Professional Documents

Culture Documents

As Cest 1527869

Uploaded by

Sadique K MuhammedCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

As Cest 1527869

Uploaded by

Sadique K MuhammedCopyright:

Available Formats

Seismic Retrofit of Concrete Shear

Walls with SMA Tension Braces

W. Leonardo Cortés-Puentes, S.M.ASCE 1; and Dan Palermo, Ph.D., A.M.ASCE 2

Abstract: A bracing system consisting of tension-only superelastic nickel-titanium shape-memory alloy (SMA) was developed and imple-

Downloaded from ascelibrary.org by RMIT UNIVERSITY LIBRARY on 12/06/17. Copyright ASCE. For personal use only; all rights reserved.

mented as a retrofitting methodology for seismically deficient squat reinforced concrete shear walls. The bracing system incorporates SMA

links that serve as resettable fuses with unique recentering and energy-dissipation properties that result in improved hysteretic response. This

paper focuses on one-third-scale walls that represent pre-1970s reinforced concrete shear walls susceptible to shear sliding and diagonal

tension cracking. Four walls, two control and two retrofitted with the SMA bracing system, were tested under reversed cyclic loading. The

SMA braces demonstrated excellent performance as a retrofitting device, improving the seismic response of squat reinforced concrete shear

walls, including lateral strength capacity, ductility, energy dissipation, and displacement recovery. The retrofitting system was central in

minimizing damage at the base of the walls. DOI: 10.1061/(ASCE)ST.1943-541X.0001936. © 2017 American Society of Civil Engineers.

Author keywords: Shape-memory alloys; Tension braces; Seismic retrofit; Reinforced concrete; Squat shear walls; Seismic effects.

Introduction beam-column joints (Nehdi et al. 2010; Youssef et al. 2008), con-

crete frames (Alam et al. 2009; Meshaly et al. 2014; Youssef and

Advancements in shape-memory alloys (SMAs) have translated Elfeki 2012; Zafar and Andrawes 2012), and concrete shear walls

into the development of smart retrofitting systems that are capable (Abdulridha and Palermo 2017; Ghassemieh et al. 2012). The ben-

of improving the seismic response of existing seismically deficient efits of superelastic SMAs as the main components in dampers and

reinforced concrete shear walls. These novel retrofitting systems restraining systems for concrete bridges (Adachi and Unjoh 1999;

possess recentering and dynamic properties that can improve DesRoches and Delemont 2002; Ozbulut and Hurlebaus 2010) and

strength, ductility, and energy dissipation while mitigating damage steel buildings (Silwal et al. 2015) have also been evaluated.

and reducing residual deformations. Comprehensive characteriza- Bracing systems based on superelastic SMAs are capable of im-

tion of superelastic SMAs (Dolce and Cardone 2001a, b; Fang et al. proving the seismic response of structures (Salichs et al. 2001; Soul

2015; McCormick et al. 2007; Nemat-Nasser and Guo 2006; and Yawny 2015). Although various researchers have developed

Piedboeuf et al. 1998; Tyber et al. 2007) has provided confidence SMA bracing systems to improve the lateral response of steel struc-

in the use of these materials for the development of reinforcing and tures (Auricchio et al. 2006; Dezfuli et al. 2017; Gao et al. 2016;

retrofitting strategies for seismic applications. The majority of these McCormick et al. 2006; Motahari et al. 2007; Qiu and Zhu 2017;

studies have focused on commercially available superelastic nickel- Speicher et al. 2017; Sultana and Youssef 2016; Yang et al. 2010),

titanium (NiTi) SMAs, which have the capacity to recover up to only a few have focused on reinforced concrete structures (Dolce

98% of the deformations experienced by the material when sub- et al. 2005; Effendy et al. 2006; Liao and Mo 2006; Meshaly et al.

jected to strains up to 6% and provide equivalent viscous damping 2014). Results from experimental and numerical studies have

approaching 7% (DesRoches et al. 2004). demonstrated that bracing systems and passive-control devices

Given the capacity to recover significant strain levels, supere- incorporating superelastic SMA wires, rods, and rings are effective

lastic SMAs have been explored as reinforcing and retrofitting ma- in reducing vibrations and improving recentering while providing

terials for a large range of concrete structures (Alam et al. 2007; energy dissipation.

Janke et al. 2005; Song et al. 2006). Experimental and numerical Although effective in improving the response of structures,

studies demonstrated that superelastic SMAs reduce residual defor- SMA braces have some limitations. Braces based on SMA wires

mations and provide excellent energy dissipation in concrete beams use a significant number of wires to develop sufficient force capac-

(Abdulridha et al. 2013; Kuang and Ou 2008; Malagisi et al. 2014; ity and require specialized fabrication not feasible in field applica-

Saiidi et al. 2007; Zafar and Andrawes 2013), concrete columns tions. Braces incorporating SMA rods may experience buckling

(Cruz Noguez and Saiidi 2012; Nakashoji 2014; Saiidi et al. because of the high compressive stresses associated with large

2009; Saiidi and Wang 2006; Tazarv and Saiidi 2015), concrete lateral-displacement demands imposed on the structure, which alter

the expected failure mode of the braces and limit the contributions

1

Graduate Student, Dept. of Civil Engineering, Univ. of Ottawa, of the SMA to strength and energy dissipation. In addition, bracing

161 Louis Pasteur St., Ottawa, Canada ON K1N 6N5 (corresponding systems based on SMA rings require stiff rigid cables or steel truss

author). E-mail: wcort032@uottawa.ca members to ensure maximum recentering. Other SMA bracing sys-

2

Associate Professor, Dept. of Civil Engineering, York Univ., 4700 tems combining traditional buckling restrained braces (BRB) with

Keele St., Toronto, Canada ON M3J 1P3. E-mail: dan.palermo@

SMA rods (Miller et al. 2012) have demonstrated satisfactory en-

lassonde.yorku.ca

Note. This manuscript was submitted on January 25, 2017; approved

ergy dissipation that can potentially reduce displacement demands

on July 10, 2017; published online on November 27, 2017. Discussion in structures. The steel core of the BRB, however, limits the recov-

period open until April 27, 2018; separate discussions must be submitted ery capacity of the braces.

for individual papers. This paper is part of the Journal of Structural En- Effendy et al. (2006) conducted the only study known by

gineering, © ASCE, ISSN 0733-9445. the authors on external bracing of squat reinforced concrete shear

© ASCE 04017200-1 J. Struct. Eng.

J. Struct. Eng., 2018, 144(2): 04017200

deformations. The SMA links are resettable elements that can be

removed or replaced, whereas the steel elements remain connected

to the retrofitted structure. By optimizing the length of the SMA

link, the cost of the brace is significantly reduced. The cost of fab-

rication and installation of the proposed SMA brace is approxi-

mately 65% greater than that of equivalent braces incorporating

ASTM A36 hot-rolled steel and SAE 316 stainless steel links.

Given the recentering effect of the SMA and potential reduction

in residual lateral drift and associated residual damage, the criteria

used to select the SMA bracing system should not be solely as-

sessed on the initial investment. Savings in postearthquake repairs

would offset the initial cost of the retrofitting system.

Downloaded from ascelibrary.org by RMIT UNIVERSITY LIBRARY on 12/06/17. Copyright ASCE. For personal use only; all rights reserved.

This paper presents experimental results for seismically defi-

cient, squat-reinforced concrete shear walls retrofitted with the pro-

posed SMA bracing system. Squat shear walls are the focus of this

Fig. 1. Retrofitted Walls SQ1S and SQ2S

paper, given the expected prevailing diagonal deformations, which

would impose large elongations in the SMA braces and activate

the beneficial recovery properties.

walls with SMAs. The walls, which were reinforced with external

bidiagonal superelastic SMA rods in combination with internal

reinforcing steel, experienced lateral strength similar to control Experimental Program

walls reinforced with equivalent internal reinforcing steel. The low

tensile straining and compression buckling of the SMA rods limited Two control walls (Wall SQ1 and Wall SQ2) and two retrofitted

the recentering and energy-dissipation benefits of the SMA. walls (Wall SQ1S and Wall SQ2S) with an aspect ratio of 1.0 were

subjected to incremental reverse cyclic lateral loading. Wall SQ1

(2,000 mm in length × 2,000 mm in height × 100 mm in thick-

Research Significance ness) represents a lightly reinforced shear wall prone to shear

sliding at the base [Fig. 2(a)], and Wall SQ2 (2,000 × 2,000 ×

Previous research has highlighted salient features of SMAs that can 125 mm) represents a stronger shear wall with boundary zones that

be exploited to improve seismic response. Conversely, a number of is controlled by diagonal tension cracking [Fig. 2(b)]. The shear

shortcomings have been encountered in the application of SMAs in walls were one-third-scale models of a prototype shear wall de-

bracing systems, in addition to limitations of SMA rods, including signed according to the 1965 edition of the National Building Code

low modulus of elasticity and high cost relative to traditional struc- of Canada (NRCC 1965). Full details of the prototype structures

tural steel. The cost of superelastic SMA rods can be up to 40 times are provided elsewhere (Cortés-Puentes and Palermo 2012).

the cost of the ASTM A36 hot-rolled steel and 20 times greater Walls SQ1 and SQ1S were reinforced with a single-layer of

than the Society of Automotive Engineers (SAE) Grade 316 stain- 5-ϕ9.5 mm vertical reinforcing bars (0.18% reinforcement ratio)

less steel rods. A36 structural steel is the typical material for and 6-ϕ9.5 mm horizontal reinforcing bars (0.21% reinforcement

tie-rod braces. To address these challenges, the authors developed ratio) as illustrated in Fig. 2 (ϕ refers to diameter). The design of

an efficient, tension-only SMA bracing system that is practical and Walls SQ2 and SQ2S included 225-mm-long boundary zones at

suitable for a wide range of concrete structures. Furthermore, the the ends of the walls with concentrated vertical reinforcement. The

proposed braces are also applicable to steel structures. web region of Walls SQ2 and SQ2S, reinforced with 5-ϕ9.5 mm

The SMA bracing system presented in Fig. 1 incorporates vertical reinforcement and 7-ϕ9.5 mm horizontal reinforcement,

optimized SMA links with reduced length that serve as fuses where contained the same vertical reinforcement ratio (0.18%) and ap-

recoverable deformations are concentrated. The links, in turn, proximately the same horizontal reinforcement ratio (0.20%) as

are coupled to rigid steel elements that sustain negligible elastic Walls SQ1 and SQ1S. The boundary zones were reinforced with

(a) (b)

Fig. 2. Detail of shear walls: (a) Wall SQ1; (b) Wall SQ2

© ASCE 04017200-2 J. Struct. Eng.

