Professional Documents

Culture Documents

A9 Mechanical Properties of Solids

Uploaded by

Ishaan JhaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A9 Mechanical Properties of Solids

Uploaded by

Ishaan JhaCopyright:

Available Formats

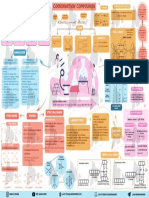

APPLICATIONS OF

STRESS & ITS MECHANICAL PROPRTIES OF SOLIDS ELASTIC BEHAVIOUR

TYPES OF SOLIDS

(1) Stress is restoring force per When weight is suspended in beam,

unit area it Strouse buckling

(2) σ = F

A STRAIN & ITS ω 3

S=

4 bd3 y

(3) It is neither scalar nor TYPES

vector, l

(4) It’s unit is N/m2

POISSON'S RATIO d

(1) Ratio of change in configuration to

original configuration of body.

(2) It is a unit less quantity Ratio of lateral to longitudinal strain is

Poisson’s ratio

∆ configuration

W

(3) Strain = HOOKE'S LAW

original configuration − Σ lateral

σ= ( −1 ≤ σ ≤ 0.5)

Σ longitudnal • Extension is measured in ropes

• When load is applied to bodies up to certain of Cranes while load is suspended

NORMAL STRESS proportionality limit, stress is directly

proportional to strain.

`on it

mg

LINEAR STRAIN σ=

Relation between Y, B, η and Σ A

(1) Tensile stress is produced when • σ∝Σ (1) Y = 3B (1 - 2σ ),

axial force acts per unit Area. (1) Linear strain is the ratio of σ = stress produced in rope

(2) Y = 2n (1 + σ )

(2) This stress

change in length to original

length.

• σ ∝ YΣ

3B − 2n

results in

∆ σ (3) σ=

Elongation; (2) ∑= • y = , where Y is the proportionality Constant 2n + 6B

Σ named as Young’s modules

VOLUMETRIC STRAIN

Li

F

(i) Ratio of change in volume to

F

original volume, A

(1) Compressive stress is produced sTRESS-STRAIN

when force compresses object ∆V GRAPH B TYPES OF

(ii) ∑=

V

F

per unit area. F

Slope of stress strain ELASTIC CONSTANTS

Stress

Lf

curve will be Young’s

(2) This stress modulus

σ

results in YOUNG’S MODULES =

Compression Σ

φ2

Limit of

φ1 • property of material, that tells how

Proportionality easily it can be stretched.

B Strain

VOLUMETRIC STRESS LATERAL STRAIN A

Elastic Limit • σ , E are normal stress and strains I - SHAPED BEAMS

respectively

• When object is immersed inside (1) Lateral strain is ratio of • I – shape of beams makes them

aw

the liquid, the hydrostatic change in breadth/ diameter sTRESS-STRAIN excellent for unidirectional

’s L

F Bi F Stress

ke

pressure decreases the volume to original breadth/ diameter, bending.

o

CURVE

Ho

of an object, that results the SHEAR MODULUS

`volumetric stress. (2) ∑ = ∆(Breadth / Diameter) • Use of rectangular shaped

• Ratio of shear stress by shear strain.

Breadth / Diameter F Bf F

• Unit is Pascal (Pa)

beams is not possible in railway

tracks as of improper load

O Strain

(3) Change occurs in the direction distribution

L

perpendicular to the applied

force. THERMAL STRESS −∆P

BULK MODULUS =

SHEAR STRAIN (i) energy stored due to elastic deformation. ∆V / V

(ii) Strain Energy density is energy per unit

(1) Angular deformation caused by volume. • measure of ability of material to

SHEAR STRESS THERMAL STRESS 1

shearing force is shearing strain. (iii) strain Energy per unit Volume = ×σ×Σ withstands the change in volume.

(1) Shear stress is produced when 2 • negative sign indicates decrease in ISOTHERMAL BULK MODULUS

(I) Difference in temperature of a rod

force acts tangentially to a results the change in configuration (2) tan θ = S / h 1 (σ) 2 volume

B=P

×

surface area. of it. This produces thermal stress. (3) For small change θ=S/h (iv) strain Energy per unit Volume =

2 y

(2) Deforming force acts

COMPRESSIBILITY = 1B

tangentially to the surface F L

ADIABATIC BULK MODULUS

= Y ∝ ∆T L

S A

F

tan θ = Shearing Area

h Shear Force h • Reciprocal of Bulk modulus

(I) B = YP,

h

(2) Y = Adiabatic constant

• Value depends on particle shape,

L F

L F density and chemical composition.

