Professional Documents

Culture Documents

05 VersaFlex

Uploaded by

Jhonathan MirandaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

05 VersaFlex

Uploaded by

Jhonathan MirandaCopyright:

Available Formats

VersaFlex® System

VersaFlex® Expandable Liner System

VersaFlex® expandable liner hanger systems combine

Halliburton’s industry-leading expandable solid liner hanger

technology with our complete range of cementing products

and services to offer a total system approach to liner

installations.

The system features a VersaFlex integral liner hanger/packer

which is made up of an integral tieback receptacle above an

expandable solid hanger body and a lower sleeve designed to

carry the tensile and torque loads during deployment.

Elastomeric elements are bonded onto the hanger body. As

the hanger body is expanded, the elastomeric elements are

compressed in the annular space. This virtually eliminates

the liner hanger/casing annulus and provides liner top

pressure integrity while delivering impressive tensile and

compressive load capacity on setting. With no moving parts,

slips, or cages, the simple VersaFlex liner system design helps

eliminate the risk of pre-setting the liner hanger/packer.

Using the knowledge gained from multiple successful

installations, Halliburton has diversified the VersaFlex system

to provide a robust set of liners suitable for a variety of

applications including:

HAL18718

• Drilling liners

• Production liners

• Tight tolerance liners

• Extended reach liners

• Openhole completions

• Horizontal completions

• Drill-in liners

VersaFlex® System 5-1

VersaFlex® Liner Features

• Liner hanger and liner top isolation packers are packaged

as a single unit.

• Packer element design allows for high circulation rates.

• Large radial clearance between hanger/packer body and

support casing improves run-in-hole speeds and

circulation rates.

• Improved fluid flow with the absence of external

components such as slips, hydraulic cylinders, cages, etc.

• Less induced stress and more even stress distribution in

supporting casing for a given liner length.

• No physical damage to the supporting casing; no slip

“wickers” to cut into the supporting casing.

• Hanger/packer actuating systems are contained in the

setting tool assembly, eliminating any potential leak path

created by actuating mechanisms.

VersaFlex® Liner Benefits

HAL18506

• Potential leak paths eliminated

• Evenly distributed stress on previous casing

• Reduced operating steps Conventional Expandable

Hanger Hanger

5-2 VersaFlex® System

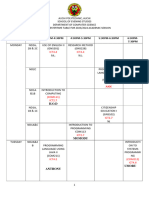

VersaFlex® Expandable Liner System Portfolio

Parent Casing Tieback

System Size Elastomer OD Tieback Length

Weight Receptacle ID

in. (mm) in. (mm) in. (cm)

lb/ft (kg/m) in. (mm)

15.5 4.810 4.192 29.75

(23.06) (122.174) (106.477) (75.565)

17.0 4.750 4.141 29.75

(24.18) (120.65) (105.181) (75.565)

3 1/2 × 5 1/2 20 4.629 4.041 29.75

(88.9 × 139.7) (26.48) (117.577) (102.641) (75.565)

23 4.513 3.946 29.75

(34.22) (114.63) (100.228) (75.565)

26 4.384 3.839 29.75

(38.68) (111.354) (97.511) (75.565)

23 6.12 5.250 95.0

(34.22) (155.45) (133.35) (241.3)

26 6 5.250 107.49

(38.68) (152.4) (133.35) (273.025)

5×7 29 5.87 5.250 94.996

(127 × 177.8) (43.15) (149.1) (133.35) (241.29)

32 5.87 5.250 94.996

(47.62) (149.1) (133.35) (241.29)

35 5.740 5.125 96.10

(52.08) (138.94) (130.17) (244.094)

20 6.245 5.250 94.3

(26.48) (158.62) (133.35) (239.522)

5 1/2 × 7 23 6.155 5.250 95.0

(139.7 × 177.8) (34.22) (156.34) (133.35) (241.3)

26 6.055 5.250 107.49

(38.68) (153.80) (133.35) (273.025)

29.7 6.49 5.750 94.3

(44.19) (164.85) (146.05) (239.522)

