Professional Documents

Culture Documents

FAJ13979 - 11 22 2021 - 12 25 22 - Summary

Uploaded by

sabirOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FAJ13979 - 11 22 2021 - 12 25 22 - Summary

Uploaded by

sabirCopyright:

Available Formats

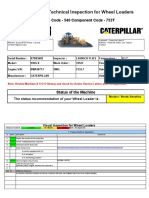

Hydraulic Excavator (HEX) TA1

TA1 0 0 73 0

Inspection Number 4521194

Make CATERPILLAR Serial Number FAJ13979

Customer Name CGGC Model 336D2

Customer Phone 03428508739 Equipment Family EXCAVATORS

Customer Email . Asset ID 1E12

Completed On 23/09/2020 15:16:22 SMU 916 Hours

Inspector Insha Ullah Khan Location Dassu Hydropower

Project.

Work Order . Coordinates 0, 0, 0

PDF Generated On 23/09/2020

Inspector

General Info & Comments

General info/Comments NORMAL

Comments: TA1 inspection

Prepare Machine for Inspection

1.1 Check with customer for operator complaints NORMAL

1.2 Perform machine inspection preparation NORMAL

1.3 Download machine fault codes PASS

1.4 Is the machine software including Product Link & VIMS Config files current with what is published in SIS? YES

1.5 Check Product Link YES

1.6 Observe engine exhaust colors NORMAL

1.7 Listen for unusual noises NORMAL

1.8 Lockout / Tagout Machine YES

Lower Level Inspection

2.1 Final drives and sprockets NORMAL

2.2 Travel Motor & Brake Valve NORMAL

2.3 Track Adjuster NORMAL

2.4 Carrier Rollers NORMAL

2.5 Track Rollers NORMAL

2.6 Front Idlers NORMAL

2.7 Track Guides NORMAL

2.8 Track Shoes NORMAL

2.9 Track Links, Pins, & Bushings NORMAL

2.10 Track Roller Frame & Carbody NORMAL

2.11 Engine Oil Pan NORMAL

Middle Level Inspection

3.1 Cab Exterior NORMAL

3.2 Cab Interior NORMAL

3.3 Steps & Handrails NORMAL

3.4 Work Lights NORMAL

3.5 Air Cleaner and Air Filter Service Indicator NORMAL

3.6 Battery & Cables NORMAL

3.7 Radiator, Air Inlet, Oil Cooler & Aftercooler Lines NORMAL

Executive Summary Report Page 1 of 2

3.8 Lower Radiator & Oil Cooler Hoses NORMAL

3.9 Counterweight NORMAL

3.10 Hydraulic Pump Compartment NORMAL

3.11 Swing Drive Gear NORMAL

Upper Level Inspection

4.1 Hood and Platform NORMAL

4.2 Exhaust Manifold NORMAL

4.3 Turbocharger NORMAL

4.4 Cylinder Head(s) & Valve Cover(s) NORMAL

4.5 Fuel Lines, Fuel Pump and Fuel Filter Base NORMAL

4.6 Engine Mounts NORMAL

4.7 Pulleys, Belts, Compressor Clutch and Alternator NORMAL

4.8 Cooling Fan, Fan Guard and Shroud NORMAL

4.9 Upper and Lower Radiator Lines, Air Inlet Lines and Aftercooler Lines NORMAL

4.10 Radiator/Oil Cooler Screen NORMAL

4.11 Water Pump(s) NORMAL

4.12 Radiator Cap NORMAL

4.13 Fuel Priming Pump NORMAL

4.14 Secondary Fuel Filter NORMAL

4.15 Fuel Injection Pump NORMAL

4.16 Engine wiring harness NORMAL

4.17 Swing Drive Compartment NORMAL

4.18 Swing Drive NORMAL

4.19 Main Hydraulic Control Valve NORMAL

4.20 Hydraulic Tank NORMAL

4.21 Fuel Tank NORMAL

Implement/Attachment Inspection

5.1 Swivel NORMAL

5.2 Lower Boom Area NORMAL

5.3 Area around Boom Cylinders NORMAL

5.4 Boom Cylinder NORMAL

5.5 Area where Boom attaches to Stick NORMAL

5.6 Stick Cylinder NORMAL

5.7 Bucket Cylinder NORMAL

5.8 Bucket linkage NORMAL

5.9 Bucket wear plates NORMAL

5.10 Bucket side cutters NORMAL

5.11 Bucket edges, tips, and adapters NORMAL

Site Conditions

6.1 Ambient Temperature in Engine Room NORMAL

6.1.1 (90° to 115°F or 0° to -20°F) - ACTION: Above 46°C or Below -29°C (Above 115° or Below -20°F)