J. Struct. Eng., 2018, 144(2): 04017200

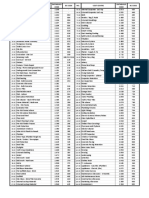

Table 1. Concrete Material Properties diameter of 11.8 mm (cross-sectional area of 110 mm2 ) over a

Wall f c0 (MPa) εc0 (%) length of 500 mm, bar-lock couplers secured at the ends of the

SMA rods with 18 shear-off bolts, and stiff steel plates placed

SQ1 22.52 0.269

on the inside of the couplers. To ensure tension-only forces in

SQ1S 24.73 0.184

SQ2 20.26 0.187

the SMA rods, one of the steel plates was welded to an end coupler,

SQ2S 27.37 0.222 whereas the other plate was free [Fig. 3(a)]. The rigid steel elements

were fabricated with 50 × 50 × 4 mm hollow structural sections

Note: f c0 = compressive strength at day of testing; εc0 = compressive strain (HSS), a 76-mm-wide × 19-mm-thick steel plate at one end, and

corresponding to fc0 .

stiff flanges at the other end to provide a connection to the SMA

links. The ends of the SMA links were placed into the HSS and

connected to the flanges of the rigid steel elements with high-

Table 2. Reinforcement Material Properties strength 15.9-mm (5=8-in:) diameter bolts [Fig. 3(c)].

Downloaded from ascelibrary.org by RMIT UNIVERSITY LIBRARY on 12/06/17. Copyright ASCE. For personal use only; all rights reserved.

ϕ (mm) f y (MPa) εy (%) f u (MPa) εu (%) The characterization of the stresses and strains of the SMA was

9.5 495 0.30 735 16 based on a loading protocol with an initial cycle to 6% strain and

11.3 460 0.30 660 16 a second cycle to rupture, following the procedures specified in

ASTM F2516-14 (ASTM 2014). The SMA rods had the following

Note: f u = ultimate stress; fy = yield stress; εu = ultimate strain; εy = yield properties:

strain; ϕ = diameter.

• Upper plateau stress (pseudoyielding) of 407 MPa at 3% strain;

• Lower plateau stress of 186 MPa at 2.5%;

• Ultimate stress (rupture) of 1,054 MPa at 19.8%; and

4-ϕ9.5 mm longitudinal reinforcing bars (1.0% reinforcement • Residual strain of 0.6% for the cycle to 6% (Fig. 4).

ratio) and ϕ − 6.35-mm transverse ties spaced at 100 mm (0.51% The second cycle to rupture resulted in an upper plateau stress

reinforcement ratio). Walls SQ1S and SQ2S were further retrofitted of 357 MPa. The minimum operating temperature of the SMA to

with four SMA tension-only diagonal braces externally attached to ensure superelastic behavior, based on the fully annealed temper-

the lower and upper corners on each side of the walls as illustrated ature, was −10°C.

in Fig. 1. The SMA braces were initially designed to experience a target

The walls were constructed on heavily reinforced foundation elongation of 38 mm, which corresponds to a strain of 6% in the

blocks (2,500 mm in length × 1,400 mm in width × 500 mm in SMA link, matching the strain-recovery capacity of the SMA rods.

height) that simulated rigid foundation conditions. The foundation Bare testing of the SMA braces under axial cyclic loading estab-

blocks were anchored with high-strength bolts to the strong floor of lished the mechanical properties of the SMA braces (Cortés-

the structures laboratory in the Civil Engineering Department at the Puentes and Palermo 2017). Testing was first conducted on SMA

University of Ottawa. Beams with a depth of 160 mm and rein- braces incorporating SMA links with the original diameter of

forced with four 10M (ϕ11.3 mm) longitudinal reinforcing bars 12.7 mm (Fig. 5). The braces experienced an average pseudoyield

were embedded within the walls at a height of 1,660 mm from stress of 353 MPa, an average lower plateau stress of 172 MPa, and

the base to serve as a strengthened zone through which the lateral an ultimate stress of 525 MPa. Pseudoyielding of the SMA braces

loading was imposed (Fig. 2). The exception was Wall SQ1, which initiated at approximately 0.4% elongation (1.6% elongation in the

was strengthened with externally bonded fiber-reinforced polymer SMA link), based on an offset of 0.05% (0.2% offset in the link).

sheets along the location of the loading beam and at the top corners. Deformations corresponding to pseudoyielding in the braces was

The vertical reinforcement of Walls SQ1 and SQ1S terminated with concentrated in the SMA links, whereas the steel components ex-

standards hooks that were cast within the foundation blocks, perienced negligible elastic deformations. Although negligible, the

whereas the vertical reinforcement in Walls SQ2 and SQ2S was elastic deformation of the steel plates connecting the SMA links to

anchored 250 mm into the existing foundation blocks with epoxy the braces resulted in a sharp decrease of approximately 10 kN in

(Walls SQ2 and SQ2S were constructed on the foundation blocks strength at the initiation of unloading. Rupture at the location of the

that were originally used for SQ1 and SQ1S). Properties of the con- couplers occurred at 41 mm elongation, corresponding to 1.61%

crete and reinforcing bars are listed in Tables 1 and 2, respectively. elongation of the full brace and 6.45% elongation of the SMA link.

The SMA braces consisted of 635-mm-long SMA links Fig. 5 illustrates a typical force-elongation response of the SMA

[Fig. 3(a)] connected to 953-mm-long rigid steel elements tension braces tested to failure.

[Fig. 3(b)]. The total length of the braces was 2,540 mm. The SMA Although the target strain was achieved, further testing was

links were fabricated with smooth 12.7-mm-diameter nickel- conducted on a SMA brace with a reduced diameter of 11.8 mm

titanium alloy (Nitinol) superelastic SMA rods with reduced in the central portion of the SMA link to provide a reserve strain

Fig. 3. SMA brace details: (a) SMA link; (b) rigid steel element; (c) connection of SMA link to rigid steel element

© ASCE 04017200-3 J. Struct. Eng.

J. Struct. Eng., 2018, 144(2): 04017200

1200

Lateral

Reaction Frame

1000 A-Fr ame Actuator

800

Stress (MPa)

Shear

1660

mm

Load

600 Wall

Cell

400

200 Strong Floor

12.7 mm SMA Rod

0

0 5 10 15 20 Fig. 6. Test setup

Downloaded from ascelibrary.org by RMIT UNIVERSITY LIBRARY on 12/06/17. Copyright ASCE. For personal use only; all rights reserved.

Strain (%)

Fig. 4. Stress-strain of 12.7-mm SMA rod

analyses were used to calculate the performance point, which

corresponded to approximately 37 mm (1.85% drift) of top lateral

displacement in Wall SQ1. The SMA links were continually rede-

Elongation (%) signed until the capacity curve of the retrofitted wall intersected

0 0.4 0.8 1.2 1.6 2 the reduced elastic demand curve at the performance point. Full

70 560 details of this analysis are provided elsewhere (Cortés-Puentes and

60 480 Palermo 2017). The performance point in this paper corresponds to

50 400

Stress (MPa) the collapse-prevention performance level defined by ASCE 41-06

(ASCE 2007).

Force (kN)

40 320

Beyond the target displacement, the loading cycles were incre-

30 240 mented by 10 mm. Each cycle consisted of two repetitions. No

20 160 external axial loads were imposed on the walls. Based on the analy-

10 80 sis of the prototype structure, the axial load ratio (P=Ag f c0 ) on the

walls ranged from 1 to 1.7%. At these levels of axial load, the re-

0 0

0 10 20 30 40 50 sponse of the shear walls was not expected to deviate significantly

Elongation (mm) relative to zero axial load. However, previous experimental testing

(Gulec and Whittaker 2009) illustrated that as the axial load in-

Fig. 5. Force-elongation response of SMA brace creases to higher levels, the shear strength increases, drift capacity

and energy dissipation are maintained, and residual displacements

are reduced. Furthermore, high axial loads increase the compres-

sive stresses in the ends of the wall, contributing to crushing

capacity. The additional SMA link was fabricated with a shape

and diagonal-compression failure modes. The in-plane lateral load-

memory–effect (SME) SMA rod. The SME-SMA had the same

ing was applied with an actuator positioned 1,660 mm from the

chemical composition and smoothness as the superelastic Nitinol

base of the wall (shear span of 0.83), as illustrated in Fig. 6.

