Professional Documents

Culture Documents

Mex 30201

Uploaded by

Yousef Adel HassanenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mex 30201

Uploaded by

Yousef Adel HassanenCopyright:

Available Formats

Engineering Encyclopedia

Saudi Aramco DeskTop Standards

Boilers - Equipment Description

Note: The source of the technical material in this volume is the Professional

Engineering Development Program (PEDP) of Engineering Services.

Warning: The material contained in this document was developed for Saudi

Aramco and is intended for the exclusive use of Saudi Aramco’s employees.

Any material contained in this document which is not already in the public

domain may not be copied, reproduced, sold, given, or disclosed to third

parties, or otherwise used in whole, or in part, without the written permission

of the Vice President, Engineering Services, Saudi Aramco.

Chapter : Vessels For additional information on this subject, contact

File Reference: MEX30201 M.Y. Naffa’a

Engineering Encyclopedia Vessels

Boilers Equipment Description

Contents Pages

INTRODUCTION................................................................................................................ 1

STEAM SYSTEM OVERVIEW .......................................................................................... 2

Terminology for the Design and Operations of Boilers............................................... 2

BOILER CHARACTERISTICS ........................................................................................... 4

Types ........................................................................................................................ 4

Major Boiler Components ........................................................................................12

Miscellaneous Boiler Components ............................................................................17

DOCUMENTS USED BY SAUDI ARAMCO AND THEIR PURPOSES...........................18

32-AMSS-021 Water-Tube Boilers ..........................................................................18

ASME Boiler and Pressure Vessel Code - Section I, Power Boilers ..............18

34-AMSS-619 Flame Monitoring and Burner Management System...............18

34-AMSS-831 Package Unit Instrumentation................................................18

AES-A-005 Safety Instruction Sheets.......................................................................18

Saudi Aramco Form 2731 - Fired Heaters .....................................................19

Saudi Aramco Form 2694 - Vessels ..............................................................19

Boiler Data Sheet .....................................................................................................19

Saudi Aramco Equipment Files.................................................................................19

GLOSSARY........................................................................................................................20

Saudi Aramco DeskTop Standards

Engineering Encyclopedia Vessels

Boilers Equipment Description

Table of Figures Pages

FIGURE 1 Typical Steam System.............................................................................. 2

FIGURE 2 Package Water-Tube Boiler..................................................................... 4

FIGURE 3 Water-Tube Boiler................................................................................... 5

FIGURE 4 Field-Erected Water-Tube Boiler ............................................................. 6

FIGURE 5 Gas Turbine Waste Heat Boiler................................................................ 7

FIGURE 6 Firetube Boiler......................................................................................... 8

FIGURE 7 Electric Steam Boiler............................................................................... 9

FIGURE 8 Saudi Aramco Boilers.............................................................................10

FIGURE 9 Boiler Components - Ras Tanura Hp Boiler No. 10 ................................12

FIGURE 10 Steam Drum Internals - Ras Tanura Hp Boiler No. 8 ............................13

FIGURE 11 Typical Water Wall Construction ..........................................................15

FIGURE 12 Typical Steam Generation System.........................................................17

Saudi Aramco DeskTop Standards

Engineering Encyclopedia Vessels

Boilers Equipment Description

INTRODUCTION

This module provides an introduction to the steam generating equipment used by Saudi Aramco,

including an overview of typical plant steam systems.

The types of boilers and boiler components used by Saudi Aramco are described.

This module also presents the types of documents used by Saudi Aramco to specify boilers for

design and purchase, and to record their inspection and maintenance history.

Saudi Aramco DeskTop Standards 1

Engineering Encyclopedia Vessels

Boilers Equipment Description

STEAM SYSTEM OVERVIEW

Terminology for the Design and Operations of Boilers

A typical steam system, shown in Figure 1, provides thermal energy in the form of steam to a

number of consumers. The key elements in this system are the steam generators, the distribution

system, and the users. Supply of boiler feedwater (BFW) to the steam generator and recovery of

condensate for recycling are also included in the steam system.

1 Boiler

2 Deaerator

3 BFW Pump

4 Continuous Blowdown Facilities

5 Intermittent Blowdown Facilities

6 Pressure Reducing Station

7 Desuperheater

8 Distribution Piping and Valving

9 Condensate Return System

SV System Safety Valves

FIGURE 1 TYPICAL STEAM SYSTEM

Saudi Aramco DeskTop Standards 2

Engineering Encyclopedia Vessels

Boilers Equipment Description

The steam generator can be either a part of a process unit using waste or surplus heat, or a

separate offsite facility burning fuel in a boiler. The fuel can be gas, oil, or coal. Steam can also

be generated by recovery of waste heat from the exhaust of a gas turbine.

Waste or surplus process heat can come from furnace flue gases, process coolers (heat

exchangers), or hot product rundown.

The steam distribution network consists of piping and valves that interconnect between the

producers and consumers of steam. Steam can be produced and consumed at various pressure

levels. These different pressure levels are usually connected via pressure reducing and steam

desuperheating stations, so that surpluses of steam at higher pressure levels can be utilized at

lower pressure levels.

Although not standardized, commonly used steam pressure levels in Saudi Aramco plants range

from 60 to 625 psig. Most plants have a high-pressure (HP) level of 600 to 625 psig, plus one or

more lower pressure levels. For example, steam pressure levels at Abqaiq are 625 and 60 psig,

and at Ras Tanura the steam pressure levels are 600, 225, 150, and 60 psig. These 60- to 225-

psig levels are referred to as medium-pressure (MP) levels. Usually there is also a low-pressure

(LP) level at 15 psig.

The steam system begins with the supply of treated water to a deaerator, where dissolved gases

such as oxygen and carbon dioxide are removed prior to introduction of the water into the boiler.