6.2 Altitude NORMAL

6.3 Haul Road Grade NORMAL

6.4 Haul Road Condition NORMAL

6.5 Humidity NORMAL

6.6 Air Quality NORMAL

6.7 Underfoot Condition NORMAL

6.8 Machine Utilization NORMAL

6.9 Working Material NORMAL

6.10 Maintenance Practices NORMAL

Executive Summary Report Page 2 of 2

You might also like

- FAJ13976 - 11 22 2021 - 12 23 13 - SummaryDocument2 pagesFAJ13976 - 11 22 2021 - 12 23 13 - SummarysabirNo ratings yet

- FAJ13978 - 11 22 2021 - 12 24 15 - SummaryDocument2 pagesFAJ13978 - 11 22 2021 - 12 24 15 - SummarysabirNo ratings yet

- FAJ13977 - 11 22 2021 - 12 23 50 - SummaryDocument2 pagesFAJ13977 - 11 22 2021 - 12 23 50 - SummarysabirNo ratings yet

- FAJ13975 - 11 22 2021 - 12 22 39 - SummaryDocument2 pagesFAJ13975 - 11 22 2021 - 12 22 39 - SummarysabirNo ratings yet

- Hydraulic Excavator (HEX) TA1: General Info & CommentsDocument5 pagesHydraulic Excavator (HEX) TA1: General Info & CommentssabirNo ratings yet

- Hydraulic Excavator (HEX) TA1Document4 pagesHydraulic Excavator (HEX) TA1sabirNo ratings yet

- GMD-PPG-Excavator (HEX) TA1 W/performance Inspection: General Info & CommentsDocument5 pagesGMD-PPG-Excavator (HEX) TA1 W/performance Inspection: General Info & CommentssabirNo ratings yet

- Hydraulic Excavator (HEX) TA1Document5 pagesHydraulic Excavator (HEX) TA1sabirNo ratings yet

- FAJ13977 11-22-2021 12-26-37 Form OrderDocument5 pagesFAJ13977 11-22-2021 12-26-37 Form OrdersabirNo ratings yet

- LN900128 - 10-7-2022 - 15-51-18 - Form - Order LN900128Document5 pagesLN900128 - 10-7-2022 - 15-51-18 - Form - Order LN900128Gmail GmailNo ratings yet

- P2H - PT Gun - Pelaksanaan Perawatan Harian - Back Hoe Loader - TuDocument4 pagesP2H - PT Gun - Pelaksanaan Perawatan Harian - Back Hoe Loader - TuKhoirul khoerNo ratings yet

- 950H (J5J, Jad) Pm2 & Ta1 Combined GCPL ReportDocument8 pages950H (J5J, Jad) Pm2 & Ta1 Combined GCPL ReportTnpl CatNo ratings yet

- Ta2 English Exc. 320D2 PmodificarDocument14 pagesTa2 English Exc. 320D2 PmodificarJose Cruz Martinez MedinaNo ratings yet

- TA1 Report 750Hr For SEM636DDocument7 pagesTA1 Report 750Hr For SEM636DLUC BALOMOCK BIIGANo ratings yet

- Dealer Process 1-23-2022!20!24-51 Form OrderDocument7 pagesDealer Process 1-23-2022!20!24-51 Form OrderTnpl CatNo ratings yet

- 320D3 Pm1 & Ta1 Combined GCPL ReportDocument7 pages320D3 Pm1 & Ta1 Combined GCPL ReportTnpl CatNo ratings yet

- SZL20712 - 2022-06-24 - PDI - FormOrderDocument13 pagesSZL20712 - 2022-06-24 - PDI - FormOrderPETER ADAMNo ratings yet