SMA link, but did not possess the recovery properties after the re-

One end of the actuator was mounted to an A-frame, whereas

moval of load. The main objectives of testing the additional link

the other end was connected to the walls. A lateral supporting frame

were to (1) assess the increase in ductility of the SMA braces and

was positioned near the top of the walls to control out-of-plane

increase in strain capacity of the SMA links; and (2) evaluate the

displacements.

ability to control the location of failure in the SMA links attribut-

Displacement cable transducers (DCTs) and LVDTs were used

able to their reduced diameter. Previous tests on SMA-reinforced

to measure lateral and vertical displacements, diagonal deforma-

beams (Abdulridha et al. 2013) demonstrated that a reduced diam-

tions, bond slip, and sliding at the base of the walls. Strain gauges

eter in superelastic SMA rods does not alter the pseudoelasticity

were attached to the internal reinforcing steel to measure local

while ensuring that rupture does not initiate at the location of the

straining where yielding and heavy damage was expected and to

couplers. This paper demonstrated that the reduced diameter did

the SMA links to monitor the response of the braces.

not affect the stress-strain response of the SMA rods. The reduced

diameter resulted in an ultimate elongation of the SMA link of

8.8%, corresponding to an elongation capacity of 56 mm. Full de- Experimental Results

tails of the bare brace testing can be found elsewhere (Cortés-

Puentes and Palermo 2017). The results presented herein focus on the strength-displacement

The pseudostatic loading protocol recommended by FEMA 461 responses and observed damage of the walls. The lateral displace-

(ATC and FEMA 2007) was implemented during testing of the ments were measured 2,000 mm from the base of the walls. The

walls. Loading initiated with a precracking cycle to 0.3 mm top positive displacements and strengths correspond to pushing the ac-

displacement. The cycles were incremented by a factor of 2 in the tuator (Fig. 6). Conversely, negative displacements and strengths

preyielding stage and by a factor of 1.4 in the postyield stage (dam- correspond to pulling the actuator.

age stage) until the predetermined target displacement of 40 mm

(2% drift) was achieved. The capacity spectrum method specified

Response of Walls SQ1 and SQ1S

by ATC-40 (ATC 1996) and FEMA 440 (ATC and FEMA 2005)

was used to establish the performance point (lateral strength and Fig. 7 illustrates the lateral load-displacement responses of Walls

displacement) for retrofitted structures. The performance point cor- SQ1 and SQ1S. First cracking along the base of the wall occurred

responds to the intersection of the capacity curve of the retrofitted during loading to 0.6 mm for SQ1 and SQ1S, corresponding to

structure with the reduced elastic demand. Nonlinear finite-element lateral strengths of 61 and 90 kN, respectively. With increases

© ASCE 04017200-4 J. Struct. Eng.

J. Struct. Eng., 2018, 144(2): 04017200

Drift (%) Drift (%)

-3.5 -2.5 -1.5 -0.5 0.5 1.5 2.5 -3.5 -2.5 -1.5 -0.5 0.5 1.5 2.5

250 250

Yield Ultimate

Yield Ultimate

150 150

Lateral Load (kN)

Lateral Load (kN)

First

First Yield

50 Yield 50

-50 -50

-150 -150

Wall SQ1 Wall SQ1S

-250 -250

-70 -50 -30 -10 10 30 50 -70 -50 -30 -10 10 30 50

(a) Lateral Displacement (mm) (b) Lateral Displacement (mm)

Downloaded from ascelibrary.org by RMIT UNIVERSITY LIBRARY on 12/06/17. Copyright ASCE. For personal use only; all rights reserved.

Fig. 7. Lateral load-displacement response of (a) Wall SQ1; (b) Wall SQ1S

in loading, damage was concentrated along the base cracking, þ4.4 mm= −17.8 mm), the wall experienced a strength differ-

resulting in behavior controlled by rocking. Because of the addi- ence of approximately 54 kN between the negative and positive

tional stiffness provided by the retrofitting system, the horizontal directions. It was realized that the full capacity of the wall was

crack in the boundary regions of Wall SQ1S shifted approximately not achieved as a result of the asymmetrical loading; therefore,

170 mm above the base. This crack formed along the weak plane an additional cycle to 50 mm was imposed on the wall to capture

introduced by the presence of the bolts in the anchor plates of the the postpeak behavior.

retrofitting system. First yielding of the vertical reinforcing bar Fig. 8 illustrates the cracking experienced by Walls SQ1 and

nearest to the ends of the walls was captured by strain gauges SQ1S at ultimate, which corresponded to the cycle prior to a de-

during the cycle to 1.2 mm at lateral strengths of 84 and 102 kN crease in lateral strength of more than 20%. Failure of Wall SQ1

for Walls SQ1 and SQ1S, respectively. Yielding of the three ver- was the result of rupturing of the longitudinal reinforcing bar near-

tical bars near the end of the walls was realized during the cycle to est to the edge of the wall at þ37 mm. Two additional bars ruptured

2.4 mm at lateral strengths of 96 and 113 kN for Walls SQ1 and at −46.3 and −58 mm, reducing the lateral strength to 36 kN. The

SQ1S, respectively. Global yielding of SQ1 and SQ1S, based on LVDTs at the base of Wall SQ1 recorded crack widths of 17 and

the equivalent elastic-plastic response (Park 1989), was 4.5 and 24 mm at the edges of the main horizontal crack, corresponding to

8.6 mm, respectively. At global yielding, the maximum width of lateral displacements of þ28 and −39 mm in the wall, respectively.

the crack at the base of the walls was approximately 3.8 mm. The Failure of Wall SQ1S occurred at þ24.7 mm as a result of ruptur-

lateral strength of Walls SQ1 and SQ1S continued to increase in ing of the vertical reinforcing bar nearest to the edge of the wall,

the postyield range. Wall SQ1 experienced peak strengths of which was triggered by concentrated damage in the horizontal

145 kN at þ37 mm and 123 kN at −19 mm, whereas Wall SQ1S crack at the base. As a result, the strength of the wall was reduced

experienced peak strengths of 213 kN at þ24.7 mm and 218 kN to 167 kN. Two additional bars ruptured while loading the wall in

at −25 mm. the negative direction to −35 mm. At ultimate, Wall SQ1S expe-

Beyond 5 mm of lateral displacement, Wall SQ1 was loaded rienced a maximum crack width of 25.8 mm. The residual strength

asymmetrically because of an instrumentation error. This resulted of Wall SQ1S was 121 kN at þ35 mm and 95 kN at −35 mm.

in recorded displacements that did not necessarily correspond Walls SQ1 and SQ1S experienced residual displacements of 42.1

with the intended target displacements. At the intended target and 13.5 mm, respectively, following loading to displacements of

displacement to 12 mm (actual recorded displacements of 50 and 25 mm.

Fig. 8. Damage of Walls SQ1 at ultimate: (a) Wall SQ1; (b) Wall SQ1S

© ASCE 04017200-5 J. Struct. Eng.

J. Struct. Eng., 2018, 144(2): 04017200

LVDTs placed 250 mm from the base of the walls measured the diagonal cracking of Wall SQ2. As a result, Wall SQ2 sustained

the base slip at the construction joint. At 20 mm of wall lateral its peak strength to ultimate. Diagonal cracking of Wall SQ2S was

displacement, base slips of 18 and 18.3 mm were recorded for controlled by the internal reinforcing steel and SMA braces, result-

Walls SQ1 and SQ1S, respectively. At ultimate for Wall SQ1, the ing in negligible degradation of response during the second repe-

large base-slip displacement exceeded the stroke capacity of the titions of loading up to 30 mm. In the postyield range, Wall SQ2S

LVDT. An ultimate slip of 25.8 mm was measured at the left continued gaining strength because of the contribution of the SMA

end of Wall SQ1S. Given the localized damage of the walls at the braces and experienced yielding of the vertical reinforcement

base, the slip corresponded to the width of the horizontal crack. An throughout the wall. This led to uniform widening of the diagonal

LVDT placed horizontally at the base of the wall measured maxi- cracks during the postyield loading phases, followed by crack clos-

mum sliding displacements of 14.1 and 2.8 mm for Walls SQ1 and ing upon load reversal because of the clamping effect of the SMA

SQ1S, respectively. braces. The wall experienced peak strengths of 390 kN at þ30 mm

and 424 kN at −42 mm.

Downloaded from ascelibrary.org by RMIT UNIVERSITY LIBRARY on 12/06/17. Copyright ASCE. For personal use only; all rights reserved.

Response of Walls SQ2 and SQ2S Fig. 10 illustrates the crack pattern of Walls SQ2 and SQ2S at

ultimate. Failure of Wall SQ2 occurred at −27 mm at a correspond-

Fig. 9 illustrates the force-displacement responses of Walls SQ2 ing strength of 133 kN while loading the second repetition to

and SQ2S. First cracking surfaced at 0.3 and 0.6 mm, respectively, 30 mm, which was caused by concentrated damage at the base

for Walls SQ2 and SQ2S, at corresponding lateral strengths of 115 (maximum crack width of approximately 15 mm) that resulted

and 170 kN. The first crack (diagonal) in Wall SQ2 appeared in the in large strains and rupturing of one longitudinal bar in the right

lower left quadrant. The first crack in Wall SQ2S appeared along boundary zone. At failure, the diagonal cracks in Wall SQ2 were,

the base at approximately one-third of the length of the wall. First

in general, smaller than 2 mm, with the exception of a number of

cracking was followed by distributed diagonal cracks that pro-

5–7-mm-wide cracks located in the lower portion of the wall near

gressed from the base of the wall to the loading beam with increas-

the left boundary zone. Six longitudinal bars ruptured by the end of

ing lateral loading. The diagonal cracks in both walls initiated as

testing, four in the boundary zones and two in the web. The strength

horizontal cracks crossing the boundary zones that propagated

of Wall SQ2 decreased to an average of 53 kN at 40 mm.

diagonally toward the base. First yielding of Walls SQ2 and SQ2S,

The postpeak damage of Wall SQ2S differed from that observed

defined by yielding of the outermost vertical reinforcing bar in

in Wall SQ2 despite similarities in the crack pattern. At 30 mm,

the boundary zone, was recorded at lateral displacements of −0.6

and −2.8 mm, respectively, corresponding to lateral strengths of prior to failure, the horizontal crack at the base in Wall SQ2S

135 and 280 kN. Yielding of all the reinforcement in the bound- widened to approximately 7 mm, whereas the majority of diagonal

ary zones was realized during loading to 5 mm. At this lateral cracks had maximum widths between 2.5 and 6 mm. At 40 mm, the

displacement, Wall SQ2 reached its peak strength of 243 kN. distributed damage of concrete and rupturing of one reinforcing bar

