Professional Documents

Culture Documents

Data Sheet ITE Separation Plant CokerSEP250 Version1 0 E

Uploaded by

GeorgeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet ITE Separation Plant CokerSEP250 Version1 0 E

Uploaded by

GeorgeCopyright:

Available Formats

ITE Separation Plant CokerSEP250 go fine!

Description

The ITE CokerSEP250 is a compact separation plant and specially designed

for separating solids from suspensions produced during the processing of

residual coke.

The CokerSEP250 is composed of two 4-panel vibration screening

machines, four hydrocyclones, one 20’ process tank with one integrated

centrifugal feed pump and two submersible agitators, one control cabinet

and accessories.

Adjustable discharge chutes, fold-away platform and pluggable railing for

safe working and good access provide a plug-and-play solution. Assembly

time is therefore reduced to a minimum. Feeding of the shakers and

cyclones is accomplished by an integrated fixed piping and wiring system in

a minimal footprint.

Instead of a collection of equipment from various sources, the ITE

CokerSEP250 is a field-proven network of separation components

specifically designed to function as a single unit. During each separation Transport dimensions

stage, a maximum of solid particles are removed from the slurry. The

Plant component Length x Width x Height [mm] Weight [kg]

modular system guarantees continuous and fast advance rates, reducing Tank 6062 x 2438 x 2591 9500

downtimes to a minimum. The innovative screening technology combined (incl. pump, platform)

with hydrocyclones constitutes a complete recycling concept, providing Screening machine 3200 x 2000 x 1620 2850

optimal removal of critical fine particles down to 45 microns and 4PSM with cyclone

guaranteeing constant slurry properties. subframe

Cyclone unit 2200 x 2200 x 4100 900

The vibration screening machines can be equipped with a wide range of Screening machine 3410 x 1690 x 1620 2380

different ITE panel screens which are available from 4mm mesh width 4PSM

down to 45µm.

Edition: Dec-11 ITE GmbH, Werner-von-Siemens-Str. 7, 46485 Wesel, Germany Page 1

Version 1.0 Phone: +49 (0) 281 319 362-0, Fax: +49 (0) 281 319 362-62, Web: www.separation.de

ITE Separation Plant CokerSEP250 go fine!

Technical Specification

Capacity (as per spec. below)*1: max. 250 m³/h Tank (2 compartments)

1. Compartment: Underflow 4PSM

Power consumption (total plant): approx. 59 kW 2. Compartment: Overflow hydrocyclones

Tank capacity: approx. 24 m³

Hydrocyclone unit

Number: 4 hydrocyclones

Dimensions: 315 mm

Cut-point (d50): 45 µm*1

Vibration screening machines 4PSM

Number installed: 2 no

Number of panel screens (on each shaker): 4 no

Screening area per shaker: 3.2 m2

Screening area total: 6.4 m²

Deck angle adjustment: -4° to +4°

Accelerating force: 6.3 G

Rated Power (per shaker): 2 x 2.2 kW

Voltage: 400 V / 50 Hz

Cyclone feed pump

Wear resistant centrifugal pump, 8 x 6 x 14

Number installed: 1 no

Rated Power: 45 kW

Voltage: 400 V / 50 Hz

Submersible agitators

Number installed: 2 no

Rated Power (each agitator): 2.5 kW

Voltage: 400 V / 50 Hz

*1 The capacity of the ITE CokerSEP250 is subject to the viscosity and density of

slurry, solids loading, grain size distribution, screen selection, and properties along

with operating conditions, and might be actually lower than specified.

Edition: Dec-11 ITE GmbH, Werner-von-Siemens-Str. 7, 46485 Wesel, Germany Page 2

Version 1.0 Phone: +49 (0) 281 319 362-0, Fax: +49 (0) 281 319 362-62, Web: www.separation.de

You might also like

- Data Sheet ITE Separation Unit TSP300-2 Version1 1 EDocument2 pagesData Sheet ITE Separation Unit TSP300-2 Version1 1 EGeorgeNo ratings yet

- Double Deck Screening MachineDocument2 pagesDouble Deck Screening MachineGeorgeNo ratings yet

- Efficient pellet classifierDocument2 pagesEfficient pellet classifierrogvilNo ratings yet