anand_mani16 DR. Anand Mani https://www.anandmani.com/ https://discord.io/anandmani t.me/anandmani001

You might also like

- Physics PDFDocument6 pagesPhysics PDFAriel Nolberto Jarita Ccama100% (1)

- CPCTCDocument12 pagesCPCTCGen Li TogyNo ratings yet

- Combination M EterDocument4 pagesCombination M Eterwilder100% (1)

- Nema-C12.1 2008Document120 pagesNema-C12.1 2008Diego Ernesto Mariño SilvaNo ratings yet

- Anti-Lenz - Anti-LenzDocument6 pagesAnti-Lenz - Anti-LenzTomislav JovanovicNo ratings yet

- Machinery Fault DiagnosisDocument1 pageMachinery Fault DiagnosisVLD DiagnosticsNo ratings yet

- MachineryFaultsDiagnosis PUTRANATADocument1 pageMachineryFaultsDiagnosis PUTRANATAdaniel_silabanNo ratings yet

- CKB 20104 - Reaction EngineeringDocument9 pagesCKB 20104 - Reaction EngineeringNoor FatihahNo ratings yet

- Surface Roughness ChartDocument1 pageSurface Roughness ChartdmayhillNo ratings yet

- Physics MapDocument30 pagesPhysics Mapkanojiyadivyansh75No ratings yet

- Analysis of StressDocument2 pagesAnalysis of StresssijyvinodNo ratings yet

- Mechanical PropertiesDocument2 pagesMechanical Propertiesadarsh29adityaNo ratings yet

- EIA WarehouseDocument3 pagesEIA WarehouseAnnabella1234No ratings yet

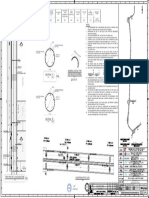

- General Detail For Lap Splice of Spiral A Section: NotesDocument1 pageGeneral Detail For Lap Splice of Spiral A Section: NotesPravin AwalkondeNo ratings yet

- Eia HPDocument5 pagesEia HPAnnabella1234No ratings yet

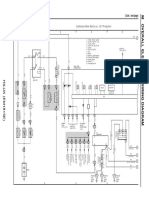

- (Cont. Next Page) 10 Toyota Fortuner: Power Source ECT and A/T Indicator (1GR-FE)Document3 pages(Cont. Next Page) 10 Toyota Fortuner: Power Source ECT and A/T Indicator (1GR-FE)alexander pintoNo ratings yet

- Darlington: Silicon NPN Triple Diffused Planar Transistor (Complement To Type 2SB1687)Document1 pageDarlington: Silicon NPN Triple Diffused Planar Transistor (Complement To Type 2SB1687)mundomusicalmeriaNo ratings yet

- Ch. 3.1 Notes For RotationDocument12 pagesCh. 3.1 Notes For RotationKhru GheraldNo ratings yet

- Elastic Deformations Basic Knowledge - English PDFDocument1 pageElastic Deformations Basic Knowledge - English PDFMuhammad Naseem Ishaq /ME Lab EngineerNo ratings yet

- Bridge No. 169b1-1x6.00mx6.00m RCC Box - v9 - Approve - p42Document1 pageBridge No. 169b1-1x6.00mx6.00m RCC Box - v9 - Approve - p42Sourav DasGuptaNo ratings yet

- Ch2 Tests Results RecordDocument2 pagesCh2 Tests Results RecordrafiNo ratings yet

- Oscillations MindmapDocument1 pageOscillations Mindmapsarthakyedlawar04No ratings yet

- Discrete Solitons en BEECDocument1 pageDiscrete Solitons en BEECPamela Catalán ContrerasNo ratings yet

- General Design 03 19Document2 pagesGeneral Design 03 19dNo ratings yet

- hdt14 Stat Equi1Document8 pageshdt14 Stat Equi1ruben madridejosNo ratings yet

- ch2 Tests Results RecordDocument2 pagesch2 Tests Results RecordRafi Mahmoud SulaimanNo ratings yet

- Recommended Laboratory TestsDocument2 pagesRecommended Laboratory TestsVishalya Nipuni LankeshiNo ratings yet

- 1 9780898718874 ch4Document22 pages1 9780898718874 ch4tingweizhou2023No ratings yet

- 35 Hilux (Cont. Next Page) : Power Source Combination Meter (Before Jun. 2011 Production)Document4 pages35 Hilux (Cont. Next Page) : Power Source Combination Meter (Before Jun. 2011 Production)tinashemariri29191No ratings yet

