesMethod Statement For Testing & Commissioning of AHUsamsul maarif100% (1)

- Method Statement for Water ChlorinationDocument7 pagesMethod Statement for Water Chlorinationarshad iqbal100% (1)

- Testing and Commissioning Check ListDocument1 pageTesting and Commissioning Check ListarifzakirNo ratings yet

- Method Statement For Flushing & Chemical Cleaning Procedure of Chilled Water SystemDocument10 pagesMethod Statement For Flushing & Chemical Cleaning Procedure of Chilled Water SystemMohammed AshrafNo ratings yet

- METHOD STATEMENT FLUSHING - StampedDocument3 pagesMETHOD STATEMENT FLUSHING - StampedMohammad OsmanNo ratings yet

- Dosing Pumps Checklist-ElecDocument2 pagesDosing Pumps Checklist-ElecDeshan SingNo ratings yet

- SKM Chiller Pre-Commissioning Check List Rev 20.06.2022Document2 pagesSKM Chiller Pre-Commissioning Check List Rev 20.06.2022Riju Scaria/EMD/QTRNo ratings yet

- MOS - Air Duct Cleaning & DisnfectionDocument4 pagesMOS - Air Duct Cleaning & DisnfectionAmal SaNo ratings yet

- Tab Report Forms PRE TAB CHECK LIST (Systems Ready For TAB)Document21 pagesTab Report Forms PRE TAB CHECK LIST (Systems Ready For TAB)MMLNo ratings yet

- Fans Checklist: Project Name: Project Ref. No.: Owner: Department: GroupDocument1 pageFans Checklist: Project Name: Project Ref. No.: Owner: Department: GroupAlvin BadzNo ratings yet

- DCI JK5 Fire Protection Site Acceptance TestDocument14 pagesDCI JK5 Fire Protection Site Acceptance TestAwaludin Angga WNo ratings yet

- Ahu ItpDocument3 pagesAhu ItpMEELMAHDYNo ratings yet

- Form No. 102B - Solenoid ValveDocument1 pageForm No. 102B - Solenoid ValveVictor NairNo ratings yet

- HVAC Chilled Water Cleaning ProcessDocument7 pagesHVAC Chilled Water Cleaning Processarshad iqbalNo ratings yet

- AC Installation - Testing Form Template - CRAC - UnitDocument4 pagesAC Installation - Testing Form Template - CRAC - UnitVincent LeeNo ratings yet

- Dust Collector Service ChecklistDocument1 pageDust Collector Service ChecklistFatemeh AziziNo ratings yet

- HVAC System: Exhaust FanDocument4 pagesHVAC System: Exhaust FanAnsari1918No ratings yet

- Novec 1230 Fire Suppression SystemDocument1 pageNovec 1230 Fire Suppression SystemvivekvpsfeNo ratings yet

- Msra T&C FM 200 SystemDocument10 pagesMsra T&C FM 200 SystemSharvin NageebNo ratings yet

- Pump Commissioning Checklist - SafetyCultureDocument3 pagesPump Commissioning Checklist - SafetyCultureAnurag IngleNo ratings yet

- 5-Corrective Maintenance FahuDocument2 pages5-Corrective Maintenance FahuUmair LiaqatNo ratings yet

- Cooling Tower TNCDocument6 pagesCooling Tower TNCAarol Hatta100% (1)

- Zincanode 620 Voc v1 Jan 2018Document2 pagesZincanode 620 Voc v1 Jan 2018Moin AltafNo ratings yet

- PI PE Drain PI PE: Mitsubishi Heavy Industries KX Installation Inspection ChecklistDocument2 pagesPI PE Drain PI PE: Mitsubishi Heavy Industries KX Installation Inspection ChecklistRajesh Singh100% (1)

- PIV Flow Verfication CommissioningDocument3 pagesPIV Flow Verfication CommissioningBharathiManiNobleNo ratings yet

- Water Cooled Reciprocating Chiller Data - 30HRC070Document1 pageWater Cooled Reciprocating Chiller Data - 30HRC070calvin.bloodaxe4478No ratings yet

