Professional Documents

Culture Documents

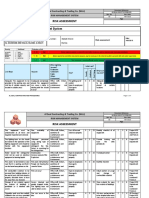

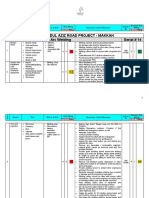

AL MASAOOD BERGUM HEALTH, SAFETY & ENVIRONMENTAL RISK ASSESSMENT

Uploaded by

Rues AgOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AL MASAOOD BERGUM HEALTH, SAFETY & ENVIRONMENTAL RISK ASSESSMENT

Uploaded by

Rues AgCopyright:

Available Formats

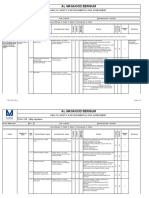

AL MASAOOD BERGUM

HEALTH, SAFETY & ENVIRONMENTAL RISK ASSESSMENT

TASK / JOB: Frame Cad Operations

Doc No: AMB 172-014 Rev: G Date: 11.05.2015 Next Review Date: 10.04.2016

Key to Risk type : H - Health, S - Safety, E - Environmental, O - Others

Residual Risk

(Risk rating)

Probability

Probability

Base Risk

Risk Type

Severity

Severity

Associated risks /

Activity Detailed Job Steps Potential Hazards / Aspect Controls Monitoring

Impact

Note: At the start of each days work STA/ToolBox Talks shall be conducted to ensure work related hazards are discussed with the crew, work related training shall be conducted as and when required.

Frame Cad Unstrapping the GI coil S Strap can be whipped with Cut, laceration, Ensure the face & body is positioned away Monitoring by

Machine . LGS tension when cut. bruise. from the coil while cutting the strap. responsible

Panel Eye Injury 3 4 M Hand gloves and safety goggles should be 2 2 L supervisor/charge

Fabrication. worn along with other mandatory PPE. hand on daily

basis

Placing GI Coil on stand S Coil can fall Amputation, Competent person should operate the

using forklift. lacerations, bruise, forklift.

eye injuries, crushing Careful operation.Correct signalling by a

injuries, puncture. competent person.

Correct manual handling technique.

Use of Rigging hand gloves and other

mandatory PPE.

4 4 H Work to be stopped and the area should be 2 2 L

free of any obstruction during loading the GI

coil.

Forklift should be in good condition with the

reverse alarm and other warning devices

fully functional.

Note: Refer to Forklifts Operation Risk Assessment

IMF 210-02, Rev E Page 1 of 3

basis

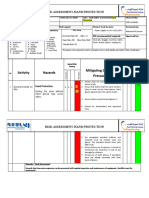

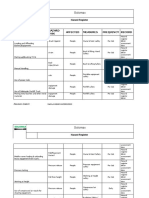

AL MASAOOD BERGUM

HEALTH, SAFETY & ENVIRONMENTAL RISK ASSESSMENT

TASK / JOB: Frame Cad Operations

Doc No: AMB 172-014 Rev: G Date: 11.05.2015 Next Review Date: 10.04.2016

Key to Risk type : H - Health, S - Safety, E - Environmental, O - Others

Residual Risk

(Risk rating)

Probability

Probability

Base Risk

Risk Type

Severity

Severity

Associated risks /

Activity Detailed Job Steps Potential Hazards / Aspect Controls Monitoring

Impact

Use of Chain block for S Fall of coil Amputation, 4 4 H Activity must be conducted by a experienced

putting coil on de-coiler lacerations, bruise, personnal

stand. eye injuries, crushing Make sure the chain block is Third party

injuries, puncture. inspected.

Ensure the chain sling is in good condition

and th hook latch is present and is used 2 2 L

while lifting until the coil is placed on the

decoiler.

The guard on the decoiler should be fitted

after the coil is loaded on the de-coiler.

(GI sheet bending into H Contact with moving Injury to personnel- Follow operational instructions & safety

channel shape) machinery Cut/laceration/ signs/rules.

Inserting GI sheet in the graze,entanglement, Adjust the guard for max. protection.

feed input of machine. amputation Maintain safe working distance from

Machine operation. machine.

Out put of job through 4 5 H Do not lean over the job. 2 2 L

channel gate. Loose cloth, jewelry and long hair should be

Channel stacking on stand avioded.

trolley. Only authorized person should operate the

Fabrication of channels into machine.

panels.

H Ergonomic hazards Sprain, Strain, Follow safe manual handling procedure.

Backaches, Muscular Use of mechanical means where possible.

