Professional Documents

Culture Documents

Radix Printable Dielectric Data Sheet

Uploaded by

AbhiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Radix Printable Dielectric Data Sheet

Uploaded by

AbhiCopyright:

Available Formats

\\\ Datasheet

Radix™ Printable Dielectric

3D-Printable Dielectric Material for use on Fortify FLUX Series Printers

\\\ Features and Benefits:

Radix™ Printable Dielectrics material has a dissipation factor

are the industry’s first low of 0.0043 at 10 GHz, and can be Industry first low loss 3D-printable

photopolymer with loss tangent of

loss DLP and sterolithography used to create structures that 0.0043 @ 10 GHz. Dielectric constant

(SLA) 3D-printable material. have a graded dielectric constant of 2.8 @ 10 GHZ

By combining a low loss resin in all three dimensions by means • Ensures high efficiency in large

system with the design freedom of a varying density lattice. These lenses and antenna structures

and speed of DLP 3D-printing, latticed structures provide even Robust thin-walled printing

this technology enables the lower dissipation factor and capability down to 225 microns

scalable manufacturing of new weight when compared against • Enables lattice structures for use

RF components that cannot a similar part made with solid up to at least 40 GHz

be made with traditional materials. Create structures that spatially vary

manufacturing processes. The in dielectric constant from 1.15 to

printable materials leverage 2.0 with a one-material system

the performance of DLP and • Enables wideband, field-of-view

SLA printing processes to allow enhancing lenses, and switch-

beam steering antenna systems

antenna engineers to implement

for mmWave applications

new dielectric components in

applications such as SATComm \\\ Typical Applications:

antenna lenses and volumetric • Gradient Index (GRIN) or Gradient

circuits for mmWave frequencies. Dielectric Constant Lenses

• 3D Antenna Systems

Radix Printable Dielectric also

enables the use of Gradient Index • Impedance matching structures

(GRIN) dielectric components • Rapid Prototyping of radomes

and other components

with little added complexity.

The solid 2.8 dielectric constant

Fortify’s FLUX series printers powered by a DLP (Digital Light Processing) engine, combine the scalability, resolution,

and surface quality of photopolymers with the performance expectations of traditional high performance polymers.

CKM (Continuous Kinetic Mixing), a proprietary subsystem built into the printers, enables printing of photopolymer

resins with uniformly distributed functional additives. The system ensures that particles stay uniformly suspended

instead of agglomerating or settling to the bottom of the vat. CKM allows for an expanded processing window

compared to other photopolymer DLP or SLA systems, processing much higher viscosity materials. Fortify partners

with Rogers Corporation and other global chemical companies to extend material properties and solve printability

challenges. www.3dfortify.com

Advanced Connectivity Solutions

1

\\\ 100 S.

S. Roosevelt

RooseveltAvenue

Avenue\\\\\\Chandler,

Chandler,AZAZ 85226

85226 \\\ \\\

Tel:Tel: 480-961-1382

480-961-1382 \\\ 480-961-4533

\\\ Fax: Fax: 480-961-4533 \\\ www.rogerscorp.com

\\\ www.rogerscorp.com \\\ IPC S

Data Sheet

Radix™ Printable Dielectric

Typical

Properties Direction Units Test Conditions Test Method

Values (1)

Electrical Properties

2.8 Z - 23˚C @ 50% RH 10 GHz IPC-TM-650 2.5.5.5

Dielectric Constant

2.8 Z - 23˚C @ 50% RH 24 GHz IPC-TM-650 2.5.5.5

0.0043 Z - 23˚C @ 50% RH 10 GHz IPC-TM-650 2.5.5.5

Dissipation Factor

0.0046 Z - 23˚C @ 50% RH 24 GHz IPC-TM-650 2.5.5.5

Volume Resistivity 1.9 X 1015 - ohm-cm - - ASTM D257

Surface Resistivity 1.8 X 1015 XY ohm/sq - - ASTM D257

Electrical Strength (dielectric strength) 446 Z V/mil - - IPC TM-650 2.5.6.2

Thermal Properties

Decomposition Temperature (Td) 313 - ˚C 2hrs @ 105˚C 5% Weight Loss IPC TM-650 2.4.24.6

Coefficient of Thermal Expansion 76, 75 XY, Z ppm/˚C - -50˚C to 50˚C IPC TM-650 2.4.41