These gases are undesirable because of their corrosive attack on metal surfaces. The water is

deaerated by heating it to its saturation temperature and then scrubbing it with steam to carry

away the dissolved gases. The deaerator operating pressure is normally the same as the LP steam

system (15 psig). Boiler feedwater pumps are used to deliver BFW from the deaerator to the

boiler steam drum. Two or more pumps are provided to ensure a reliable supply of water to the

boiler.

Wherever possible, condensed steam from the steam users is collected in a condensate system and

returned to the deaerator for recycling.

Saudi Aramco DeskTop Standards 3

Engineering Encyclopedia Vessels

Boilers Equipment Description

BOILER CHARACTERISTICS

Types

The three main types of boilers used by Saudi Aramco are water-tube, firetube, and electric.

Water-tube boilers are illustrated in Figures 2 through 5. These are the largest and most common

boiler types. A firetube boiler is illustrated in Figure 6, and an electric boiler is illustrated in

Figure 7.

Water-tube boilers have no real pressure or size limitations. The basic configuration is a firebox

surrounded by tubes filled with water. Located at the top of the water-tube boiler is a drum in

which steam is separated from the water. Water circulates from the steam drum down through

the water tubes and back to the steam drum. This usually occurs because of natural circulation,

although some boilers have forced circulation systems.

The smaller-sized water-tube boilers are usually shop assembled and delivered to the field in a

complete unit. These units are referred to as package boilers. The maximum size of package

boilers depends largely on transportation limits. Larger units can be shipped in a few modules

which are assembled in the field. Many Saudi Aramco boilers are package units, with the largest

having a capacity of about 600,000 lb/hr of steam at a design pressure of about 880 psig. Typical

package boilers are shown in Figures 2 and 3. Larger sized water-tube boilers are field erected. A

typical field-erected boiler is shown in Figure 4.

Source: Combustion Engineering.

FIGURE 2 PACKAGE WATER-TUBE BOILER

Saudi Aramco DeskTop Standards 4

Engineering Encyclopedia Vessels

Boilers Equipment Description

Steam

Drum

Burners

Mud

Drum

Source: Steam, Its Generation and Use, 38th Edition, © 1972. With permission from Babcock & Wilcox.

FIGURE 3 WATER-TUBE BOILER

Saudi Aramco DeskTop Standards 5

Engineering Encyclopedia Vessels

Boilers Equipment Description

Source: Combustion Engineering.

FIGURE 4 FIELD-ERECTED WATER-TUBE BOILER

A gas turbine waste heat boiler is illustrated in Figure 5. These boilers are usually a special

design. They can be designed as unfired units operating on waste heat only, or as supplementary

fired units, with gas or liquid fuel, to increase steam production. Because of the type of

supplementary firing used, the boiler shown in Figure 5 can also be referred to as a duct-fired

waste heat boiler. Boiler size is dependent on the size of the gas turbine. They typically produce

100,000 to 400,000 lb/hr of steam at 150 to 600 psig.

Saudi Aramco DeskTop Standards 6

Engineering Encyclopedia Vessels

Boilers Equipment Description

1 Gas Turbine 6 Superheater

2 Dump Stack 7 Boiler Section

3 Bypass Damper 8 Downcomers

4 Boiler Shut-Off Damper 9 Economizer

5 Supplemental Burner 10 Steam Drum

With permission from Henry Vogt Machine Company.

FIGURE 5 GAS TURBINE WASTE HEAT BOILER

Saudi Aramco DeskTop Standards 7

Engineering Encyclopedia Vessels

Boilers Equipment Description

Firetube boilers are generally of small size (under 100,000 lb/hr and more commonly under

50,000 lb/hr) and low pressure (under 250 psig and more commonly 150 psig or lower). The

steam is usually not superheated. The name "firetube" comes from the arrangement where hot

combustion products flow inside tubes that are located in a water-filled cylindrical shell. Firetube

boilers are less expensive than water-tube boilers of the same size and pressure rating. Firetube

boilers are usually packaged and skid mounted.

With permission from Power Magazine.

FIGURE 6 FIRETUBE BOILER

Saudi Aramco DeskTop Standards 8

Engineering Encyclopedia Vessels

Boilers Equipment Description

Electric boilers are often used for small steam loads at locations outside of main plants, for

example, mechanical shops, dining halls, and hospitals. Electric boilers are usually very small in

size (generally less than 25,000 lb/hr) and low pressure (less than 100 psig). In a resistance boiler,

electric resistance heating elements are immersed in a water bath that is enclosed in an outer

pressure vessel. Heat input and steam output are regulated by controls which select the number

of heating elements to be energized.

Manual Reset High Limit Control

Safety Valve

Steam Pressure Gauge

Steam Outlet

Operating

Pressure

Control

Automatic

Blowdown

Vacuum Breaker

Control

Low Water Cutoff

and Pump Control

Sight Glass

Heating

Elements

Fuses, Terminal

Insulation Blocks, and

Contactors

Automatic Check Valve

Blowdown

Water Feed

Valve

Strainer

Gate Valves

With permission from Chromalox.

FIGURE 7 ELECTRIC STEAM BOILER

Saudi Aramco DeskTop Standards 9

Engineering Encyclopedia Vessels

Boilers Equipment Description

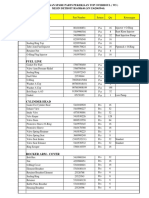

A summary of boiler types and their typical ranges of applications is shown in Work Aid 1. This

can be used to make preliminary boiler selections for study purposes. Figure 8 lists the major

boilers in Saudi Aramco plants.