Pain, Minimize the distance.

Dislocation.Muscular Obtain help if load is too heavy.

Pain, Dislocation. 4 3 M Adopt correct posture. 2 2 L

Minimum weight should not exceed more

20kg in optimum condition.

Appropriate PPE's should be used.

IMF 210-02, Rev E Page 2 of 3

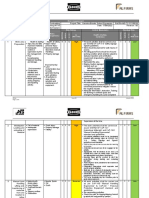

(GI sheet bending into

channel shape)

Inserting GI sheet in the

feed input of machine.

Machine operation.

Out put of job through

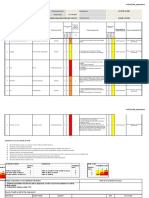

AL MASAOOD BERGUM

channel gate.

Channel stacking on stand HEALTH, SAFETY & ENVIRONMENTAL RISK ASSESSMENT

trolley.

Fabrication TASK

of channels

/ JOB:into

Frame Cad Operations

panels.

Doc No: AMB 172-014 Rev: G Date: 11.05.2015 Next Review Date: 10.04.2016

Key to Risk type : H - Health, S - Safety, E - Environmental, O - Others

Residual Risk

(Risk rating)

Probability

Probability

Base Risk

Risk Type

Severity

Severity

Associated risks /

Activity Detailed Job Steps Potential Hazards / Aspect Controls Monitoring

Impact

H Noise Noise induced Check for elevated sound.

hearing loss Reduce noise exposure.

4 3 H 2 2 L

Mental Ensure ear plug/muff is in place

stress/annoyance

S Slip and trip Lacerations, bruise, Proper housekeeping to be maintained.

puncture, fracture, 4 3 M 2 2 L

dislocation

Material stacking to be taken care.

S Sharp and Jagged objects Lacerations, bruise, Use of Rigger gloves while handling the GI

puncture. 4 4 H panels. 2 2 L

No horse play.

S Electical Shock Electric shock- Switch off main power supply whilst

Pain/trauma, burn, inspection &

damage to nervous maintenace activities.

system ELCB to be provided and ensure proper

Spark, fire, property earthing and testing to be conducted.

damage 4 4 H Only trained 2 2 L

and authorized person should operate the

machine

Periodical inspection of

machine to be carried out and colour coded.

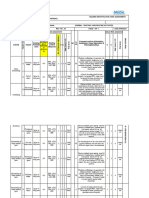

HSERA PERFORMED BY HSERA APPROVED BY

SIGNATURE : SIGNATURE : SIGNATURE : SIGNATURE :

NAME : Yathu.Sivadasan NAME : Rajeev NAME : Pradeep S.Pillai NAME : Ram Saran

Panicker

DESIGNATION : HSE Officer DESIGNATION : Sr HSE Officer DESIGNATION : QHSE Manager DESIGNATION : Production Manager

IMF 210-02, Rev E Page 3 of 3

You might also like

- CHCCCS025 Support Relationships With Carers and Families EKDocument67 pagesCHCCCS025 Support Relationships With Carers and Families EKIkhsan Misbahuddin75% (8)

- RA 024 Risk Assessment - Precast Concrete WorksDocument14 pagesRA 024 Risk Assessment - Precast Concrete Worksthomson75% (8)

- Case Study The Teaching HospitalDocument4 pagesCase Study The Teaching HospitalDerick DarkZide100% (4)

- RA-LBC-007 Risk Assessment Concrete WorksDocument8 pagesRA-LBC-007 Risk Assessment Concrete Worksjones100% (1)

- HIRA For Civil WorkDocument11 pagesHIRA For Civil WorkYogesh Nath100% (1)

- RA-LBC-007 Risk Assessment Drilling Operations and WorkDocument5 pagesRA-LBC-007 Risk Assessment Drilling Operations and Workjones100% (1)

- Brick WorkDocument1 pageBrick WorkGyanendra Narayan NayakNo ratings yet

- SAP 1 Expansion Bellows RenewalDocument3 pagesSAP 1 Expansion Bellows Renewalgullipalli srinivasa raoNo ratings yet

- Health, Safety & Environmental Risk Assessment for Lifting OperationsDocument3 pagesHealth, Safety & Environmental Risk Assessment for Lifting OperationsRues AgNo ratings yet

- AMB-172-003 Insulation WorksDocument2 pagesAMB-172-003 Insulation WorksRues AgNo ratings yet

