Professional Documents

Culture Documents

IMG - 0134 PSME Code 2008 126

Uploaded by

Arwyn BermasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IMG - 0134 PSME Code 2008 126

Uploaded by

Arwyn BermasCopyright:

Available Formats

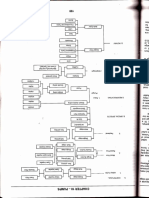

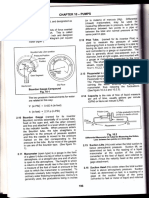

GHAPTER 6 - ELEVATORS, DUMBWAITERS, ESCALATORS AND MOVING WALKS

distance from center to center of adjoining the slider bed shall be reasonably smooth-

grooves shall be not more than 13 mm. It shall be so constructed and it will nct

Sides of the grooves may slope for mold support combustion.

draft purposes and may be filleted the

bottom. b. Roller Bed. Where the treadwaY b

supported on a series of rollers, ttte

c. lntermeshing Pellets' Alternate cleats on combination of roller spacing, belt tension,

adjacent pallets hsall intermesh so that and belt stiffness shall be such that the

there is no continuous transverse gap deflection of the treadway surface, midway

between adjacent Pallets. between roller, shall not exceed the quantity

0.239 mm plus 0.004 times the center b

d. Alignment of Pallet Tread Surfaces' center distance of rollers in millimeter when

Adjacent ends of pallets shall not vary in measures as follows:

elevation more than 1'6 mm.

The treadway surface shall be loaded

9.1.7 Treadway Slope. The slope of the treadway midway between rollers with a 11.3 kg

shall not exceed 3 degrees within 914 mm of weight concentrated on a cylindricd

the entrance and exit and shall not exceed 12 footpiece 51 mm long by 25 mm in diameter

placed with its long axis across the belL

beflection of this footpiece from its unloaded

Speed. Treadway speed shallconform to the position shall not exceed the figure obtained

9.1.8

following: above.

a. Maximum Speed. The maximum speed of The rollers shall be conventric and true

a treadway shall depend on the maximum running within commercially acceptable

slope at any point on the treadway. This tolerances.

speed shall not exceed the value

determined bY Table 6'9'1.8 (a).

c. Edge Supported Belt. When the treadway

b. Higher Speeds. The maximum speeds beli is transversely rigid and is supported by

listed in Table 6.9.1'8 (a) apply only to rollers along its edges, the following

' moving'walks having an entrance or exit to requirements shall aPPIY:

landings. lt is not intended to preclude

development of moving walk systems in 1. With the belt tensioned through the

which higher sPeeds are made safe take-uP sYstem, the Permissibb

practical, subject to the approval of the slope of a straight line from the top

enforcirig authoritY. of a treadwaY rib adjacent to the

balustrade, in a plane perpendicula

Table 6.9.1.8 (a) to the Path of the treadwaY shall nd

Tread Speed exceed 3% when the treadwaY b

loaded with a 68 kg weight on a 152

Maximum TreadwaY SloPe Maximum Treadway mm bY 254 mm Plate located on the

At any Point on TreadwaY, deg Speed, fpm centerline of the treadway with 25t

0to8 180 mm dimension in the direction d

Above 8lo 12 140 treadway travel.

NOTE:

2. ln order to support the treadway h

, case of localized overload, supports

1 radian = deg. x 0.0175

shall be suPPlied at intervals' nd

m/s = fpmx0.00508

exceeding 183 mm along tE

to centerline of the treadway. TtE

9.1.9 Supports. SuPPort shall conform the

supports shall be located at a

following:

not more than 51 mm below

underside of the treadwaY when it b

a. Slider Bed. The carrying portion of the

loaded under the test conditions

treadway shall be supported for its entire

width and length except where it passes required by the Prececirg

paragraph.

from a support to a pulley. The surface of

126

You might also like

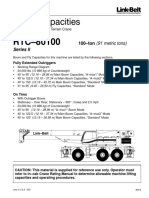

- Link-Belt HTC 8660Document8 pagesLink-Belt HTC 8660Gustavo276No ratings yet

- Activarlo en CMDDocument1 pageActivarlo en CMDGuillermina Delgado92% (12)

- Link Belt HTC 8660Document8 pagesLink Belt HTC 8660Diana Gabriela VillaNo ratings yet

- RTC8040-SII Linkbelt CapsDocument12 pagesRTC8040-SII Linkbelt CapsMongia MoghiNo ratings yet

- Load Charts RT890E: Serial NumberDocument22 pagesLoad Charts RT890E: Serial NumberFranck SPERZAGNI PUBNo ratings yet