Coefficient of Thermal Expansion 123, 120 XY, Z ppm/˚C - 50˚C to 250˚C IPC TM-650 2.4.41

Thermal Conductivity 0.3 Z W/(m.K) 50˚C - ASTM D5470

Mechanical Properties

Tensile Stress at Break 38 XY MPa - - ASTM D638

Elongation at Failure 2.3 XY % - - ASTM D638

Young’s Modulus 2.7 XY GPa - - ASTM D638

Heat Deflection Temperature @ 0.455 MPa 76.7 - ˚C - - ASTM D648

Heat Deflection Temperature @ 1.82 MPa 59.1 - ˚C - - ASTM D648

Physical Properties

Dark

Color - - - - -

blue/black

Flammability HB - - - - UL 94

Moisture Absorption 0.08 - wt % D24/23 - ASTM D570

Specific Gravity 1.36 - - 23˚C - ASTM D792

1

Typical values are a representation of an average value for the population of the property. For specification values contact Rogers Corporation.

\\\ 100 S. Roosevelt Avenue \\\ Chandler, AZ 85226 \\\ Tel: 480-961-1382 \\\ Fax: 480-961-4533 \\\ www.rogerscorp.com

The information in this data sheet is intended to assist you in designing with Rogers’ materials. It is not intended to and does not create any

warranties express or implied, including any warranty of merchantability or fitness for a particular purpose or that the results shown on this

data sheet will be achieved by a user for a particular purpose. The user should determine the suitability of Rogers’ materials for each application.

These commodities, technology and software are exported from the United States in accordance with the Export Administration regulations. Diversion contrary to

U.S. law prohibited.

The Rogers’ logo, Radix and Helping power, protect, connect our world, are trademarks of Rogers Corporation or one of its subsidiaries.

©2021 Rogers Corporation, Printed in U.S.A., All rights reserved.

Issued 1538 111621 Publication #92-205

Helping power, protect, connect our world

TM

You might also like

- Design and Test Strategies for 2D/3D Integration for NoC-based Multicore ArchitecturesFrom EverandDesign and Test Strategies for 2D/3D Integration for NoC-based Multicore ArchitecturesNo ratings yet

- A New Standard: AffordableDocument4 pagesA New Standard: AffordableTEDY-RNo ratings yet

- Li2018 PDFDocument11 pagesLi2018 PDFbaluNo ratings yet

- RO3200 Laminate Data Sheet RO3203 RO3206 RO3210Document2 pagesRO3200 Laminate Data Sheet RO3203 RO3206 RO3210MRousstiaNo ratings yet

- Siemens SW Improving The Reliability and Performance of RF ICS WP 83544 C2Document9 pagesSiemens SW Improving The Reliability and Performance of RF ICS WP 83544 C2J HARSHA YADAVNo ratings yet

- ANRITSU S331B Datasheet PDFDocument13 pagesANRITSU S331B Datasheet PDFParco Camasca VidalNo ratings yet

- 04 1120 PoenningerDocument6 pages04 1120 PoenningerChristian HollaenderNo ratings yet

- SIMULIA EM EMC For Electonics DatasheetDocument3 pagesSIMULIA EM EMC For Electonics Datasheetkutlu küçükvuralNo ratings yet

- Level TransmiterDocument24 pagesLevel TransmitercarlosNo ratings yet

- What Is Ro4003c Dielectric ConstantDocument11 pagesWhat Is Ro4003c Dielectric ConstantjackNo ratings yet

- Highcon Beam: Digital Cutting and Creasing For Mainstream ProductionDocument4 pagesHighcon Beam: Digital Cutting and Creasing For Mainstream ProductionshruthiNo ratings yet

- B MoonRay Brochure in EnglishDocument5 pagesB MoonRay Brochure in EnglishLaura GheorgheNo ratings yet

- Approximate Multipliers For Optimal Utilization of FPGA ResourcesDocument6 pagesApproximate Multipliers For Optimal Utilization of FPGA Resourcesisha chaubeyNo ratings yet

- DistributionFrameHDCableManagement Complete R330101 1.0Document2 pagesDistributionFrameHDCableManagement Complete R330101 1.0CE M.No ratings yet

- Dragonfly LDM: Lights-Out Digital Additive Manufacturing For Printed ElectronicsDocument4 pagesDragonfly LDM: Lights-Out Digital Additive Manufacturing For Printed Electronicspapa abdoul sowNo ratings yet