- Hazard Identification and Risk AssessmentDocument8 pagesHazard Identification and Risk Assessmentشاز إياس100% (1)

- Hand Protection RADocument3 pagesHand Protection RAAsif HussainNo ratings yet

- AL QOOZ CONTRACTING HAZARD ASSESSMENTDocument7 pagesAL QOOZ CONTRACTING HAZARD ASSESSMENTشاز إياسNo ratings yet

- HSE Documents-Fit-Out Work-Ris AssessmentDocument3 pagesHSE Documents-Fit-Out Work-Ris AssessmentTom BobanNo ratings yet

- AMB-172-004 Cement Gypsum BoardDocument2 pagesAMB-172-004 Cement Gypsum BoardRues AgNo ratings yet

- AMB 172-024 Forklift OperationsDocument2 pagesAMB 172-024 Forklift OperationsRues AgNo ratings yet

- ALBAZ General RA - Construction Well Pads-Rev A.Document2 pagesALBAZ General RA - Construction Well Pads-Rev A.Ali HadiNo ratings yet

- Ra For Transpo and LiftingDocument5 pagesRa For Transpo and LiftingEdsel RosalesNo ratings yet

- Construction Risk Assessments361241720220223Document2 pagesConstruction Risk Assessments361241720220223Afaan gani Inamdar100% (1)

- 22-RA FORM OP-20-01 FrezzingDocument1 page22-RA FORM OP-20-01 Frezzingelnaas1993No ratings yet

- Hazards Identification and Risk Assessment - New FormatDocument2 pagesHazards Identification and Risk Assessment - New FormatBIIS QAQC Babu Siva100% (1)

- Larsen & Toubro Limited Buildings and Factories Independent CompanyDocument5 pagesLarsen & Toubro Limited Buildings and Factories Independent CompanyabbasNo ratings yet

- RA For TC DismantlingDocument13 pagesRA For TC Dismantlingsalauddin0mohammedNo ratings yet

- Risk Assessment - Installation of Air-Cooled ChillersDocument4 pagesRisk Assessment - Installation of Air-Cooled ChillersBabar ShehzadNo ratings yet

- Risk Assessment/Management Form CivilDocument1 pageRisk Assessment/Management Form CivilGyanendra Narayan NayakNo ratings yet

- Risk Assessment/Management Form CivilDocument1 pageRisk Assessment/Management Form CivilGyanendra Narayan NayakNo ratings yet

- Risk assessment form for painting workDocument1 pageRisk assessment form for painting workNarender BhardwajNo ratings yet

- Foot Wear Risk AssessmentDocument3 pagesFoot Wear Risk AssessmentAsif HussainNo ratings yet

- Risk Assessment - Rev - 00 (Construction of High Voltage Sub Station Autho R Arber Dogani - 01.01.2015Document8 pagesRisk Assessment - Rev - 00 (Construction of High Voltage Sub Station Autho R Arber Dogani - 01.01.2015Arber DoganiNo ratings yet

- RA 020 Risk Assessment - Risk Assessment - Installation of Cables in Ducts & TrenchesDocument11 pagesRA 020 Risk Assessment - Risk Assessment - Installation of Cables in Ducts & Trenchesthomson100% (1)

- RA 023 Risk Assessment - FireDocument4 pagesRA 023 Risk Assessment - Firethomson100% (4)

- Risk Assessment Block WorksDocument11 pagesRisk Assessment Block WorkskannanjaduzzNo ratings yet

- Insulation Works For Heat ExchangerDocument3 pagesInsulation Works For Heat ExchangerVenodaren VelusamyNo ratings yet

- Risk Assesment (Service Staircase)Document2 pagesRisk Assesment (Service Staircase)Fawad KhanNo ratings yet

- Risk Assessment SummaryDocument8 pagesRisk Assessment SummaryJhOichriz Reginaldo CuevasNo ratings yet

- Hira - Excavation, PCC, RCCDocument6 pagesHira - Excavation, PCC, RCCPrithika AnbuNo ratings yet

- HIRARC - AHU UVGI InstallationDocument2 pagesHIRARC - AHU UVGI InstallationDon McleanNo ratings yet

- E-Ia - HAZARD REGISTERDocument4 pagesE-Ia - HAZARD REGISTERSOLOMAXNo ratings yet

- Risk Assessment - Hvac SystemDocument8 pagesRisk Assessment - Hvac SystemJhOichriz Reginaldo CuevasNo ratings yet

- Job Safety Analysis (Jsa) N2.Document5 pagesJob Safety Analysis (Jsa) N2.Joseph Paul IlaganNo ratings yet