- Badiou On BeckettDocument98 pagesBadiou On Beckettsensekang100% (3)

- NN Bhargava Basic Electronics and Linear Circuits PDFDocument169 pagesNN Bhargava Basic Electronics and Linear Circuits PDFJovin Pallickal Thomas67% (3)

- Brochure Movialsa Gasification Plant EnglishDocument0 pagesBrochure Movialsa Gasification Plant EnglishApri ApriyantoNo ratings yet

- IMG - 0130 PSME Code 2008 121Document1 pageIMG - 0130 PSME Code 2008 121Bugoy2023No ratings yet

- Weightometers in IndustryDocument3 pagesWeightometers in IndustryRamoutar (Ken) SeecharranNo ratings yet

- Link Belt HTC 8670 Charts PDFDocument8 pagesLink Belt HTC 8670 Charts PDFJose MorenoNo ratings yet

- Link Belt RTC8060Document12 pagesLink Belt RTC8060Jerome YangNo ratings yet

- Recommendations For Machine Design: Siegling TransilonDocument20 pagesRecommendations For Machine Design: Siegling Transilondesky nguyenNo ratings yet

- VHM CalculationDocument3 pagesVHM CalculationUjjwal Kumar SinghNo ratings yet

- Mobile Crane Safety: Factors Affecting Rated CapacityDocument3 pagesMobile Crane Safety: Factors Affecting Rated Capacityparamarthasom1974No ratings yet

- Figure 9.7 - Typical Confinement in Beam: 9.9.2.1 Longitudinal ReinforcementDocument2 pagesFigure 9.7 - Typical Confinement in Beam: 9.9.2.1 Longitudinal Reinforcementkc chanNo ratings yet

- CRW90 Computer VersionDocument97 pagesCRW90 Computer VersionRogelio Castillo AvalosNo ratings yet

- IMG - 0061 PSME Code 2008 50Document1 pageIMG - 0061 PSME Code 2008 50Master JaguarNo ratings yet

- On Site RTC 80130 R3K4-3399Document308 pagesOn Site RTC 80130 R3K4-3399srikanthc85No ratings yet

- Anexo Grove TMS 700B Tabla de Carga Load Chart - MCST 4A - 4B (v1.1)Document10 pagesAnexo Grove TMS 700B Tabla de Carga Load Chart - MCST 4A - 4B (v1.1)HERSON BORIS RIVERA REFULIONo ratings yet

- Lifting Capacities: Series IIDocument28 pagesLifting Capacities: Series IIsrikanthc85No ratings yet

- IMG - 0136 PSME Code 2008 128Document1 pageIMG - 0136 PSME Code 2008 128Arwyn BermasNo ratings yet

- Manual HTC-8690 PDFDocument243 pagesManual HTC-8690 PDFJennifer Ramos100% (1)

- Liftcrane Boom Capacities 555 SERIES 2: Manitowoc Cranes, IncDocument5 pagesLiftcrane Boom Capacities 555 SERIES 2: Manitowoc Cranes, IncDudu MartinezNo ratings yet

- IMG - 0132 PSME Code 2008 124Document1 pageIMG - 0132 PSME Code 2008 124Arwyn BermasNo ratings yet

- IMG - 0085 PSME Code 2008 76Document1 pageIMG - 0085 PSME Code 2008 76Bugoy2023No ratings yet

- Manitowoc 8500 1Document24 pagesManitowoc 8500 1Mohd FadliNo ratings yet

- IMG - 0069 PSME Code 2008 58Document1 pageIMG - 0069 PSME Code 2008 58Arwyn BermasNo ratings yet

- IMG - 0095 PSME Code 2008 86Document1 pageIMG - 0095 PSME Code 2008 86Arwyn BermasNo ratings yet

- Rigid Rod SystemDocument9 pagesRigid Rod SystemArun BabuNo ratings yet

- Filatex Project - O & M MANUAL - VOLUME I OF IIDocument48 pagesFilatex Project - O & M MANUAL - VOLUME I OF IID.V.S.S Ram PrasadNo ratings yet

- Verification Manual For Weighbridge1Document17 pagesVerification Manual For Weighbridge1afsajareenaNo ratings yet

- Hoistable Ramps: Technical InformationDocument4 pagesHoistable Ramps: Technical InformationAbdullah YılmazNo ratings yet

- 14.horizontal Assembly: Bucking UnitDocument8 pages14.horizontal Assembly: Bucking UnitBivolaru AndreiNo ratings yet

