Professional Documents

Culture Documents

MV Fuses Protect Circuits

Uploaded by

MrOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MV Fuses Protect Circuits

Uploaded by

MrCopyright:

Available Formats

2.

1 Medium Voltage Fuses

Protective Devices Hydro Circcuit Protection

MEDIUM VOLTAGE FUSES

Fuses are the oldest and most simple protective devices. When the current flowing through the fuse exceeds a

predetermined value, the heat produced by the current in the fusible link melts the link and interrupts the current. Since the

current must last long enough for the link to melt, fuses have inherently a time delay. Typical time-current curve is shown

in figure 5. Fuses are relatively economical devices, they do not need any auxiliary devices such as instrument

transformers and relays, they are reliable, and available in a large range of sizes. Their one disadvantage is that they are

destroyed in the process of opening the circuit, and then they must be replaced.

Figure 5 shows a typical time vs current characteristic for a fuse. The melting time is the time required for the fusible

element to heat up to the point when it starts to melt. The clearing time is time from the moment the fault current starts

flowing to the moment the circuit is interrupted. The time between the clearing time and the melting time is referred as the

arcing time. No two fuses are exactly alike. The American National Standards Institute (ANSI) allows a tolerance of plus

or minus 10% in the melting current for any given time. Manufacturers provide two sets of curves for all types of fuses -

one set is for the minimum melting time, the other set is for the total clearing time. Each individual fuse must operate

within the band between the two characteristics.

file:///D|/Engineering%20Stuff%2015-june-2008/Electri...ion%20and%20relays/2_1%20Medium%20Voltage%20Fuses.htm (1 of 8)7/5/2008 9:27:24 AM

2.1 Medium Voltage Fuses

Figure 5 Time-current characteristic for a power fuse.

There are four quantities that are important for a particular fuse application:

1. Maximum Rated Voltage is the highest nominal system voltage at which the fuse can be used. The voltage is given as

an rms and line to line value. The idea is that a blown fuse should be able to withstand the system voltage.

2. Maximum Continuous Current is the maximum rms current the fuse should be able to carry indefinitely. This current

is given by an allowable temperature rise for the fuse, and therefore it also depends on the ambient temperature.

3. Maximum Interrupting Current is the largest current the fuse is capable of interrupting . This value should be higher

than the maximum possible fault current on this circuit.

4. Time Response. This is given by the time-current characteristic.

Medium voltage fuses are available up to voltages of 36 kV for indoor use, and up to 161 kV for outdoor use.

There are two categories of the medium voltage fuses:

1. distribution fuse cutouts developed for overhead distribution lines

2. power fuses developed for substations applications. Power fuses are available at higher voltage and current ratings than

the distribution fuse cutouts. They come in two types:

a) current limiting fuses

b) solid material fuses

Medium Voltage Current Limiting Fuses

These fuses operate on the same principle as the current limiting low voltage fuses. The fusing element must be much

longer than for low voltage fuses since it must dissipate much larger amounts of energy. It is usually wound helically on a

file:///D|/Engineering%20Stuff%2015-june-2008/Electri...ion%20and%20relays/2_1%20Medium%20Voltage%20Fuses.htm (2 of 8)7/5/2008 9:27:24 AM

2.1 Medium Voltage Fuses

porcelain support and placed in a ceramic container filled with silica sand. A typical fuse rated 11 kV, 85 A, 250 MVA

breaking capacity will have a container about 6 cm in diameter and 35 cm long. Because of their fast action, they are most

often used as the last overcurrent device in the circuit.

Medium Voltage Solid Material Fuses

These fuses operate by melting the fusible element and at the same time a spring pulls the element and elongates the arc

inside the interrupting chamber. The arc heats the solid material and creates gas that helps to extinguish the arc. The hot

gas is expelled down into the exhaust control device.

file:///D|/Engineering%20Stuff%2015-june-2008/Electri...ion%20and%20relays/2_1%20Medium%20Voltage%20Fuses.htm (3 of 8)7/5/2008 9:27:24 AM

2.1 Medium Voltage Fuses

Figure 7 Mounting of Power Fuses

(a) open type

(b) enclosed type

(c) spring type

file:///D|/Engineering%20Stuff%2015-june-2008/Electri...ion%20and%20relays/2_1%20Medium%20Voltage%20Fuses.htm (4 of 8)7/5/2008 9:27:24 AM

2.1 Medium Voltage Fuses

Loadbreak Cutout, A.B. Chance Co., Chance TiPS, vol.51, No. 1, p. 10

Manufactured for rated voltages 15/27 kV (125 kV BIL) and 22/36.4 kV (150 kV BIL)

file:///D|/Engineering%20Stuff%2015-june-2008/Electri...ion%20and%20relays/2_1%20Medium%20Voltage%20Fuses.htm (5 of 8)7/5/2008 9:27:24 AM