- 35 Hilux (Cont. Next Page) : Power Source Combination Meter (Before Jun. 2011 Production)Document4 pages35 Hilux (Cont. Next Page) : Power Source Combination Meter (Before Jun. 2011 Production)Tito alanesNo ratings yet

- 35 Hilux (Cont. Next Page) : Power Source Combination Meter (Before Jun. 2011 Production)Document4 pages35 Hilux (Cont. Next Page) : Power Source Combination Meter (Before Jun. 2011 Production)MartinThangDeihTungNo ratings yet

- 35 Hilux (Cont. Next Page) : Power Source Combination Meter (Before Jun. 2011 Production)Document4 pages35 Hilux (Cont. Next Page) : Power Source Combination Meter (Before Jun. 2011 Production)WilliamZabaletaNo ratings yet

- 35 Hilux (Cont. Next Page) : Power Source Combination Meter (Before Jun. 2011 Production)Document4 pages35 Hilux (Cont. Next Page) : Power Source Combination Meter (Before Jun. 2011 Production)Fawad ShahNo ratings yet

- Incorporation of A Fault Factor Into TheDocument35 pagesIncorporation of A Fault Factor Into TheCARLOS OSIEL SEBASTIÁN VALDÉSNo ratings yet

- 11 Hilux (Cont. Next Page) : Power Source ECT and A/T Indicator (1GR-FE)Document3 pages11 Hilux (Cont. Next Page) : Power Source ECT and A/T Indicator (1GR-FE)Muzaffar AljaeleNo ratings yet

- Eia FGDocument8 pagesEia FGAnnabella1234No ratings yet

- Coulombs Law HTML Guide - enDocument2 pagesCoulombs Law HTML Guide - enJaenewton LimaNo ratings yet

- Poster DSHARDSofKazeruncountyDocument2 pagesPoster DSHARDSofKazeruncountyMark Joshua NaborNo ratings yet

- 00 FEM Part 2Document10 pages00 FEM Part 2Dawit TesfayeNo ratings yet

- Instabilities Legend Prism Status Chart of Status Instrumentation Legend Vector Legend Prism Legend Prisms ReadingsDocument1 pageInstabilities Legend Prism Status Chart of Status Instrumentation Legend Vector Legend Prism Legend Prisms ReadingsEdson OoNo ratings yet

- At At: Internal 'Viscosity'Document10 pagesAt At: Internal 'Viscosity'Leidy OsorioNo ratings yet

- 2SD 2017 PDFDocument1 page2SD 2017 PDFtabassam7801No ratings yet

- Design WeldDocument1 pageDesign WeldPabloScurraNo ratings yet

- P843 GEM Poster - JK CiDocument1 pageP843 GEM Poster - JK CiTsubasa OozoraNo ratings yet

- C9 Coordination CompoundsDocument1 pageC9 Coordination CompoundsPARAMBATH ANUP KUMARNo ratings yet

- M/S Vindhya Telelinks Limited Gaja Engineering PVT - LTD JV: A E B C D A E B C DDocument1 pageM/S Vindhya Telelinks Limited Gaja Engineering PVT - LTD JV: A E B C D A E B C DTarun SinghalNo ratings yet

- Ashish Minotaur Monk Hermit L1-MPMBDocument2 pagesAshish Minotaur Monk Hermit L1-MPMBSamNo ratings yet

- 123519-Article Text-338003-1-10-20151009Document6 pages123519-Article Text-338003-1-10-20151009santoshNo ratings yet

- Reston Dulles Special Study 2009E4 ParksDocument1 pageReston Dulles Special Study 2009E4 ParksTerry MaynardNo ratings yet

- 2sd2560 Ds enDocument1 page2sd2560 Ds enMarius IggyNo ratings yet

- Poster FinalDocument1 pagePoster FinalTalha HussainNo ratings yet

- CS3500 Computer Graphics Module: Projective Geometry: P. J. NarayananDocument16 pagesCS3500 Computer Graphics Module: Projective Geometry: P. J. Narayananapi-3799599No ratings yet

- ShipS G5 Santos Nevarez Ortega Ortega ZambranoDocument7 pagesShipS G5 Santos Nevarez Ortega Ortega ZambranoPaúl ZambranoNo ratings yet

- 1996 - DiscuciónDocument3 pages1996 - DiscuciónPaul KohanNo ratings yet

- Poster Miranda PDFDocument1 pagePoster Miranda PDFxabihdez05No ratings yet

- Atellica IM Analyzer Assay Chart, 11314389 Rev03, EN DXDCM 09017fe980577c45-1621893892636Document10 pagesAtellica IM Analyzer Assay Chart, 11314389 Rev03, EN DXDCM 09017fe980577c45-1621893892636chinuswami100% (1)

