Professional Documents

Culture Documents

05usage of Portable Power Tool

05usage of Portable Power Tool

Uploaded by

Rues Ag0 ratings0% found this document useful (0 votes)

3 views2 pagesThis document provides a risk assessment for the usage of portable power tools. It identifies hazards such as electricity, moving parts, flying objects, dust, and noise. The severity, likelihood, and risk rating are provided for each hazard. Control measures are outlined to reduce the risks, including ensuring tools have inspection tags, using guards, PPE, and following legal requirements. Persons exposed are those using the tools and nearby workers. The assessment was performed by a risk assessment committee.

Original Description:

Original Title

05Usage of portable power tool

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a risk assessment for the usage of portable power tools. It identifies hazards such as electricity, moving parts, flying objects, dust, and noise. The severity, likelihood, and risk rating are provided for each hazard. Control measures are outlined to reduce the risks, including ensuring tools have inspection tags, using guards, PPE, and following legal requirements. Persons exposed are those using the tools and nearby workers. The assessment was performed by a risk assessment committee.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views2 pages05usage of Portable Power Tool

05usage of Portable Power Tool

Uploaded by

Rues AgThis document provides a risk assessment for the usage of portable power tools. It identifies hazards such as electricity, moving parts, flying objects, dust, and noise. The severity, likelihood, and risk rating are provided for each hazard. Control measures are outlined to reduce the risks, including ensuring tools have inspection tags, using guards, PPE, and following legal requirements. Persons exposed are those using the tools and nearby workers. The assessment was performed by a risk assessment committee.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

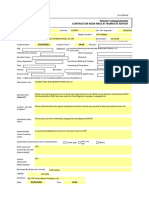

Document No OHS/RA/G-05

Risk Assessment Record

Revision No 00

Issue Date 01/01/2008

Power Projects USAGE OF PORTABLE POWER TOOL

Page No 1 of 2

Activity Description:- Usage of portable power tool.

Risk assessment reference number: PPD/RA/G-05

Details of the task/ operation:

• Tools/ machines involved: grinding m/ c, drill m/c, cutting m/c, buffing m/c

• Location specific hazards shall be identified by the site before starting the activity

Sub Activities

• Connecting the power tool to power line.

• Placement of job

• Carrying out required operation on job

• Removal of job

• Removal of Power connection

Hazard Severity Likelihood Risk Rating

(H- Hazards, C- Controls) (S) (L) (S*L)

H1 Electricity (C1,C2,C5,C13) 6 6 36

H2 Machinery - Moving parts (C1,C3,C4,C5,C6,C14,C15,C17,C18,C20) 3 3 9

H3 Flying objects/ particles 3 3 9

(C3,C4,C7,C8,C9,C10,C11,C12,C15,C19,C21)

H4 Fire (C16) 2 1 2

H5 Dust (respiratory) (C3,C4,C15) 2 3 6

H6 Noise (C15) 2 6 12

Harm

1. Injury to persons

2. Electric shock

3. fatality

4. Burn

5. Wrist pain

6. Breathing problem

7. Work related upper arm disorder.

8. Ringing in the ear/ deafness

Persons exposed

Person engaged in the work and persons working near by area.

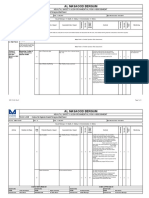

Document No OHS/RA/G-05

Risk Assessment Record

Revision No 00

Issue Date 01/01/2008

Power Projects USAGE OF PORTABLE POWER TOOL

Page No 2 of 2

Control measures to be taken:

C1 Ensure that the power tools are having inspection tags.

C2 Electric connection to be routed through ELCB’s only.

C3 Do not use PPT without guard wherever applicable.

C4 Do not leave the machine unattended while on the job.

C5 Do not attempt to carry out any adjustments / repair / cleaning while the machine is running.

C6 Do not meddle with ON / OFF switch of the power tool

C7 Periodically clean the goggles while working.

C8 Inspect the wheels for damage, expiry dates etc before fixing and carry out “tap test”.

C9 Grinding wheel shall be changed as per manufacturer’s instructions.