Global yielding of SQ2 and SQ2S was determined at 1.7 and at the left end of the wall preceded crushing and out-of-plane failure

−6.3 mm, at corresponding strengths of 179 and 305 kN, re- of the right boundary zone, reducing the postpeak strength specifi-

spectively. The global yielding of SQ2S was established for the cally in the positive direction. Given the heavy damage at the right

negative direction, in which the full cyclic response of the wall end of the wall, loading in the positive direction was halted at

was captured. 50-mm displacement, but loading continued to 70 mm in the neg-

Additional diagonal and horizontal cracks surfaced in Walls ative direction. Rupture of two longitudinal bars in the right boun-

SQ2 and SQ2S after yielding. Notably, a major horizontal crack dary zone decreased the strength of the wall during the cycles to

appeared at the construction joint at the base of the walls. The spac- −60 and −70 mm. The strength of Wall SQ2S at ultimate displace-

ing of the main diagonal cracks ranged between 200 and 300 mm. ment of −57 mm was 407 kN. The residual strengths of Wall SQ2S

In the boundary zones, the horizontal cracks were spaced between at þ50 and −70 mm was 285 and 265 kN, respectively. Wall SQ2

100 and 200 mm, in conformity with the spacing of the transverse sustained a residual displacement of 23 mm at ultimate cycle to

reinforcement. Concentrated damage along the horizontal crack at 30 mm, whereas Wall SQ2S experienced an average residual dis-

the base of Wall SQ2 led to significant rocking of the wall and placement of 26.7 mm at the cycle to 50 mm.

localized yielding of the longitudinal reinforcement. This resulted During loading to 30 mm, the LVDTs at the base of the walls

in notable degradation in strength and stiffness during the second measured base slip of 15.9 and 12.4 mm and base horizontal slid-

repetitions of loading. Above the base, the reinforcement controlled ing of 16.8 and 2.5 mm for Walls SQ2 and SQ2S, respectively.

Drift (%) Drift (%)

-4 -3 -2 -1 0 1 2 3 -4 -3 -2 -1 0 1 2 3

500 500

300 Ultimate 300

Lateral Load (kN)

Lateral Load (kN)

Yield

100 100

-100 First -100

Yield

First

-300 -300 Yield

Wall SQ2 Ultimate Yield Wall SQ2S

-500 -500

-80 -60 -40 -20 0 20 40 60 -80 -60 -40 -20 0 20 40 60

(a) Lateral Displacement (mm) (b) Lateral Displacement (mm)

Fig. 9. Lateral load-displacement response of (a) Wall SQ2; (b) Wall SQ2S

© ASCE 04017200-6 J. Struct. Eng.

J. Struct. Eng., 2018, 144(2): 04017200

Downloaded from ascelibrary.org by RMIT UNIVERSITY LIBRARY on 12/06/17. Copyright ASCE. For personal use only; all rights reserved.

Fig. 10. Damage of Walls SQ2 at ultimate: (a) Wall SQ2; (b) Wall SQ2S

Wall SQ2S experienced a maximum sliding displacement of the SMA braces was approximately 9 mm at 12.8-mm elongation,

15.5 mm at the right end of the wall at ultimate. This large sliding it was less than 5 mm at 18.9-mm elongation. No rupture of the

was the result of heavy localized damage in the lower portion of SMA braces and links was observed while testing Wall SQ1S.

the boundary zone. Based on the force-elongation response of the bare SMA brace

(Fig. 5) and the strains recorded in the brace (Fig. 11), the maxi-

Response of SMA Braces mum force developed in the SMA braces was approximately

48 kN. At the end of testing, the maximum residual elongation of

Fig. 11 shows typical responses of the SMA braces and SMA links

the links was approximately 2 mm, corresponding to approximately

in Wall SQ1S. The SMA braces experienced tension-only forces

0.3% elongation. The negligible residual elongations of the SMA

and further served to restore the wall to its original position. The

links in Wall SQ1S and the elastic response of the steel components

onset of pseudoyielding of the SMA braces at 0.4% occurred at

permitted reuse of the SMA braces for Wall SQ2S.

approximately þ21 and −23 mm of lateral displacement in the wall

Fig. 12 illustrates typical responses of the SMA braces and

during the cycle to the ultimate displacements. At ultimate, the

braces and links experienced elongations of 12.8 mm (0.5% elon- SMA links in Wall SQ2S. Two SMA braces sustained maximum

gation) and 14.5 mm (2.28% elongation), respectively. Beyond ul- elongation of 1.1% at þ50 mm of lateral displacement of the wall

timate, the braces were subjected to maximum elongations of 18.9 [Fig. 12(a)], whereas the other two braces sustained maximum

and 23.7 mm during loading of the wall to the positive and negative elongation of 1.76% at −60 mm. The corresponding elongations

directions, respectively. The corresponding maximum percent elon- in the SMA links at þ50 and −60 mm were 5.37% [Fig. 12(b)]

gations were 0.74 and 0.93% in the braces and 2.97 and 3.73% in and 6.76%, respectively. Pseudoyielding of the SMA braces initi-

the links. Rupturing of the internal reinforcing steel bars at ultimate ated approximately at 16 mm of lateral displacement. A maximum

reduced the resistance of the shear wall from recovering, resulting force of 57.5 kN was calculated for the SMA braces based on the

in an increase in the elongation recovery of the SMA braces in maximum strain in the links and stress-strain response of the SMA

the subsequent cycles. rods (Fig. 4) [stress-strain response of the bare brace could not

The internal reinforcement follows the behavior of ductile black be used to calculate the force because the maximum strain of

carbon steel, where the postyield response is characterized by sig- the SMA braces exceeded the rupture strain of 1.61% of the bare

nificant residual straining. Although the residual elongation of braces (Fig. 5)].

Elongation (%) Elongation (%)

-0.6 -0.4 -0.2 0 0.2 0.4 0.6 0.8 1 -2.4 -1.6 -0.8 0 0.8 1.6 2.4 3.2 4

250 250

150 150

Lateral Load (kN)

Lateral Load (kN)

50 50

-50 -50

-150 -150

Wall SQ1S Wall SQ1S

-250 -250

-15 -10 -5 0 5 10 15 20 25 -15 -10 -5 0 5 10 15 20 25

(a) Elongation (mm) (b) Elongation (mm)

Fig. 11. Typical wall lateral load-elongation response of SMA braces in Wall SQ1S: (a) SMA brace; (b) SMA link

© ASCE 04017200-7 J. Struct. Eng.

J. Struct. Eng., 2018, 144(2): 04017200

Elongation (%) Elongation (%)

-1.6 -1.2 -0.8 -0.4 0 0.4 0.8 1.2 1.6 -3.2 -1.6 0 1.6 3.2 4.7 6.3

500 500

300 300

Lateral Load (kN)

Lateral Load (kN) 100 100

-100 -100

-300 -300

Wall SQ2S Wall SQ2S

-500 -500

-40 -30 -20 -10 0 10 20 30 40 -20 -10 0 10 20 30 40

(a) (b)

Downloaded from ascelibrary.org by RMIT UNIVERSITY LIBRARY on 12/06/17. Copyright ASCE. For personal use only; all rights reserved.

Elongation (mm) Elongation (mm)

Fig. 12. Typical wall lateral load-elongation response of SMA braces in Wall SQ2S: (a) SMA brace; (b) SMA link

As a result of out-of-plane damage of the wall beyond 40 mm approximately 80%, which eliminated kinking of the longitudinal

displacement, the SMA braces and SMA links sustained bending reinforcement at the base and improved the global response

that resulted in negative elongations. The largest negative elonga- [Fig. 7(b)].

tion in the brace was approximately 33 mm (Fig. 12). Posttest Walls SQ2 and SQ2S experienced widespread diagonal crack-

inspection revealed that the SMA braces and links did not rupture, ing caused by the presence of concentrated reinforcement in the

the alignment of the retrofitting system remained intact, and the boundary zones. In the postyield range of SQ2, the rocking and

tension-only mechanism did not sustain any damage from the out- sliding at the base caused significant pinching in the lateral load-

of-plane displacements of the wall. After removal from the wall, displacement response [Fig. 9(a)]. The SMA braces in SQ2S con-

the two braces that were active during loading to þ50 mm of wall trolled shear sliding and improved closure of the diagonal cracks

displacement experienced marginal residual elongation. The other in the postpeak range. As a result, the wall experienced an im-

two braces that resisted loading while the wall was subjected to proved flexural response with reduced pinching [Fig. 9(b)]. The

−70 mm of displacement experienced a permanent elongation of pinching arose because of the recentering effect of the SMA

2 mm (0.08%). braces. At 30 mm of lateral displacement, the retrofitting system

reduced sliding displacement and width of the horizontal crack at

the base by 85 and 53%, respectively. The vertical slip in the

Discussion of Results lower 250 mm at the ends of the wall were reduced by 22%.

The size of the diagonal cracks, however, increased by up

Table 3 summarizes the main behavioral parameters of the walls:

to 200%.

shear strength (V), lateral displacement (Δ), drift (%), secant stiff-

ness (K), and failure mechanism. The data correspond to the direc-

tion of loading where the walls reached ultimate. Peak lateral Strength

capacity corresponds to the maximum force experienced by the

walls, and ultimate capacity corresponds to the maximum displace- The envelopes of the lateral load-displacement responses are illus-

ment prior to a drop in strength caused by rupturing of the trated in Fig. 13. The presence of the SMA braces substantially

reinforcement. increased the peak shear strength and reduced strength degradation

during the second repetitions of loading of Walls SQ1S and SQ2S.

The increases in strength of Walls SQ1S and SQ2S with respect

Damage and Failure Mechanism to the corresponding control walls were 47 and 74%, respectively.