5 1/2 × 7 5/8 33.7 6.490 5.750 94.3

(139.7 × 193.8) (50.15) (164.85) (146.05) (239.522)

39 6.37 5.750 91.75

(58.03) (161.8) (146.05) (233.045)

7, 7 5/8 × 9 3/8 39 8.36 7.750 116.50

(177.8, 193.7 × 238.1) (58.03) (212.34) (196.85) (295.91)

36 8.531 7.750 118.0

(53.58) (216.69) (196.85) (299.72)

HAL32972

40 8.36 7.750 116.50

(59.3) (212.34) (196.85) (295.91)

7, 7 5/8 × 9 5/8 43.5 8.36 7.750 116.50

(177.8, 193.7 × 244.5) (64.80) (212.34) (196.85) (295.91)

47 8.31 7.750 116.50

(69.94) (211.07) (196.85) (295.91)

53.5 8.31 7.750 116.50

(79.61) (211.07) (196.85) (295.91)

VersaFlex® System 5-3

VersaFlex® Expandable Liner System Portfolio

Parent Casing Tieback

System Size Elastomer OD Tieback Length

Weight Receptacle ID

in. (mm) in. (mm) in. (cm)

lb/ft (kg/m) in. (mm)

7 5/8 × 9 7/8 62.8 8.31 7.750 116.50

(193.7 × 250.83) (93.46) (211.07) (196.85) (295.91)

55.5 9.625 8.404 125.34

7 3/4 × 10 3/4 (82.60) (235.331) (213.331) (318.364)

(196.85 × 273.05) 60.7 9.625 8.404 125.34

(90.34) (235.331) (213.331) (318.364)

54 10.46 9.755 166.0

9 5/8 × 11 5/8 (80.36) (265.684) (247.777) (421.64)

(244.5 × 298.45) 60.0 10.504 9.659 43.155

(89.28) (266.80) (245.330) (109.614)

65 10.36 9.659 43.155

9 5/8 × 11 3/4, 11 7/8 (96.72) (263.14) (245.330) (109.614)

(244.5 × 298.45, 301.63) 71.8 10.36 9.659 43.155

(106.84) (263.14) (245.330) (109.614)

61 12.14 11.475 43.585

(90.77) (308.36) (291.465) (110.706)

68 12.14 11.475 43.585

11 7/8 × 13 3/8, 13 5/8, 14.0 (101.18) (308.36) (291.465) (110.706)

(301.63 × 339.7, 346.08, 355.60) 72 12.14 11.475 43.585

(107.14) (308.36) (291.465) (110.706)

88.2 12.14 11.475 43.585

(131.24) (308.36) (291.465) (110.706)

129.33 17.545

N/A N/A

(192.47) (445.640)

133.0 17.510

N/A N/A

(197.94) (444.75)

16 × 20 (346.08 × 508.00)

147.0 17.510

N/A N/A

(218.77) (444.75)

169.0 17.415

N/A N/A

(251.51) (442.34)

For sizes or service not listed, contact your local Halliburton representative.

HAL32972

5-4 VersaFlex® System

VersaFlex® Liner Hanger Setting Tools

VersaFlex® liner hanger expansion (setting) is accomplished

with a hydraulically actuated liner running/setting tool

assembly. This unique system provides the necessary

expansion mechanics, cementing pack-off seals, a collet

assembly to carry the liner weight and transfer that weight to

the drill string, and an expansion indicator assembly. The

running/setting tool assembly features a primary and

secondary releasing system for maximum reliability.

Features

Each tool design is unique, however, each cementing liner

hanger running tool contains three major components which

simplify processes and enhance reliability.

• Crossover valve – incorporates multiple porting which

allows fluid flow paths for hydraulic expansion pressure

and fluid returns during the expansion process.

• Expansion cone assembly – provides the lower seal at the

expansion face which is machined into the transition

area between the tieback receptacle and the hanger body.

• Collet assembly – transfers the liner string load being

conveyed into the wellbore to the drillpipe and transmits

torque to the liner through contact with the collet

retainer to torque adaptor.