- Hydraulic Excavator (HEX) TA1Document15 pagesHydraulic Excavator (HEX) TA1Tnpl CatNo ratings yet

- Copy of TA 12 English - Generator Set 2Document6 pagesCopy of TA 12 English - Generator Set 2Eddie UnivoNo ratings yet

- Ta-2 Cargadores de RuedasDocument13 pagesTa-2 Cargadores de RuedasjogremaurNo ratings yet

- 006 Mobile Crane Pre-Use Checklist - NO NEED FOR UPDATEDocument1 page006 Mobile Crane Pre-Use Checklist - NO NEED FOR UPDATELijo JohnNo ratings yet

- Dealer Process - 1-2-2022 - 4-4-58 - Form - OrderDocument7 pagesDealer Process - 1-2-2022 - 4-4-58 - Form - OrderTnpl CatNo ratings yet

- Week Day Remarks S S M T W T FDocument1 pageWeek Day Remarks S S M T W T Fwei heNo ratings yet

- Pre Use Inspection Vehicle (HCM - OFO.FRM.035.R00) - TUDocument2 pagesPre Use Inspection Vehicle (HCM - OFO.FRM.035.R00) - TUYeremiaNo ratings yet

- Equipment No. Model: Date From: To: 3. Lights 5. Warning Signs 4. Stick 1. CabinDocument2 pagesEquipment No. Model: Date From: To: 3. Lights 5. Warning Signs 4. Stick 1. Cabinwei heNo ratings yet

- Pre Trip 360 InspectionDocument2 pagesPre Trip 360 Inspectionrigor vicencioNo ratings yet

- 304D TYK00743 TA1 - Excavator Inpection ReportDocument11 pages304D TYK00743 TA1 - Excavator Inpection ReportCesar Eduardo Contreras CastilloNo ratings yet

- Dealer Process - 12-2-2021 - 22-16-9 - Severity - OrderDocument28 pagesDealer Process - 12-2-2021 - 22-16-9 - Severity - OrderTnpl CatNo ratings yet

- At1 - ExcavadoraDocument14 pagesAt1 - ExcavadoraFREDDY NICOLAS ESCOBEDO LOZANONo ratings yet

- Crane Checklist PDFDocument2 pagesCrane Checklist PDFWaqar IftikharNo ratings yet

- Translation Equipment No. Date From: To: 1. Cabin 3. BoomDocument1 pageTranslation Equipment No. Date From: To: 1. Cabin 3. Boomwei heNo ratings yet

- Ta 2 c15 Mcw07240 Arjuna#01Document6 pagesTa 2 c15 Mcw07240 Arjuna#01Engineering ArjunaNo ratings yet

- 021 Crane Operator ChecklistDocument1 page021 Crane Operator ChecklistJunard Lu HapNo ratings yet

- Phase Item No. Item Name OK NOT OK N/A DeficiencyDocument1 pagePhase Item No. Item Name OK NOT OK N/A DeficiencyMartine OtienoNo ratings yet

- English ForkliftDocument2 pagesEnglish Forkliftwei heNo ratings yet

- 120 Ad4 ServicemanualDocument438 pages120 Ad4 ServicemanualTeknik Makina100% (2)

- Conversions Guidelines X82-pt1 PDFDocument127 pagesConversions Guidelines X82-pt1 PDFpabloNo ratings yet

- Crane Daily Inspection Checklist-Sa 9466Document1 pageCrane Daily Inspection Checklist-Sa 9466Ricardo DalisayNo ratings yet

- Fabco TC 142 TC 1421 Service ManualDocument48 pagesFabco TC 142 TC 1421 Service ManualMounir GagiNo ratings yet

- 7907 Ela80-3000 Rev - 7 PDFDocument54 pages7907 Ela80-3000 Rev - 7 PDFDavid デビッドブエノ BuenoNo ratings yet

- Installation and Operating Instructions: 0.1 Mbar VersionsDocument20 pagesInstallation and Operating Instructions: 0.1 Mbar Versionsinge VazquwzNo ratings yet

- Busch R 5 RA 0165, 0205, 0255, 0305 DDocument20 pagesBusch R 5 RA 0165, 0205, 0255, 0305 DEduardo Efrain Rubio100% (2)