Cracking at the base of Walls SQ1 and SQ1S was the result of the The SMA braces in Wall SQ2S contributed to larger lateral strength

minimum longitudinal reinforcement not having the capacity to because of the higher strains that developed in the braces at larger

transfer tensile stresses to the surrounding concrete. The observed displacement demands. Walls SQ1S and SQ2S sustained residual

rocking and sliding in SQ1 resulted in a highly pinched lateral load- strengths very similar to the peak strengths of their corresponding

displacement response [Fig. 7(a)]. Although similar cracking was control walls. The residual strength improved stability of the walls

observed at the base in SQ1S and rocking was evident, the hori- at the end of testing. Fig. 14 provides typical cycles prior to failure,

zontal component of the forces that developed in the SMA braces demonstrating improvements in strength, energy dissipation, and

controlled sliding. Sliding in Wall SQ1S was reduced by up to flexural response of Walls SQ1S and SQ2S.

Table 3. Behavioral Parameters of Walls

Yield Peak Ultimate

Wall V y (kN) Δy (mm) Drift (%) K (kN=mm) V p (kN) Δp (mm) Drift (%) V u (kN) Δu (mm) Drift (%) Failure mechanism

SQ1 109 4.5 0.23 24.2 145 37 1.85 145 37 1.85 Sliding/rupture steel

SQ1S 159 8.6 0.43 18.5 213 25 1.25 213 25 1.25 Rupture steel

SQ2 179 1.7 0.09 105.3 243 5 0.25 239 30 1.50 Rupture steel

SQ2S −305 −6.3 −0.32 48.4 −424 −42 −2.10 −407 −57 −2.85 Crushing/rupture steel

Note: Minus sign refers to a negative direction of loading.

© ASCE 04017200-8 J. Struct. Eng.

J. Struct. Eng., 2018, 144(2): 04017200

Drift (%) Drift (%)

-4 -3 -2 -1 0 0 1 2 3 4

0 500

-100 400

Lateral Load (kN)

Lateral Load (kN)

SQ1

-200 SQ1S 300

SQ2

-300 SQ2S 200

SQ1

SQ1S

-400 100 SQ2

SQ2S

-500 0

-80 -60 -40 -20 0 0 20 40 60 80

(a) (b)

Downloaded from ascelibrary.org by RMIT UNIVERSITY LIBRARY on 12/06/17. Copyright ASCE. For personal use only; all rights reserved.

Lateral Displacement (mm) Lateral Displacement (mm)

Fig. 13. Envelope of lateral load-displacement response of shear walls: (a) negative direction; (b) positive direction

Drift (%) Drift (%)

-1.5 -1 -0.5 0 0.5 1 -2 -1.5 -1 -0.5 0 0.5 1 1.5 2

250 500

150 300

Lateral Load (kN)

Lateral Load (kN)

50 100

-50 -100

-150 SQ1 -300 SQ2

SQ1S SQ2S

-250 -500

-30 -20 -10 0 10 20 -40 -30 -20 -10 0 10 20 30 40

(a) Lateral Displacement (mm) (b) Lateral Displacement (mm)

Fig. 14. Typical cycles prior to failure: (a) Walls SQ1 and SQ1S; (b) Walls SQ2 and SQ2S

Stiffness and Drift Capacity Given the rigid body behavior and single horizontal crack at the

base of the wall, the crack width was expected to be approximately

The secant stiffness-lateral displacement responses are illustrated in

40 mm at the ultimate lateral displacement of 37 mm. At this level

Fig. 15. Wall SQ1S experienced slightly greater stiffness than Wall

of localized crack opening, the reinforcement should have ruptured.

SQ1 up to yielding (15% increase). Beyond 10 mm to failure, the

Conversely, Wall SQ1S was not affected by debonding and sliding,

stiffness of Walls SQ1 and SQ1S was comparable. Wall SQ1S ex-

resulting in a wider crack at the base. The maximum widths of the

perienced lower drift capacity than Wall SQ1 because of increased

horizontal cracks were 16 and 26 mm in SQ1 and SQ1S, respec-

straining of the longitudinal reinforcement associated with greater

tively, at 25 mm of lateral displacement.

flexural capacity. Furthermore, Wall SQ1 was subjected to a load-

The secant stiffness of Wall SQ2S at yielding and 40 mm of

ing protocol that imposed a single large cycle to ultimate that may

displacement was 29 and 53% greater in comparison with Wall

have rapidly deteriorated the bond of the longitudinal reinforcing

SQ2. Localized damage at the base contributed to degradation

steel to the concrete, thereby delaying rupture of the reinforcement. of stiffness in Wall SQ2. Conversely, the SMA braces in SQ2S re-

duced shear sliding, mitigating stiffness degradation. Wall SQ2S

provided increased stiffness up to 40 mm of lateral displacement.

1000

SQ1 The out-of-plane damage during loading to 40 mm resulted in sig-

SQ1S nificant degradation in stiffness between the cyclic repetitions in

SQ2 SQ2S [Fig. 9(b)]. Wall SQ2S sustained a maximum drift of 2.85%,

Stiffness (kN/mm)

100 SQ2S and Wall SQ2 sustained a maximum drift of 1.5% in the negative

direction of loading. This represents an increase of 90% in drift

capacity. In the positive direction, the walls sustained a drift capac-

ity of 1.5%.

10

Energy Dissipation

1 Fig. 16 provides the cumulative energy dissipation of the walls,

0 10 20 30 40 50 taking into account the two repetitions of loading. The energy dis-

Lateral Displacement (mm) sipation of SQ1 in the positive direction of loading was assumed to

be equal to that calculated in the negative direction of loading (the

Fig. 15. Secant stiffness of walls (stiffness in logarithmic scale)

positive loading did not follow the intended protocol; therefore,

© ASCE 04017200-9 J. Struct. Eng.

J. Struct. Eng., 2018, 144(2): 04017200

Drift (%)

to recover. In contrast to the control walls, the retrofitted walls

0 0.5 1 1.5 2 2.5 3 3.5

200

experienced a slight increase in recovery capacity during the last

SQ1 loading stage. This increase was the result of rupturing of the in-

SQ1S ternal longitudinal reinforcing steel, which reduced resistance to

150

the recentering action of the SMA braces.

Energy (kN-m)

SQ2

SQ2S

100

Shear Distortion

50 Average shear strains in the walls, γ avg , were calculated from the

displacements measured by two diagonal cable transducers that

were connected at the bottom and the top of the walls, following

0

0 10 20 30 40 50 60 70 the expression suggested by Oesterle et al. (1976)

Downloaded from ascelibrary.org by RMIT UNIVERSITY LIBRARY on 12/06/17. Copyright ASCE. For personal use only; all rights reserved.

Lateral Displacement (mm)

δ 1 d1 − δ 2 d2

γ avg ¼ ð1Þ

Fig. 16. Cumulative energy dissipation of walls 2hl

where d1 and d2 = original lengths of the diagonal transducers; δ 1

and δ 2 = corresponding change of lengths; and h and l = vertical

a direct measure of energy dissipation was not possible). To provide and horizontal projections, respectively, of the original lengths. For

a direct comparison with the retrofitted wall, the energy dissipated Walls SQ1 and SQ2, the diagonal displacements were measured

by SQ1 during a number of cycles to −10 and −20 mm that did not inside a 1,800 × 1,800 mm square formed by 100-mm offsets from

correspond to the loading protocol of SQ1S were not included. the corners. For Walls SQ1S and SQ2S, the diagonal displacements

Increases in strength and drift capacity (specifically for Wall SQ2S) corresponded to the elongation of the SMA braces between the pin

as well as reductions of strength and stiffness degradation resulted connections at the anchor plates. The original length of the diag-

in greater cumulative energy dissipation for the retrofitted walls at onals were 2,545.6 mm for Walls SQ1 and SQ2 and 2,540 mm for

the end of the response. Walls SQ1S and SQ2S dissipated 42.9 and Walls SQ1S and SQ2S. The corresponding vertical and horizontal

projections were calculated based on the inclination of the diago-

165.4 kN-m, respectively, corresponding to increases of 90 and

nals (45°). Fig. 18 provides the envelope of the average shear dis-

219% with respect to the control walls.

tortions for the positive direction of loading.

The control walls experienced significantly less shear distortion.

Displacement Recovery The diagonal deformations of Wall SQ1 were negligible because

of the rigid body motion of the wall. At 40 mm of lateral displace-

Fig. 17 provides the recovery capacity of the lateral displace- ment (ultimate), the shear distortion was only 0.27 × 10−3 rad, and

ments of the walls in the positive direction of loading, calculated at 50 mm displacement, the distortion was 1.16 × 10−3 rad. The

as the ratio of the difference between peak displacement and latter increase of distortion was caused by localized damage at the

residual displacement to the peak displacement. The retrofitted toes of the walls as a result of rupturing of the steel and crushing of

walls experienced greater recovery capacity relative to the control concrete. Therefore, the distortion at 50 mm does not represent the

walls at comparable displacements. Recentering, however, was lim- global shear distortion of the wall. Wall SQ2 sustained slightly

ited by yielding of the internal longitudinal reinforcing steel. Walls greater shear distortion than Wall SQ1, linearly increasing to 2.39 ×

SQ1S and SQ2S recovered 50 and 54% of lateral displacements at 10−3 rad at ultimate lateral displacement of 30 mm. Thereafter, the

ultimate positive drifts to 1.25 and 1.5%, respectively. During the distortion remained constant. The shear distortion was attributed to

last imposed positive displacements, Walls SQ1S and SQ2S recov- the distributed diagonal cracking in the wall.

ered 64 and 61%, respectively, whereas the corresponding control Walls SQ1S and SQ2S experienced maximum shear distortions

Walls SQ1 and SQ2 recovered 11 and 24%, respectively. Wall of 8.6 × 10−3 and 15.5 × 10−3 rad, respectively. The positioning

SQ1S experienced greater recovery because of localized yielding of the displacement transducers along the SMA bracing system

of the internal reinforcement at the base. The distributed damage also captured base rotations attributable to slippage of the internal

and yielding of the internal longitudinal reinforcement in Wall reinforcement (rigid body motion) in addition to the shear distor-

SQ2S slightly reduced the effectiveness of the retrofitting system tions within the wall panels. The greater diagonal distortions in

Drift (%) Drift (%)

0 0.5 1 1.5 2 2.5 3 0 0.5 1 1.5 2 2.5 3

100 20

10-3)

SQ1 SQ1S SQ1

80 SQ2 SQ2S SQ1S

15

SQ2

Recovery (%)

Shear Distortion (rad

60 SQ2S

10

40

20 5

0 0

0 10 20 30 40 50 60 0 10 20 30 40 50 60

Lateral Displacement (mm) Lateral Displacement (mm)

Fig. 17. Displacement recovery of walls Fig. 18. Shear distortion of walls

© ASCE 04017200-10 J. Struct. Eng.

