Professional Documents

Culture Documents

Control

Uploaded by

Beke derejeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Control

Uploaded by

Beke derejeCopyright:

Available Formats

The human lab or requires frequent opening and closing of the valve in the middle.

The operation time is

too long and the human resources will be wasted a lot. Therefore, we propose a control system

composed of S7-200PLC through the connector of SINEC L1 network. And add 1 solenoid valve (2 in

total) to the original two venting valves, and add 4 solenoid valves to the drainage system of the two

sewage tanks respectively, and the 10 solenoid valves are S7-200PLC SMART Control system to the

extent of design, Sewerage purification control systems have been established to achieve the purpose of

automatic extraction and purification of sewage. The structure of the control system is

shown in Figure 1.The operation panel has function buttons of the washing machine, and the detection

signals include position detection of various nozzles, position detection of the blowing device, position

detection of the body of the washing machine, detection of the defect position of each motor, position

detection of the body of the washing machine, and each Motor defect and overload detection. This

detection signal is connected to the input of the S7-200 SMART as the opening point of the detection

device. If there is a problem in the working part, the fault point can be found according to the status of

the various indicators on the input of the S7-200 SMART, which is very beneficial for the later

maintenance and repair work. The output load of the PLC includes a motor-controlled AC contactor, a

DC solenoid valve that controls the vehicle and the water supply, a light-emitting diode that is indicated

by the panel, and a buzzer alarm for the fault reminder.

You might also like

- Control of DC Motor Using Different Control StrategiesFrom EverandControl of DC Motor Using Different Control StrategiesNo ratings yet

- El - SRP - STP 550 Up To 4500Document44 pagesEl - SRP - STP 550 Up To 4500waleedyehiaNo ratings yet

- PLC Ans Scada ProjectDocument31 pagesPLC Ans Scada ProjectMaya Mayaa100% (1)

- Engine Fan Control Solenoid Circuit - Test: TroubleshootingDocument8 pagesEngine Fan Control Solenoid Circuit - Test: Troubleshootingtommy lanyonNo ratings yet

- Control Valves ArrangementDocument11 pagesControl Valves ArrangementPrasanna kumar subudhi100% (1)

- Automatic Water Pump ControllerDocument5 pagesAutomatic Water Pump Controllershannali50% (2)

- PLC Ans Scada ProjectDocument36 pagesPLC Ans Scada ProjectshinyNo ratings yet

- Smart Traffic Control System Using PLC ScadaDocument14 pagesSmart Traffic Control System Using PLC ScadaSaravanan ViswakarmaNo ratings yet

- ESD Valve Self Testing SystemDocument24 pagesESD Valve Self Testing SystempcherukaraNo ratings yet

- User's Manual: Oil Content Meter Model GQS-206Document19 pagesUser's Manual: Oil Content Meter Model GQS-206Bhayu alfianNo ratings yet

- Linear Control TCDocument46 pagesLinear Control TCjibranbaladiNo ratings yet

- FFFinal Car Wash PlanDocument19 pagesFFFinal Car Wash PlanBeke dereje100% (1)

- Lot 1 - WTP Operation Manual ReducedDocument43 pagesLot 1 - WTP Operation Manual Reducedapi-287457399No ratings yet

- Water LevelDocument36 pagesWater LevelPreet ChahalNo ratings yet

- The PROCON PH Process Control System Is Based Around The PH Rig and Is A SelfDocument10 pagesThe PROCON PH Process Control System Is Based Around The PH Rig and Is A Selfmiantahir89No ratings yet

- Project PLCDocument18 pagesProject PLCnarendramohan22No ratings yet

- Electrohydraulic Proportional Controls: User's Guidelines: A Due Stadi, Pilotate, Dimensioni ISO/Cetop 07 e 08Document5 pagesElectrohydraulic Proportional Controls: User's Guidelines: A Due Stadi, Pilotate, Dimensioni ISO/Cetop 07 e 08haggNo ratings yet

- Lab ReportDocument13 pagesLab ReportHemal MenukaNo ratings yet

- PLC Based Sequential Batch Process Control SystemDocument11 pagesPLC Based Sequential Batch Process Control SystemAmol PawarNo ratings yet

- Report - Pump Room AutomationDocument12 pagesReport - Pump Room AutomationtanujgateNo ratings yet