- Layout GuideDocument9 pagesLayout Guiderapidindustries100% (1)

- Siemens Belt ScalesDocument66 pagesSiemens Belt ScalesGilbertDominguezNo ratings yet

- RT 8090 TDocument96 pagesRT 8090 TjairseguraNo ratings yet

- Chapter 11. Cost Calculations For Highly Mechanized Cut-and-Fill StopingDocument50 pagesChapter 11. Cost Calculations For Highly Mechanized Cut-and-Fill StopingEdward RmzNo ratings yet

- Harvesting Systems and Equipment in British Columbia: Ministry of Forests Forest Practices BranchDocument13 pagesHarvesting Systems and Equipment in British Columbia: Ministry of Forests Forest Practices BranchJuan ReyesNo ratings yet

- IMG - 0029 PSME Code 2008 18Document1 pageIMG - 0029 PSME Code 2008 18Hnqr584hNo ratings yet

- Load Charts TMS750B: 85% StabilityDocument18 pagesLoad Charts TMS750B: 85% StabilityDarío Ache EmeNo ratings yet

- 305-Fms Recommendation Machine Design enDocument20 pages305-Fms Recommendation Machine Design envhbernaltNo ratings yet

- Img - 0020 Psme Code 2008 9Document1 pageImg - 0020 Psme Code 2008 9Hnqr584hNo ratings yet

- Transition Curves Superelevation and Pavement Widening DFSDocument2 pagesTransition Curves Superelevation and Pavement Widening DFSمهندس يحيى ابن وابريNo ratings yet

- TVF Tranšėjos Apsaugų Surinkimo Instrukcija ENDocument12 pagesTVF Tranšėjos Apsaugų Surinkimo Instrukcija ENemat41No ratings yet

- 4100 Ringer Traveling ConditionsDocument1 page4100 Ringer Traveling ConditionsStuart EdwardsNo ratings yet

- Application Guidelines: RF Belt Scale Application ManualDocument9 pagesApplication Guidelines: RF Belt Scale Application ManualBerada Otomasyon100% (1)

- 1.5 Belt Conveyors: Maximum Slope Raw Material, Wet Slag Clinker Cement Coal/PetcokeDocument4 pages1.5 Belt Conveyors: Maximum Slope Raw Material, Wet Slag Clinker Cement Coal/Petcokesigit s81No ratings yet

- 02 StabilityDocument8 pages02 StabilityLucky BoatNo ratings yet

- Callibrate Weigh FeederDocument6 pagesCallibrate Weigh FeederkINGNo ratings yet

- Safe Work Method - ConcretingDocument11 pagesSafe Work Method - ConcretingJustin Ranjit100% (1)

- Re Alignment After Wriggle Can Save Time and Money PDFDocument16 pagesRe Alignment After Wriggle Can Save Time and Money PDFArunNo ratings yet

- HW Installation Maintenance Troubleshooting Guide en PDFDocument48 pagesHW Installation Maintenance Troubleshooting Guide en PDFlukky prasetyoNo ratings yet

- IMG - 0128 PSME Code 2008 119Document1 pageIMG - 0128 PSME Code 2008 119Bugoy2023No ratings yet

- National - 1300 SeriesDocument10 pagesNational - 1300 SeriesELIZABETH FLETSCHERNo ratings yet

- Link Belt Rough Terrain Cranes Spec 9d470bDocument96 pagesLink Belt Rough Terrain Cranes Spec 9d470bMauro BatalhaNo ratings yet

- IRPWMDocument36 pagesIRPWMRanjeet Singh100% (1)

- Rigging Types and ConceptsDocument24 pagesRigging Types and ConceptsBoom DizzleNo ratings yet

- Spun Pile MosDocument5 pagesSpun Pile MosTinesh K RamanNo ratings yet

- Dynamic Load Test 1200mm DiaDocument6 pagesDynamic Load Test 1200mm DiaVB665100% (1)

- Back OffDocument3 pagesBack OffSasan AbbasiNo ratings yet

- IMG - 0313 MCQ Industrial Plant Engg 209Document1 pageIMG - 0313 MCQ Industrial Plant Engg 209Arwyn BermasNo ratings yet

- IMG - 0320 MCQ Industrial Plant Engg 223Document1 pageIMG - 0320 MCQ Industrial Plant Engg 223Arwyn BermasNo ratings yet