J. Struct. Eng., 2018, 144(2): 04017200

500

• The tensile forces that developed in the SMA braces increased

the lateral strength relative to the control walls. Furthermore, the

300

SMA braces were effective at reducing strength and stiffness

Lateral Load (kN) degradation and pinching of the hysteretic responses;

100 • The SMA braces increased the drift capacity of Wall SQ2S,

reduced shear damage at the base, and redistributed damage

-100 throughout the wall. The drift capacity of Wall SQ1S was not

improved by the SMA braces as a result of behavior being con-

-300 trolled by base rocking in both the control Wall SQ1 and retro-

SQ2

fitted Wall SQ1S. This suggests that walls governed by rocking

SQ2S

-500 require additional retrofitting to control localized cracking and

-6 -4 -2 0 2 4 6 8 base rigid rotations as well as to promote distributed damage to

Downloaded from ascelibrary.org by RMIT UNIVERSITY LIBRARY on 12/06/17. Copyright ASCE. For personal use only; all rights reserved.

Shear Distortion (rad 10-3) improve drift capacity;

• Energy dissipation was substantially increased by the SMA

Fig. 19. Typical net shear distortion response of Walls SQ2 and SQ2S

braces owing to improvements in the lateral load-displacement

at 30-mm displacement

response. Furthermore, the energy dissipation of Wall SQ1S was

similar to the control Wall SQ2, demonstrating the capacity of

the SMA braces to improve the seismic performance of lightly

reinforced concrete shear walls; and

SQ2S were the result of distributed damage with wider diagonal • Walls SQ1S and SQ2S recovered over 50% of the imposed

cracks. Net shear distortions in the wall panels were calculated from lateral displacements. The reduced residual displacements in

the difference between the average shear distortions (including the the retrofitted walls improved closure of cracks and reduced

base rotations) and rotations at the top of the wall to provide a com- damage associated with hysteretic shear degradation. Although

parison with the shear distortions measured in the control walls. the retrofitted shear walls experienced greater diagonal elonga-

The rotation at the top of the walls was calculated from the vertical tions and associated shear distortions, the net residual shear dis-

displacements measured at the ends of the walls. The resulting net tortions were approximately the same as those experienced by

shear distortion for Wall SQ1S was 1.7 × 10−3 rad at ultimate the control walls, demonstrating the recentering capabilities of

lateral displacement, which was similar to the control Wall SQ1. the SMA braces.

No damage was evident in Wall SQ1S above the horizontal crack In general, the squat shear walls retrofitted with the SMA braces

at the base of the wall at the end of testing, confirming the negli- experienced improved seismic performance, including increases

gible shear distortion in the wall panel. Net shear distortion of in strength, drift capacity, and energy dissipation. Furthermore, the

11.2 × 10−3 rad at ultimate was calculated for SQ2S. The greater presence of the SMA braces reduced the residual displacements,

shear distortion in Wall SQ2S was the result of minimal rigid body improved displacement recovery, enhanced crack closure, and re-

rotation at the base and distributed shear cracking in the wall. duced damage at the base of the walls.

The base rotation of Wall SQ1S and shear distortion of Wall

SQ2S introduced significant diagonal elongations that engaged

the strengthening and energy-dissipation properties of the SMA Acknowledgments

braces. The diagonal elongations were sufficiently recovered, re-

Financial support provided by the Canadian Seismic Research

sulting in residual rotations and shear distortions similar to those

Network (Grant No. NETGP/350698-07), a Natural Sciences and

experienced by the control walls. Fig. 19 provides the net shear Engineering Research Council of Canada strategic network, is

distortions calculated for Walls SQ2 and SQ2S during loading gratefully acknowledged.

to 30 mm of displacement.

References

Conclusions

Abdulridha, A., and Palermo, D. (2017). “Behaviour and modelling of

An experimental program was conducted to study the performance hybrid SMA-steel reinforced concrete slender shear wall.” Eng. Struct.,

of tension-only SMA braces to improve the seismic response of 147, 77–89.

Abdulridha, A., Palermo, D., Foo, S., and Vecchio, F. J. (2013). “Behavior

squat reinforced concrete shear walls. The walls were susceptible

and modeling of superelastic shape memory alloy reinforced concrete

to shear-related damage, and the SMA braces were controlled by beams.” Eng. Struct., 49, 893–904.

the superelastic behavior of the SMA links. Based on the experi- Adachi, Y., and Unjoh, S. (1999). “Development of shape memory alloy

mental results, the following conclusions are drawn: damper for intelligent bridge systems.” Smart Structures and Materials

• The SMA braces slightly shifted the location of the governing 1999: Smart Systems for Bridges, Structures, and Highways, Society of

crack at the base of Wall SQ1S compared with the control Wall Photo-Optical Instrumentation Engineers, Bellingham, WA, 31–42.

SQ1; however, both walls experienced similar rocking behavior; Alam, M. S., Nehdi, M., and Youssef, M. A. (2009). “Seismic performance

• The SMA braces in SQ2S limited the base horizontal crack and of concrete frame structures reinforced with superelastic shape memory

base rotation that governed the response of the control Wall alloys.” Smart Struct. Syst., 5(5), 565–585.

SQ2. Wall SQ2S experienced pronounced distributed diagonal Alam, M. S., Youssef, M. A., and Nehdi, M. (2007). “Utilizing shape

memory alloys to enhance the performance and safety of civil infra-

cracking in the wall panel and distributed yielding of the internal

structure: A review.” Can. J. Civil Eng., 34(9), 1075–1086.

reinforcement. The SMA braces imposed additional compres- ASCE. (2007). “Seismic rehabilitation of existing buildings.” ASCE/SEI

sive stresses in the wall in the postpeak, triggering crushing 41-06, Reston, VA.

and out-of-plane buckling of one of the boundary zones, limit- ASTM. (2014). “Standard test method for tension testing of nickel-

ing the stability and strength capacity of the wall in the positive titanium superelastic materials.” ASTM F2516-14, West Conshohocken,

direction of loading; PA.

© ASCE 04017200-11 J. Struct. Eng.

J. Struct. Eng., 2018, 144(2): 04017200

ATC (Applied Technology Council). (1996). “Seismic evaluation and retro- McCormick, J., DesRoches, R., Fugazza, D., and Auricchio, F. (2006).

fit of concrete buildings.” ATC-40, Redwood City, CA. “Seismic vibration control using superelastic shape memory alloys.”

ATC (Applied Technology Council) and FEMA. (2005). “Improvement of J. Eng. Mater. Technol., 128(3), 294–301.

nonlinear static seismic analysis procedures.” FEMA 440, Washington, McCormick, J., Tyber, J., DesRoches, R., Gall, K., and Maier, H. J. (2007).

DC. “Structural engineering with NiTi. II: Mechanical behavior and scal-

ATC (Applied Technology Council) and FEMA. (2007). “Interim test- ing.” J. Eng. Mech., 10.1061/(ASCE)0733-9399(2007)133:9(1019),

ing protocols for determining the seismic performance characteristics 1019–1029.

of structural and nonstructural components.” FEMA 461, Washington, Meshaly, M. E., Youssef, M. A., and Elfath, H. M. A. (2014). “Use of SMA

DC. bars to enhance the seismic performance of SMA braced RC frames.”

Auricchio, F., Fugazza, D., and DesRoches, R. (2006). “Earthquake per- Earthquakes and Struct., 6(3), 267–280.

formance of steel frames with Nitinol braces.” J. Earthquake Eng., Miller, D. J., Fahnestock, L. A., and Eatherton, M. R. (2012). “Develop-

10(spec01), 45–66. ment and experimental validation of a nickel-titanium shape mem-

Cortés-Puentes, W. L., and Palermo, D. (2012). “Towards design of shear ory alloy self-centering buckling-restrained brace.” Eng. Struct., 40,

Downloaded from ascelibrary.org by RMIT UNIVERSITY LIBRARY on 12/06/17. Copyright ASCE. For personal use only; all rights reserved.

walls retrofitted with shape memory alloys.” Proc., 15th World Conf. 288–298.

on Earthquake Engineering, Sociedade Portuguesa de Engenharia Motahari, S. A., Ghassemieh, M., and Abolmaali, S. A. (2007). “Imple-

Sismica, Lisbon, Portugal. mentation of shape memory alloy dampers for passive control of struc-

Cortés-Puentes, W. L., and Palermo, D. (2017). “SMA tension brace for tures subjected to seismic excitations.” J. Constr. Steel Res., 63(12),

retrofitting concrete shear walls.” Eng. Struct., 140, 177–188. 1570–1579.

