Professional Documents

Culture Documents

Sheet Pi PC 200

Uploaded by

Fajar ArdiantoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sheet Pi PC 200

Uploaded by

Fajar ArdiantoCopyright:

Available Formats

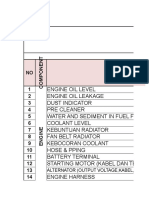

APLICABLE FOR : PC 200-8 MECHANIC : 1.

CHECK SHEET PERIODIC INSPECTION DATE : : 2.

PC200-8 PIT STOP LOC : : 3.

: 4.

ZONE 1 : Upper Front Area & Central Frame GROUP LEADER :

CN UNIT

TIME

NO PICTURE ITEM ACTIVITY

(SEC) HM UNIT

SAFETY

1 Lock out and emergency stop switch function Check

2 Unit number (Front) Check

TOP,CABIN AND ELECTRIC

3 Head lamp,fog lamp,side lamp,rear lamp and turn lamp condition Check

4 Operator complain Ask

5 Cat Walk Cabbin Check

6 Lh and Rh front step and vertical ladder condition Check

7 Engine air filter service indicator & air cleaner Check

8 Radiator coolant level Check/add

9 Air intake lines system Check

10 All warning lamp and fault code Check

C

11 B All lighting switch function Check

12 Wiper function Check

D

13 Side and front mirror condition Check

14 Operator seat,seat belt and mounting condition Check

15 A Instrument panel,wiring and gauge function Check

16 E Air conditioner function and filter condition Check

17 Operator cabin for dirt,mounting and damage accessories Check

18 Hand rail and mounting Check

19 Battery condition (electrolyte,terminal,wiring and clamp) Check

20 Exhaust tube / flexible muffler condition Check

H D

21 Fire supression and APAR pressure indicator must in the green area Check

22 Grease pump,tank,level,harness,and hoses condition Check/add

I

23 Horn & APAR Check

24 Joystick LH & RH Check

25 Pedal travel RH & LH Check

Radio Check

START UP PREPARATION & RUNNING Check

26 Starting and charging system Check

27 Engine Abnormal noise Check

28 Exhaust smoke colour Check

Check

Check

Time start

NOTE : Time finish

Duration

Sign

Assigned by Reported by

(Supervisor) (Group Leader)

APLICABLE FOR : PC 200-8 MECHANIC : 1.

CHECK SHEET PERIODIC INSPECTION

DATE : : 2.

PC200-8 PIT STOP LOC : : 3.

: 4.

ZONE 2 : Front Attachment and Track Group GROUP LEADER :

CN UNIT

TIME

NO PICTURE ITEM ACTIVITY

(SEC) HM UNIT

SAFETY

1 Lock out and emergency stop switch function Check

2 Unit number (Rh,Lh,Rear) Check

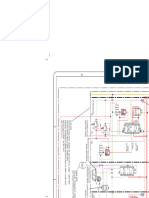

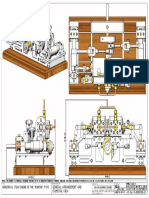

ENGINE,HYDRAULIC,TRANSMISSION,FINAL DRIVE & FRAME

3 Arround the unit Check

4 Water and sediment separator Check

5 Water,fuel,or oil leakage arround engine Check

6 Fuel pump and water pump condition Check

7 Wiring,sensor and connector for loosenes Check

8 Engine oil level Check/add

9 Engine fan,radiator fin,V- Belt condition and tension Check/adjust

10 Engine mounting bolt tighten Check

11 Hydraulic oil level and hydraulic tank mounting & breather Check/add

12 Main PUMP Check

13 Related Hose of Main Pump Check

14 Damper of Main pump Check/add

15 Electric Related of Main Pump Check

16 Related Hose & Filter Pilot Control Check

17 Lubrication Tube of PTO Check

18 Control Valve Check

19 Related Hose & piping of C/V Check

20 Damper of C/V Check

21 Electric Sensor & Wiring Condition Check

22 Piping around control valve Check

23 Front Swing Machinery Oil Level Check/add

24 Front Swing Motor Related Hose Check

25 Rear Swing Machinery Oil Level Check/add

26 Rear Swing Motor Related Hose Check

27 Swivel Joint Check

28 Swivel Joint Hose Connection Check

29 All joints / pin for dry grease Check

30 Revolving Frame & Chasis crack condition Check

31 Fan Radiator Check

32 Fan Drive Motor Radiator Check

33 TRACK Frame RH & LH Check

34 Idler RH & LH Check

35 Sprocket RH & LH Check

36 ALL Roller Check

37 Tension of Track RH & LH Check

38 Attachment Boom,Arm & Bucket Check

39 Arm Attachment Check

40 Cylinder Boom, Arm & bucket Check

41 Trave Motor & Cover ( RH- LH ) Check

42 FINAL DRIVE oil level & oil leaks ( RH - LH ) Check

Time start

NOTE : Time finish

Duration

Sign

Assigned by Reported by

(Supervisor) (Group Leader)