2.1 Medium Voltage Fuses

15 kV loadbreak Chance "C" cutouts, A.B. Chance Co., Chance TiPS, vol.51, No. 1, p. 11

file:///D|/Engineering%20Stuff%2015-june-2008/Electri...ion%20and%20relays/2_1%20Medium%20Voltage%20Fuses.htm (6 of 8)7/5/2008 9:27:24 AM

2.1 Medium Voltage Fuses

file:///D|/Engineering%20Stuff%2015-june-2008/Electri...ion%20and%20relays/2_1%20Medium%20Voltage%20Fuses.htm (7 of 8)7/5/2008 9:27:24 AM

2.1 Medium Voltage Fuses

file:///D|/Engineering%20Stuff%2015-june-2008/Electri...ion%20and%20relays/2_1%20Medium%20Voltage%20Fuses.htm (8 of 8)7/5/2008 9:27:24 AM

You might also like

- Fuse Vs Circuit BreakerDocument4 pagesFuse Vs Circuit BreakerBurning SunNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Robway SLI ManualDocument135 pagesRobway SLI ManualBatagor H. Isan100% (1)

- A 732 - A732M - 02 Equivalencia Ic AstmDocument8 pagesA 732 - A732M - 02 Equivalencia Ic AstmorivaldopenaNo ratings yet

- Electrical Fuse Characteristics and ParametersDocument31 pagesElectrical Fuse Characteristics and ParametersMouna NjNo ratings yet

- Electronics equipment overcurrent protectionDocument36 pagesElectronics equipment overcurrent protectionManpreet SachdevaNo ratings yet

- Fuse (Electrical) - WikipediaDocument14 pagesFuse (Electrical) - WikipediaNisar AhmedNo ratings yet

- Fuse Theory and OperationDocument4 pagesFuse Theory and OperationsuryaNo ratings yet

- Technical Notes - FuseDocument16 pagesTechnical Notes - FusesiddharthangandhiNo ratings yet

- SGP Activity DoneDocument22 pagesSGP Activity DoneAE MDHalliNo ratings yet

- Fuse (Electrical) : From Wikipedia, The Free EncyclopediaDocument18 pagesFuse (Electrical) : From Wikipedia, The Free EncyclopediaAshwini PatleNo ratings yet

- Fuse PDFDocument17 pagesFuse PDFAKSHAY K SNo ratings yet

- How To Select The Right Fuse For Power Systems ProtectionDocument4 pagesHow To Select The Right Fuse For Power Systems ProtectionrajeshNo ratings yet

- FusesDocument192 pagesFusesjokanovNo ratings yet

- Power System ProtectionDocument15 pagesPower System ProtectionLucky AranetaNo ratings yet

- Fuses ExplainedDocument5 pagesFuses Explainedchinthaka111No ratings yet

- Fuse and Circuit BreakerDocument36 pagesFuse and Circuit BreakerJonathan LeeNo ratings yet

- FusesDocument8 pagesFusescatherinejeanasNo ratings yet

- FUSE RATINGS AND TYPES FOR SIGNAL SYSTEMSDocument11 pagesFUSE RATINGS AND TYPES FOR SIGNAL SYSTEMSPankaj PalawatNo ratings yet

- Fuse Theory and OperationDocument3 pagesFuse Theory and OperationsuryaNo ratings yet

- SMPS - Fuse SelectionDocument7 pagesSMPS - Fuse SelectionrajeshNo ratings yet

- Power Semiconductor Fuse Applications GuideDocument52 pagesPower Semiconductor Fuse Applications GuidePelmus LiviuNo ratings yet

- Find The Right Fuse!: What Are The Advantages of Using An Electrical Fuse?Document4 pagesFind The Right Fuse!: What Are The Advantages of Using An Electrical Fuse?ShirishNo ratings yet

- Module - 3: Switches and FusesDocument53 pagesModule - 3: Switches and FusesdemokykNo ratings yet

- Overcurrent Protection DeviceDocument9 pagesOvercurrent Protection DeviceUmi YumiNo ratings yet

- FuseDocument4 pagesFuseapi-3741659100% (1)

- BY Jalpa Mahadev S.Avinash Sneha MittraDocument32 pagesBY Jalpa Mahadev S.Avinash Sneha MittraGuru MnNo ratings yet

- 1.12 Overcurrent Protective DevicesDocument62 pages1.12 Overcurrent Protective DevicesChristian MuliNo ratings yet