- Summit Success StoryDocument2 pagesSummit Success StoryAWR CorporationNo ratings yet

- 2. Radio SRAL XDDocument12 pages2. Radio SRAL XDMário Silva NetoNo ratings yet

- LASER Scanning Presentation (Point)Document21 pagesLASER Scanning Presentation (Point)Luis M. LuisNo ratings yet

- Session 1 DRDocument33 pagesSession 1 DRapi-3833807100% (2)

- Anritsu Site Master S331a Specifications Spec Sheet 6c34Document12 pagesAnritsu Site Master S331a Specifications Spec Sheet 6c34Freddyo59No ratings yet

- Magazine LResDocument8 pagesMagazine LResahmedNo ratings yet

- Computed Radiography Testing (CRT) : A Solution For Corrosion Under InsulationDocument2 pagesComputed Radiography Testing (CRT) : A Solution For Corrosion Under InsulationGistek MarcoNo ratings yet

- Solid Edge Wiring and Harness Design Software Streamlines Electromechanical DesignDocument2 pagesSolid Edge Wiring and Harness Design Software Streamlines Electromechanical DesignSusheel GuptaNo ratings yet

- 4125 HFSSv12 PreviewDocument2 pages4125 HFSSv12 PreviewxyzabcutubeNo ratings yet

- MFG Portfolio Barcode Testing ChartDocument2 pagesMFG Portfolio Barcode Testing Chartcadoni9667No ratings yet

- 9 2.05pm John HennesseyDocument45 pages9 2.05pm John Hennesseysasi kiran sNo ratings yet

- Mid PPT Grp11Document24 pagesMid PPT Grp11Shreya DiwanNo ratings yet

- RT/duroid 6202PR: High Frequency LaminatesDocument2 pagesRT/duroid 6202PR: High Frequency LaminatesmaamriaNo ratings yet

- Full-Wave, TwinAx, Differential Cable Modeling 2008Document6 pagesFull-Wave, TwinAx, Differential Cable Modeling 2008john BronsonNo ratings yet

- PECVD Processes For CS DevicesDocument2 pagesPECVD Processes For CS DevicesRithvik ReddyNo ratings yet

- Kodak Copper Micro Wire Transparent RF Applications White PaperDocument4 pagesKodak Copper Micro Wire Transparent RF Applications White PaperZypno ZypnoNo ratings yet

- Dielectric Resin Prints Millimeter-Wave PartsDocument3 pagesDielectric Resin Prints Millimeter-Wave PartsZahid Hameed QaziNo ratings yet

- Comparison Excimer Vs NdYAGDocument2 pagesComparison Excimer Vs NdYAGAnthonyNo ratings yet

- Device Noise Simulation of ΔΣ Modulators: The Designer's Guide CommunityDocument23 pagesDevice Noise Simulation of ΔΣ Modulators: The Designer's Guide CommunitySujib BarmanNo ratings yet

- Low-Cost Ku-Band Waveguide Devices Using 3D Printing and Liquid Metal FillingDocument8 pagesLow-Cost Ku-Band Waveguide Devices Using 3D Printing and Liquid Metal FillingAhmed HamoudaNo ratings yet

- On Chopper EffectsDocument12 pagesOn Chopper Effectskijiji userNo ratings yet

- Ecndt-0004-2018 (#SPIE) LennartDocument7 pagesEcndt-0004-2018 (#SPIE) LennartrhinemineNo ratings yet

- 23-Nanoscribe GMBH - BookletDocument20 pages23-Nanoscribe GMBH - BookletDestonius DhiraviamNo ratings yet

- Mentorpaper 102410Document7 pagesMentorpaper 102410Sandesh Kumar B VNo ratings yet

- Low Noise 7 - Digit Autoranging Multimeter: Ordering InformationDocument2 pagesLow Noise 7 - Digit Autoranging Multimeter: Ordering Informationhugo_cortes5275No ratings yet

- Device Noise Simulation of ΔΣ Modulators (Designers-guide)Document22 pagesDevice Noise Simulation of ΔΣ Modulators (Designers-guide)alirezadNo ratings yet

- Best Lighting Solutions For Modern Workspaces - 0 1536749871Document9 pagesBest Lighting Solutions For Modern Workspaces - 0 1536749871AbhijeetJangidNo ratings yet