Benefits

• Allows for washing and reaming during deployment

• Higher circulating rates and pressures

• Allows rotation and reciprocation during cementing

operations

• Debris-tolerant porting

• Field-proven setting components

• Contingency release features

HAL33016

VersaFlex® Liner Hanger

Setting Tool

VersaFlex® System 5-5

VersaFlex® Portfolio

Tool Types Sizes Primary Applications Distinguishing Features

HAL33065

Internal piston design

5 in. x 7 in.

Drilling liners Primary expansion by ball set (rupture disk)

Standard 5 1/2 in. x 7 5/8 in.

Production liners Threaded mandrel connections

7 5/8 in. x 9 5/8 in.

Weight down contingency release

HAL33016

Drilling liners Internal piston design

9 5/8 in. x 11 3/4 in.

Production liners Primary expansion by flapper valve (secondary ball set)

Flapper-Set Tool 9 5/8 in. x 11 7/8 in.

Tight tolerance liners Threaded mandrel connections

11 7/8 in. x 13 3/8 in.

Drill-in liners Weight down contingency release

HAL33014

Internal piston design

5 in. x 7 in. Drilling liners Pinned mandrel connections

High Torque Tool 5 1/2 in. x 7 5/8 in. Production liners Primary expansion by flapper valve

7 5/8 in. x 9 5/8 in. Drill-in liners Two redundant setting methods

Left hand J-slot contingency release

HAL33017

External piston modules

Primary expansion by plug bump

Drilling liners

ECD 7 5/8 in. x 9 5/8 in. Redundant setting (ball drop)

Production liners

Castellated mandrel connections

Weight down contingency release

HAL33015

Drilling liners External piston modules

Production liners Primary expansion by ball set

Big Bore 16 in. x 20 in.

Tight tolerance liners Castellated mandrel connections

Drill-in liners Weight down contingency release

HAL33013

Non cemented liners Internal piston design

4 1/2 in. x 7 in. Screen installations Primary expansion by ball drop

Open Hole Horizontal

7 5/8 in. x 9 5/8 in. Drop off liners Threaded mandrel connections

Slotted/perforated liners Weight down contingency release

5-6 VersaFlex® System

Tieback Seal Units

The VersaFlex® tieback seal unit is designed to be installed

into the upper tieback receptacle (TBR) of the liner hanger

assembly. Tieback seal units allow for the upper casing string

to be tied back to surface while leaving the largest possible ID

in the hanger assembly.

• Tieback seal units are designed to be fully landed,

allowing a no-go locator to locate at the top of the TBR.

• When required to cement surface casing in place, the

tieback seal unit can be used alone or in conjunction

with Halliburton SuperFill™ TB equipment.

(See additional data located within the Casing

Equipment PSL.)

• Metallurgy and seal units can be selected to suit well

conditions.

• Seal units come in three types of elastomer

configurations—premium, molded, and bonded.

HAL33164

Tieback

Seal Unit

VersaFlex® System 5-7

VersaFlex® Expandable Liner Hanger Plug Systems

The VersaFlex® plug system consists of three main

components—the VersaFlex plug assembly, wiper dart, and

landing collar. Each component must be ordered separately

to meet material requirements. The VersaFlex plug set is

supported by the Casing Equipment group located in

Duncan, Oklahoma.

VersaFlex Plug Assembly

The plug design utilizes the proven HWE® High Wiping

Efficiency cementing plug design to provide superior wiping

performance and fluid separation with a single wiper plug.

The plug design has several unique features that provide

improved functionality and reliability, including:

• Integral swivel mechanism along with an equalizing

feature

• Incorporates dual release features to ensure plug launch

during displacement operations

• Incorporates a spacer tube to fully encapsulate the

drillpipe wiper plug and precludes debris interfering

with the transmission of hydraulic forces to the

contingency release mechanism

• Designed for the most common casing sizes

• Designed to be used in conjunction with a landing collar

• Two distinct types:

– Standard HWE plug assembly for use in mud

weights < 16ppg

– Heavy mud HWE plug assembly for use in mud

HAL32969

weights > 16ppg

HAL32968

Standard Heavy Mud

HWE® Plug HWE® Plug

Assembly Assembly

5-8 VersaFlex® System

VersaFlex® DP Wiper Dart

The VersaFlex® DP wiper dart is a unique releasing plug

designed specifically for use with the VersaFlex plug

assembly. (SSR® subsurface release wiper plugs are not

compatible with this system.)