- Guide To ProtectionDocument32 pagesGuide To ProtectionpjaengjaikulNo ratings yet

- Electrical Installations GuideDocument8 pagesElectrical Installations Guidedh25881No ratings yet

- EE101 6 Electrical InstallationsDocument8 pagesEE101 6 Electrical InstallationsKasun WerangaNo ratings yet

- Fuse Terminology: From ANSI/ NEMA FU1-86Document2 pagesFuse Terminology: From ANSI/ NEMA FU1-86bertovalenNo ratings yet

- Power system protection techniques and protective devices explained by Dr. Prof. Mohammed Tawfeeq LazimDocument20 pagesPower system protection techniques and protective devices explained by Dr. Prof. Mohammed Tawfeeq Lazimmughees_itcompNo ratings yet

- Power System Protection - Part 04Document20 pagesPower System Protection - Part 04Jeff CayetanoNo ratings yet

- Fuses LectureDocument14 pagesFuses LectureWilfred AsonmwonririNo ratings yet

- Electric Fuse: Presented by Smaranika Barik Regd No:0801214396Document14 pagesElectric Fuse: Presented by Smaranika Barik Regd No:0801214396Dev KumarNo ratings yet

- Electric Fuse: Presented by Smaranika Barik Regd No:0801214396Document14 pagesElectric Fuse: Presented by Smaranika Barik Regd No:0801214396Dev KumarNo ratings yet

- Seminar Report On Ultra ConductorDocument18 pagesSeminar Report On Ultra ConductorNavneet Singh100% (1)

- ABB High Voltage Fuses CatalogueDocument64 pagesABB High Voltage Fuses CataloguerocketvtNo ratings yet

- FUSESDocument9 pagesFUSESعلي صالحNo ratings yet

- Five Criteria For Fuse Selection - Engineers' Insight - Avnet AbacusDocument3 pagesFive Criteria For Fuse Selection - Engineers' Insight - Avnet AbacusrajeshNo ratings yet

- Notes21 ProtectionDocument22 pagesNotes21 ProtectionJerome SantosNo ratings yet

- Eaton 15kV Current Limiting FusesDocument78 pagesEaton 15kV Current Limiting FusespwmvsiNo ratings yet

- MEDIA TENSÃO Fusiveis CurtocircuitoDocument22 pagesMEDIA TENSÃO Fusiveis CurtocircuitoandreisraelNo ratings yet

- Electrical Overcurrent Protection GuideDocument46 pagesElectrical Overcurrent Protection Guidepraveen kumaraNo ratings yet

- Fuse EOTDocument29 pagesFuse EOTKushagr SinghNo ratings yet

- Fault ProtectDocument34 pagesFault ProtecterollNo ratings yet

- Topic 4 - Circuit Protection (Part 1)Document22 pagesTopic 4 - Circuit Protection (Part 1)quartermaster2.tpesc2324No ratings yet

- Electrical Fuse HRC Fuse High Rupturing Capacity - Electrical EngineeringDocument5 pagesElectrical Fuse HRC Fuse High Rupturing Capacity - Electrical EngineeringAmit DebnathNo ratings yet

- Circuit Protection Devices: Fuses Guide Overcurrents, Overloads, Short CircuitsDocument5 pagesCircuit Protection Devices: Fuses Guide Overcurrents, Overloads, Short CircuitsM Qamar NazeerNo ratings yet

- 2ND Quarter - Slm-Week 5Document23 pages2ND Quarter - Slm-Week 5Ben Erick CompuestoNo ratings yet

- Introducton 1.1 Overview:: Power Transformer Protection Using Microcontroller-Based RelayDocument51 pagesIntroducton 1.1 Overview:: Power Transformer Protection Using Microcontroller-Based RelayManoj NagarajanNo ratings yet

- High-Voltage Fuse-LinksDocument11 pagesHigh-Voltage Fuse-LinksSatheesh Kumar NatarajanNo ratings yet

- Fuse and Types of FusesDocument5 pagesFuse and Types of FusesYasir JamilNo ratings yet

- Assignment of System Protection Eeg 806Document24 pagesAssignment of System Protection Eeg 806emechetasamuel27No ratings yet

- UNIT-VII Electrical Protection: RelayDocument17 pagesUNIT-VII Electrical Protection: RelayMonte CarloNo ratings yet

- Ficha de Fusibles CefDocument56 pagesFicha de Fusibles Ceflgp500h2No ratings yet

- Topic 1a: Fuses: Dr. E. A. FeilatDocument23 pagesTopic 1a: Fuses: Dr. E. A. FeilatMohammedNasserNo ratings yet