- Ote Fp-S Filter Press Eng Web PDFDocument8 pagesOte Fp-S Filter Press Eng Web PDFRegina Choque HuallpaNo ratings yet

- Lamella For SettlersDocument4 pagesLamella For Settlersaev65No ratings yet

- DMLM - X Line - Bro - 8 - US - EN - v1Document4 pagesDMLM - X Line - Bro - 8 - US - EN - v1devalpscNo ratings yet

- TDS-Dualpotsandfilter 10K HT-HFDocument3 pagesTDS-Dualpotsandfilter 10K HT-HFBambang Yan ArdiantoNo ratings yet

- Technical Proposal for Olympic Pool Filtration SystemDocument10 pagesTechnical Proposal for Olympic Pool Filtration SystemAlma DerajNo ratings yet

- Vibrations-Kontrollsiebmaschine kts-vs2 GB ScreenDocument2 pagesVibrations-Kontrollsiebmaschine kts-vs2 GB ScreenzolikaNo ratings yet

- Mobile Vibration Screening MachineDocument2 pagesMobile Vibration Screening MachineGeorgeNo ratings yet

- Red Rhino 5000 Series Mini Crusher: Technical SpecsDocument2 pagesRed Rhino 5000 Series Mini Crusher: Technical SpecsMohammed AttiaNo ratings yet

- NAFFCODocument12 pagesNAFFCOOuadihi MouhcineNo ratings yet

- FCCL Web Coater (Roll To Roll)Document14 pagesFCCL Web Coater (Roll To Roll)Beverly PamanNo ratings yet

- Vacuumschmelze EMC Nanocrystalline VITROPERMDocument28 pagesVacuumschmelze EMC Nanocrystalline VITROPERMShri KulkarniNo ratings yet

- Comby Plants Rct1: Machine DescriptionDocument2 pagesComby Plants Rct1: Machine DescriptionFelipe BrainNo ratings yet

- ENSCO 120 Series: Ultra-Premium Harsh Environment JackupsDocument4 pagesENSCO 120 Series: Ultra-Premium Harsh Environment JackupsDayanand Wasate100% (1)

- 06 BandScreenDocument13 pages06 BandScreenPraisesonAlexanderNo ratings yet

- Single module screening for 10,000 t/h SAG mill slurryDocument21 pagesSingle module screening for 10,000 t/h SAG mill slurryCesar Rodriguez GuzmanNo ratings yet

- QUOTATION Shri Akshay Chaugule Ji Sangli 32M3 CapacityDocument8 pagesQUOTATION Shri Akshay Chaugule Ji Sangli 32M3 CapacityAkshayNo ratings yet

- Brochure Break Duo - enDocument8 pagesBrochure Break Duo - enRoberto CecchinatoNo ratings yet

- 02 Complete Cleaning SolutionsDocument12 pages02 Complete Cleaning SolutionsGabriel T. BastosNo ratings yet

- Flotation CellsDocument6 pagesFlotation CellsrgongoravNo ratings yet

- Turbodry®: Agitated Vacuum Pan DryerDocument5 pagesTurbodry®: Agitated Vacuum Pan DryerCak Eko SusiloNo ratings yet

- White Grade PaperDocument28 pagesWhite Grade PaperGabriel T. BastosNo ratings yet

- 1-Vicky, Quotation of 1-1.2TPH Wood Pellet Line, RICHIDocument17 pages1-Vicky, Quotation of 1-1.2TPH Wood Pellet Line, RICHICarlos SolerNo ratings yet

- D25KS/D245S: Rotary Blast Hole DrillsDocument12 pagesD25KS/D245S: Rotary Blast Hole DrillsPeMar León ChangNo ratings yet

- Camelway 75m /H Concrete Batching PlantDocument5 pagesCamelway 75m /H Concrete Batching PlantErikNo ratings yet

- I Electro Mechanical Equipments II STP Panel III Statutory Approval ChargeDocument11 pagesI Electro Mechanical Equipments II STP Panel III Statutory Approval ChargeSajeshKumarNo ratings yet

- Paint Booth System ProposalDocument9 pagesPaint Booth System ProposalVeenaNo ratings yet