- 0final GRSLpaper PDFDocument6 pages0final GRSLpaper PDFКираNo ratings yet

- Certified Optical Network Training Programme GuideDocument2 pagesCertified Optical Network Training Programme Guiderikii80No ratings yet

- Transducer CatalogDocument7 pagesTransducer CatalogJ. Rodrigo Rizatti Rodrigo RizattiNo ratings yet

- CADSTAR Signal Integrity Verify: DatasheetDocument3 pagesCADSTAR Signal Integrity Verify: DatasheetMPIMLACNo ratings yet

- Computational Fluid Dynamics: Accurate Performance PredictionDocument3 pagesComputational Fluid Dynamics: Accurate Performance PredictionPhilippe LAVOISIERNo ratings yet

- Model Connectivity RAK PresentationDocument31 pagesModel Connectivity RAK PresentationHien HaNo ratings yet

- Rambus 112G XSR and LR SerDes PHYs EbookDocument10 pagesRambus 112G XSR and LR SerDes PHYs EbookLe Tan100% (1)

- All PresentationsDocument27 pagesAll Presentationsabdalrhman alqatawnehNo ratings yet

- Point Cloud Processing Software: Geotechnical Analysis Using Modern 3D Imaging TechnologiesDocument2 pagesPoint Cloud Processing Software: Geotechnical Analysis Using Modern 3D Imaging TechnologiesGiuseppe EspositoNo ratings yet

- Laser Structuring For LookandfeelDocument6 pagesLaser Structuring For LookandfeelNandakumar M BasavarajNo ratings yet

- Wang 2008Document6 pagesWang 2008Ameya DeshpandeNo ratings yet

- Nano Dimension: Lab-On-ChipDocument4 pagesNano Dimension: Lab-On-Chipyufencha1548No ratings yet

- Electronics: A Hidden DCT-Based Invisible Watermarking Method For Low-Cost Hardware ImplementationsDocument25 pagesElectronics: A Hidden DCT-Based Invisible Watermarking Method For Low-Cost Hardware ImplementationsARUN CHILUKURINo ratings yet

- DWDM ThesisDocument7 pagesDWDM Thesishaleyjohnsonpittsburgh100% (2)

- AVEVA Laser ModellerDocument2 pagesAVEVA Laser ModellerSlobodan GaracaNo ratings yet

- Journal 1Document8 pagesJournal 1mkhNo ratings yet

- CasingWear DatasheetDocument4 pagesCasingWear DatasheetSaeed AraNo ratings yet

- Ro3000 Laminate Data Sheet Ro3003 - Ro3006 - Ro3010 - Ro3035Document4 pagesRo3000 Laminate Data Sheet Ro3003 - Ro3006 - Ro3010 - Ro3035Jurgen AzevedoNo ratings yet

- SpaceX ApplicationDocument68 pagesSpaceX ApplicationAbhiNo ratings yet

- Get The Most From Xeon Scalable With Accelerators Eguide Tier1Document12 pagesGet The Most From Xeon Scalable With Accelerators Eguide Tier1AbhiNo ratings yet

- Holzworth - WP - Measuring Phase Noise of DROs - Sept2022Document6 pagesHolzworth - WP - Measuring Phase Noise of DROs - Sept2022AbhiNo ratings yet

- National ConfOnEWST2023FLYER04JanDocument7 pagesNational ConfOnEWST2023FLYER04JanAbhiNo ratings yet

- Infineon-EXCELON TM F-RAM Functional Safety EXCELON TM Auto EXCELON TM Ultra-Whitepaper-V01 00-En63Document15 pagesInfineon-EXCELON TM F-RAM Functional Safety EXCELON TM Auto EXCELON TM Ultra-Whitepaper-V01 00-En63AbhiNo ratings yet

- Automating Deep Space Network Scheduling and ConflDocument8 pagesAutomating Deep Space Network Scheduling and ConflAbhiNo ratings yet

- Epofine 337 - Finehard 3918Document4 pagesEpofine 337 - Finehard 3918Karishma PrabhuNo ratings yet

- Ohm's LawDocument79 pagesOhm's Laweugene rellamaNo ratings yet

- Aircraft Fabric Covering and Finishing ModDocument142 pagesAircraft Fabric Covering and Finishing ModEjigayehu Lemma75% (4)