C10 Check the casing of the tools for any damage.

C11 Do not apply more pressure assuming that it will speed up the job.

C12 RPM rating of the grinding wheel should be more than the RPM of the machine

C13 Do not abuse the power tool. Use only industrial plugs and connectors

C14 Do not use the sides of the cutting wheel for sharpening etc. since it will lead to breakage of the wheel.

C15 Use PPE such as face shield (with elastic head band)/ goggles, ear plugs, dust mask

C16 Use hot work permit system wherever necessary. Remove flammable materials nearby

C17 Store the cutting/ grinding wheels in dry locations in the stores.

C18 Use proper hand tools for fixing wheels

C19 Keep the objects properly fixed. Do not hold the objects in an unsafe manner

C20 Avoid loose clothing/ use hair net

C21 Use appropriate barriers to control flying particles

Legal Requirements to be followed:

Section no: 10.1 of code of construction safety practice of DM. (ii) DM-TG-9,14,15,16,18,19

Training requirements of the personnel involved:

Inspection of Power tools, CPR, First Aid

Related emergency procedures, if any:

Emergency vehicle

Verification of the implementation of control measures:

Power tool inspection check sheet

Any other information:

Assessed by: Risk Assessment Committee

Review instructions:

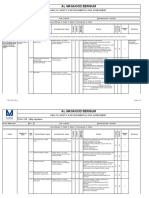

SEVERITY LIKELIHOOD

1 Negligible 91 to 100 1

2 Minor 75 to 90 2

3 Lost time injury 50 to 74 3

4 Major 25 to 49 4

5 Severe 6 to 24 5

6 Fatality 0 to 5 6

Severity of the Hazard × Likelihood of Occurrence = Risk rating.

1 – 7 Low

8 – 16 Medium

17- 36 High

You might also like

- 004 Risk Assesment Format For Arc WeldingDocument1 page004 Risk Assesment Format For Arc WeldingRavi Shankar Turlapati100% (3)

- BOTAI LED Display Price List 202310Document27 pagesBOTAI LED Display Price List 202310petermbiyu8447No ratings yet

- Induction Questionnaire A - NEW 2019Document2 pagesInduction Questionnaire A - NEW 2019Edgar Checa33% (3)

- AMB 172-014 Frame Cad OperationDocument3 pagesAMB 172-014 Frame Cad OperationRues AgNo ratings yet

- Theories, Models and Approaches Applied To Midwifery PracticesDocument111 pagesTheories, Models and Approaches Applied To Midwifery Practicesdr.anu Rk90% (10)

- Bibibonbon Yuta - The Little DogDocument7 pagesBibibonbon Yuta - The Little DogNastyа Sheyn100% (4)

- Chiller Plant RADocument2 pagesChiller Plant RAarifzakir67% (9)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- 10 WeldingDocument2 pages10 WeldingRues AgNo ratings yet

- 04 Piling Works 1Document2 pages04 Piling Works 1Rues AgNo ratings yet

- 09installation of Light FittingDocument2 pages09installation of Light FittingRues AgNo ratings yet

- 01installation of Construction SupplyDocument2 pages01installation of Construction SupplyRues AgNo ratings yet

- 04erection of PanelsDocument2 pages04erection of PanelsRues AgNo ratings yet

- 10installation of Cable TraysDocument2 pages10installation of Cable TraysRues AgNo ratings yet

- 17sheet Metal WorkDocument2 pages17sheet Metal WorkRues AgNo ratings yet

- 02erection of Heavy EquipmentDocument2 pages02erection of Heavy EquipmentRues AgNo ratings yet

- 11EOT Crane Hoist Load TestDocument2 pages11EOT Crane Hoist Load TestRues AgNo ratings yet

- Bryant C. Roldan: Project Management Contractor Near-Miss at Worksite ReportDocument15 pagesBryant C. Roldan: Project Management Contractor Near-Miss at Worksite ReportAyaz AhmadNo ratings yet