- ReNEW Series Fact SheetDocument4 pagesReNEW Series Fact Sheetjpsingh75No ratings yet

- Equipment Earmould Lab: Silicone Materials Silicone Lacquers Earmould Manufacturing ToolsDocument22 pagesEquipment Earmould Lab: Silicone Materials Silicone Lacquers Earmould Manufacturing ToolsLuisita AlzateNo ratings yet

- CORONA & PLASMA FOR FILM ADHESIONDocument8 pagesCORONA & PLASMA FOR FILM ADHESIONHuy Tuan QuachNo ratings yet

- Care For Life and Equipment: Dust Suppression For Bulk Transfer Points Made in GermanyDocument8 pagesCare For Life and Equipment: Dust Suppression For Bulk Transfer Points Made in GermanyMaikPortnoyNo ratings yet

- Downdraft LRDocument4 pagesDowndraft LRkenNo ratings yet

- PPSPPA Solid Waste GuidelineDocument32 pagesPPSPPA Solid Waste GuidelineSooYung YongNo ratings yet

- Telestack Track Conveyors Brochure 2017Document12 pagesTelestack Track Conveyors Brochure 2017Alok MehtaNo ratings yet

- Textile Technology Internship ReportDocument24 pagesTextile Technology Internship Reportgunashekarkalluri100% (1)

- Russian GFRP Rebars Bend Mesh Machines and Technology 1667726954Document20 pagesRussian GFRP Rebars Bend Mesh Machines and Technology 1667726954Rdvn YgtNo ratings yet

- Ote Outotec Vibrating Compactor Eng WebDocument4 pagesOte Outotec Vibrating Compactor Eng WebGupta AnacoolzNo ratings yet

- Film Processor Operation Manual: Protec Medizintechnik GMBH & Co. KGDocument46 pagesFilm Processor Operation Manual: Protec Medizintechnik GMBH & Co. KGEdward Pérez ArangurenNo ratings yet

- HT Xlpe CableDocument10 pagesHT Xlpe CableJaks JaksNo ratings yet

- 12d. Chain Washing Unit (Compact)Document2 pages12d. Chain Washing Unit (Compact)Ronald Fernandez ManubuluNo ratings yet

- Corona & Plasma: For ExtrusionDocument8 pagesCorona & Plasma: For ExtrusionHuy Tuan QuachNo ratings yet

- Spec Sheet 2000CDocument2 pagesSpec Sheet 2000CJamal HabbasNo ratings yet

- Static Cartridge Cleaning StationDocument10 pagesStatic Cartridge Cleaning StationsergeyNo ratings yet

- Drum Sieve Removes Coarse Particles for Machine ProtectionDocument4 pagesDrum Sieve Removes Coarse Particles for Machine ProtectionMauricio Viola CastellaNo ratings yet

- Lontto QT4-15 Fully Automatic Block Machine Production LineDocument15 pagesLontto QT4-15 Fully Automatic Block Machine Production LinegeoNo ratings yet

- LN Series PDFDocument18 pagesLN Series PDFLa Factoría de la CreatividadNo ratings yet

- Prospekt-844 EN LowResDocument6 pagesProspekt-844 EN LowResIslam ElhabsheNo ratings yet

- Glassware Washer Enquiry ProhsDocument1 pageGlassware Washer Enquiry ProhsSwingster SatNo ratings yet

- Midco Vaccum 6pagesDocument6 pagesMidco Vaccum 6pagesLuc DuchesneNo ratings yet

- DO-AT - 20181204 - CF-FBR ModuleDocument1 pageDO-AT - 20181204 - CF-FBR ModuleMohamed SalahNo ratings yet

- 1.0 Ethos 900 1.1 Introduction 1.2 Technical SpecificationsDocument80 pages1.0 Ethos 900 1.1 Introduction 1.2 Technical SpecificationsMuhannad NasifNo ratings yet

- Bromma - EH170U PDFDocument458 pagesBromma - EH170U PDFTopo MendigoNo ratings yet

- STREICHER Datenblatt Tiefbohranlage VDD 200 RUDocument4 pagesSTREICHER Datenblatt Tiefbohranlage VDD 200 RUShuriqqNo ratings yet