Boiler Year MCR** Press Temp

Number Built Type * Manufacturer k lb/hr psig °F Fuel

Abqaiq High-Pressure Boilers

1 1952 VU-50 Comb. Eng'g 220 700/625 725 Gas

2 1948 VU-50 Comb. Eng'g 220 700/625 725 Gas

3 1947 VU-50 Comb. Eng'g 220 700/625 725 Gas

4 1952 VU-50 Comb. Eng'g 220 700/625 725 Gas

5 1952 VU-50 Comb. Eng'g 220 700/625 725 Gas

6 1951- VU-50 Comb. Eng'g 220 700/625 725 Gas

2

7 1965 VU-60 Mitsubishi 450 700/625 725 Gas

8 1967 VU-60 Mitsubishi 450 700/625 725 Gas

9 1969 VU-60 Mitsubishi 450 700/625 725 Gas

10 1971 VU-60 Mitsubishi 450 700/625 725 Gas

11 1971 VU-60 Mitsubishi 750 700/625 725 Gas

12 1972 VU-60 Mitsubishi 750 700/625 725 Gas

13 1973 VU-60 Mitsubishi 750 700/625 725 Gas

14 1974 VU-60 Mitsubishi 750 700/625 725 Gas

Berri Gas Plant

F1A 1975 P*33 A18 Comb. Eng'g 250 450 400 Gas

F1B 1975 P 33 A18 Comb. Eng'g 250 450 400 Gas

F2A 1975 P 40VP-26W Comb. Eng'g 530 450 400 Gas

F2B 1975 P 40VP-26W Comb. Eng'g 530 450 400 Gas

F2C 1975 P 40VP-26W Comb. Eng'g 530 450 400 Gas

Juaymah

F-103 1976 P 34 VP-18 Comb. Eng'g 300 200 400 Gas

F-104 1976 P 34 VP-18 Comb. Eng'g 300 200 400 Gas

F-105 1976 P 40 VP-26W Mitsubishi 530 700/625 725 Gas/Oil

F-106 1976 P 40 VP-26W Mitsubishi 530 700/625 725 Gas/Oil

F-108 1976 P 40 VP-26W Mitsubishi 530 700/625 725 Gas/Oil

F-109 1976 P 40 VP-26W Mitsubishi 530 700/625 725 Gas/Oil

Juaymah Industrial

- 1974 P 33 A15 Comb. Eng'g 200 200 400 Gas

- 1974 P 33 A15 Comb. Eng'g 200 200 400 Gas

*P = Package Boiler (others are field erected)

** MCR = Maximum Continuous Rating

FIGURE 8 SAUDI ARAMCO BOILERS

Saudi Aramco DeskTop Standards 10

Engineering Encyclopedia Vessels

Boilers Equipment Description

SAUDI ARAMCO BOILERS (CONT'D)

Boiler Year MCR** Press Temp

Number Built Type * Manufacturer k lb/hr psig °F Fuel

Ras Tanura Low-Pressure Boilers

F-101 1974 P 33 Comb. Eng'g 200 200 400 Gas

F-102 1974 P 33 Comb. Eng'g 200 200 400 Gas

F-103 1974 P 33 Comb. Eng'g 200 200 400 Gas

F-104 1974 P 33 Comb. Eng'g 200 200 400 Gas

F-105 1976 P 34 VP-18 Comb. Eng'g 300 200 400 Gas

F-106 1976 P 34 VP-18 Comb. Eng'g 300 200 400 Gas

F-107 1978 P 40 VP-26W Foster Wheeler 530 200 400 Gas

F-108 1978 P 40 VP-26W Foster Wheeler 530 200 400 Gas

Ras Tanura High-Pressure Boilers

5 1958 VU-50 Mannesmann - F. Tosi 220 700/625 725 Oil/Gas

6 1963 VU-50 Mitsubishi 220 700/625 725 Oil/Gas

7 1971 VU-60 Mitsubishi 450 700/625 725 Oil/Gas

8 1973 VU-60 Mitsubishi 450 700/625 725 Oil/Gas

9 1974 VU-60 Mitsubishi 750 700/625 725 Oil/Gas

10 1980 VU-60 Mitsubishi 750 700/625 725 Oil/Gas

Shedgum Gas Plant

101 1976 P 40 VP-26W Mitsubishi 530 800/625 725 Gas

102 1976 P 40 VP-26W Mitsubishi 530 800/625 725 Gas

103 1976 P 40 VP-26W Mitsubishi 530 800/625 725 Gas

104 1976 P 40 VP-26W Mitsubishi 530 800/625 725 Gas

105 1976 P 40 VP-26W Mitsubishi 530 800/625 725 Gas

106 1976 P 40 VP-26W Mitsubishi 530 800/625 725 Gas

107 1976 P 40 VP-26W Mitsubishi 530 800/625 725 Gas

Uthmaniyah Gas Plant

F-101 1977 P 40 VP-26W Babcock & Wilcox 530 800/625 625 Gas

F-102 1977 P 40 VP-26W Babcock & Wilcox 530 800/625 625 Gas

F-103 1977 P 40 VP-26W Babcock & Wilcox 530 800/625 625 Gas

F-104 1977 P 40 VP-26W Babcock & Wilcox 530 800/625 625 Gas

F-105 1977 P 40 VP-26W Babcock & Wilcox 530 800/625 625 Gas

F-106 1977 P 40 VP-26W Babcock & Wilcox 530 800/625 625 Gas

Yanbu Gas Plant

F-124A 1980 P VU-60 Royal Schelde 600 880 896 Oil/Gas

F-124B 1980 P VU-60 Royal Schelde 600 880 896 Oil/Gas

F-124C 1980 P VU-60 Royal Schelde 600 880 896 Oil/Gas

F-121 1980 P 40 VP-26W Mitsubishi 530 880/625 750 Gas

*P = Package Boiler (others are field erected)

** MCR = Maximum Continuous Rating

FIGURE 8

Saudi Aramco DeskTop Standards 11

Engineering Encyclopedia Vessels

Boilers Equipment Description

Major Boiler Components

The major components of a typical Saudi Aramco boiler are shown in Figure 9, which is an

illustration of Ras Tanura HP Boiler No. 10. The upper drum (steam drum) provides space for

separating steam from water. It also provides liquid holdup capacity (typically from 10 to 60

seconds) to allow for a dynamic response to load changes without losing liquid in the water tubes.