- Method Statement For HoistingDocument5 pagesMethod Statement For HoistingKAY UNANo ratings yet

- Testing and Commissioning of Emergency Light SystemDocument1 pageTesting and Commissioning of Emergency Light SystemUmair BaBerNo ratings yet

- Disinfection Procedure For Water Distribution LinesDocument3 pagesDisinfection Procedure For Water Distribution Linesfa forb100% (1)

- Book5 CHILLER TESTING REPORT FORMDocument6 pagesBook5 CHILLER TESTING REPORT FORMSaodahSheikhHassan100% (1)

- LVFR Sprinkler System RequirementsDocument4 pagesLVFR Sprinkler System RequirementsridwanNo ratings yet

- Descaling SOPDocument2 pagesDescaling SOPTauqir Shaukat100% (1)

- Inspectation Test PlanDocument1 pageInspectation Test Planazimr157No ratings yet

- Mech Checklist Ceiling Cassette UnitsDocument2 pagesMech Checklist Ceiling Cassette UnitsAzwan SunlineNo ratings yet

- Supporting Documents For SWR 30B2 CUDocument69 pagesSupporting Documents For SWR 30B2 CUDeshan SingNo ratings yet

- SST Test Run DataDocument1 pageSST Test Run DataDeshan SingNo ratings yet

- VALUE Manual Overwrite Gearbox DatasheetDocument1 pageVALUE Manual Overwrite Gearbox DatasheetDeshan SingNo ratings yet

- Solenoid Valves 5 2 5 3 Aluminium 551 531C001MSDocument4 pagesSolenoid Valves 5 2 5 3 Aluminium 551 531C001MSDeshan SingNo ratings yet

- 23DN0056 - Ace WaterDocument1 page23DN0056 - Ace WaterDeshan SingNo ratings yet

- 23si0055 - Ace WaterDocument1 page23si0055 - Ace WaterDeshan SingNo ratings yet

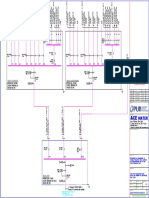

- SLD For 30A1A2 Rev2-ModelDocument1 pageSLD For 30A1A2 Rev2-ModelDeshan SingNo ratings yet

- Comment ReplyDocument1 pageComment ReplyDeshan SingNo ratings yet

- How To Create A Cheese Board ENTERTAINING WITH BETH - mp3Document2 pagesHow To Create A Cheese Board ENTERTAINING WITH BETH - mp3Deshan SingNo ratings yet

- 7 Things To Do in Your 20s To Avoid Being Miserable in Your 30sDocument1 page7 Things To Do in Your 20s To Avoid Being Miserable in Your 30sDeshan SingNo ratings yet

- The Design of Crane GirdersDocument3 pagesThe Design of Crane GirdersDeshan SingNo ratings yet

- Easy Platter Breakfast Video DescriptionDocument1 pageEasy Platter Breakfast Video DescriptionDeshan SingNo ratings yet

- Why Relaxation Is Important - Mindfulness in Action - mp3Document2 pagesWhy Relaxation Is Important - Mindfulness in Action - mp3Deshan SingNo ratings yet

- The Perfect Fish - ChipsDocument2 pagesThe Perfect Fish - ChipsDeshan SingNo ratings yet

- How To Make Smoked Salmon CanapesDocument2 pagesHow To Make Smoked Salmon CanapesDeshan SingNo ratings yet

- What Do You Know About SoupsDocument8 pagesWhat Do You Know About SoupsDeshan SingNo ratings yet

- 3 Easy Chicken Salad RecipesDocument4 pages3 Easy Chicken Salad RecipesDeshan SingNo ratings yet

- Foods That Boost Your Immune SystemDocument3 pagesFoods That Boost Your Immune SystemDeshan SingNo ratings yet

- How To Make A Tuna SandwichDocument2 pagesHow To Make A Tuna SandwichDeshan SingNo ratings yet

- YSI IQ SensorNet Wastewater Process Monitoring and Control InstrumentationDocument24 pagesYSI IQ SensorNet Wastewater Process Monitoring and Control InstrumentationYSI, a Xylem brandNo ratings yet