- HQ - 350 XT X-Ray ProcessorDocument4 pagesHQ - 350 XT X-Ray ProcessorBashir MtwaklNo ratings yet

- Daftar Keb Peralatan Ekofis 2012Document3 pagesDaftar Keb Peralatan Ekofis 2012Juang NugrahaNo ratings yet

- Elgin Hydrocyclone Cut Sheet 2019Document1 pageElgin Hydrocyclone Cut Sheet 2019Andrew GoadNo ratings yet

- The Engineering of Microprocessor Systems: Guidelines on System DevelopmentFrom EverandThe Engineering of Microprocessor Systems: Guidelines on System DevelopmentNo ratings yet

- 2022.10.28 3 Phase Decanter CentrifugeDocument14 pages2022.10.28 3 Phase Decanter CentrifugeGeorgeNo ratings yet

- 2020.4 GNZCQ Vacuum Degasser Manual (REV01)Document36 pages2020.4 GNZCQ Vacuum Degasser Manual (REV01)GeorgeNo ratings yet

- BHDecat072013_bu0930Lexar_From080607 10/3/14 12:15 Am Page 12Document1 pageBHDecat072013_bu0930Lexar_From080607 10/3/14 12:15 Am Page 12Prime Energy Warehouse-YemenNo ratings yet

- User Manual for GNZYQ Mud Gas SeparatorDocument14 pagesUser Manual for GNZYQ Mud Gas SeparatorGeorge100% (1)

- 2021.05.21 Vertical Cuttings DryerDocument12 pages2021.05.21 Vertical Cuttings DryerGeorgeNo ratings yet

- 2021.07.08 ViST Vacuum Screen TechnologyDocument11 pages2021.07.08 ViST Vacuum Screen TechnologyGeorgeNo ratings yet

- Solids Control & Waste Management: 02/april/2023Document48 pagesSolids Control & Waste Management: 02/april/2023GeorgeNo ratings yet

- V4 10M Mining Vibrating Screen 2023.02.10Document41 pagesV4 10M Mining Vibrating Screen 2023.02.10GeorgeNo ratings yet

- Screw Conveyor U-Type Conveying EquipmentDocument8 pagesScrew Conveyor U-Type Conveying EquipmentGeorgeNo ratings yet

- 2022.10.27B Dewatering Screw PressDocument16 pages2022.10.27B Dewatering Screw PressGeorgeNo ratings yet

- Innovative Separation Technology Provider Develops Customized SolutionsDocument12 pagesInnovative Separation Technology Provider Develops Customized SolutionsGeorgeNo ratings yet

- Data Sheet ITE Vertical Clarifier VC2500 Version1 3 EDocument2 pagesData Sheet ITE Vertical Clarifier VC2500 Version1 3 EGeorgeNo ratings yet

- Zoho Workplace Vs G WorkspaceDocument12 pagesZoho Workplace Vs G WorkspaceGeorgeNo ratings yet

- Mobile Vibration Screening MachineDocument2 pagesMobile Vibration Screening MachineGeorgeNo ratings yet

- Data Sheet ITE AutoFlock3000 Version1 3 EDocument2 pagesData Sheet ITE AutoFlock3000 Version1 3 EGeorgeNo ratings yet

- 2022.11.09 Oil Sludge Treatment SystemDocument41 pages2022.11.09 Oil Sludge Treatment SystemGeorgeNo ratings yet

- Data Sheet ITE MiniFlock Version1 3 EDocument2 pagesData Sheet ITE MiniFlock Version1 3 EGeorgeNo ratings yet

- Data Sheet ITE HVR300 HVR380 Version1 3 EDocument2 pagesData Sheet ITE HVR300 HVR380 Version1 3 EGeorgeNo ratings yet

- Section 14 - Solids Control and Drilling Waste Management PDFDocument153 pagesSection 14 - Solids Control and Drilling Waste Management PDFEjaz ul Haq kakar100% (1)

- GFEI International Comparison of Light-Duty Vehicle Fuel Economy - Evolution Over Eight Years From 2005 To 2013 - TransportDocument21 pagesGFEI International Comparison of Light-Duty Vehicle Fuel Economy - Evolution Over Eight Years From 2005 To 2013 - TransportRayane LimaNo ratings yet