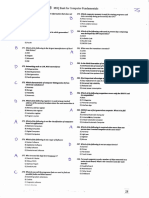

- IMG - 0094 MCQ Bank For Computer Fundamentals MRC 19Document1 pageIMG - 0094 MCQ Bank For Computer Fundamentals MRC 19Arwyn BermasNo ratings yet

- IMG - 0091 MCQ Bank For Computer Fundamentals MRC 16Document1 pageIMG - 0091 MCQ Bank For Computer Fundamentals MRC 16Arwyn BermasNo ratings yet

- IMG - 0100 MCQ Bank For Computer Fundamentals MRC 25Document1 pageIMG - 0100 MCQ Bank For Computer Fundamentals MRC 25Arwyn BermasNo ratings yet

- IMG - 0092 MCQ Bank For Computer Fundamentals MRC 17Document1 pageIMG - 0092 MCQ Bank For Computer Fundamentals MRC 17Arwyn BermasNo ratings yet

- IMG - 0292 MCQ Industrial Plant Engg 169Document1 pageIMG - 0292 MCQ Industrial Plant Engg 169Arwyn BermasNo ratings yet

- IMG - 0099 MCQ Bank For Computer Fundamentals MRC 24Document1 pageIMG - 0099 MCQ Bank For Computer Fundamentals MRC 24Arwyn BermasNo ratings yet

- IMG - 0095 MCQ Bank For Computer Fundamentals MRC 20Document1 pageIMG - 0095 MCQ Bank For Computer Fundamentals MRC 20Arwyn BermasNo ratings yet

- IMG - 0093 MCQ Bank For Computer Fundamentals MRC 18Document1 pageIMG - 0093 MCQ Bank For Computer Fundamentals MRC 18Arwyn BermasNo ratings yet

- IMG - 0096 MCQ Bank For Computer Fundamentals MRC 21Document1 pageIMG - 0096 MCQ Bank For Computer Fundamentals MRC 21Arwyn BermasNo ratings yet

- IMG - 0295 MCQ Industrial Plant Engg 175Document1 pageIMG - 0295 MCQ Industrial Plant Engg 175Arwyn BermasNo ratings yet

- IMG - 0097 MCQ Bank For Computer Fundamentals MRC 22Document1 pageIMG - 0097 MCQ Bank For Computer Fundamentals MRC 22Arwyn BermasNo ratings yet

- IMG - 0208 PSME Code 2008 197Document1 pageIMG - 0208 PSME Code 2008 197Arwyn BermasNo ratings yet

- IMG - 0210 PSME Code 2008 199Document1 pageIMG - 0210 PSME Code 2008 199Arwyn BermasNo ratings yet

- IMG - 0291 MCQ Industrial Plant Engg 167Document1 pageIMG - 0291 MCQ Industrial Plant Engg 167Arwyn BermasNo ratings yet

- IMG - 0205 PSME Code 2008 194Document1 pageIMG - 0205 PSME Code 2008 194Arwyn BermasNo ratings yet

- IMG - 0203 PSME Code 2008 192Document1 pageIMG - 0203 PSME Code 2008 192Arwyn BermasNo ratings yet

- IMG - 0207 PSME Code 2008 196Document1 pageIMG - 0207 PSME Code 2008 196Arwyn BermasNo ratings yet

- IMG - 0209 PSME Code 2008 198Document1 pageIMG - 0209 PSME Code 2008 198Arwyn BermasNo ratings yet

- IMG - 0201 PSME Code 2008 190Document1 pageIMG - 0201 PSME Code 2008 190Arwyn BermasNo ratings yet

- IMG - 0077 MCQ EE Board Problem 2012 34Document1 pageIMG - 0077 MCQ EE Board Problem 2012 34Arwyn BermasNo ratings yet

- IMG - 0075 MCQ EE Board Problem 2012 32Document1 pageIMG - 0075 MCQ EE Board Problem 2012 32Arwyn BermasNo ratings yet

- IMG - 0072 MCQ EE Board Problem 2012 29Document1 pageIMG - 0072 MCQ EE Board Problem 2012 29Arwyn BermasNo ratings yet

- IMG - 0073 MCQ EE Board Problem 2012 30Document1 pageIMG - 0073 MCQ EE Board Problem 2012 30Arwyn BermasNo ratings yet

- IMG - 0079 MCQ EE Board Problem 2012 36Document1 pageIMG - 0079 MCQ EE Board Problem 2012 36Arwyn BermasNo ratings yet

- IMG - 0076 MCQ EE Board Problem 2012 33Document1 pageIMG - 0076 MCQ EE Board Problem 2012 33Arwyn BermasNo ratings yet