- Service Manual CD2001-4001Document114 pagesService Manual CD2001-4001KP ServiceNo ratings yet

- Technical Manual DIWA.5Document187 pagesTechnical Manual DIWA.5Michael.Smith100% (5)

- Yudian Ai708 PDFDocument30 pagesYudian Ai708 PDFEhitishamNo ratings yet

- GeN2-Regen (680-1000kg) Scaffold-Less FIM ENDocument198 pagesGeN2-Regen (680-1000kg) Scaffold-Less FIM ENAbubeker Jemal100% (2)

- CCB - IIDocument135 pagesCCB - IIPraveen KumarNo ratings yet

- User Manual: GeneratorDocument60 pagesUser Manual: GeneratorgebremichaelNo ratings yet

- Maintenance Manual: Downloaded From Manuals Search EngineDocument44 pagesMaintenance Manual: Downloaded From Manuals Search EngineEudis PinedaNo ratings yet

- PM 1 (250 Hour Interval)Document3 pagesPM 1 (250 Hour Interval)Tnpl CatNo ratings yet

- 1.0 Prepare Generator Set Inspection: Table 1Document3 pages1.0 Prepare Generator Set Inspection: Table 1miguel oswaldo gonzalez benitezNo ratings yet

- EDC-DTS-MV005 - Overhead Conductors and AccessoriesDocument78 pagesEDC-DTS-MV005 - Overhead Conductors and AccessoriesJoe bilouteNo ratings yet

- AKD Installation Manual en (REV AA)Document216 pagesAKD Installation Manual en (REV AA)Royal Enfield ApprenticeNo ratings yet

- TA1 English - Generator SetDocument13 pagesTA1 English - Generator Setahmad adelNo ratings yet

- MANUAL - Power Tong Model 01F05C - March 29, 2019Document43 pagesMANUAL - Power Tong Model 01F05C - March 29, 2019Son DDarrellNo ratings yet

- RM Reliability and Maintenance Data For Equipment ISO 142242016Document1 pageRM Reliability and Maintenance Data For Equipment ISO 142242016wajihu9618No ratings yet

- AT1 992G CastellanoDocument18 pagesAT1 992G CastellanoFranquNo ratings yet

- Asme B30.16, BS 3243, BS 4898Document2 pagesAsme B30.16, BS 3243, BS 4898engmuhmudNo ratings yet

- SM-664 Blowby Test ReportDocument6 pagesSM-664 Blowby Test ReportSandeep NikhilNo ratings yet

- FAJ13977 - 11 22 2021 - 12 26 13 - ActionableDocument1 pageFAJ13977 - 11 22 2021 - 12 26 13 - ActionablesabirNo ratings yet

- FAJ13978 - 11 22 2021 - 12 25 42 - ActionableDocument1 pageFAJ13978 - 11 22 2021 - 12 25 42 - ActionablesabirNo ratings yet

- FAJ13977 11-22-2021 12-26-37 Form OrderDocument5 pagesFAJ13977 11-22-2021 12-26-37 Form OrdersabirNo ratings yet

- GMD-PPG-Excavator (HEX) TA1 W/performance Inspection: General Info & CommentsDocument5 pagesGMD-PPG-Excavator (HEX) TA1 W/performance Inspection: General Info & CommentssabirNo ratings yet

- Hydraulic Excavator (HEX) TA1Document4 pagesHydraulic Excavator (HEX) TA1sabirNo ratings yet

- Hydraulic Excavator (HEX) TA1Document5 pagesHydraulic Excavator (HEX) TA1sabirNo ratings yet

- Quotation No: Quotation Date: 0 A#: Validity: Customer Number: China State Construction Engg - Corp. Customer Name: 81213Document2 pagesQuotation No: Quotation Date: 0 A#: Validity: Customer Number: China State Construction Engg - Corp. Customer Name: 81213sabirNo ratings yet

- Prepare. Procure. Perform.: What'S NewDocument2 pagesPrepare. Procure. Perform.: What'S NewsabirNo ratings yet

- IELTS Essay Economic ProgressDocument9 pagesIELTS Essay Economic ProgresssabirNo ratings yet