- Pressure Electric CurrentDocument72 pagesPressure Electric CurrentsheanNo ratings yet

- Sir C.R.Reddy College of Engineering: PLC Based Sequential Batch Process Control SystemDocument11 pagesSir C.R.Reddy College of Engineering: PLC Based Sequential Batch Process Control SystemParag RekhiNo ratings yet

- Ultra-Pure Water Treatment Power Supply MS Series: The Products Are Used For EDI, CEDI ModuleDocument41 pagesUltra-Pure Water Treatment Power Supply MS Series: The Products Are Used For EDI, CEDI ModuleBilal Malik100% (1)

- Ministry of Education West Yangon Technological University Department of Electronic EngineeringDocument9 pagesMinistry of Education West Yangon Technological University Department of Electronic EngineeringKg Myat HtutNo ratings yet

- Design and Application of Marine Boiler Control System Based On PLC and Touch ScreenDocument4 pagesDesign and Application of Marine Boiler Control System Based On PLC and Touch ScreenWai Min ThuNo ratings yet

- Festo Basic PLCDocument179 pagesFesto Basic PLCemylangamNo ratings yet

- IJSRDV8I20003Document3 pagesIJSRDV8I20003Ahmad HamoudaNo ratings yet

- Final Year ProjectDocument4 pagesFinal Year ProjectZain RiazNo ratings yet

- Hindustan Zinc Limited, Debari: Summer Training atDocument28 pagesHindustan Zinc Limited, Debari: Summer Training atJai MeenaNo ratings yet

- Automation of Hydraulic Structure: Indian Institute of Technology RoorkeeDocument31 pagesAutomation of Hydraulic Structure: Indian Institute of Technology RoorkeeTerex Z. LarvexNo ratings yet

- Chapter10 (Governors)Document10 pagesChapter10 (Governors)Zohaib Anser100% (1)

- Group 1 ProgressDocument8 pagesGroup 1 ProgressTharindu WimalasekaraNo ratings yet

- E21valve Remote Control SystemDocument13 pagesE21valve Remote Control System백승훈No ratings yet

- Ladder LogicDocument7 pagesLadder LogicCesar ChangNo ratings yet

- 1911 5805 1 PBDocument4 pages1911 5805 1 PBtt cheneyNo ratings yet

- Automata Severn TrentDocument8 pagesAutomata Severn Trentgeza_szabo5001No ratings yet

- Water Level Control LabDocument6 pagesWater Level Control Labdks697bvhcNo ratings yet

- Module # 1 Introduction To Control SystemDocument7 pagesModule # 1 Introduction To Control SystemImran ShaukatNo ratings yet

- PLC Basic Progr AM: Technological University of The Philippines - TaguigDocument30 pagesPLC Basic Progr AM: Technological University of The Philippines - Taguigch0k3 iiiNo ratings yet

- Systems Operation (SENR9167-02)Document11 pagesSystems Operation (SENR9167-02)Anderson Oliveira SilvaNo ratings yet

- PLC Final Project (Uthm)Document15 pagesPLC Final Project (Uthm)K.Magenthran (UTHM)100% (1)

- Speed Control SystemDocument8 pagesSpeed Control SystemDalton WiseNo ratings yet

- Bandyopadhyay 2018Document6 pagesBandyopadhyay 2018Sairam A J 18MAC0002No ratings yet

- Re95350 2006-03 PDFDocument12 pagesRe95350 2006-03 PDFrenatNo ratings yet

- 100-0320 - Válvula Cloromatica 70CV3000Document8 pages100-0320 - Válvula Cloromatica 70CV3000Armando Arboleda DuqueNo ratings yet

- Guidelines For Online ApplicationDocument26 pagesGuidelines For Online ApplicationAnonymous Xf4w0D2cNo ratings yet

- Implementation of Scada in Gas PipelineDocument50 pagesImplementation of Scada in Gas PipelinenwabukingzNo ratings yet

- PLC Based ProjectDocument4 pagesPLC Based ProjecteliasNo ratings yet

- Electrical Output Components: Operación de SistemasDocument11 pagesElectrical Output Components: Operación de SistemasPatricio Esteban Gallegos Tiska100% (1)