• The wiper dart is available to cover a variety of standard

drillpipe sizes.

• Wiper darts for tandem string scenarios also available.

VersaFlex Landing Collar

The VersaFlex plug assembly is designed to be used in

conjunction with a landing collar. The VersaFlex plug

assemblies and landing collars have been designed for the

most common casing sizes.

• Uniquely designed to mate with the VersaFlex plug

assembly.

• The specially designed landing collar helps ensure a

positive seal is created when plug bump is achieved and

is primarily available in P-110 or P-110/Q-125 grades.

HAL32938

To request information on VersaFlex plug sets, compatible

wiper darts, and special threads, materials, or blanking VersaFlex®

dimensions for use on the landing collar, email the Casing DP Wiper Dart

Equipment PSL at

resource.casingequipment@Halliburton.com.

HAL32941

VersaFlex®

Landing Collar

VersaFlex® System 5-9

Float Equipment

Super Seal II® Float Equipment

Super Seal II® floating equipment is installed in and becomes

an integral part of the casing string. This equipment helps

float and cement the casing in the well. The equipment's

basic backpressure and temperature ratings (5,000 psi and

400°F) allow it to be used in most wells. The plastic valve

materials and surrounding shear and shockload-resistant

concrete exceed the strength requirements for landing

cementing plugs. The valve assembly and the cement holding

the valve assembly in place can be drilled out easily with

HAL8101

roller-cone rock bits or polycrystalline diamond compact

(PDC) bits after cementing operations. All casing-size

Super Seal II float shoes and collars are supplied with an Super Seal II®

autofill feature. Customers can request Super Seal II float Float Collar

equipment for any casing grade or premium thread.

Super Seal II Float Collar

The Super Seal II float collar includes the Super Seal II

backpressure valve, which prevents cement pumped into the

casing/wellbore annulus from re-entering the casing ID after

cementing operations. The float collar is normally installed

one or two joints above the float or guide shoe.

HAL8097

Float Shoe

The high-port up-jet (HPUJ) float shoe jets the formation Super Seal II® High-Port

face to remove detrimental mud cake and cuttings, Up-Jet (HPUJ)

increasing the chances of a successful cement-to-formation Float Shoe

bond. The high circulation rates and cement flow rates that

are possible with the Super Seal II float valve allow turbulent

flow at the shoe without damaging the float valve.

• Approximately 40% of the fluid pumped through the

equipment is discharged at a high velocity through the

bottom of the float shoe.

• All Super Seal II HPUJ float shoe casing sizes use the

same autofill strap used for the Super Seal II float valve.

5-10 VersaFlex® System

You might also like

- Versaflex Select Expandable Liner Hanger System: FeaturesDocument2 pagesVersaflex Select Expandable Liner Hanger System: FeatureskirankirkNo ratings yet

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- Ieback EAL Ipple: Tieback Seal Nipple (TSN), Orifi Ce Float Collar (OFC) and An ExistingDocument3 pagesIeback EAL Ipple: Tieback Seal Nipple (TSN), Orifi Ce Float Collar (OFC) and An ExistingGhinet Teodor-ioanNo ratings yet

- Microbial Enhancement of Oil Recovery - Recent AdvancesFrom EverandMicrobial Enhancement of Oil Recovery - Recent AdvancesNo ratings yet

- Stuffing Box EmpaquesDocument4 pagesStuffing Box EmpaquesJaime RuizNo ratings yet

- Pollution Control Stuffing Box (PCSB™)Document1 pagePollution Control Stuffing Box (PCSB™)2643108No ratings yet

- VersaFlex ELH Cementing Plug System - H06448Document2 pagesVersaFlex ELH Cementing Plug System - H06448rodrigo788No ratings yet

- C 2 Hipstock Ystems: HapterDocument16 pagesC 2 Hipstock Ystems: HapterRazvan Radu100% (1)