- Reynaldo Darcera: Project Management Contractor Near-Miss at Worksite ReportDocument15 pagesReynaldo Darcera: Project Management Contractor Near-Miss at Worksite ReportAyaz AhmadNo ratings yet

- Bryant C. Roldan: Project Management Contractor Near-Miss at Worksite ReportDocument15 pagesBryant C. Roldan: Project Management Contractor Near-Miss at Worksite ReportAyaz AhmadNo ratings yet

- Near Miss ReportDocument15 pagesNear Miss ReportAyaz AhmadNo ratings yet

- Nearmiss Report Uncoupling Trailer W #13Document15 pagesNearmiss Report Uncoupling Trailer W #13Alok SinghNo ratings yet

- IRP 22 Hazard and Risk Assessment Register: Column Headings Column LetterDocument29 pagesIRP 22 Hazard and Risk Assessment Register: Column Headings Column LetterKhuda Buksh100% (2)

- 2-Near Miss FormDocument15 pages2-Near Miss FormZeeshan AbbasiNo ratings yet

- Jorge Tariga: Project Management Contractor Near-Miss at Worksite ReportDocument15 pagesJorge Tariga: Project Management Contractor Near-Miss at Worksite ReportEever Paul De LeonNo ratings yet

- Reynaldo Darcera: Project Management Contractor Near-Miss at Worksite ReportDocument15 pagesReynaldo Darcera: Project Management Contractor Near-Miss at Worksite ReportAyaz AhmadNo ratings yet

- Construction Job Hazards Analysis: Hot TapDocument2 pagesConstruction Job Hazards Analysis: Hot TapMohammed MinhajNo ratings yet

- IGC2 Element4 Work Equipment HazardsDocument69 pagesIGC2 Element4 Work Equipment HazardsZakirhasNo ratings yet

- Project Management Contractor Near-Miss at Worksite Report: Jose A. ArigDocument3 pagesProject Management Contractor Near-Miss at Worksite Report: Jose A. ArigEever Paul De LeonNo ratings yet

- Near Miss Report NM SIN 025Document15 pagesNear Miss Report NM SIN 025za8319712No ratings yet

- Reynaldo Darcera: Project Management Contractor Near-Miss at Worksite ReportDocument15 pagesReynaldo Darcera: Project Management Contractor Near-Miss at Worksite ReportAyaz AhmadNo ratings yet

- Rahul Ap: Project Management Contractor Near-Miss at Worksite ReportDocument15 pagesRahul Ap: Project Management Contractor Near-Miss at Worksite ReportEever Paul De LeonNo ratings yet

- Emergency Response Plan Sri City Project Rev 00Document23 pagesEmergency Response Plan Sri City Project Rev 00HSE OFFICENo ratings yet

- 010 Electrical Tool & EquipmentDocument2 pages010 Electrical Tool & EquipmentWahyu Endra PurwantoNo ratings yet

- TCF 1 - Daily Safety Report 03-May - 2021 .Document4 pagesTCF 1 - Daily Safety Report 03-May - 2021 .Muhammad TariqNo ratings yet

- Grand Toolbox (Monthly)Document3 pagesGrand Toolbox (Monthly)Suresh Praba PNo ratings yet

- Mohammed Mustafa: Project Management Contractor Near-Miss at Worksite ReportDocument15 pagesMohammed Mustafa: Project Management Contractor Near-Miss at Worksite ReportUsman RajputNo ratings yet

- Installation Guide For Cat Terrain For Drilling On The MD6250Document64 pagesInstallation Guide For Cat Terrain For Drilling On The MD6250Sain MezaNo ratings yet

- Eqt 3Document10 pagesEqt 3santosh pasayatNo ratings yet

- 11 ErpDocument7 pages11 Erpprakash pandeyNo ratings yet

- Near Miss 02-02-2022Document15 pagesNear Miss 02-02-2022Zeeshan AbbasiNo ratings yet

- XBTGT Instruction GuideDocument8 pagesXBTGT Instruction Guideferas rahilNo ratings yet

- 2.2 Equipment Risk AssessmentsDocument57 pages2.2 Equipment Risk Assessmentsalthaf2010No ratings yet