- Job Risk Assessment Form: Vessel: M/V Gemini 2Document1 pageJob Risk Assessment Form: Vessel: M/V Gemini 2Danilo OralNo ratings yet

- Risk Assessment - Fire Pump SetDocument8 pagesRisk Assessment - Fire Pump SetJhOichriz Reginaldo CuevasNo ratings yet

- Hazrd Identification & Risk Assessment: Mmf100 Nov 2009 - Pm/105/01 © Mott Macdonald 2009Document2 pagesHazrd Identification & Risk Assessment: Mmf100 Nov 2009 - Pm/105/01 © Mott Macdonald 2009SuperuserAsadhussainNo ratings yet

- Compaction Risk AssessmentDocument5 pagesCompaction Risk AssessmentKashif RehmanNo ratings yet

- Risk Assessment - Plumbing Pump SetDocument8 pagesRisk Assessment - Plumbing Pump SetJhOichriz Reginaldo Cuevas100% (1)

- Health and Safety Risk Assessment for Column ConcretingDocument7 pagesHealth and Safety Risk Assessment for Column Concretingbasil aliNo ratings yet

- Hira - Erection Work - Metal Scope - DPWDocument18 pagesHira - Erection Work - Metal Scope - DPWrubinakumari136No ratings yet

- Ra09 Lifting ActivitiesDocument4 pagesRa09 Lifting Activitiesluatdolphin100% (1)

- Hand Tools SHE Risk AssessmentDocument3 pagesHand Tools SHE Risk AssessmentMuhammed yahiyaNo ratings yet

- Excavation & Backfilling Risk - AssessmentDocument9 pagesExcavation & Backfilling Risk - AssessmentKashif RehmanNo ratings yet

- 5.2.2.9 Laydown Drill Pipes1Document2 pages5.2.2.9 Laydown Drill Pipes1khrayzie bhone100% (1)

- Chaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentDocument4 pagesChaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentCPP EI DSpNo ratings yet

- RA 021 Risk Assessment - Installation of External Landscape Lighting WorksDocument13 pagesRA 021 Risk Assessment - Installation of External Landscape Lighting Worksthomson50% (2)

- Pre Cast Coping Works - EPC10-RA33-R0Document4 pagesPre Cast Coping Works - EPC10-RA33-R0salauddin0mohammedNo ratings yet

- Block Cutting - EPC10-RA04-R1Document4 pagesBlock Cutting - EPC10-RA04-R1salauddin0mohammedNo ratings yet

- Risk AssessmentDocument2 pagesRisk Assessmentapi-477226036No ratings yet

- SKC S Aerosol Safety Data Sheet EnglishDocument5 pagesSKC S Aerosol Safety Data Sheet EnglishkhairurNo ratings yet

- Risk Assessment - SanitarywaresDocument9 pagesRisk Assessment - SanitarywaresJhOichriz Reginaldo CuevasNo ratings yet

- 5.#hiradec - CWPDocument7 pages5.#hiradec - CWPPankaj PandeyNo ratings yet

- 14 - RA - Electric Arc WeldingDocument3 pages14 - RA - Electric Arc WeldingravindraNo ratings yet

- AVN-MAR-PIP-RA-003 - R0 - Installation of Drain Line Below HelipadDocument3 pagesAVN-MAR-PIP-RA-003 - R0 - Installation of Drain Line Below HelipadtaufikNo ratings yet

- AMB-172-004 Cement Gypsum BoardDocument2 pagesAMB-172-004 Cement Gypsum BoardRues AgNo ratings yet

- 17sheet Metal WorkDocument2 pages17sheet Metal WorkRues AgNo ratings yet

- AMB 172-024 Forklift OperationsDocument2 pagesAMB 172-024 Forklift OperationsRues AgNo ratings yet

- 10 WeldingDocument2 pages10 WeldingRues AgNo ratings yet

- 09installation of Light FittingDocument2 pages09installation of Light FittingRues AgNo ratings yet

- 10installation of Cable TraysDocument2 pages10installation of Cable TraysRues AgNo ratings yet

- 04 Piling Works 1Document2 pages04 Piling Works 1Rues AgNo ratings yet

- EOT CRANE LOAD TESTDocument2 pagesEOT CRANE LOAD TESTRues AgNo ratings yet

- Erection of Heavy Equipment Risk AssessmentDocument2 pagesErection of Heavy Equipment Risk AssessmentRues AgNo ratings yet