- IMG - 0074 MCQ EE Board Problem 2012 31Document1 pageIMG - 0074 MCQ EE Board Problem 2012 31Arwyn BermasNo ratings yet

- IMG - 0078 MCQ EE Board Problem 2012 35Document1 pageIMG - 0078 MCQ EE Board Problem 2012 35Arwyn BermasNo ratings yet

- IMG - 0071 MCQ EE Board Problem 2012 28Document1 pageIMG - 0071 MCQ EE Board Problem 2012 28Arwyn BermasNo ratings yet

- 10-Effect of Chest Physical Therapy On Pediatrics Hospitalized With Pneumonia PDFDocument8 pages10-Effect of Chest Physical Therapy On Pediatrics Hospitalized With Pneumonia PDFandina100% (1)

- Complete Business Statistics: Simple Linear Regression and CorrelationDocument50 pagesComplete Business Statistics: Simple Linear Regression and CorrelationAli ElattarNo ratings yet

- Full Download Test Bank For Canadian Organizational Behaviour 8th Edition Mcshane PDF Full ChapterDocument36 pagesFull Download Test Bank For Canadian Organizational Behaviour 8th Edition Mcshane PDF Full Chapterpeelefisc7vnzww100% (17)

- How Does A Plant GrowDocument12 pagesHow Does A Plant GrowNajia UmarNo ratings yet

- Hpe0 J57Document29 pagesHpe0 J57malikanjum718435No ratings yet

- Lotus Sametime 3DDocument23 pagesLotus Sametime 3DsvrbchaudhariNo ratings yet

- The Strenuous Life - Scott JoplinDocument4 pagesThe Strenuous Life - Scott JoplinSirkSamaNo ratings yet

- Critical Reading, Using Reading Prompts To Promote Active Engagement With Text Final PDFDocument6 pagesCritical Reading, Using Reading Prompts To Promote Active Engagement With Text Final PDFemysamehNo ratings yet

- VenomDocument68 pagesVenomAbhishekNo ratings yet

- Maria Vail ResumeDocument2 pagesMaria Vail Resumeapi-360258460No ratings yet

- Datasheet Mikrokontroler AT89S51Document27 pagesDatasheet Mikrokontroler AT89S51Sri Maya SariNo ratings yet

- Marikina Polytechnic College: M1 Electrical Installation and Maintenance John Honorio A. CorderoDocument9 pagesMarikina Polytechnic College: M1 Electrical Installation and Maintenance John Honorio A. CorderoJohn Andrew Valenzuela PianoNo ratings yet

- Revision For The Midterm TestDocument3 pagesRevision For The Midterm TestLinh Tran KhanhNo ratings yet

- Synopsis On Employee Satisfaction Bhel NewDocument6 pagesSynopsis On Employee Satisfaction Bhel NewArchi guptaNo ratings yet

- Erp Sap Cours PDFDocument2 pagesErp Sap Cours PDFMattNo ratings yet

- Omnivista 8770 Network Management System Datasheet enDocument2 pagesOmnivista 8770 Network Management System Datasheet enAlexander MoralesNo ratings yet

- Delphi and Microsoft OfficeDocument27 pagesDelphi and Microsoft Officerico-alves7216No ratings yet

- Discursive Pragmatics Handbook of Pragmatics - Highlights - 2011Document325 pagesDiscursive Pragmatics Handbook of Pragmatics - Highlights - 2011Shaimaa Suleiman100% (6)

- Simulasi Vending Machine Dengan Mengimplementasikan Finite State AutomataDocument7 pagesSimulasi Vending Machine Dengan Mengimplementasikan Finite State AutomataSinggih PramanaNo ratings yet

- Bottle Jack: TON ToneladasDocument4 pagesBottle Jack: TON ToneladasMarĭo Isaac Manrĭquéz LealNo ratings yet

- Presentation OpenfoamDocument29 pagesPresentation OpenfoamSattar Al-JabairNo ratings yet

- Ch15 MaintenanceDocument12 pagesCh15 MaintenanceNdomadu100% (2)

- Scientific MethodDocument2 pagesScientific MethodEmerson Nunez100% (2)

- Wrench Time AnalysisDocument2 pagesWrench Time AnalysisJuan Pablo Villazon RichterNo ratings yet

- RRL - Perceived Effects of Laissez-Faire in Research Group SatisfactionDocument39 pagesRRL - Perceived Effects of Laissez-Faire in Research Group SatisfactionMark Darrel PerezNo ratings yet

- Module 3Document38 pagesModule 3Czarina GuillermoNo ratings yet