- Protective Devices For Control Equipment, Part 1: Fuses, Circuit Breakers, Chop-Off Circuits, Crowbars, ThermostatsDocument9 pagesProtective Devices For Control Equipment, Part 1: Fuses, Circuit Breakers, Chop-Off Circuits, Crowbars, ThermostatsAngel GutierrezNo ratings yet

- Selecting A Fuse Value - in Compliance MagazineDocument5 pagesSelecting A Fuse Value - in Compliance MagazinerajeshNo ratings yet

- Circuit Protection Devices: Figure 10-1Document30 pagesCircuit Protection Devices: Figure 10-1deep4u2009No ratings yet

- Unit-I Circuit BreakersDocument13 pagesUnit-I Circuit Breakerspurushg62No ratings yet

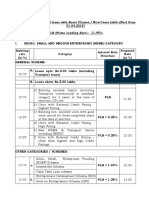

- Overcurrent Coordination Setting Guidelines MotorsDocument7 pagesOvercurrent Coordination Setting Guidelines MotorsMrNo ratings yet

- ANSI-IEC Comparision For MV Switchgear DesignDocument12 pagesANSI-IEC Comparision For MV Switchgear DesignSathish KumarNo ratings yet

- Specification - For - 460 - Volt - MCC Rev 0Document83 pagesSpecification - For - 460 - Volt - MCC Rev 0MrNo ratings yet

- Equipment Damage Curves ConductorsDocument4 pagesEquipment Damage Curves ConductorsMrNo ratings yet

- Equipment Damage Curves GeneratorsDocument4 pagesEquipment Damage Curves GeneratorsMrNo ratings yet

- Cover Document For LV CablesDocument2 pagesCover Document For LV CablesMrNo ratings yet

- XLPE/SWA/PVC cable specsDocument2 pagesXLPE/SWA/PVC cable specsNMulyonoNo ratings yet

- ITB - Electrical Works For No. 2 API Separator Rev ADocument84 pagesITB - Electrical Works For No. 2 API Separator Rev AMrNo ratings yet

- 01 RC CTC 0070.1Document3 pages01 RC CTC 0070.1MrNo ratings yet

- ITB - Electrical Works For WWTF Chemical Dosing Unit Rev A (Wit Sig)Document86 pagesITB - Electrical Works For WWTF Chemical Dosing Unit Rev A (Wit Sig)MrNo ratings yet

- 06060-01-RC-CTC-0070 - SignedDocument2 pages06060-01-RC-CTC-0070 - SignedMrNo ratings yet

- Dosing Unit Modifications FinalDocument11 pagesDosing Unit Modifications FinalMrNo ratings yet

- New Cover Document 2 Api Separator MCCDocument2 pagesNew Cover Document 2 Api Separator MCCMrNo ratings yet

- Specification For 460 Volt MCCDocument4 pagesSpecification For 460 Volt MCCMrNo ratings yet

- ELP-IP1881 CameraDocument4 pagesELP-IP1881 CameraMrNo ratings yet

- Cover Letter - EEDocument1 pageCover Letter - EEMrNo ratings yet

- ITB - CCR Naptha Transfer PumpsDocument36 pagesITB - CCR Naptha Transfer PumpsMrNo ratings yet

- Corporation Tax Act 2016 (75.02)Document65 pagesCorporation Tax Act 2016 (75.02)MrNo ratings yet

- I-Gard Consultant Specification GuideDocument16 pagesI-Gard Consultant Specification GuideMrNo ratings yet

- MJCVDocument5 pagesMJCVMrNo ratings yet

- IEEEPESApr14 - Grounding Configurations and Detection!Document66 pagesIEEEPESApr14 - Grounding Configurations and Detection!MrNo ratings yet

- Neutral Earthing in LV SystemsDocument1 pageNeutral Earthing in LV SystemsMrNo ratings yet

- Resistance Grounded SystemsDocument2 pagesResistance Grounded SystemsMrNo ratings yet

- Grounding - 3 PhaseDocument4 pagesGrounding - 3 PhaseMrNo ratings yet

- Principles of Grounding DesignDocument16 pagesPrinciples of Grounding DesignvanpatoNo ratings yet

- Grounding Pada PLTUDocument15 pagesGrounding Pada PLTUyogacruiseNo ratings yet

- NEGRP Test Data Shows Chem-Rod EffectivenessDocument8 pagesNEGRP Test Data Shows Chem-Rod Effectivenessgary hillNo ratings yet

- Ground Fault Currents From Delta WindingsDocument5 pagesGround Fault Currents From Delta WindingsMrNo ratings yet