You might also like

- Mazda B2600 PDFDocument166 pagesMazda B2600 PDFluis sanchez100% (3)

- 21-Crane Inspection Check ListDocument2 pages21-Crane Inspection Check ListKhuda Buksh100% (1)

- Fm200 System Test Report Formats Index SL - No Description Document No. A Erection Control Forms For FM200 SystemDocument2 pagesFm200 System Test Report Formats Index SL - No Description Document No. A Erection Control Forms For FM200 SystemAneesh ConstantineNo ratings yet

- Transformer Check ListDocument2 pagesTransformer Check ListKanhiya Prasad100% (3)

- Grader Daily Inspection ChecklistDocument2 pagesGrader Daily Inspection ChecklistRolly89% (9)

- Marine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersFrom EverandMarine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersRating: 5 out of 5 stars5/5 (2)

- Yanmar Models YSM8-R YSM8-Y YSM12-R YSM12-Y Marine Diesel EnginesDocument197 pagesYanmar Models YSM8-R YSM8-Y YSM12-R YSM12-Y Marine Diesel EnginesHal PalmerNo ratings yet

- Field Quality Plan: BusbarsDocument3 pagesField Quality Plan: BusbarsSourav RanaNo ratings yet

- Maintenance Lift & EscalatorDocument6 pagesMaintenance Lift & EscalatorAndrie Eka saputraNo ratings yet

- Chemical Reactions For KS3 - WorksheetDocument3 pagesChemical Reactions For KS3 - Worksheetmadam100% (1)

- B25D+Mk6.1 Rev.A First+Issue Jan+2010Document678 pagesB25D+Mk6.1 Rev.A First+Issue Jan+2010Ravinder SinghNo ratings yet

- Inspection Unit PC 200Lc - 8moDocument28 pagesInspection Unit PC 200Lc - 8moBima AditamaNo ratings yet

- Sauer Danfoss PV PumpDocument11 pagesSauer Danfoss PV PumpCristian100% (2)

- Side Boom Crane Daily Inspection ChecklistDocument1 pageSide Boom Crane Daily Inspection ChecklistBorislav VulićNo ratings yet

- Function Checks Is Not Applicable For This Panel: Switchgear Functional TestDocument3 pagesFunction Checks Is Not Applicable For This Panel: Switchgear Functional Testeswaran005No ratings yet

- FAT Precedure - R 072 Nitrogen PackageDocument10 pagesFAT Precedure - R 072 Nitrogen PackageBudi UtomoNo ratings yet

- Manual Verifier HR FSX 090Document70 pagesManual Verifier HR FSX 090Stephen Jackson100% (1)

- Chapter 03Document49 pagesChapter 03Ubeimar Rivera Ospina100% (1)

- ENG Connecting DEC To MErcedes m102Document3 pagesENG Connecting DEC To MErcedes m102Vincent RenaNo ratings yet

- QAF 2001 Rev. 1 Batch Mixer PM1 ChecklistDocument1 pageQAF 2001 Rev. 1 Batch Mixer PM1 ChecklistMohamed El-SawahNo ratings yet

- 00 Truck Crane Inspection FormDocument10 pages00 Truck Crane Inspection FormRiza DSNo ratings yet

- Form Comissioning EXCAVATORDocument1 pageForm Comissioning EXCAVATORAysenNo ratings yet

- Periodical Service Form Unit Model: Komatsu HM 400Document3 pagesPeriodical Service Form Unit Model: Komatsu HM 400lilikNo ratings yet

- Daily PC1250 FormDocument1 pageDaily PC1250 FormlilikNo ratings yet

- Daily Check Sheet PC2000-8 & PC1250 0708Document6 pagesDaily Check Sheet PC2000-8 & PC1250 0708Ferry SandraNo ratings yet

- DTC P0418 Secondary Air Injection System Control "A" CircuitDocument7 pagesDTC P0418 Secondary Air Injection System Control "A" CircuitOrkhon GanchimegNo ratings yet

- MXR Merged PDFDocument6 pagesMXR Merged PDFIzzeldin ZakiNo ratings yet

- Form Commisioning - Dozer-EDITEDDocument2 pagesForm Commisioning - Dozer-EDITEDWahyuni HSENo ratings yet

- Crane (Lifting Eq) Commissioning Safety ChecklistDocument2 pagesCrane (Lifting Eq) Commissioning Safety Checklistjeffry EscletoNo ratings yet

- Inspection Fact Sheet Remote Operated Choke Units - R42 V2 May2010Document1 pageInspection Fact Sheet Remote Operated Choke Units - R42 V2 May2010eng7mohamed7hashimNo ratings yet