- (J. A Short) Drilling A Source Book On Oil and Ga PDFDocument588 pages(J. A Short) Drilling A Source Book On Oil and Ga PDFZana QadirNo ratings yet

- Slimhole Drilling Paper Revised June 2016 PDFDocument28 pagesSlimhole Drilling Paper Revised June 2016 PDFAbhinav GoyalNo ratings yet

- C 06.C Wellhead DesignDocument6 pagesC 06.C Wellhead DesignJose David Hernandez OteroNo ratings yet

- Ring Type Joint Gaskets Styles: R, RX, BXDocument2 pagesRing Type Joint Gaskets Styles: R, RX, BXiswantmachooNo ratings yet

- Brochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedDocument8 pagesBrochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedNightNo ratings yet

- Control of Paraffin Deposition in Production Operations: SPE, Conoco Inc. SPE, Conoco IncDocument6 pagesControl of Paraffin Deposition in Production Operations: SPE, Conoco Inc. SPE, Conoco IncAlesa Acosta JaraNo ratings yet

- Perforating Catalog: ISSUE 5 - March 2020Document218 pagesPerforating Catalog: ISSUE 5 - March 2020Aboozar Fathinejad100% (1)

- Wellbore Integrity Restoration Services Brochure PDFDocument8 pagesWellbore Integrity Restoration Services Brochure PDFDavid LuhetoNo ratings yet

- Unu-Gtp-Sc-06-42 Geothermal Drilling and Well PumpsDocument13 pagesUnu-Gtp-Sc-06-42 Geothermal Drilling and Well PumpsPrince MubaiwaNo ratings yet

- Pressure Control GroupDocument4 pagesPressure Control GroupAbdelhamid HaramiNo ratings yet

- LandRig PosterDocument1 pageLandRig PosterRaúl MárquezNo ratings yet

- Spe 196232 MSDocument18 pagesSpe 196232 MShijoetigreNo ratings yet

- Santrol Pocket Guide InternationalDocument2 pagesSantrol Pocket Guide Internationalintoyou2007No ratings yet

- Radial Cutting Torch 070415Document4 pagesRadial Cutting Torch 070415Carlos Alberto Aguilera MendezNo ratings yet

- Cwor-Brochure WebDocument8 pagesCwor-Brochure WebMartin McCaffreyNo ratings yet

- Logan Taper Taps Catch Stuck ToolsDocument2 pagesLogan Taper Taps Catch Stuck ToolsrezaNo ratings yet

- Weatherford Lamb Libya Limited - Casing Exit & Selective ReDocument75 pagesWeatherford Lamb Libya Limited - Casing Exit & Selective ReRicardo Hurtado HernándezNo ratings yet

- Maxfire Electronic Firing Systems: Conveyance and Triggering OptionsDocument7 pagesMaxfire Electronic Firing Systems: Conveyance and Triggering OptionsGabriel GonzalezNo ratings yet

- Wellhead Connector H4 TypeDocument9 pagesWellhead Connector H4 Typeste7ieNo ratings yet

- 3 - Arenas Curables y ActivadoresDocument52 pages3 - Arenas Curables y ActivadoresPablo SotoNo ratings yet

- National Commission Report on the Deepwater Horizon DisasterDocument11 pagesNational Commission Report on the Deepwater Horizon Disasterjonsmith2009No ratings yet

- Packer HP 6 Technical LiteratureDocument7 pagesPacker HP 6 Technical LiteratureRaul Diaz100% (1)

- API Monogram Mud Gas SeparatorDocument1 pageAPI Monogram Mud Gas SeparatorKapwell LimitedNo ratings yet

- Spe 96810 MS PDocument10 pagesSpe 96810 MS PSlim.BNo ratings yet

- TPS MULTISEAL TS-6 Connection Data SheetDocument1 pageTPS MULTISEAL TS-6 Connection Data SheetKhairilsyam Abdul RashidNo ratings yet

- Grant Prideco Field Service For Atlas Bradford ConnectionsDocument12 pagesGrant Prideco Field Service For Atlas Bradford Connectionsnardo_ingNo ratings yet