- NEC Requirements For Classified CablesDocument4 pagesNEC Requirements For Classified CablesMrNo ratings yet

- GNDG Design PracticesDocument5 pagesGNDG Design PracticesMrNo ratings yet

- GCSE Biology - Homeostasis - WorksheetDocument2 pagesGCSE Biology - Homeostasis - WorksheetalexNo ratings yet

- FliesDocument14 pagesFliesaguilarmvzNo ratings yet

- Case Study Fire IncidentDocument7 pagesCase Study Fire IncidentD21Sanjana Ubale100% (1)

- 20 Rules of Parenting (Specific To Mothers)Document2 pages20 Rules of Parenting (Specific To Mothers)Karen KitchellNo ratings yet

- Praying in The Spirit Series-Conceiving in The SpiritDocument11 pagesPraying in The Spirit Series-Conceiving in The SpiritPrecious O. OkaforNo ratings yet

- 2021 Prosthetics Lower Limb Catalogue - enDocument524 pages2021 Prosthetics Lower Limb Catalogue - enBianca Denisse Arreola MascarenoNo ratings yet

- Bảng Tính Cột Áp QuạtDocument4 pagesBảng Tính Cột Áp QuạtNguyen PhamNo ratings yet

- Bio-Diesel Production From Waste Cooking OilDocument51 pagesBio-Diesel Production From Waste Cooking OilDemostenes DeceoNo ratings yet

- b2 Open Cloze - EpidemicsDocument3 pagesb2 Open Cloze - EpidemicsJose Manuel Morín BarriosNo ratings yet

- GFT 4 Rail Installation Guide 20171219 1Document31 pagesGFT 4 Rail Installation Guide 20171219 1Comsip400No ratings yet

- 1 - KSU Research Methodology Overview (A Mandil, Oct 2009)Document25 pages1 - KSU Research Methodology Overview (A Mandil, Oct 2009)Fatamii IiiNo ratings yet

- Journal 1Document2 pagesJournal 1Nick ViNo ratings yet

- Tupad Orientation Presentation 2017Document54 pagesTupad Orientation Presentation 2017Anonymous EvbW4o1U7100% (5)

- Relationship Wide of House VentilationDocument5 pagesRelationship Wide of House VentilationNova RizkenNo ratings yet

- Tiic Interest RateDocument3 pagesTiic Interest RatePriyaNo ratings yet

- Hubungan Antara Aktivitas Fisik Dan Screen Time Dengan Status Gizi Pada Siswa-Siswa SMP Kristen Eben Haezar 2 ManadoDocument11 pagesHubungan Antara Aktivitas Fisik Dan Screen Time Dengan Status Gizi Pada Siswa-Siswa SMP Kristen Eben Haezar 2 ManadorezkaNo ratings yet

- Report 1690018110488Document2 pagesReport 1690018110488Krishna ChaitanyaNo ratings yet

- 7.nuclear Chemistry and Environmental Chemistry ExerciseDocument38 pages7.nuclear Chemistry and Environmental Chemistry ExerciseYogy YNo ratings yet

- Muskuloskeletal Disorder Menggunakan: Analisa Dan Penilaian Risiko Metode Manual Tasks Risk Assessment (Mantra)Document8 pagesMuskuloskeletal Disorder Menggunakan: Analisa Dan Penilaian Risiko Metode Manual Tasks Risk Assessment (Mantra)Dirgntra AlanNo ratings yet

- Petition For Modification of Child Support Order (Administrative Hearing)Document3 pagesPetition For Modification of Child Support Order (Administrative Hearing)Shared EmailNo ratings yet

- CALIMOVEDocument46 pagesCALIMOVERasheedAladdinNGuiomala0% (1)

- Soal Usbn MGMP Binggris UtamaDocument10 pagesSoal Usbn MGMP Binggris UtamaNurlinah SakkaNo ratings yet

- Smartyou 21 Day PDF PlannerDocument9 pagesSmartyou 21 Day PDF PlannerYarelis Montero Mercado100% (1)

- Birth Control GuideDocument4 pagesBirth Control GuideNessaNo ratings yet

- Chapter 1 To 7Document152 pagesChapter 1 To 7Jhane Sager ManahanNo ratings yet

- Chemistry Ssc-I: Answer Sheet No.Document7 pagesChemistry Ssc-I: Answer Sheet No.Mohsin SyedNo ratings yet

- DJ Brothers ISO 22000-2018 ManualDocument40 pagesDJ Brothers ISO 22000-2018 ManualSunith Desai100% (1)

- IS01 Service Pension OverviewDocument12 pagesIS01 Service Pension OverviewNige McIntoshNo ratings yet