- Risk Assessment Implementation Sheet (Work Name・Process Name:)Document11 pagesRisk Assessment Implementation Sheet (Work Name・Process Name:)ciafootNo ratings yet

- Nearmiss Report Bench Vise W #14Document15 pagesNearmiss Report Bench Vise W #14Alok SinghNo ratings yet

- Airr CPPDocument121 pagesAirr CPPsanjeev kumarNo ratings yet

- Safety AwarenessDocument27 pagesSafety AwarenessSuraj JhaNo ratings yet

- Please Print or Type Project Management Contractor Near-Miss at Worksite ReportDocument17 pagesPlease Print or Type Project Management Contractor Near-Miss at Worksite ReportPeshteenNo ratings yet

- CVX (1) (2) (4) Area/Building: Location of Work: Rodi Level of WorkDocument10 pagesCVX (1) (2) (4) Area/Building: Location of Work: Rodi Level of WorkSeven SantosNo ratings yet

- Week 11 - TE-MSC Safety DayDocument29 pagesWeek 11 - TE-MSC Safety DayKing JakeNo ratings yet

- Electrical Thermal ImagingDocument6 pagesElectrical Thermal ImagingPillai Sreejith90% (10)

- Eqt 4Document10 pagesEqt 4santosh pasayatNo ratings yet

- Wa0008.Document3 pagesWa0008.Noor BeeNo ratings yet

- Project Management Contractor Near-Miss at Worksite Report: Muhammad Anwar HussainDocument3 pagesProject Management Contractor Near-Miss at Worksite Report: Muhammad Anwar HussainEever Paul De LeonNo ratings yet

- DCD 708Document18 pagesDCD 708ezbinNo ratings yet

- A Dimensions: (MM) B Recommended Land Pattern: (MM) : WE-MAPI SMD Shielded Power InductorDocument6 pagesA Dimensions: (MM) B Recommended Land Pattern: (MM) : WE-MAPI SMD Shielded Power InductorderplesmcgeeNo ratings yet

- SOP-22 AC Compressore Replacement WorkDocument4 pagesSOP-22 AC Compressore Replacement WorkNarendra SinghNo ratings yet

- TCF 1 - Daily Safety Report 04-May - 2021 .Document4 pagesTCF 1 - Daily Safety Report 04-May - 2021 .Muhammad TariqNo ratings yet

- FORM 08 - Intervention Report - CRANK SHEAR - Copie - CopieDocument3 pagesFORM 08 - Intervention Report - CRANK SHEAR - Copie - CopieRamy Hassan EmaraNo ratings yet

- Hazard Risk AssessmentDocument15 pagesHazard Risk Assessmentfairoos aliNo ratings yet

- 8 Flushing and Chemical Cleaning MS-AC-08Document3 pages8 Flushing and Chemical Cleaning MS-AC-08Marwan NizarNo ratings yet

- Design and Development of Automatic Loading and UnloadingDocument7 pagesDesign and Development of Automatic Loading and UnloadingProduction TrainingNo ratings yet

- ESMS Annex 29.17 - Tools & Machines Checklists FormatDocument37 pagesESMS Annex 29.17 - Tools & Machines Checklists FormatAhmed AbdulmajeedNo ratings yet

- Siemens: Cqú'ñæteDocument10 pagesSiemens: Cqú'ñæteFava yavarNo ratings yet

- AMB-172-004 Cement Gypsum BoardDocument2 pagesAMB-172-004 Cement Gypsum BoardRues AgNo ratings yet

- AMB-172-003 Insulation WorksDocument2 pagesAMB-172-003 Insulation WorksRues AgNo ratings yet

- AMB 172-016 LiftingDocument3 pagesAMB 172-016 LiftingRues AgNo ratings yet

- 17sheet Metal WorkDocument2 pages17sheet Metal WorkRues AgNo ratings yet

- AMB 172-024 Forklift OperationsDocument2 pagesAMB 172-024 Forklift OperationsRues AgNo ratings yet

- 11EOT Crane Hoist Load TestDocument2 pages11EOT Crane Hoist Load TestRues AgNo ratings yet