- Sec 3 Well ServicingDocument38 pagesSec 3 Well ServicingWilliam EvansNo ratings yet

- Introduction To OCTG: API Steel Grades Handout 03Document4 pagesIntroduction To OCTG: API Steel Grades Handout 03AHMEDNo ratings yet

- PST 21 FH Hydro Hydraulic PackerDocument1 pagePST 21 FH Hydro Hydraulic Packerjainendra_ism100% (1)

- PPE I PR 005Document11 pagesPPE I PR 005MahanderOadNo ratings yet

- EXP Well Testing Commisioning A4 24p ProofDocument24 pagesEXP Well Testing Commisioning A4 24p ProofMohan RajaNo ratings yet

- Drain Valve - Bussines CatalogDocument2 pagesDrain Valve - Bussines CatalogAnne SophiaNo ratings yet

- Tomax AST Tool User ManualDocument4 pagesTomax AST Tool User ManualChinyere NkereNo ratings yet

- H00707Document2 pagesH00707AQUILES CARRERANo ratings yet

- CHAMP® XHP PackerDocument2 pagesCHAMP® XHP PackerservicemenruNo ratings yet

- Inspection Casing On Location Procedure22222222Document11 pagesInspection Casing On Location Procedure22222222hamdi hamdiNo ratings yet

- Acid-Tunneling Technique Shows Success in Stimulating Carbonate ReservoirsDocument3 pagesAcid-Tunneling Technique Shows Success in Stimulating Carbonate ReservoirsFisher YohannesNo ratings yet

- Wellhead - Manual S2100559Document47 pagesWellhead - Manual S2100559Parag PadoleNo ratings yet

- TSH BR Torque Values PDFDocument120 pagesTSH BR Torque Values PDFaliNo ratings yet

- Magnum Composite Plug Catalog 06-30-10 PDFDocument21 pagesMagnum Composite Plug Catalog 06-30-10 PDFEmad JamshidiNo ratings yet

- Cleancut CCB PDFDocument2 pagesCleancut CCB PDFbruce lian100% (1)

- Pipe Body Performance PropertiesDocument118 pagesPipe Body Performance Propertieshamid nobakhtNo ratings yet

- Understanding Special Drift CasingDocument2 pagesUnderstanding Special Drift CasingLuis David Concha CastilloNo ratings yet

- Botil Model BTCN Mechanical Set PackerDocument2 pagesBotil Model BTCN Mechanical Set PackerReivaj JavierNo ratings yet

- Otc 15179 MSDocument10 pagesOtc 15179 MSHafiz AsyrafNo ratings yet

- Coiled Tubing Calculation: Sws - Career Development System (Phase - I) Coiled Tubing Service Class Room TrainingDocument16 pagesCoiled Tubing Calculation: Sws - Career Development System (Phase - I) Coiled Tubing Service Class Room TrainingNardo AvalosNo ratings yet

- Scab Liner Packer (SLP) : Specification GuideDocument1 pageScab Liner Packer (SLP) : Specification Guidecatalin calinNo ratings yet

- 4.500 in 18.90 PPF 0.430 in SM2535-125 VAM HTF-NR Ref. 27-11-17Document1 page4.500 in 18.90 PPF 0.430 in SM2535-125 VAM HTF-NR Ref. 27-11-17Ahmed Elwany100% (1)

- Spider Varco 375Document1 pageSpider Varco 375Hany AhmedNo ratings yet

- Hydraquaker: Hydraulic Drilling Jar Delivers High ImpactDocument4 pagesHydraquaker: Hydraulic Drilling Jar Delivers High ImpactPavin PiromNo ratings yet

- API Casing Float Collar and ShoeDocument2 pagesAPI Casing Float Collar and Shoeisrar haiderNo ratings yet

- SPE20077120210612Document15 pagesSPE20077120210612Jhonathan MirandaNo ratings yet

- TruformDocument8 pagesTruformJhonathan MirandaNo ratings yet

- Liner Hanger Systems Data SheetDocument1 pageLiner Hanger Systems Data SheetJhonathan MirandaNo ratings yet