- Problem solving and decision making in nutrition postgraduate studiesDocument55 pagesProblem solving and decision making in nutrition postgraduate studiesteklayNo ratings yet

- Mfi in GuyanaDocument19 pagesMfi in Guyanadale2741830No ratings yet

- Course 4Document3 pagesCourse 4Ibrahim SalahudinNo ratings yet

- Air Brake System For Railway CoachesDocument40 pagesAir Brake System For Railway CoachesShashwat SamdekarNo ratings yet

- Sample Id: Sample Id: 6284347 Icmr Specimen Referral Form Icmr Specimen Referral Form For For Covid-19 (Sars-Cov2) Covid-19 (Sars-Cov2)Document2 pagesSample Id: Sample Id: 6284347 Icmr Specimen Referral Form Icmr Specimen Referral Form For For Covid-19 (Sars-Cov2) Covid-19 (Sars-Cov2)Praveen KumarNo ratings yet

- Synchronous Motor - InstruDocument12 pagesSynchronous Motor - InstruMohit IndurkarNo ratings yet

- Few Words About Digital Protection RelayDocument5 pagesFew Words About Digital Protection RelayVasudev AgrawalNo ratings yet

- Difference between Especially and SpeciallyDocument2 pagesDifference between Especially and SpeciallyCarlos ValenteNo ratings yet

- Letter of Invitation ESVC 3000 2024 1Document2 pagesLetter of Invitation ESVC 3000 2024 1pradeep kumarNo ratings yet

- CENELEC RA STANDARDS CATALOGUEDocument17 pagesCENELEC RA STANDARDS CATALOGUEHamed AhmadnejadNo ratings yet

- Confidentiality Agreement With Undertaking and WaiverDocument1 pageConfidentiality Agreement With Undertaking and WaiverreddNo ratings yet

- Audiology DissertationDocument4 pagesAudiology DissertationPaperWritingHelpOnlineUK100% (1)

- BRTU-2000 Remote Terminal Unit for High Voltage NetworksDocument2 pagesBRTU-2000 Remote Terminal Unit for High Voltage NetworksLaurentiuNo ratings yet

- Introduction To Google SheetDocument14 pagesIntroduction To Google SheetJohn Rey Radoc100% (1)

- Workbook. Unit 3. Exercises 5 To 9. RESPUESTASDocument3 pagesWorkbook. Unit 3. Exercises 5 To 9. RESPUESTASRosani GeraldoNo ratings yet

- Alicrite StringDocument4 pagesAlicrite Stringtias_marcoNo ratings yet

- Marvin Elevate-Catalog Feb 2023 19981914Document27 pagesMarvin Elevate-Catalog Feb 2023 19981914DiegoNo ratings yet

- Pro Ducorit UkDocument2 pagesPro Ducorit Uksreeraj1986No ratings yet

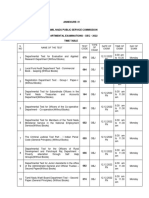

- ANNEXURE IV Dec 2022 enDocument17 pagesANNEXURE IV Dec 2022 enadvocacyindyaNo ratings yet

- Panasonic SA-HT878Document82 pagesPanasonic SA-HT878immortalwombatNo ratings yet

- Practical Problems On CustomsDocument13 pagesPractical Problems On Customsnousheen riya67% (3)

- Continuous Improvement Strategies in TQMDocument28 pagesContinuous Improvement Strategies in TQMSimantoPreeomNo ratings yet

- Bioprocess Engineering QuestionsDocument13 pagesBioprocess Engineering QuestionsPalanisamy Selvamani100% (1)

- Lesson Plan in ESPDocument4 pagesLesson Plan in ESPkaren daculaNo ratings yet

- PBL PgamboaDocument6 pagesPBL PgamboaLeanne Princess GamboaNo ratings yet

- NAFTA CertificateDocument2 pagesNAFTA Certificateapi-522706100% (4)

- Barcode BasicsDocument3 pagesBarcode Basicsnikhilbajpai_88No ratings yet

- Appendix A - Status Messages: Armed. Bad Snubber FuseDocument9 pagesAppendix A - Status Messages: Armed. Bad Snubber Fuse이민재No ratings yet