- Lead Stringer Monthly Check ListDocument2 pagesLead Stringer Monthly Check ListkotimarriagephotosNo ratings yet

- Check Sheet Hd785-7Document11 pagesCheck Sheet Hd785-7Alexander IaNo ratings yet

- Form Recom Water TruckDocument2 pagesForm Recom Water TruckARNo ratings yet

- Chapter 03 CompleteDocument80 pagesChapter 03 CompleteUbeimar Rivera OspinaNo ratings yet

- Chapter 03 Machine FamiliarizationDocument57 pagesChapter 03 Machine FamiliarizationUbeimar RiveraNo ratings yet

- Assesor PC 135Document2 pagesAssesor PC 135Smk Muhammadiyah Tiga SamarindaNo ratings yet

- Hardrock Attachments Pvt. LTD.: Preventive Maintenance ChecklistDocument1 pageHardrock Attachments Pvt. LTD.: Preventive Maintenance ChecklistSandeep KumarNo ratings yet

- Excitation System & Governor ChecksheetDocument1 pageExcitation System & Governor ChecksheetNazim MirzaNo ratings yet

- Ceeq-Imsf-64 Preventive Maintenance ReportDocument1 pageCeeq-Imsf-64 Preventive Maintenance ReportinfoNo ratings yet

- Daily Safety Check-List For The Passenger Hoists: Month: Date Site Name: Machine Sr. No.Document1 pageDaily Safety Check-List For The Passenger Hoists: Month: Date Site Name: Machine Sr. No.Avinash MulikNo ratings yet

- Ac Previntive and Corrective MaintenanceDocument3 pagesAc Previntive and Corrective MaintenanceRaed Al-HajNo ratings yet

- Auto Buff PM Check ListDocument1 pageAuto Buff PM Check ListPiyush VyasNo ratings yet

- Yatih B1.3 TasksDocument4 pagesYatih B1.3 TasksGovind SinghNo ratings yet

- Operation Patrol Checklist - CIP IIDocument5 pagesOperation Patrol Checklist - CIP IIJaime Hiquiana Jr.No ratings yet

- Profitest Gossen MetrawattDocument90 pagesProfitest Gossen MetrawattDalibor StojanovicNo ratings yet

- ThermOrion Monitor 1811EL Instr D802Document49 pagesThermOrion Monitor 1811EL Instr D802Karim MagdyNo ratings yet

- (HSE-ForM-A.05) Form Inspection Rough Terrain CraneDocument6 pages(HSE-ForM-A.05) Form Inspection Rough Terrain CraneIvansyah SastrowardoyoNo ratings yet

- General Equipment Symbols: Control Signs and SymbolsDocument6 pagesGeneral Equipment Symbols: Control Signs and SymbolsSophie MendezNo ratings yet

- Climatemaster Tch060afc30clss Article 1399042103489 en IIDocument52 pagesClimatemaster Tch060afc30clss Article 1399042103489 en IIwojciech.matenkaNo ratings yet

- f5071240 WLST1305-02W.book PDFDocument6 pagesf5071240 WLST1305-02W.book PDFdhanysiregarNo ratings yet

- Formulario de Mantenimiento 1Document2 pagesFormulario de Mantenimiento 1Marco Arias MartinezNo ratings yet

- Inspection Feb&part 2022Document26 pagesInspection Feb&part 2022Ainur Bamol NamsembilanNo ratings yet

- TDC - YER.1.00000 Updated (TDS-3)Document4 pagesTDC - YER.1.00000 Updated (TDS-3)Mohamed AnwarNo ratings yet

- New Form Daily Check WADocument3 pagesNew Form Daily Check WAAzura ZameNo ratings yet

- SOP Inspection of Ligtning Arrester GIS & MTR 150KV - Number UpdateDocument7 pagesSOP Inspection of Ligtning Arrester GIS & MTR 150KV - Number UpdateInghon SilalahiNo ratings yet

- AC FL-Electric CircuitDocument32 pagesAC FL-Electric CircuitRenato SanchezNo ratings yet

- PCM Inspection (L8, LF, L3) Using SST (WDS or Equivalent) NoteDocument15 pagesPCM Inspection (L8, LF, L3) Using SST (WDS or Equivalent) NotenikolaiNo ratings yet

- Check ListDocument9 pagesCheck ListekoimampNo ratings yet

- Electrical Panel Inspection Form: Function Ampere Trip of ELCB Function The Trip Time of ELCBDocument1 pageElectrical Panel Inspection Form: Function Ampere Trip of ELCB Function The Trip Time of ELCBdaryonoNo ratings yet

- Truck Check List FormatDocument2 pagesTruck Check List FormatScribdTranslationsNo ratings yet