- 51 Albpetrol Sha Stream Oil Gas LTD Delvina Block Psa 2007 PDFDocument67 pages51 Albpetrol Sha Stream Oil Gas LTD Delvina Block Psa 2007 PDFIbrahim SalahudinNo ratings yet

- Centralizer WTFDocument8 pagesCentralizer WTFJhonathan MirandaNo ratings yet

- 02 - Multilateral SolutionsDocument6 pages02 - Multilateral SolutionsJhonathan MirandaNo ratings yet

- HP+Series+Catalog+Rev +CDocument6 pagesHP+Series+Catalog+Rev +CJhonathan MirandaNo ratings yet

- Caso Fishing Services1Document1 pageCaso Fishing Services1Jhonathan MirandaNo ratings yet

- TruformDocument8 pagesTruformJhonathan MirandaNo ratings yet

- PackerDocument10 pagesPackerJhonathan Miranda100% (1)

- Caso Fishing Services2Document1 pageCaso Fishing Services2Jhonathan MirandaNo ratings yet

- Caso Fishing Services3Document1 pageCaso Fishing Services3Jhonathan MirandaNo ratings yet

- Non-Rotational Safety Shear Sub GuideDocument3 pagesNon-Rotational Safety Shear Sub GuideJhonathan MirandaNo ratings yet

- Caso Fishing ServicesDocument1 pageCaso Fishing ServicesJhonathan MirandaNo ratings yet

- Good PDFDocument141 pagesGood PDFHanaNo ratings yet

- Redacoil Lower Connector PsDocument1 pageRedacoil Lower Connector PsJhonathan MirandaNo ratings yet

- Guia de C#Document2,358 pagesGuia de C#Jhonathan Miranda100% (1)

- 15 800 7040 00 00 PLDocument1 page15 800 7040 00 00 PLJhonathan MirandaNo ratings yet

- Slickline E Line Combo TruckDocument1 pageSlickline E Line Combo TruckJhonathan MirandaNo ratings yet

- 4.000 LOCATOR SEAL ASSEMBLY PARTS LISTDocument1 page4.000 LOCATOR SEAL ASSEMBLY PARTS LISTJhonathan MirandaNo ratings yet

- 15-280 282 283 and 285 Tech Manual Rev BDocument8 pages15-280 282 283 and 285 Tech Manual Rev BJhonathan MirandaNo ratings yet

- 13 Operation Manual Ows Wenzel Double Acting Hydraulic Drilling JarDocument10 pages13 Operation Manual Ows Wenzel Double Acting Hydraulic Drilling JarYaqoob IbrahimNo ratings yet

- 15-603 - Technical Manual Rev CDocument12 pages15-603 - Technical Manual Rev CJhonathan MirandaNo ratings yet

- ASBP 7 17-26 26-32 CurrentDocument10 pagesASBP 7 17-26 26-32 CurrentJhonathan MirandaNo ratings yet

- 15-281 Tech Manual Rev BDocument4 pages15-281 Tech Manual Rev BJhonathan MirandaNo ratings yet

- 15-280 282 283 and 285 Tech Manual Rev BDocument8 pages15-280 282 283 and 285 Tech Manual Rev BJhonathan MirandaNo ratings yet

- 15-725 - Tech Manual Rev CDocument13 pages15-725 - Tech Manual Rev CJhonathan MirandaNo ratings yet

- PackerDocument10 pagesPackerJhonathan Miranda100% (1)

- Automatic Rework Order Using Reason of Variance Key: Applies ToDocument21 pagesAutomatic Rework Order Using Reason of Variance Key: Applies ToRitesh Tiwari50% (4)

- Datcon Tachometer Installation Instructions PDFDocument2 pagesDatcon Tachometer Installation Instructions PDFHanNo ratings yet

- Robosapien X Manual PDFDocument20 pagesRobosapien X Manual PDFbiroupersonal100% (1)

- SMB-R Melt Blender Installation ManualDocument12 pagesSMB-R Melt Blender Installation ManualNestor Mario NesralaNo ratings yet

- Full - Doc (LC Corrections)Document8 pagesFull - Doc (LC Corrections)Liam CarterNo ratings yet