- PLC11Document4 pagesPLC11GODFREY MASHINGAIDZENo ratings yet

- PLC Program For ValveDocument5 pagesPLC Program For ValveInstrumentation ToolsNo ratings yet

- Annex 4-Draft Electrical Design Theme Phase 2-MariusDocument7 pagesAnnex 4-Draft Electrical Design Theme Phase 2-Mariusmarius barbuNo ratings yet

- Research On Servo Motor Motion Control System BaseDocument8 pagesResearch On Servo Motor Motion Control System BaseAhmed AliNo ratings yet

- F001Document6 pagesF001Leo VanNo ratings yet

- Modulo de Control de Osmosis PDFDocument15 pagesModulo de Control de Osmosis PDFrafaelNo ratings yet

- Vici Valco Manual PDFDocument9 pagesVici Valco Manual PDFTimor ForexNo ratings yet

- Water Level IndicatorDocument17 pagesWater Level Indicatorsubir_sealNo ratings yet

- Re95300 2007-12 PDFDocument16 pagesRe95300 2007-12 PDFrenatNo ratings yet

- Modul 4 PCT-100 Flow ControlDocument10 pagesModul 4 PCT-100 Flow ControlBagas Ghosa HidajatNo ratings yet

- Auto TransmissionDocument61 pagesAuto Transmissionlamping_apNo ratings yet

- CH 3Document11 pagesCH 3Beke derejeNo ratings yet

- Social ExclusionDocument1 pageSocial ExclusionBeke derejeNo ratings yet

- Basic StatDocument31 pagesBasic StatBeke derejeNo ratings yet

- CH 4Document14 pagesCH 4Beke derejeNo ratings yet

- CH 5Document21 pagesCH 5Beke derejeNo ratings yet

- CH 2Document28 pagesCH 2Beke derejeNo ratings yet

- UNITY UNIVERSITY KnouzDocument1 pageUNITY UNIVERSITY KnouzBeke derejeNo ratings yet

- UNITY UNIVERSITY MeronDocument1 pageUNITY UNIVERSITY MeronBeke derejeNo ratings yet

- Unity University SebrinDocument1 pageUnity University SebrinBeke derejeNo ratings yet

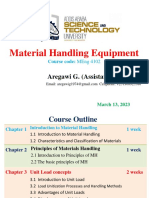

- Chapter 1 Introduction To MH - AregawiDocument32 pagesChapter 1 Introduction To MH - AregawiBeke derejeNo ratings yet

- ME 306 Part 4 Compressible FlowDocument15 pagesME 306 Part 4 Compressible FlowBeke derejeNo ratings yet

- SH Pump Rules SectionDocument10 pagesSH Pump Rules SectionBeke derejeNo ratings yet

- Aastu: DR by Bekele Dereje CHKD By: Amenu DATE:12-01-2023 ID NO:0121/12 Course Name: Mechanism SecDocument1 pageAastu: DR by Bekele Dereje CHKD By: Amenu DATE:12-01-2023 ID NO:0121/12 Course Name: Mechanism SecBeke derejeNo ratings yet

- MECH 430 Assignment 8Document6 pagesMECH 430 Assignment 8Beke derejeNo ratings yet

- Appendix Tables and ChartsDocument90 pagesAppendix Tables and ChartsBeke derejeNo ratings yet

- CHP 7 LectDocument18 pagesCHP 7 LectBeke derejeNo ratings yet

- Development of PIC18F4431 Microcontroller ControllDocument8 pagesDevelopment of PIC18F4431 Microcontroller ControllBeke derejeNo ratings yet

- Docsity Solution For Homework 2 Questions Mechatronics I Me 4734Document2 pagesDocsity Solution For Homework 2 Questions Mechatronics I Me 4734Beke derejeNo ratings yet

- Modulating Actuators Fa5a7804cab222efDocument16 pagesModulating Actuators Fa5a7804cab222efBeke derejeNo ratings yet

- M9203-AGx-2 Series On - Off and Floating Point Electric Spring Return Actuators Installation InstructionsDocument10 pagesM9203-AGx-2 Series On - Off and Floating Point Electric Spring Return Actuators Installation InstructionsBeke derejeNo ratings yet

- Air Conditioner Actuation SystemDocument2 pagesAir Conditioner Actuation SystemBeke derejeNo ratings yet

- PLC2Document3 pagesPLC2Beke derejeNo ratings yet