- Form Mekanik AndrewDocument19 pagesForm Mekanik AndrewDoedoey ChNo ratings yet

- E0 Operation and Maintenance ManualDocument41 pagesE0 Operation and Maintenance ManualVoicu KostyNo ratings yet

- Form Recom TrailerDocument2 pagesForm Recom TrailerARNo ratings yet

- Schematic Manual 9-20-05Document66 pagesSchematic Manual 9-20-05Алексей МироновNo ratings yet

- Cat Dcs Sis Controller4Document15 pagesCat Dcs Sis Controller4Seba BoreseNo ratings yet

- Part B - Fire Safety - (2017) Volume 2 - Dwelling HousesDocument98 pagesPart B - Fire Safety - (2017) Volume 2 - Dwelling HousesBarry WalshNo ratings yet

- 3 of 3 Worksheet Class Viii Science L-6combustion and FlameDocument4 pages3 of 3 Worksheet Class Viii Science L-6combustion and FlameRekha kumariNo ratings yet

- M Monitor A3 Sheet 01Document1 pageM Monitor A3 Sheet 01منبر العلمNo ratings yet

- Electrician TestDocument6 pagesElectrician TestHassan AlawamiNo ratings yet

- PT PJB Services - Local Grid - Hybrid Power Plants On The Bawean Island Isolated SystemDocument21 pagesPT PJB Services - Local Grid - Hybrid Power Plants On The Bawean Island Isolated SystemilhamNo ratings yet

- Physics Work Energy Power MCQDocument6 pagesPhysics Work Energy Power MCQdavididosa40No ratings yet

- WH-SDC0509L3E5_+_WH-WDG05LE5-huDocument4 pagesWH-SDC0509L3E5_+_WH-WDG05LE5-hupipacsharcosNo ratings yet

- STANADYNEDocument1 pageSTANADYNELabib MoussaNo ratings yet

- Prexos 10 144 GG 22 R04Document2 pagesPrexos 10 144 GG 22 R04lsjayakumarNo ratings yet

- General Notes:: This SiteDocument4 pagesGeneral Notes:: This SiteLouJanisLaudeNo ratings yet

- Piping Design According To International Codes To Prevent Acoustically Induced Vibration Fatigue FailuresDocument11 pagesPiping Design According To International Codes To Prevent Acoustically Induced Vibration Fatigue FailuresTeknologi TermutakhirNo ratings yet

- Improvement of Power Quality in Wind Energy System Using StatcomDocument8 pagesImprovement of Power Quality in Wind Energy System Using StatcomRtkNo ratings yet

- 02 - Cabin Slim Ac Ug 2 D - 21 enDocument13 pages02 - Cabin Slim Ac Ug 2 D - 21 enkdc termice100% (1)

- Ideal Panel ScheduleDocument10 pagesIdeal Panel ScheduleAbdelrahman shokryNo ratings yet

- BS 5472 Low Voltage Switchgear and Controlgear For Industrial Use. Terminal Marking and Distinctive NumberDocument14 pagesBS 5472 Low Voltage Switchgear and Controlgear For Industrial Use. Terminal Marking and Distinctive NumberMohamed987No ratings yet

- BS en 60335-2-109-2010+a2-2018 - (2020-02-12 - 12-40-25 PM)Document24 pagesBS en 60335-2-109-2010+a2-2018 - (2020-02-12 - 12-40-25 PM)Felipe BastiasNo ratings yet

- Clean Energy Technology Observatory Renewable fuels-KJNA31292ENNDocument59 pagesClean Energy Technology Observatory Renewable fuels-KJNA31292ENNismailayarNo ratings yet

- C2 Epa2Document59 pagesC2 Epa2Rimac založno pravoNo ratings yet

- 6 Syllabus ISEDocument22 pages6 Syllabus ISEDHANUSH KILVIDHI VIJAYNo ratings yet

- System Operation Engine Cooling 1.6 Duratec 16V Ti VCTDocument2 pagesSystem Operation Engine Cooling 1.6 Duratec 16V Ti VCTIsmael LopezNo ratings yet

- Pinched Tube ReactorDocument8 pagesPinched Tube ReactorManoj BNo ratings yet

- Philippine Electrical Wiring PECDocument70 pagesPhilippine Electrical Wiring PECRichard CelinoNo ratings yet

- Participants BioDocument1 pageParticipants BioDobler LilianaNo ratings yet

- Fimer Stringsizer - Configuration Report: Location Temperature (°C) Amb Cell Mounting MethodDocument1 pageFimer Stringsizer - Configuration Report: Location Temperature (°C) Amb Cell Mounting MethodIvan BychekNo ratings yet

- Philippine Inventions: Jeffsalonga, PTRPDocument54 pagesPhilippine Inventions: Jeffsalonga, PTRPANDREA RABANGNo ratings yet