- ICSE Class 10 CHEMISTRY Previous Year Question Paper 2011Document8 pagesICSE Class 10 CHEMISTRY Previous Year Question Paper 2011Madhu SudanNo ratings yet

- Nuclear Fission Chain Reaction ExplainedDocument13 pagesNuclear Fission Chain Reaction ExplainedSmexy PatataNo ratings yet

- W2DU - Analisys Coaxial DipoleDocument14 pagesW2DU - Analisys Coaxial DipolebyponsNo ratings yet

- Automatic Bottle Washing MachineDocument14 pagesAutomatic Bottle Washing Machineheisnoble100% (1)

- 4FE-28Y-40P With FHU+60Document17 pages4FE-28Y-40P With FHU+60tedychrNo ratings yet

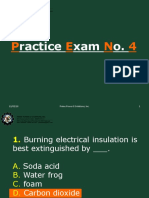

- Practice Exam No. 4 2018 PDFDocument43 pagesPractice Exam No. 4 2018 PDFJevan CalaqueNo ratings yet

- Cement CalculationsDocument25 pagesCement CalculationsKristi MicheleNo ratings yet

- Lecture 3 - Protein Adsorption Part 1 PDFDocument17 pagesLecture 3 - Protein Adsorption Part 1 PDFWesley ChiangNo ratings yet

- Switching Power Supply Design: A Concise Practical Handbook: February 2022Document5 pagesSwitching Power Supply Design: A Concise Practical Handbook: February 2022Juan Gil RocaNo ratings yet

- Characterization of The Halcyon Multileaf Collimator SystemDocument9 pagesCharacterization of The Halcyon Multileaf Collimator Systemzack988No ratings yet

- SF6 Circuit Breaker Nameplate Details ExplanationDocument7 pagesSF6 Circuit Breaker Nameplate Details Explanationlooyd alforqueNo ratings yet

- Astm D5333Document3 pagesAstm D5333dghadiaNo ratings yet

- MF4202 Additive ManufacturingDocument159 pagesMF4202 Additive ManufacturingOptimMart InternationaleNo ratings yet

- Trigonometric Function and Its Application Worksheet AnswerDocument11 pagesTrigonometric Function and Its Application Worksheet AnswerMichael Diptana Setiawan SutedjaNo ratings yet

- GR 9, Chem P-1Document23 pagesGR 9, Chem P-1kashif mohammedNo ratings yet

- Offer For 48V 700AH Li-Ion Battery PDFDocument1 pageOffer For 48V 700AH Li-Ion Battery PDFJosé MoralesNo ratings yet

- 1 s2.0 S2213956721001821 MainDocument13 pages1 s2.0 S2213956721001821 MainChigoChigoNo ratings yet

- Experiment 12:: SCR CharacteristicsDocument3 pagesExperiment 12:: SCR CharacteristicsPerumal NamasivayamNo ratings yet

- Mec 201 04 Aug 20Document18 pagesMec 201 04 Aug 20hemanth singhNo ratings yet

- Chapter 3 Diode CircuitsDocument64 pagesChapter 3 Diode CircuitsAmged TahaNo ratings yet

- 25-07-2021 - INCOMING JR CO-SC-N120 - Jee-Adv (2012-P2) - Q.PDocument13 pages25-07-2021 - INCOMING JR CO-SC-N120 - Jee-Adv (2012-P2) - Q.PAaryan KumarNo ratings yet

- Experiment-2: Title: Generation of Signals & Signal Operations ObjectivesDocument10 pagesExperiment-2: Title: Generation of Signals & Signal Operations ObjectivesPuri AshutoshNo ratings yet

- Latest Progress in TGD: The Geometry of World of Classical Worlds and Emergence of Unitary S-MatrixDocument77 pagesLatest Progress in TGD: The Geometry of World of Classical Worlds and Emergence of Unitary S-MatrixLuciano FagundesNo ratings yet

- Chap 1Document17 pagesChap 1Esiyak MengeshaNo ratings yet

- Irs InsDocument6 pagesIrs Insadrian hNo ratings yet

- Chilled Water Pipe DESIGNDocument22 pagesChilled Water Pipe DESIGNTanjim FakirNo ratings yet

- Unit 16 ExplanationDocument12 pagesUnit 16 ExplanationAnh MaiNo ratings yet