- PHY 108 - Circular Motion Practice QuestionsDocument3 pagesPHY 108 - Circular Motion Practice QuestionsShiloh FrederickNo ratings yet

- Study of RefrigiratorDocument14 pagesStudy of RefrigiratorRobo RajaNo ratings yet

- Thermal Properties of MatterDocument2 pagesThermal Properties of MatterRiya BhardwajNo ratings yet

- Pro/Ii Excel - Engine Unitid XXX: NcalDocument32 pagesPro/Ii Excel - Engine Unitid XXX: NcalYves-donald MakoumbouNo ratings yet

- Short Circuit Withstand of Power Cables A Calculation ExampleDocument59 pagesShort Circuit Withstand of Power Cables A Calculation Exampleramadani bimaNo ratings yet

- Motorcycle Maximal Safe Speed in Cornering Situation: Hamid Slimi, Dalil Ichalal, Hichem Arioui, Sa Id MammarDocument8 pagesMotorcycle Maximal Safe Speed in Cornering Situation: Hamid Slimi, Dalil Ichalal, Hichem Arioui, Sa Id MammararstjunkNo ratings yet

- Physics: SN Chapter 2006 2007 2008 2009 2010 2011 2012 2013 2016 2017 2018Document3 pagesPhysics: SN Chapter 2006 2007 2008 2009 2010 2011 2012 2013 2016 2017 2018AdityaNo ratings yet

- Chapter 3 - Equilibrium of Particles: ObjectivesDocument17 pagesChapter 3 - Equilibrium of Particles: ObjectivesRhey LuceroNo ratings yet

- Newtonian Mechanics 5Document2 pagesNewtonian Mechanics 5Nachiketa SarkarNo ratings yet

- Onken CalcDocument4 pagesOnken Calcapi-3727858100% (2)

- AC Inductance and Inductive ReactanceDocument9 pagesAC Inductance and Inductive ReactanceAbdullah Al AsikNo ratings yet

- Class 26 Washing and LeachingDocument26 pagesClass 26 Washing and LeachingFabian RamirezNo ratings yet

- PPIInfo FL Corner FEIM2 PP11ThermodynamicsDocument7 pagesPPIInfo FL Corner FEIM2 PP11ThermodynamicsImee LignesNo ratings yet

- Exp 4Document4 pagesExp 4Rakesh KumarNo ratings yet

- 7182 C007 PDFDocument18 pages7182 C007 PDFankitsarvaiyaNo ratings yet

- Callister Ch18Document6 pagesCallister Ch18Alan Ahlawat SumskiNo ratings yet

- 6 Power Generation From Piezoelectric Footstep Muhammad Aamir Vol 13 No 4Document7 pages6 Power Generation From Piezoelectric Footstep Muhammad Aamir Vol 13 No 4N MeghanaNo ratings yet

- WS1 GP2 Q3 Pelina JTDocument3 pagesWS1 GP2 Q3 Pelina JTJohn Tristan HilaNo ratings yet

- Classical Mechanics A Minimal Standard Course, WinitzkiDocument65 pagesClassical Mechanics A Minimal Standard Course, Winitzkiluis cabralNo ratings yet

- Moment-Curvature Model For Steel Plate-Concrete CoDocument8 pagesMoment-Curvature Model For Steel Plate-Concrete CoTamir EnkhNo ratings yet

- FullDocument203 pagesFullPaul MacatunoNo ratings yet

- Newton'S Law: Prepared By: Mariane Gioiella Casem Cindy Claire BermudezDocument9 pagesNewton'S Law: Prepared By: Mariane Gioiella Casem Cindy Claire BermudezAngel Jimmyly EstanillaNo ratings yet

- Register For Exam: Osiris: Capillary RiseDocument24 pagesRegister For Exam: Osiris: Capillary RiseShwet KumarNo ratings yet

- FM SYLLABUS PolyDocument7 pagesFM SYLLABUS PolyprasobhaNo ratings yet

- Introduction To Causal Sets: An Alternate View of Spacetime StructureDocument12 pagesIntroduction To Causal Sets: An Alternate View of Spacetime StructureManoj Kumar YennapureddyNo ratings yet

- Week 9 12 MDL 4q Nts112 PhysicsDocument36 pagesWeek 9 12 MDL 4q Nts112 PhysicsDionel RizoNo ratings yet