Professional Documents

Culture Documents

Instruction of TS27R Calibration and Measurement

Instruction of TS27R Calibration and Measurement

Uploaded by

Роман Дедов0 ratings0% found this document useful (0 votes)

32 views3 pagesCalibrate and measure the TS27R tool by:

1. Leveling the equipment and fixing the probe.

2. Running program O8000 to move the tool 10mm above the probe and execute calibration.

3. Measure tool length, diameter, and length plus diameter by running program O8010 and inputting the tool radius and compensation number corresponding to the spindle tool number.

Original Description:

Original Title

Instruction of TS27R calibration and measurement

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCalibrate and measure the TS27R tool by:

1. Leveling the equipment and fixing the probe.

2. Running program O8000 to move the tool 10mm above the probe and execute calibration.

3. Measure tool length, diameter, and length plus diameter by running program O8010 and inputting the tool radius and compensation number corresponding to the spindle tool number.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

32 views3 pagesInstruction of TS27R Calibration and Measurement

Instruction of TS27R Calibration and Measurement

Uploaded by

Роман ДедовCalibrate and measure the TS27R tool by:

1. Leveling the equipment and fixing the probe.

2. Running program O8000 to move the tool 10mm above the probe and execute calibration.

3. Measure tool length, diameter, and length plus diameter by running program O8010 and inputting the tool radius and compensation number corresponding to the spindle tool number.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Instruction of TS27R calibration and measurement

1 92 years machine manufacturer 1

1. Fix the euipment and make the levelling well.

2. Calibration:

Move the tool around 10mm higher to top of probe, then execute O8000 program.

Example:

Dia. of probe Tool compensation No.

( Note: Please preset the correct

tool length.

O8000 G65 P9855 D12.7 R12 T1 E.g H1=-200. D1=6, data that

measured after should take this

data as datum to calculate out.

Tool diameter

Input macro #520-#526

2 92 years machine manufacturer 2

3. Measurement B1=Tool length

B2=Tool diameter

Example:

B3=Tool length +tool

diameter

O8010 G65 P9857 T4 D6 Tool radius

Tool compensation No.

Set the corresponding tool

compensation No. with relatively

accurate H value and D value

T#4120 is current spindle tool number,

tool compensation No. should be in

accordance with spindle tool No.

3 92 years machine manufacturer 3

You might also like

- Parts Catalogue Kriss110Document82 pagesParts Catalogue Kriss110Syahrom Niezam100% (1)

- The Tool Measure Test of Fanuc VMCDocument5 pagesThe Tool Measure Test of Fanuc VMCRobert Dăboi100% (1)

- Bolting-Up CalcDocument21 pagesBolting-Up CalcJayanth TSNo ratings yet

- DPI 515 Manual K245Document116 pagesDPI 515 Manual K245Andreea Oltean100% (2)

- CPT Mill Thread Tool Twin InsertDocument4 pagesCPT Mill Thread Tool Twin InsertÁdám RáczNo ratings yet

- Cnccodes Msnc500 enDocument14 pagesCnccodes Msnc500 enigorNo ratings yet

- Centro de Giro 640MtDocument2 pagesCentro de Giro 640MtRafaelNo ratings yet

- Machine Operation Calculations: TurningDocument10 pagesMachine Operation Calculations: TurningRahulChampNo ratings yet

- MT-II LM-319F VSemDocument18 pagesMT-II LM-319F VSemHarkulvinder SinghNo ratings yet

- NclatheDocument16 pagesNclatheapi-356462562No ratings yet

- CNC Programming Concepts and Commonly Used G-Codes inDocument54 pagesCNC Programming Concepts and Commonly Used G-Codes inMel ParasNo ratings yet

- Job Plan 102, 103, 104Document2 pagesJob Plan 102, 103, 104Damn ScaredNo ratings yet

- Batc Rally 97 Sunday April 27Th Sports Connexion CoventryDocument11 pagesBatc Rally 97 Sunday April 27Th Sports Connexion CoventryRahulChampNo ratings yet

- PR No. 61084690 (280KW)Document4 pagesPR No. 61084690 (280KW)Haze DiazNo ratings yet

- Appendix DDocument1 pageAppendix DYeung Shing HoNo ratings yet

- 00 C47G 30 313 - NC - FIXTURE.Report Post - SetupDocument3 pages00 C47G 30 313 - NC - FIXTURE.Report Post - SetupАлександр ШеинNo ratings yet

- Parts Catalogue Kriss 110 Disc BrakeDocument84 pagesParts Catalogue Kriss 110 Disc BrakeMuhammad DanialNo ratings yet

- Typical CNC Machining Centre: Horizontal Axis Milling Vertical Axis MillingDocument82 pagesTypical CNC Machining Centre: Horizontal Axis Milling Vertical Axis MillingAbdul RehmanNo ratings yet

- Parts Catalogue Ct115sDocument82 pagesParts Catalogue Ct115sMuhammad hazimanNo ratings yet

- WWW Online Iso Calculator Com Online Bolt Torque CalculatorDocument6 pagesWWW Online Iso Calculator Com Online Bolt Torque CalculatormashudiNo ratings yet

- Machine Operation Calculations: TurningDocument10 pagesMachine Operation Calculations: TurningRahulChampNo ratings yet