Steam drum internals for this type boiler are shown in Figure 10. Included are baffles and screens

to assist in separating the steam and water mixture entering from the tubes. Other devices, such

as cyclone separators, are also used in some boilers to separate the steam. Other drum internals

include feedwater piping, blowdown piping, and chemical injection piping.

Relief Tube Upper Left Side Header

Superheater Connecting Tube

Roof Tube

Upper Drum

Upper Right Side Header

Furnace Side Tube

Superheater Tube

Boiler Rear Tube

Gas and Oil Burner Superheater Steam-Cooled Spacer Tube

Baffle Plate

Furnace Rear Tube

Peep Hole

Boiler Bank Tube

Front Tube

Floor Tube Gas Duct

Air Duct

Fire Brick

Lower Right Side Header

Supply Tube

Superheater Header

Boiler Side Tube

Lower Drum

FIGURE 9 BOILER COMPONENTS - RAS TANURA HP BOILER NO. 10

Saudi Aramco DeskTop Standards 12

Engineering Encyclopedia Vessels

Boilers Equipment Description

FIGURE 10 STEAM DRUM INTERNALS - RAS TANURA HP BOILER NO. 8

Most water-tube boilers have a lower drum (mud drum) for collecting sediment and impurities.

This drum also acts as a lower header for connection of the water tubes.

Saudi Aramco DeskTop Standards 13

Engineering Encyclopedia Vessels

Boilers Equipment Description

The water circuit between the drums consists of downcomers and risers. A downcomer is a tube

in an unheated or less heated area of the boiler. A riser is a tube in the heated or hotter section of

the boiler. Water tends to flow by natural circulation from the steam drum to the mud drum via

the downcomers and then back to the steam drum via the risers. Evaporation takes place in the

risers, and the steam/water mixture weighs less than the water in the downcomers. In some

boilers, circulation is forced by pumping.

Most water-tube boilers have wall, floor, and roof tubes surrounding the firebox. Water flows in

these tubes from the mud drum to the steam drum. In addition to absorbing heat, these tubes cool

the boiler enclosure and reduce the amount of refractory required. In Figure 9, the floor, front wall,

and roof tubes are shown forming a continuous flowpath from the mud drum to the steam drum. A

refractory layer is often placed on the floor tubes to reduce the heat transfer to these tubes. The

sidewall tubes are connected to bottom and top headers, which in turn are connected to the drums

by supply and relief tubes. Adjacent tubes in these walls are often welded to connecting steel strips

to form a continuous membrane wall, which is illustrated in Figure 11. This construction permits a

pressure-tight enclosure.

Saudi Aramco DeskTop Standards 14

Engineering Encyclopedia Vessels

Boilers Equipment Description

Outer Casing

Insulation

Membrane Wall Tubes

Welded to

Tubes

Combustion Zone

FIGURE 11 TYPICAL WATER WALL CONSTRUCTION

Most water-tube boilers also have steam superheaters. When steam is separated from water in the

steam drum, it is saturated at the drum pressure. This steam is routed through the superheater

tubes to raise the steam temperature above saturation temperature. The superheater is usually

located at the exit of the firebox, where the flue gas temperature is high enough for efficient heat

transfer. However, screen tubes are often used just ahead of the superheater, to shield the

superheater from direct radiation from the hot combustion gases.

Headers are used to distribute the steam to the parallel flowpaths used in the superheater, and to

collect it. As shown in Figure 9, these headers are located at the bottom of the superheater so

that the entire superheater coil is drainable (a Saudi Aramco requirement).

Saudi Aramco DeskTop Standards 15

Engineering Encyclopedia Vessels

Boilers Equipment Description

Safety valves are usually installed both on the steam drum and at the boiler outlet to protect both

the boiler and the superheater from overpressure.

Boilers can be designed to fire nearly any fuel, either solid, liquid, or gas, or combinations of each.

Saudi Aramco's boilers fire gas and oil fuels, and these will be considered in this course.

Combustion air is supplied to the boiler by a forced draft fan. This air enters the boiler through a

windbox, where it is distributed to the burners. The air mixes with the fuel in the burners, and

combustion takes place in the combustion zone of the boiler. There are many types and

configurations of burners, depending upon the fuels fired and the size and design of the boiler.

Heat is transferred from the burning fuel and hot gases to the water wall tubes surrounding the

combustion zone. These flue gases then flow past the superheater tubes and through the boiler

bank tubes. Baffles are often used in the boiler bank to define the flue gas flow- path. The flue

gases then exit the boiler through a flue gas duct and stack.

To improve efficiency, many boilers have economizers. These are heat exchangers that transfer

heat from the flue gas leaving the boiler to the boiler feedwater. This reduces the stack

temperature.

Some boilers may also use a combustion air preheater to improve efficiency. This is also a heat

exchanger and is used to transfer heat from the flue gas leaving the boiler to the air that is used for

combustion.

Figure 12 is a simplified flow plan of a boiler and its auxiliaries. It shows how these components,

and those described in the following pages, fit into the overall steam generation system.

Saudi Aramco DeskTop Standards 16

Engineering Encyclopedia Vessels

Boilers Equipment Description

FIGURE 12 TYPICAL STEAM GENERATION SYSTEM

Miscellaneous Boiler Components

Some boilers require attemperators downstream of the steam superheater to control the boiler

steam outlet temperature at various loads. The superheater is designed to provide a specific

steam temperature at design conditions. At other conditions, this temperature may be exceeded

and is controlled by spraying high-quality water into the outlet steam to cool, or attemperate, it.

Oil-fired boilers usually require sootblowers to periodically clean the boiler tubes. Soot-blowers

direct a blast of steam at tubes in the dirtiest part of the boiler to blast combustion products off

the tube surfaces. This cleans the tubes and increases heat transfer.

Boilers have blowdown connections in both the steam and mud drums to remove concentrated

sediment and impurities that result from evaporation of the boiler water. Blowdown from the

steam drum is usually continuous, and the amount is set to control impurity levels below specified

maximums. The blowdown rate may be increased or decreased occasionally, depending upon

boiler water analysis. Blowdown from the mud drum is usually intermittent, based on experience.