- Technical Trading Co. LLC Fire Projects Division Fm-200 SystemDocument7 pagesTechnical Trading Co. LLC Fire Projects Division Fm-200 SystemmuthuvelaaNo ratings yet

- Clio Brochure Uk PDFDocument52 pagesClio Brochure Uk PDFTõnis TranzeNo ratings yet

- Senior Digital Marketing Director in Denver CO Resume Clark RappDocument6 pagesSenior Digital Marketing Director in Denver CO Resume Clark RappClarkRappNo ratings yet

- Application Software Installation - Lesson PlanDocument3 pagesApplication Software Installation - Lesson PlanLeo Loven Lumacang100% (9)

- MACC Manual Guide Solid State Converter Installation Operation MaintenanceDocument26 pagesMACC Manual Guide Solid State Converter Installation Operation Maintenancelnoriega9637No ratings yet

- Compact Transformer Substation Technical SpecificationDocument43 pagesCompact Transformer Substation Technical SpecificationADNAN MURAT İNCAMAN100% (1)

- Object Motion Detection in Home Security System Using The Binary-Image Comparison Method Based On Robot Operating System 2 and Raspberry PiDocument8 pagesObject Motion Detection in Home Security System Using The Binary-Image Comparison Method Based On Robot Operating System 2 and Raspberry PiRukmyy SapsuhaNo ratings yet

- CH 1Document62 pagesCH 1Aratrika SinghNo ratings yet

- 1.1 - Chapter 1 - The Worlds of Database SystemsDocument31 pages1.1 - Chapter 1 - The Worlds of Database SystemsPhạm Nhựt HàoNo ratings yet

- Simulation of 2.4Ghz Microstrip Patch Antenna Using Ebg StructureDocument5 pagesSimulation of 2.4Ghz Microstrip Patch Antenna Using Ebg StructureSanjeev KumarNo ratings yet

- Sudeep C Sawant - Program ManagerDocument4 pagesSudeep C Sawant - Program ManagerAniket mishraNo ratings yet

- Sikkim Manipal University ProjectDocument7 pagesSikkim Manipal University ProjectAnil Kumar SinghNo ratings yet

- Infineon-CE217633 BLE Blood Pressure Sensor With PSoC 6 MCU With BLE Connectivity-Code Example-V01 00-EnDocument17 pagesInfineon-CE217633 BLE Blood Pressure Sensor With PSoC 6 MCU With BLE Connectivity-Code Example-V01 00-EnJose PereiraNo ratings yet

- FJRX 84 EngDocument22 pagesFJRX 84 EngPalade LiviuNo ratings yet

- Unit 7Document54 pagesUnit 7Pavankumar GorpuniNo ratings yet

- Fdas765 Data SheetDocument2 pagesFdas765 Data SheettanadfNo ratings yet

- Paving The Pathways To Impact: in Horizon EuropeDocument10 pagesPaving The Pathways To Impact: in Horizon Europefatmama7031No ratings yet

- EasyEDA-Std-Tutorial - v6 5 22Document427 pagesEasyEDA-Std-Tutorial - v6 5 22Frédéric QuérinjeanNo ratings yet

- G-Stomper 7 - Drum SamplerDocument27 pagesG-Stomper 7 - Drum SamplerpapschmearNo ratings yet

- SRNC CRNC DRNCDocument1 pageSRNC CRNC DRNCSYA100% (1)

- Unit1 McqsDocument34 pagesUnit1 McqsAbhishekNo ratings yet

- Timetable First Semester 2023-2024Document12 pagesTimetable First Semester 2023-2024promiseikosimi43No ratings yet

- Red Hat Enterprise Linux 9: Package ManifestDocument415 pagesRed Hat Enterprise Linux 9: Package ManifestMichał GabryelskiNo ratings yet

- IP Lab Manual - PROGRAM ALONEDocument39 pagesIP Lab Manual - PROGRAM ALONEsuchdev darshanNo ratings yet

- Qoe by HuaweiDocument54 pagesQoe by HuaweiTahitii ObiohaNo ratings yet