Cruz Noguez, C. A., and Saiidi, M. S. (2012). “Shake-table studies of Nakashoji, B. A. (2014). “Seismic performance of square nickel-titanium

a four-span bridge model with advanced materials.” J. Struct. Eng., reinforced ECC columns with headed couplers.” Ph.D. thesis, Univ. of

10.1061/(ASCE)ST.1943-541X.0000457, 183–192. Nevada, Reno, NV.

DesRoches, R., and Delemont, M. (2002). “Seismic retrofit of simply Nehdi, M., Alam, M. S., and Youssef, M. A. (2010). “Development

supported bridges using shape memory alloys.” Eng. Struct., 24(3), of corrosion-free concrete beam-column joint with adequate seismic

325–332. energy dissipation.” Eng. Struct., 32(9), 2518–2528.

DesRoches, R., McCormick, J., and Delemont, M. (2004). “Cyclic proper- Nemat-Nasser, S., and Guo, W.-G. (2006). “Superelastic and cyclic re-

ties of superelastic shape memory alloy wires and bars.” J. Struct. Eng., sponse of NiTi SMA at various strain rates and temperatures.” Mech.

10.1061/(ASCE)0733-9445(2004)130:1(38), 38–46. Mater., 38(5–6), 463–474.

Dezfuli, M. A., Dolatshahi, K. M., Mofid, M., and Eshkevari, S. S. (2017). NRCC (National Research Council Canada). (1965). National building

“Coreless self-centering braces as retrofitting devices in steel struc- code of Canada, Ottawa.

tures.” J. Constr. Steel Res., 133, 485–498. Oesterle, R. G., Fiorato, A. E., Johal, L. S., Carpenter, J. E., Russell, H. G.,

Dolce, M., and Cardone, D. (2001a). “Mechanical behaviour of shape and Corley, W. G. (1976). “Earthquake resistant structural walls—Tests

memory alloys for seismic applications. 1: Martensite and austenite of isolated walls.” Rep. PCA R/D Series 1571, Portland Cement

NiTi bars subjected to torsion.” Int. J. Mech. Sci., 43(11), 2631–2656. Association, Skokie, IL.

Dolce, M., and Cardone, D. (2001b). “Mechanical behaviour of shape Ozbulut, O. E., and Hurlebaus, S. (2010). “Evaluation of the perfor-

memory alloys for seismic applications. 2: Austenite NiTi wires sub- mance of a sliding-type base isolation system with a NiTi shape

jected to tension.” Int. J. Mech. Sci., 43(11), 2657–2677. memory alloy device considering temperature effects.” Eng. Struct.,

Dolce, M., Cardone, D., Ponzo, F. C., and Valente, C. (2005). “Shaking 32(1), 238–249.

table tests on reinforced concrete frames without and with passive Park, R. (1989). “Evaluation of ductility of structures and structural as-

control systems.” Earthquake Eng. Struct. Dyn., 34(14), 1687–1717. semblages from laboratory testing.” Bull. N. Z. Nat. Soc. Earthquake

Effendy, E., Liao, W. I., Song, G., Mo, Y. L., and Loh, C. H. (2006). Eng., 22(3), 155–166.

“Seismic behavior of low-rise shear walls with SMA bars.” Earth and Piedboeuf, M. C., Gauvin, R., and Thomas, M. (1998). “Damping behav-

space 2006, ASCE, Reston, VA, 1–8. iour of shape memory alloys: Strain amplitude, frequency and temper-

Fang, C., Yam, M. C. H., Ma, H., and Chung, K. F. (2015). “Tests on ature effects.” J. Sound Vib., 214(5), 885–901.

superelastic Ni-Ti SMA bars under cyclic tension and direct-shear: Qiu, C.-X., and Zhu, S. (2017). “Performance-based seismic design of

Towards practical recentring connections.” Mater. Struct., 48(4), self-centering steel frames with SMA-based braces.” Eng. Struct., 130,

1013–1030. 67–82.

Gao, N., Jeon, J.-S., Hodgson, D. E., and DesRoches, R. (2016). “An in- Saiidi, M. S., O’Brien, M., and Sadrossadat-Zadeh, M. (2009). “Cyclic

novative seismic bracing system based on a superelastic shape memory response of concrete bridge columns using superelastic nitinol and

alloy ring.” Smart Mater. Struct., 25(5), 055030. bendable concrete.” ACI Struct. J., 106(1), 69–77.

Ghassemieh, M., Bahaari, M. R., Ghodratian, S. M., and Nojoumi, S. A. Saiidi, M. S., Sadrossadat-Zadeh, M., Ayoub, C., and Itani, A. (2007).

(2012). “Improvement of concrete shear wall structures by smart “Pilot study of behavior of concrete beams reinforced with shape

materials.” Open J. Civil Eng., 2(3), 87–95. memory alloys.” J. Mater. Civ. Eng., 10.1061/(ASCE)0899-1561

Gulec, C. K., and Whittaker, A. S. (2009). “Performance-based assessment (2007)19:6(454), 454–461.

and design of squat reinforced concrete shear walls.” Earthquake en- Saiidi, M. S., and Wang, H. (2006). “Exploratory study of seismic re-

gineering to extreme events, Technical Rep., State Univ. of New York sponse of concrete columns with shape memory alloys reinforcement.”

at Buffalo, Buffalo, NY, 291. ACI Struct. J., 103(3), 436–443.

Janke, L., Czaderski, C., Motavalli, M., and Ruth, J. (2005). “Applications Salichs, J., Hou, Z., and Noori, M. (2001). “Vibration suppression of struc-

of shape memory alloys in civil engineering structures—Overview, lim- tures using passive shape memory alloy energy dissipation devices.”

its and new ideas.” Mater. Struct., 38(5), 578–592. J. Intell. Mater. Syst. Struct., 12(10), 671–680.

Kuang, Y., and Ou, J. (2008). “Self-repairing performance of concrete Silwal, B., Michael, R. J., and Ozbulut, O. E. (2015). “A superelastic

beams strengthened using superelastic SMA wires in combination with viscous damper for enhanced seismic performance of steel moment

adhesives released from hollow fibers.” Smart Mater. Struct., 17(2), frames.” Eng. Struct., 105, 152–164.

025020. Song, G., Ma, N., and Li, H.-N. (2006). “Applications of shape memory

Liao, W. I., and Mo, Y. L. (2006). “Shake table tests of RC frame with shape alloys in civil structures.” Eng. Struct., 28(9), 1266–1274.

memory alloy bracing bars.” 4th Int. Conf. on Earthquake Engineering, Soul, H., and Yawny, A. (2015). “Self-centering and damping capabilities

National Center for Research on Earthquake Engineering, Taipei, of a tension-compression device equipped with superelastic NiTi

Taiwan. wires.” Smart Mater. Struct., 24(7), 075005.

Malagisi, S., Marfia, S., Sacco, E., and Toti, J. (2014). “Modeling of smart Speicher, M. S., DesRoches, R., and Leon, R. T. (2017). “Investigation

concrete beams with shape memory alloy actuators.” Eng. Struct., 75, of an articulated quadrilateral bracing system utilizing shape memory

63–72. alloys.” J. Constr. Steel Res., 130, 65–78.

© ASCE 04017200-12 J. Struct. Eng.

J. Struct. Eng., 2018, 144(2): 04017200

Sultana, P., and Youssef, M. A. (2016). “Seismic performance of steel Youssef, M. A., Alam, M. S., and Nehdi, M. (2008). “Experimental in-

moment resisting frames utilizing superelastic shape memory alloys.” vestigation on the seismic behavior of beam-column joints reinforced

J. Constr. Steel Res., 125, 239–251. with superelastic shape memory alloys.” J. Earthquake Eng., 12(7),

Tazarv, M., and Saiidi, S. (2015). “Reinforcing NiTi superelastic SMA for 1205–1222.

concrete structures.” J. Struct. Eng., 10.1061/(ASCE)ST.1943-541X Youssef, M. A., and Elfeki, M. A. (2012). “Seismic performance of

.0001176, 04014197. concrete frames reinforced with superelastic shape memory alloys.”

Tyber, J., McCormick, J., Gall, K., DesRoches, R., Maier, H. J., and Smart Struct. Syst., 9(4), 313–333.

Maksoud, A. E. A. (2007). “Structural engineering with NiTi. I: Basic Zafar, A., and Andrawes, B. (2012). “Incremental dynamic analysis of con-

materials characterization.” J. Eng. Mech., 10.1061/(ASCE)0733-9399 crete moment resisting frames reinforced with shape memory composite

(2007)133:9(1009), 1009–1018. bars.” Smart Mater. Struct., 21(2), 025013.

Yang, C.-S. W., DesRoches, R., and Leon, R. T. (2010). “Design and analy- Zafar, A., and Andrawes, B. (2013). “Experimental flexural behavior of

sis of braced frames with shape memory alloy and energy-absorbing SMA-FRP reinforced concrete beam.” Front. Struct. Civil Eng., 7(4),

hybrid devices.” Eng. Struct., 32(2), 498–507. 341–355.

Downloaded from ascelibrary.org by RMIT UNIVERSITY LIBRARY on 12/06/17. Copyright ASCE. For personal use only; all rights reserved.

© ASCE 04017200-13 J. Struct. Eng.