Mud drum blowdown primarily removes sediment.

Saudi Aramco DeskTop Standards 17

Engineering Encyclopedia Vessels

Boilers Equipment Description

DOCUMENTS USED BY SAUDI ARAMCO AND THEIR PURPOSES

Several standards and codes are used to cover the minimum requirements of new equipment

purchased by Saudi Aramco. Additional documents are used to record details of the equipment

actually purchased and installed, and to record the boiler's history during its operating life.

32-AMSS-021 Water-Tube Boilers

This specification is mainly used for the purchase of new boilers. It covers the minimum Saudi

Aramco requirements for industrial water-tube boilers, including the following:

• Mechanical design requirements, including the type of construction to be used, steam drum

internals, burners and fans, platforms, stacks, and ducts.

• Inspection and testing.

• Required connections and auxiliary equipment.

• Boiler performance.

• This specification also states that the proposed boiler type and size must have been

satisfactorily demonstrated, based on at least five years operating experience.

This specification also references other documents that cover certain aspects of the boiler supply

and design. The most important are listed below:

ASME Boiler and Pressure Vessel Code - Section I, Power Boilers

This code covers the design, fabrication, and testing of boiler pressure parts. Application of this

code to boiler design will be covered in the next module.

34-AMSS-619 Flame Monitoring and Burner Management System

34-AMSS-831 Package Unit Instrumentation

These specifications cover the instruments and controls required for safe and satisfactory

operation of the boiler.

AES-A-005 Safety Instruction Sheets

The purpose of the Safety Instruction Sheets (SIS) is to provide operating, maintenance, and

inspection personnel with important information about certain pressure-containing and rotating

equipment in the plants. This information is presented in a consistent format and includes safe

operating limits for the equipment, protective devices, and any special safety precautions required.

SIS are initially prepared for new equipment, and then revised when existing equipment is re-

rated.

Saudi Aramco DeskTop Standards 18

Engineering Encyclopedia Vessels

Boilers Equipment Description

AES-A-005 provides detailed instructions for filling out the SIS.

For boilers, SIS are required for the pressure parts covered by the ASME code (tubes, headers,

and drums). Since specific forms have not been developed for boilers, the most applicable SIS are

used, as follows:

Saudi Aramco Form 2731 - Fired Heaters

This SIS is used for all boiler tubes. Work Aid 2 is a copy of this SIS.

Saudi Aramco Form 2694 - Vessels

This SIS is used for boiler drums and headers. Work Aid 3 is a copy of this SIS.

Boiler Data Sheet

This document is provided by the boiler manufacturer and includes a summary of the boiler's

physical characteristics and its predicted operating performance. It is usually part of the

manufacturer's original proposal and is subsequently modified to incorporate any changes that

occur as the boiler detail design progresses. The final issue should reflect the as-built boiler.

Saudi Aramco Equipment Files

Details of the boiler and its auxiliary equipment are contained in several sources.

• Plant Record Books. The contractor prepares a plant record book for the boiler. This

contains details of the boiler design and construction. Adequate information should be

included to permit necessary inspection and maintenance of the boiler. The plant record

book should also contain information on components purchased by the manufacturer of the

boiler from sub-suppliers, such as burners, fans and drivers, safety valves, and instruments.

• Drawing Files. Drawings covering boiler details should be available for reference and to

permit boiler inspection and maintenance. Modifications made to the boiler throughout its

life should be recorded on the original drawings or on new drawings.

• Inspection Record Books. Inspection record books should include inspection results and a

record of maintenance and repairs. Any modifications to the boiler should also be

documented in this file. This file should provide a valuable history of boiler performance

and assist in determining future maintenance requirements.

Saudi Aramco DeskTop Standards 19

Engineering Encyclopedia Vessels

Boilers Equipment Description

GLOSSARY

attemperator A boiler accessory for reducing and controlling the

steam outlet temperature from the boiler.

blowdown Removal of water from the boiler to control the

level of dissolved impurities in the boiler water.

boiler feedwater or Treated water which has been heated, deaerated,

BFW and dosed with chemicals to remove residual

oxygen.

boiler MCR MCR is an abbreviation for Maximum Continuous

Rating, which is the design output capacity of the

boiler, in lb/hr.

burner A mechanical device used to introduce air and fuel

into the boiler at the proper conditions to establish

and maintain ignition and combustion.

economizer A device for transferring heat from the flue gas to

the BFW before the BFW enters the boiler drum.

field-erected boiler A boiler which is assembled at the construction

site.

HP An abbreviation for high pressure used in reference

to steam system pressure levels above about

250 psig.

LP An abbreviation for low pressure used in reference

to steam system pressure levels less than about 60

psig.

MP An abbreviation for medium pressure used in

reference to steam system pressure levels of about

60 to 250 psig.

mud or lower drum A cylindrical vessel near the bottom of the boiler

which acts as a collection and distribution header.

Solids and sediment tend to accumulate in this

drum and are removed by intermittent blowdown.

packaged or shop- A boiler which is assembled in the vendor's shop

assembled boilers into one or more large pieces and then shipped to

the site for final assembly.

Saudi Aramco DeskTop Standards 20

Engineering Encyclopedia Vessels

Boilers Equipment Description

skid mounted Mounted on a skid as a package which can be

shipped or moved from place to place.

sootblower A mechanical device utilizing steam to clean boiler

tubes by removing particles of unburned carbon or

ash.

steam or upper A cylindrical vessel near the top of the boiler which

drum acts as a distribution and collection header and a

releasing point for steam. The drum also houses

separation equipment to dry the steam.

steam turbine Steam turbines are used to drive mechanical

equipment, such as pumps or compressors and

electrical generators.

superheater A heat transfer surface, downstream of the steam

drum, that is designed to raise the steam

temperature above the saturation temperature. The

superheater is arranged within the boiler to absorb

heat by radiation, convection, or both.

treated water Raw water which has been processed in the water

treating plant to reduce the level of suspended and

dissolved impurities.

turndown ratio The ratio of the maximum to the minimum flow

rates associated with a steam system component.