- DB Tav131 enDocument6 pagesDB Tav131 enCalandrasReyCalandrasreyNo ratings yet

- 35MANFANXYDocument8 pages35MANFANXYkravchenkovdimNo ratings yet

- Bolt Up CalculationDocument12 pagesBolt Up CalculationAniket GaikwadNo ratings yet

- Cad Manual 2dDocument27 pagesCad Manual 2dSankar KNo ratings yet

- tGFm9Document83 pagestGFm9Febry IllustNo ratings yet

- VMC Slot ProgramingDocument5 pagesVMC Slot ProgramingMechanical FactsNo ratings yet

- Manual de PartesDocument138 pagesManual de PartesrvhkiNo ratings yet

- Roundness Check Record of 1St Shell CourseDocument1 pageRoundness Check Record of 1St Shell CourseRhannie GarciaNo ratings yet

- Overzicht Afname-Normen Gereedschapswerktuigen en Het Aangeven Van Enkele ProbleemgebiedenDocument18 pagesOverzicht Afname-Normen Gereedschapswerktuigen en Het Aangeven Van Enkele Probleemgebiedenmarcel habersNo ratings yet

- Completed Camd Lab DocumentDocument89 pagesCompleted Camd Lab DocumentAjesh MANo ratings yet

- Technical Information Release Dnm-Tir 005 ACDocument1 pageTechnical Information Release Dnm-Tir 005 ACTeymur AliyevNo ratings yet

- 1st - T - Lect No.6 - CAM - Length OffestDocument38 pages1st - T - Lect No.6 - CAM - Length OffestHazem AhmedNo ratings yet

- IT3401C Codeur RotatifDocument4 pagesIT3401C Codeur RotatifDejuan HuffNo ratings yet

- Modenas Kriss Mr2Document81 pagesModenas Kriss Mr2Affendy LatipNo ratings yet

- P 7.8a, 7.8B 7.8CDocument23 pagesP 7.8a, 7.8B 7.8Csyahmi samirNo ratings yet

- Attachment 1 BEA ProcedureDocument7 pagesAttachment 1 BEA ProcedureFateh AliyaNo ratings yet

- Machine Operation CalculationsDocument9 pagesMachine Operation CalculationsGangadhar NavnageNo ratings yet

- NAKA Tool Ofset CancelDocument4 pagesNAKA Tool Ofset CancelPatryk MarczewskiNo ratings yet

- CNC MCT Job Sheet (Sentrol, Fanuc Basic1) 65pDocument57 pagesCNC MCT Job Sheet (Sentrol, Fanuc Basic1) 65pmarciano1980100% (1)

- sEW20Document78 pagessEW20Wan AzmiNo ratings yet

- Bhavya Forge & Fittings (India) .: Dimension Report-As Per Asme B16.9: 2013Document10 pagesBhavya Forge & Fittings (India) .: Dimension Report-As Per Asme B16.9: 2013Niraj PandeyNo ratings yet

- SEW Eurodrive Drive Unit For 4821-FDB-2005Document6 pagesSEW Eurodrive Drive Unit For 4821-FDB-2005Farobi RifqiNo ratings yet

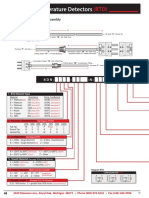

- Resistance Temperature Detectors: Style D - Quick Disconnect AssemblyDocument5 pagesResistance Temperature Detectors: Style D - Quick Disconnect AssemblyShivam TiwariNo ratings yet

- CNC ProgrammingDocument48 pagesCNC Programminglakshmichandranath889No ratings yet

- Training Copy Not For Execution: Sop No. Supersedes Effective Date Next Review DateDocument5 pagesTraining Copy Not For Execution: Sop No. Supersedes Effective Date Next Review Datemanohar kumarNo ratings yet

- NIKHILKUMAR 201229065225264 01 - DraftDocument7 pagesNIKHILKUMAR 201229065225264 01 - DraftAmit BidlanNo ratings yet

- Cost Optimization of Slab Milling Operation Using Genetic AlgorithmsDocument8 pagesCost Optimization of Slab Milling Operation Using Genetic AlgorithmsPelekani SakalaNo ratings yet

- viewNitPdf 2547183Document19 pagesviewNitPdf 2547183EMJAYNo ratings yet

- 143 13 English Catalogue 2014 PDFDocument319 pages143 13 English Catalogue 2014 PDFJa Pa JaNo ratings yet

- Calibrador ElectrónicoDocument6 pagesCalibrador ElectrónicoJaiatiNo ratings yet

- TS27R - BlumDocument14 pagesTS27R - BlumtranhoachbnNo ratings yet

- Report Edm Wire CutDocument12 pagesReport Edm Wire CutGEEKIjatsNo ratings yet

- RO1364Document2 pagesRO1364shiauyunn.yeohNo ratings yet

- 1315 - Air J S EnterprisesDocument1 page1315 - Air J S EnterprisesJaffer AliNo ratings yet

- Air Cooled Heat Exchanger Design Calculator (Estimation) : To ModifyDocument9 pagesAir Cooled Heat Exchanger Design Calculator (Estimation) : To ModifyBilal BhattiNo ratings yet

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Document32 pagesPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNo ratings yet

- Trisquare Switchgear Pvt. LTD.: Commercial OfferDocument8 pagesTrisquare Switchgear Pvt. LTD.: Commercial OfferaaaaNo ratings yet