J. Struct. Eng., 2018, 144(2): 04017200

You might also like

- In Architecture Chris Van UffelenDocument5 pagesIn Architecture Chris Van UffelenPIYUSH GAUTAM0% (1)

- ANSI Mh27.1 (2003) Patented Track Underhung Cranes and Monorail SystemsDocument0 pagesANSI Mh27.1 (2003) Patented Track Underhung Cranes and Monorail SystemsJavier Gamboa RNo ratings yet

- Precast Reinforced Concrete Monolithic Box Sections For Culverts, Storm Drains, and SewersDocument25 pagesPrecast Reinforced Concrete Monolithic Box Sections For Culverts, Storm Drains, and SewersSadique K Muhammed100% (1)

- Setting and Hardening of ConcreteDocument30 pagesSetting and Hardening of ConcreteManjer123No ratings yet

- Kits Opcionais DoosanDocument75 pagesKits Opcionais DoosanChakroune100% (2)

- Cost Engineers Notebook!!!!!Document5 pagesCost Engineers Notebook!!!!!Anonymous 19hUyem0% (2)

- Procedure For Alkali BoiloutDocument9 pagesProcedure For Alkali BoiloutBapu612345No ratings yet

- Arita Katalog Building - SmallDocument16 pagesArita Katalog Building - SmallAlamsyah PutraNo ratings yet

- Seismic Retrofit of Concrete Shear Walls With SMA Tension BracesDocument13 pagesSeismic Retrofit of Concrete Shear Walls With SMA Tension BracesRAHUL DasNo ratings yet

- Seismic Assessment of Concentrically Braced Steel Frames With Shape Memory Alloy BracesDocument9 pagesSeismic Assessment of Concentrically Braced Steel Frames With Shape Memory Alloy BracesabdulghafrNo ratings yet

- Improvement of Concrete Shear Wall Structures by Smart MaterialsDocument9 pagesImprovement of Concrete Shear Wall Structures by Smart MaterialsAndreea NanNo ratings yet

- (Asce) ST 1943-541X 0002284Document12 pages(Asce) ST 1943-541X 0002284Sergio Alejandro barreiroNo ratings yet

- Siyam 2015Document14 pagesSiyam 2015William AvilaNo ratings yet

- 2022 Capacity Design of Coupled Composite Plate Shear Wall ConcreteDocument18 pages2022 Capacity Design of Coupled Composite Plate Shear Wall ConcreteHamid GoodarziNo ratings yet

- Nikolaidou (2018)Document11 pagesNikolaidou (2018)CynthiaNo ratings yet

- Parametric Study On Equivalent Damping Ratio of Different Composite Structural Building SystemsDocument10 pagesParametric Study On Equivalent Damping Ratio of Different Composite Structural Building SystemsPatel TosifNo ratings yet

- Seismic Response Analysis of A Reinforced Concrete Block Shear Wall Asymmetric BuildingDocument12 pagesSeismic Response Analysis of A Reinforced Concrete Block Shear Wall Asymmetric BuildingMohammed Junaid ShaikhNo ratings yet

- Jsendh Steng-11693Document21 pagesJsendh Steng-11693陈飞No ratings yet

- Bi Layer Diaphragm Walls Structural andDocument8 pagesBi Layer Diaphragm Walls Structural andLuthfi NNo ratings yet

- Simplified Mechanistic Model For Seismic Response Prediction of Coupled Cross-Laminated Timber Rocking WallsDocument11 pagesSimplified Mechanistic Model For Seismic Response Prediction of Coupled Cross-Laminated Timber Rocking WallsnavidNo ratings yet

- Variability in Seismic Collapse Probabilities of Solid - and Coupled-Wall BuildingsDocument17 pagesVariability in Seismic Collapse Probabilities of Solid - and Coupled-Wall BuildingsAristotle MedinaNo ratings yet

- Steel Slit Shear Walls With An Efficient GeometryDocument13 pagesSteel Slit Shear Walls With An Efficient GeometryTY ZNo ratings yet

- 1 s2.0 S0267726123000957 MainDocument15 pages1 s2.0 S0267726123000957 Mainxin yanNo ratings yet

- Cyclic Behavior of Traditional and Innovative CompositeShear Walls (ASCE) 0733-9445 (2004) 130 - 2Document14 pagesCyclic Behavior of Traditional and Innovative CompositeShear Walls (ASCE) 0733-9445 (2004) 130 - 2Hari Om Tamrakar ce21d019No ratings yet

- Parametric Study On Mechanical Responses of Corrugated-Core Sandwich Panels For Bridge DecksDocument14 pagesParametric Study On Mechanical Responses of Corrugated-Core Sandwich Panels For Bridge DecksDuraBraceNo ratings yet

- Ezzeldin 2016Document13 pagesEzzeldin 2016William AvilaNo ratings yet

- Restrepo Rahman 2007 ASCESJDocument12 pagesRestrepo Rahman 2007 ASCESJMatías Pino YáñezNo ratings yet

- Simplified Structural Analysis of Retaining Walls On Stepped FootingsDocument15 pagesSimplified Structural Analysis of Retaining Walls On Stepped Footingsalvaro sangurimaNo ratings yet

- Seismic Strengthening of Masonry-Infilled RC FramesDocument12 pagesSeismic Strengthening of Masonry-Infilled RC FramesHussain AhmedNo ratings yet

- 2096 6712 1 PBDocument12 pages2096 6712 1 PBrafsandjanialwiNo ratings yet

- Cold-Formed Steel Framed Gypsum Shear Walls: In-Plane ResponseDocument10 pagesCold-Formed Steel Framed Gypsum Shear Walls: In-Plane ResponseJesus SilvaNo ratings yet

- 1 s2.0 S0263823122009715 MainDocument19 pages1 s2.0 S0263823122009715 MainSerban IacobNo ratings yet

- Use of Steel Bracing in Reinforced Concrete FramesDocument8 pagesUse of Steel Bracing in Reinforced Concrete Framesرهف نوفلNo ratings yet

- (2017 Zhang) Corrugated SPSW Under Lateral and Gravity LoadDocument13 pages(2017 Zhang) Corrugated SPSW Under Lateral and Gravity LoadCynthiaNo ratings yet

- Lateral Cyclic Behavior of Bridge Columns Confined With Pre Stressed Shape Memory Alloy WiresDocument15 pagesLateral Cyclic Behavior of Bridge Columns Confined With Pre Stressed Shape Memory Alloy WiresRani HendrikusNo ratings yet

- Truss-Moment Frames by Subhash C. Goel, I Member, ASCE, and Ahmad M. Itani, 2 Associate Member, ASCEDocument17 pagesTruss-Moment Frames by Subhash C. Goel, I Member, ASCE, and Ahmad M. Itani, 2 Associate Member, ASCEPARISNo ratings yet

- (P) 2008 JCSR MohebkhahDocument10 pages(P) 2008 JCSR MohebkhahLucas EncarnaçãoNo ratings yet

- (Asce) ST 1943-541X 0002538 PDFDocument13 pages(Asce) ST 1943-541X 0002538 PDFJayti GuptaNo ratings yet

- Behavior of Steel Fiber-Reinforced Concrete Deep Beams With Large OpeningDocument12 pagesBehavior of Steel Fiber-Reinforced Concrete Deep Beams With Large OpeningSuman.SNo ratings yet

- Comparative Response Assessment of Steel Frames With Different Bracing PDFDocument14 pagesComparative Response Assessment of Steel Frames With Different Bracing PDFaxl_calin82No ratings yet

- Capacity Design of Retaining Structures and Bridge Abutments With Deep FoundationsDocument11 pagesCapacity Design of Retaining Structures and Bridge Abutments With Deep FoundationsValerioNo ratings yet

- TADAS Dampers in Very Large DeformationsDocument10 pagesTADAS Dampers in Very Large DeformationsMohsen MNo ratings yet

- Experimental Study of Typical and Retrofitted Jack Arch Slabs in A SingleDocument11 pagesExperimental Study of Typical and Retrofitted Jack Arch Slabs in A SingleÖzgün Furkan SaralNo ratings yet

- Design Aspects On Steel Fiber-ReinforcedDocument9 pagesDesign Aspects On Steel Fiber-ReinforcedjayanthNo ratings yet

- Dual StructureDocument21 pagesDual StructureSauhardra OjhaNo ratings yet

- Effect of Lead Rubber Bearing CharacteristicsDocument11 pagesEffect of Lead Rubber Bearing Characteristicsümit özkanNo ratings yet

- Seismic Performance of AAC MasonryDocument9 pagesSeismic Performance of AAC MasonrySandip AdhikariNo ratings yet

- In-Plane Cyclic Performance of Confined Partially Grouted Masonry Walls With Joint and Vertical ReinforcementDocument12 pagesIn-Plane Cyclic Performance of Confined Partially Grouted Masonry Walls With Joint and Vertical ReinforcementPanayioti ZoupantisNo ratings yet

- Seismic Performance Evaluation of Multistoried RC Framed Buildings With Shear Wall PDFDocument6 pagesSeismic Performance Evaluation of Multistoried RC Framed Buildings With Shear Wall PDFSahil OzaNo ratings yet

- Seismic Performance of Emulative Precast Concrete Beam-Column Connections With Alternative Reinforcing DetailsDocument14 pagesSeismic Performance of Emulative Precast Concrete Beam-Column Connections With Alternative Reinforcing DetailsMălíķ ĂsfęnđýårNo ratings yet

- Asce1 As PublishedDocument11 pagesAsce1 As PublishedWendell Ariel LanzasNo ratings yet

- 10.1016 - j.tws.2016.02.008 Analysis and Design Recommendations For Diagonally Stiffened Steel Plate Shear WallsDocument9 pages10.1016 - j.tws.2016.02.008 Analysis and Design Recommendations For Diagonally Stiffened Steel Plate Shear WallsmahdiNo ratings yet

- Structural Performance of Hybrid GFRP/Steel Concrete Sandwich PanelsDocument7 pagesStructural Performance of Hybrid GFRP/Steel Concrete Sandwich PanelsSmriti RajNo ratings yet

- Heerema2015Document13 pagesHeerema2015Dulio Nils MHNo ratings yet

- Numerical Modeling of RM Walls Under Lateral LoadingDocument17 pagesNumerical Modeling of RM Walls Under Lateral LoadingRaul Robledo AlvaradoNo ratings yet

- (Asce) ST 1943-541X 0002281Document16 pages(Asce) ST 1943-541X 0002281Sergio Alejandro barreiroNo ratings yet

- 1 s2.0 S0143974X22002760 MainDocument17 pages1 s2.0 S0143974X22002760 MainwflowerNo ratings yet