This term is used to express the range over which a

component must function to meet requirements of

the design.

Saudi Aramco DeskTop Standards 21

You might also like

- Furnaces - An Engineering Encyclopedia GuideDocument24 pagesFurnaces - An Engineering Encyclopedia GuideYousef Adel HassanenNo ratings yet

- Variable Speed Pumping: A Guide to Successful ApplicationsFrom EverandVariable Speed Pumping: A Guide to Successful ApplicationsRating: 3 out of 5 stars3/5 (2)

- Mex 30210Document43 pagesMex 30210Yousef Adel HassanenNo ratings yet

- Steam Generation PlantDocument38 pagesSteam Generation PlantsenaNo ratings yet

- PCI20107, Overview of Boiler Commissioning and Startup PDFDocument17 pagesPCI20107, Overview of Boiler Commissioning and Startup PDFMarc AnmellaNo ratings yet

- Mex 10404Document61 pagesMex 10404Garlin MunarNo ratings yet

- Calculating-Boiler and-Process-Heater-Thermal Efficiency PDFDocument57 pagesCalculating-Boiler and-Process-Heater-Thermal Efficiency PDFAlejandro Lopez100% (1)

- Saudi Aramco's Guide to Steam TurbinesDocument45 pagesSaudi Aramco's Guide to Steam TurbinesFadoooll100% (2)

- FinishedDocument40 pagesFinishedFelagot SisayNo ratings yet

- Mex 30203Document19 pagesMex 30203Yousef Adel HassanenNo ratings yet

- CHE10705, Steam Generation andDocument34 pagesCHE10705, Steam Generation andNacer KisyNo ratings yet

- Saudi Aramco Furnace Guide150150Vertical CylindricalVertical Cylindrical5050Vertical CylindricalVertical Cylindrical15050Vertical CylindricalVertical Cylindrical150150150BoxBoxBoxDocument23 pagesSaudi Aramco Furnace Guide150150Vertical CylindricalVertical Cylindrical5050Vertical CylindricalVertical Cylindrical15050Vertical CylindricalVertical Cylindrical150150150BoxBoxBoxMohammad RawoofNo ratings yet

- Shell and Tube Heat Exchanger ConceptsDocument22 pagesShell and Tube Heat Exchanger Conceptsdineshnandhu007No ratings yet

- Engr Encyclopedia AramcoHeatExchangers PDFDocument51 pagesEngr Encyclopedia AramcoHeatExchangers PDFhelden50229881100% (4)

- Combustion Gas TurbinesDocument33 pagesCombustion Gas Turbinesgavski100% (3)

- Pereko Manual For Batch Fed Boilers enDocument32 pagesPereko Manual For Batch Fed Boilers enghiocel apinteiNo ratings yet

- BoilerDocument39 pagesBoilerFelagot SisayNo ratings yet

- Installation & Operation Manual for Henan Province Sitong Boiler DZH Series Biomass BoilerDocument34 pagesInstallation & Operation Manual for Henan Province Sitong Boiler DZH Series Biomass BoilervijayNo ratings yet

- Proper Steam Turbine OperationDocument32 pagesProper Steam Turbine OperationBalasubramanian C100% (1)

- Eko-Vimar Orlański Super Wood Gasification Boiler Instruction ManualDocument24 pagesEko-Vimar Orlański Super Wood Gasification Boiler Instruction ManualglynisNo ratings yet

- Orlan Manual enDocument24 pagesOrlan Manual enLucian Stan0% (1)

- Mex 21301Document47 pagesMex 21301Yousef Adel HassanenNo ratings yet

- Steam Generation PlantDocument38 pagesSteam Generation Plantsena100% (1)

- Introduction To Gas Turbines PDFDocument37 pagesIntroduction To Gas Turbines PDFMBA103003100% (1)

- Saudi Aramco Steam Turbine Training CourseDocument45 pagesSaudi Aramco Steam Turbine Training CourseDhananjay B K100% (2)

- Mex 30207Document36 pagesMex 30207Yousef Adel HassanenNo ratings yet

- Mex 21302Document38 pagesMex 21302Yousef Adel HassanenNo ratings yet

- 2015 12 Cozzi PDFDocument108 pages2015 12 Cozzi PDFAkhmad ramadhanNo ratings yet

- Boiler ManualDocument22 pagesBoiler Manualengrasadullah000No ratings yet

- Boilers and Furnaces Refractory and InsulationDocument56 pagesBoilers and Furnaces Refractory and InsulationKhaled BOUALINo ratings yet

- Manual Podajnikowe v2 enDocument32 pagesManual Podajnikowe v2 enFrancisco MartínezNo ratings yet

- Pool ReactorDocument13 pagesPool ReactorFerran Cordoba del CuraNo ratings yet

- Mex 10406Document53 pagesMex 10406Yousef Adel HassanenNo ratings yet

- Khulna 225 MW Combined Cycle Power Plant Heat Recovery Boiler Operation ManualDocument184 pagesKhulna 225 MW Combined Cycle Power Plant Heat Recovery Boiler Operation ManualMd Suzon MahmudNo ratings yet

- Introduction To Gas TurbinesDocument37 pagesIntroduction To Gas TurbinesAndreasNo ratings yet

- (BP Process Safety Series) BP Safety Group-Safe Furnace and Boiler Firing-Institution of Chemical Engineers (IChemE) (2005)Document86 pages(BP Process Safety Series) BP Safety Group-Safe Furnace and Boiler Firing-Institution of Chemical Engineers (IChemE) (2005)William Villarreal100% (6)

- Ashrae Handbook 2000 CHDocument8 pagesAshrae Handbook 2000 CHKazuto NakazatoNo ratings yet

- Cascade Boiler Rooms: Catalogue of ComponentsDocument40 pagesCascade Boiler Rooms: Catalogue of Componentsabu7omar-1No ratings yet