- Optical Theremin LabDocument9 pagesOptical Theremin LabKyle EmersonNo ratings yet

- HOOBICO900cap0125 0150 ManualDocument4 pagesHOOBICO900cap0125 0150 ManualJarolphNo ratings yet

- Diploma Kemahiran MalaysiaDocument20 pagesDiploma Kemahiran MalaysiaSuresh GanesanNo ratings yet

- 3bds009030-600 C en Ac 800m 6.0 Profibus DP ConfigurationDocument106 pages3bds009030-600 C en Ac 800m 6.0 Profibus DP Configurationjuan montufarNo ratings yet

- Hospital Management System SoftwareDocument11 pagesHospital Management System SoftwareNikesh Solanki50% (2)

- SWDD TemplateDocument6 pagesSWDD TemplateSulthonul MubarokNo ratings yet

- Manual R88D GTDocument508 pagesManual R88D GTcarlos_w_marques7522No ratings yet

- GNS 312 by PlatoDocument332 pagesGNS 312 by PlatoDeandre SpencerNo ratings yet

- EE6303-Linear Integrated Circuits and Applications QBDocument7 pagesEE6303-Linear Integrated Circuits and Applications QBveerananNo ratings yet

- STM32F3 TimersDocument75 pagesSTM32F3 TimersVport Port100% (1)

- Lenovo v330 14ikb Compal La f481p La d562p SchematicDocument66 pagesLenovo v330 14ikb Compal La f481p La d562p Schematicnew b13No ratings yet

- Capacitive Voltage Transformers (CVT) For HV Measurements - EEPDocument8 pagesCapacitive Voltage Transformers (CVT) For HV Measurements - EEPNeelakandan MasilamaniNo ratings yet

- ProcessRoom 2022.10.14-3Document1 pageProcessRoom 2022.10.14-3Muharram SeptionoNo ratings yet

- What Is PowerPointDocument32 pagesWhat Is PowerPointNabeel ShoukatNo ratings yet

- Technology and Psychology - (Yair - Amichai-Hamburger) PDFDocument303 pagesTechnology and Psychology - (Yair - Amichai-Hamburger) PDFAyu Puji LestariNo ratings yet

- CRM DellDocument10 pagesCRM DellSaurabh SharmaNo ratings yet

- Podcasting and VodcastingDocument14 pagesPodcasting and VodcastingJules GajesNo ratings yet

- A9800 Anes. MachineDocument2 pagesA9800 Anes. MachinejoaksadaNo ratings yet

- 20MK02 - Exercise 02Document6 pages20MK02 - Exercise 02SuthanNo ratings yet

- ZF 665 Series: Product DetailsDocument4 pagesZF 665 Series: Product DetailsJhonAlexRiveroNo ratings yet

- 10 - MPK708A Trouble ListDocument3 pages10 - MPK708A Trouble ListArmandRoseNo ratings yet

- Design and Development of Sensor Based Traffic Light SystemDocument5 pagesDesign and Development of Sensor Based Traffic Light SystemAyan BiswasNo ratings yet

- 1N5408Document5 pages1N5408thailanNo ratings yet

- V8 Engine SeminarDocument13 pagesV8 Engine SeminarChandan Kumar25% (4)

- Az5b0s 01FDocument6 pagesAz5b0s 01FJC CNo ratings yet

- Power Dissipation DerivationDocument11 pagesPower Dissipation DerivationHarshal AmbatkarNo ratings yet

- Mcqs in Computer Science 5nbsped 9789351342496 - CompressDocument487 pagesMcqs in Computer Science 5nbsped 9789351342496 - CompressAsimullah, M.Phil. Scholar Department of Computer Science, UoPNo ratings yet

- Film Punch LUT - How To GuideDocument5 pagesFilm Punch LUT - How To GuideHello KiddoNo ratings yet

- Smart Parking System Using Machine Learning and Internet of ThingsDocument9 pagesSmart Parking System Using Machine Learning and Internet of ThingsIJRASETPublicationsNo ratings yet

- ControlM Installation Guide FE8DB562d01Document418 pagesControlM Installation Guide FE8DB562d01omgg1No ratings yet