- Construction Supply Installation Risk AssessmentDocument2 pagesConstruction Supply Installation Risk AssessmentRues AgNo ratings yet

- 04erection of PanelsDocument2 pages04erection of PanelsRues AgNo ratings yet

- DPH Form 3300 PDFDocument2 pagesDPH Form 3300 PDFtomtranNo ratings yet

- المعدات وغرف الانتاج والتنظيف والصيانة دليل الطالبDocument56 pagesالمعدات وغرف الانتاج والتنظيف والصيانة دليل الطالبbionorluxeNo ratings yet

- Your Guide To The Good Life Winter EditionDocument9 pagesYour Guide To The Good Life Winter EditionPaola Jiménez GómezNo ratings yet

- Gcas 17 Week 2 3Document14 pagesGcas 17 Week 2 3Shyne HazyNo ratings yet

- Diurinal VariationDocument5 pagesDiurinal VariationKEERTIMAAN JOSHINo ratings yet

- A-Vocabulary & Structure: 1 - Underline The Correct Word(s) in Brackets: (10 Marks)Document3 pagesA-Vocabulary & Structure: 1 - Underline The Correct Word(s) in Brackets: (10 Marks)ririNo ratings yet

- Sorry, Wrong NumberDocument12 pagesSorry, Wrong NumberLaarni Airalyn CabreraNo ratings yet

- NABH Series4 PREDocument50 pagesNABH Series4 PREPallavi Deepak DongreNo ratings yet

- Ovary Female Reproductive SystemDocument1 pageOvary Female Reproductive SystemtheodorastanerNo ratings yet

- Best Practices For EconomistsDocument4 pagesBest Practices For EconomistsMahlatse MabebaNo ratings yet

- How Do You Assess Biopure's Potential in The Human Market? The Animal Market? Human MarketDocument8 pagesHow Do You Assess Biopure's Potential in The Human Market? The Animal Market? Human MarketYilei RenNo ratings yet

- Inverse Transcription 2Document4 pagesInverse Transcription 2Berenice CázaresNo ratings yet

- Kejadian Plebitis Bulan April 2019Document326 pagesKejadian Plebitis Bulan April 2019Ridho YulfiahNo ratings yet

- Research EssayDocument12 pagesResearch Essayapi-608972617No ratings yet

- Dat e Physicians Order RationaleDocument4 pagesDat e Physicians Order Rationaleember parkNo ratings yet

- BRAC Internship ApplicationDocument4 pagesBRAC Internship ApplicationShahanaj S. TanniNo ratings yet

- Colles FractureDocument5 pagesColles FractureKimbraPataraNo ratings yet

- Post Primal and Genital Character A Critique of JanovDocument13 pagesPost Primal and Genital Character A Critique of Janovpacoaraz1311No ratings yet

- Tarot Psychology Spectrums of Possibility (Arthur Rosengarten PHD) (Z-Library)Document314 pagesTarot Psychology Spectrums of Possibility (Arthur Rosengarten PHD) (Z-Library)Jéssica AméricoNo ratings yet

- WMSTU Student Services Satisfaction and Academic PerformanceDocument16 pagesWMSTU Student Services Satisfaction and Academic PerformanceTherese Janine HetutuaNo ratings yet

- CPCWHS3001 - Learner Guide V1.0Document20 pagesCPCWHS3001 - Learner Guide V1.0sharma SoniaNo ratings yet

- Chapter 4 - Inference Conclusion AssumptionDocument9 pagesChapter 4 - Inference Conclusion AssumptionHalim NordinNo ratings yet

- Prodia Blood Test Results - Heavy Metals and ParasitesDocument2 pagesProdia Blood Test Results - Heavy Metals and ParasitesMichael Sheehan AlahouzosNo ratings yet

- HG-G12 Module 4 RTPDocument10 pagesHG-G12 Module 4 RTPFrancine Dela CruzNo ratings yet

- Factors On Thesis Writing Anxiety Among Science, Technology, Engineering, and Mathematics StudentsDocument9 pagesFactors On Thesis Writing Anxiety Among Science, Technology, Engineering, and Mathematics StudentsPsychology and Education: A Multidisciplinary JournalNo ratings yet

- Lesson 2 - BTVNDocument3 pagesLesson 2 - BTVNHoàng HiềnNo ratings yet

- Teaching Demonstration Activity Guide Template PDFDocument3 pagesTeaching Demonstration Activity Guide Template PDFRosarioEsperManisanNo ratings yet