- Steam Purity Turbine OperationDocument37 pagesSteam Purity Turbine Operationak_thimiri100% (1)

- 1015t/h Subcritical Pressure Natural Circulation Boiler InstructionDocument74 pages1015t/h Subcritical Pressure Natural Circulation Boiler InstructioncynaiduNo ratings yet

- GEI 69688F Steam BlowingDocument20 pagesGEI 69688F Steam Blowingparvesh_awasthy100% (1)

- PP SK655 755 ENeDocument64 pagesPP SK655 755 ENeAlexandar Davidov100% (1)

- Installation Manual Aux Engines - N38143Document96 pagesInstallation Manual Aux Engines - N38143Habibi Dark Edition100% (1)

- Understanding Coal Power Plant CycleDocument47 pagesUnderstanding Coal Power Plant CycledaveNo ratings yet

- Westinghouse Technology Systems Manual Section 3.2 Reactor Coolant SystemDocument62 pagesWestinghouse Technology Systems Manual Section 3.2 Reactor Coolant SystemSheikh ShoaibNo ratings yet

- P Wer: GuidelineDocument57 pagesP Wer: GuidelineWater Treatment & Process Technology waterNo ratings yet

- Pot furnace Transport Row regulation JourneyDocument282 pagesPot furnace Transport Row regulation JourneyMuhummad Tanzeel RanaNo ratings yet

- GB VIADRUS HERCULES U22 P N Navod K Obsluze A Instalaci 7 2011Document28 pagesGB VIADRUS HERCULES U22 P N Navod K Obsluze A Instalaci 7 2011FlowersOfRomanceNo ratings yet

- Muhammad Abdullah - 346027 - 2Document9 pagesMuhammad Abdullah - 346027 - 2Sheikh SaadNo ratings yet

- Paper Dimas GilangDocument20 pagesPaper Dimas GilangDimas DwiNo ratings yet

- SDFSDFSDFDocument74 pagesSDFSDFSDFcmarkobubamarkoNo ratings yet

- Boiler Operation & ControlDocument56 pagesBoiler Operation & ControlMohammad Rawoof100% (2)

- Uni AssignmentDocument10 pagesUni AssignmentIt's MaharNo ratings yet

- Boiler Operation and Installation ManualDocument24 pagesBoiler Operation and Installation ManualbzvzNo ratings yet

- Steam Power Plants (An Introduction and Components)Document115 pagesSteam Power Plants (An Introduction and Components)Ahmed NowarNo ratings yet

- Steam SystemsDocument32 pagesSteam SystemsYoussry Elsayed MohamedNo ratings yet

- Gek 107061Document10 pagesGek 107061Anup MitraNo ratings yet

- Installation and servicing guide for Ideal Classic SE FF boilersDocument44 pagesInstallation and servicing guide for Ideal Classic SE FF boilersbladeblowerNo ratings yet

- Set-S-3 (Ipc) - 09 06 12Document2 pagesSet-S-3 (Ipc) - 09 06 12Yousef Adel HassanenNo ratings yet

- PT SEV - YE III +ûRNEK SORULAR - NG - L - ZCEDocument18 pagesPT SEV - YE III +ûRNEK SORULAR - NG - L - ZCEYousef Adel HassanenNo ratings yet

- PT Level II Test PaperDocument7 pagesPT Level II Test PaperYousef Adel HassanenNo ratings yet

- M/s. Smart Technocrats & Consultancy Services (I) PVT. LTDDocument7 pagesM/s. Smart Technocrats & Consultancy Services (I) PVT. LTDYousef Adel HassanenNo ratings yet

- Set-Cr - Ipc - 07.07.12Document8 pagesSet-Cr - Ipc - 07.07.12Yousef Adel HassanenNo ratings yet

- msr3 5aprDocument3 pagesmsr3 5aprYousef Adel HassanenNo ratings yet

- PT Sev - Ye Ii Deneme Test - NG - L - ZceDocument10 pagesPT Sev - Ye Ii Deneme Test - NG - L - ZceYousef Adel HassanenNo ratings yet

- PT Theory FromDocument75 pagesPT Theory FromYousef Adel HassanenNo ratings yet

- PT Theory FromDocument75 pagesPT Theory FromYousef Adel HassanenNo ratings yet

- Liquid Penetrant Examination of Non-Porous Materials: 1. StatusDocument24 pagesLiquid Penetrant Examination of Non-Porous Materials: 1. StatusYousef Adel HassanenNo ratings yet

- PT03 PDFDocument15 pagesPT03 PDFKhaled BouhlelNo ratings yet

- PT04 PDFDocument25 pagesPT04 PDFKhaled BouhlelNo ratings yet

- PTINDocument0 pagesPTINSihem BenNo ratings yet

- PT16Document19 pagesPT16Pradeep Kumar BowmarajuNo ratings yet

- PT General 2Document4 pagesPT General 2Yousef Adel HassanenNo ratings yet

- PT2SDocument4 pagesPT2SYousef Adel HassanenNo ratings yet

- Electric Power Applications of Liquid Penetrant Testing: HapterDocument18 pagesElectric Power Applications of Liquid Penetrant Testing: HaptertariqNo ratings yet

- PT2 Specific - MasterDocument4 pagesPT2 Specific - MasterYousef Adel HassanenNo ratings yet

- PT Specfic 2Document2 pagesPT Specfic 2Yousef Adel HassanenNo ratings yet

- PT2 Specific - EsconDocument3 pagesPT2 Specific - EsconMangalraj MadasamyNo ratings yet

- PT2 Specific-Article 6Document3 pagesPT2 Specific-Article 6Yousef Adel HassanenNo ratings yet

- Liquid Penetrant Testing: Level-II GeneralDocument8 pagesLiquid Penetrant Testing: Level-II GeneralYousef Adel HassanenNo ratings yet