- 10installation of Cable TraysDocument2 pages10installation of Cable TraysRues AgNo ratings yet

- 02erection of Heavy EquipmentDocument2 pages02erection of Heavy EquipmentRues AgNo ratings yet

- Communication System 4th Sem. ECEDocument52 pagesCommunication System 4th Sem. ECETapuNo ratings yet

- The Fifth Largest Among The Nine Planets That Make Up Our Solar SystemDocument8 pagesThe Fifth Largest Among The Nine Planets That Make Up Our Solar SystemHoàng Bảo ChâuNo ratings yet

- Shock Pulse Measurement (Vibration Analysis) : Supplementary Operating ManualDocument8 pagesShock Pulse Measurement (Vibration Analysis) : Supplementary Operating ManualRajagopal SNo ratings yet

- 2006 - Amc - 10 BDocument13 pages2006 - Amc - 10 BSUNGMIN CHOI100% (1)

- Hydrogen Economy, Hydrogen Storage and Fuelcell StackDocument20 pagesHydrogen Economy, Hydrogen Storage and Fuelcell StackpolysourceNo ratings yet

- Determining Total Impulse and Specific Impulse From Static Test DataDocument4 pagesDetermining Total Impulse and Specific Impulse From Static Test Datajai_selvaNo ratings yet

- CLE7 ThirdQuarter Module1Document10 pagesCLE7 ThirdQuarter Module1Roella Mae Tudias AlodNo ratings yet

- Alg 9.1 PacketDocument5 pagesAlg 9.1 PacketAN NGUYENNo ratings yet

- Rapid Determination of Benzalkonium Chloride in A Cosmetic: Key WordsDocument4 pagesRapid Determination of Benzalkonium Chloride in A Cosmetic: Key Wordsahmetgezer34No ratings yet

- Zero Energy Building YCCEDocument15 pagesZero Energy Building YCCEChinmay ChintawarNo ratings yet

- Omni Wheel BrochureDocument2 pagesOmni Wheel BrochureJederVieiraNo ratings yet

- Selected References: Ion ImplantationDocument34 pagesSelected References: Ion Implantationmskumar_554No ratings yet

- How To Answer A Fool and To Translate THDocument30 pagesHow To Answer A Fool and To Translate THPishoi ArmaniosNo ratings yet

- DdarDocument300 pagesDdarbitok214No ratings yet

- 1918 Flu - How It HappenedDocument7 pages1918 Flu - How It Happenedhhelp12255No ratings yet

- ExosomesDocument18 pagesExosomesMahmood-S ChoudheryNo ratings yet

- A GNU Radio Based Software-Defined RadarDocument126 pagesA GNU Radio Based Software-Defined RadarVanidevi ManiNo ratings yet

- ENG Yak40 ManualDocument57 pagesENG Yak40 ManualHồ Zy ĐanNo ratings yet

- ABS Parametric RollDocument2 pagesABS Parametric RollAdvan Zuidplas100% (1)

- Amazing Hydroski-Foil PDFDocument3 pagesAmazing Hydroski-Foil PDFfrannetoNo ratings yet

- Gynae T and D Expl - 1Document44 pagesGynae T and D Expl - 1vivekanurag97No ratings yet

- Linearization Techniques in Power AmplifiersDocument22 pagesLinearization Techniques in Power AmplifiersSalma KhanNo ratings yet

- Fosroc Nitomortar MH: Solvent Free Epoxy Lining and Benching MortarDocument4 pagesFosroc Nitomortar MH: Solvent Free Epoxy Lining and Benching MortarVincent JavateNo ratings yet

- En (1464)Document1 pageEn (1464)reacharunkNo ratings yet

- Furse Datasheet Bimetallic Connectors DGT 281021Document2 pagesFurse Datasheet Bimetallic Connectors DGT 281021KhaledNo ratings yet

- Kema B.V. High Power Laboratory and High Voltage LaboratoryDocument9 pagesKema B.V. High Power Laboratory and High Voltage LaboratoryFranciscoUrgilesNo ratings yet