- Asset Management Plan 2020-2030: Horizon NetworksDocument311 pagesAsset Management Plan 2020-2030: Horizon NetworksANDY YONEL VILLAR LOBATONo ratings yet

- Scada AbbDocument111 pagesScada AbbmdfarakNo ratings yet

- Chapter 4 - Information SecurityDocument29 pagesChapter 4 - Information SecurityLaith Fadi BushnaqNo ratings yet

- M00108 BR en 1 FastNet BrochureDocument2 pagesM00108 BR en 1 FastNet BrochureFlorin StancuNo ratings yet

- SCADA Systems Vulnerabilities and Blockchain TechnologyDocument3 pagesSCADA Systems Vulnerabilities and Blockchain TechnologyEditor IJTSRDNo ratings yet

- multiCELL 8619 - Waste Water Equipment and Water Quality Monitoring - EN PDFDocument1 pagemultiCELL 8619 - Waste Water Equipment and Water Quality Monitoring - EN PDFCarlos FrancoNo ratings yet

- Vol1 Crude Oil Transmission PipelineDocument93 pagesVol1 Crude Oil Transmission PipelineWAHA COMPUTERNo ratings yet

- 2.8.1 Flood Mitigation Controller (FMC) PDFDocument3 pages2.8.1 Flood Mitigation Controller (FMC) PDFViraj Prasanna GunawardanaNo ratings yet

- EcoStruxure Hybrid DCS Process Templates User Guide - Eng - EIO0000000987.14Document227 pagesEcoStruxure Hybrid DCS Process Templates User Guide - Eng - EIO0000000987.14João Carlos AlmeidaNo ratings yet

- Case Study Using IEC 61850 Methods For RTU Replacement and Distributed AutomationDocument17 pagesCase Study Using IEC 61850 Methods For RTU Replacement and Distributed AutomationDanielAlejandroRamosQueroNo ratings yet

- Catalog EcoStruxure Automation Expert For Industrial AutomationDocument28 pagesCatalog EcoStruxure Automation Expert For Industrial AutomationRicardo Andrés Hinestroza LamusNo ratings yet

- Atics-2-Iso D00046 M XxenDocument104 pagesAtics-2-Iso D00046 M XxenPaulo BrituNo ratings yet

- DS Agile 7.0: Grid SolutionsDocument8 pagesDS Agile 7.0: Grid SolutionsthankNo ratings yet

- ALS70 Präsentation New Design enDocument44 pagesALS70 Präsentation New Design enOscar WongsoNo ratings yet

- MCMSB ComProfile Ver2Document39 pagesMCMSB ComProfile Ver2Mohd Fauzi Mohamad YusofNo ratings yet

- Advantech Automation Devices and Computing Star Product GuideDocument24 pagesAdvantech Automation Devices and Computing Star Product GuideQuantumAutomationNo ratings yet

- CIM HT006 Database Logger SetupDocument19 pagesCIM HT006 Database Logger SetupTony Choque RamosNo ratings yet

- Aveva System Platform: Game Changer For Industrial SoftwareDocument1 pageAveva System Platform: Game Changer For Industrial SoftwaredlamphuongNo ratings yet

- Substation Automation and SCADA ProtocolsDocument6 pagesSubstation Automation and SCADA ProtocolsDrAshok Kumar TiwariNo ratings yet

- DDS Industry 4.0 Profile - NEWDocument37 pagesDDS Industry 4.0 Profile - NEWSathish Kumar RockkzzNo ratings yet

- APPS 2019 - Session 53 - Substation Communications - IntroductionDocument39 pagesAPPS 2019 - Session 53 - Substation Communications - IntroductionDileep GantaNo ratings yet

- DESCO Architectural Design CompetitionDocument16 pagesDESCO Architectural Design CompetitionJafor Sadequl100% (1)

- Muhammad Imran's Engineering Career SummaryDocument5 pagesMuhammad Imran's Engineering Career Summarylucky yadavNo ratings yet