- CBIP Examination PTL1 GeneralDocument4 pagesCBIP Examination PTL1 GeneralHeather SullivanNo ratings yet

- PMT 30105Document29 pagesPMT 30105Yousef Adel HassanenNo ratings yet

- Saudi Aramco Contracting Process GuideDocument17 pagesSaudi Aramco Contracting Process GuideYousef Adel HassanenNo ratings yet

- PMT 30108Document30 pagesPMT 30108Yousef Adel HassanenNo ratings yet

- PT Specfic 1Document2 pagesPT Specfic 1Mangalraj MadasamyNo ratings yet

- PMT 30104Document22 pagesPMT 30104Yousef Adel HassanenNo ratings yet

- PMT 30101Document37 pagesPMT 30101Yousef Adel HassanenNo ratings yet

- PMT 30106Document36 pagesPMT 30106Yousef Adel HassanenNo ratings yet

- اسئلة مكائن كهربائيةDocument2 pagesاسئلة مكائن كهربائيةAhmed JamalNo ratings yet

- Prashant KumarDocument47 pagesPrashant KumarAftab AhmadNo ratings yet

- Testing and Sampling Parameters for Boiler Water FeedDocument17 pagesTesting and Sampling Parameters for Boiler Water FeedGuruNo ratings yet

- Act Sheet For RoboticsDocument4 pagesAct Sheet For RoboticsErah Kim GomezNo ratings yet

- Java Basics - Key Elements of a Java ProgramDocument21 pagesJava Basics - Key Elements of a Java ProgramAsh LeeNo ratings yet

- Caterpillar Performance Handbook 49 62020 Partie605Document4 pagesCaterpillar Performance Handbook 49 62020 Partie605ali alilouNo ratings yet

- Python Regular Expressions (RegEx) Cheat SheetDocument4 pagesPython Regular Expressions (RegEx) Cheat SheetbabjeereddyNo ratings yet

- 1016 Greenhouse PlansDocument9 pages1016 Greenhouse Planslagumbeg100% (1)

- MATH 5 Worksheet Q1Week 1 4Document6 pagesMATH 5 Worksheet Q1Week 1 4Criza Bill LauNo ratings yet

- Cyber Hunter Installation Log Documents File Installation ProcessDocument18 pagesCyber Hunter Installation Log Documents File Installation ProcessGregory JNo ratings yet

- Redwan Ahmed Miazee - HW - 1Document3 pagesRedwan Ahmed Miazee - HW - 1REDWAN AHMED MIAZEENo ratings yet

- Memorandum: From: TJC and Associates, Inc. Date: March, 2014 Subject: Seismic Anchorage Submittals ChecklistDocument2 pagesMemorandum: From: TJC and Associates, Inc. Date: March, 2014 Subject: Seismic Anchorage Submittals ChecklistponjoveNo ratings yet

- Agile vs Waterfall: Which Project Methodology is BestDocument29 pagesAgile vs Waterfall: Which Project Methodology is BestAhmad Adeniyi SharafudeenNo ratings yet

- HPA4 Service ManualDocument7 pagesHPA4 Service ManualMarcelo ArayaNo ratings yet

- Saved Copy Internship 1Document1 pageSaved Copy Internship 1Mu Jta BaNo ratings yet

- Object-Oriented Programming Assignment 2 - Library Management SystemDocument13 pagesObject-Oriented Programming Assignment 2 - Library Management SystemMohamed AhmedNo ratings yet

- 2 CEMEX Synhelion CemNet Webinar VFDocument15 pages2 CEMEX Synhelion CemNet Webinar VFChophel TashiNo ratings yet

- C ProgrammingDocument14 pagesC ProgrammingSakib MuhaiminNo ratings yet

- Introduction To Information Systems Supporting and Transforming Business 6th Edition Ebook PDFDocument41 pagesIntroduction To Information Systems Supporting and Transforming Business 6th Edition Ebook PDFrobert.cervantes686100% (33)

- How To Write A Project ReportDocument6 pagesHow To Write A Project ReportderwerwerwerNo ratings yet

- 16V2000 Detroit W5Document2 pages16V2000 Detroit W5Rendy Chavez LesmanaNo ratings yet

- Gixxer 250 GSX250FRLZM0Document81 pagesGixxer 250 GSX250FRLZM0Nelson Rodrigo100% (1)

- Cinchoo ETL - Parquet Writer - CodeProjectDocument35 pagesCinchoo ETL - Parquet Writer - CodeProjectgfgomesNo ratings yet

- T Rec L.156 201803 I!!pdf eDocument16 pagesT Rec L.156 201803 I!!pdf eluxofNo ratings yet

- Merlin Gerin Medium Voltage Distribution Switchgear Technical ManualDocument18 pagesMerlin Gerin Medium Voltage Distribution Switchgear Technical ManualMohammed Madi100% (1)

- About UsDocument16 pagesAbout UsManam BerampuramNo ratings yet

- Construction Management LecturesDocument8 pagesConstruction Management LecturesJosua MenisNo ratings yet

- Sigma Mod Master Clock: Installation and Start-Up InstructionsDocument62 pagesSigma Mod Master Clock: Installation and Start-Up InstructionsFiceaNo ratings yet

- Acquiring Host-Based EvidenceDocument21 pagesAcquiring Host-Based EvidencejigyanshuNo ratings yet

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisFrom EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisNo ratings yet

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsFrom EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsRating: 5 out of 5 stars5/5 (1)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

- Pipeline Integrity: Management and Risk EvaluationFrom EverandPipeline Integrity: Management and Risk EvaluationRating: 4.5 out of 5 stars4.5/5 (6)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesFrom EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Biostratigraphic and Geological Significance of Planktonic ForaminiferaFrom EverandBiostratigraphic and Geological Significance of Planktonic ForaminiferaRating: 4 out of 5 stars4/5 (5)

- Mooring System Engineering for Offshore StructuresFrom EverandMooring System Engineering for Offshore StructuresRating: 5 out of 5 stars5/5 (1)