Professional Documents

Culture Documents

20) 01.+FF-000 Deluge+water+system+general+notes

Uploaded by

shahnawaznOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

20) 01.+FF-000 Deluge+water+system+general+notes

Uploaded by

shahnawaznCopyright:

Available Formats

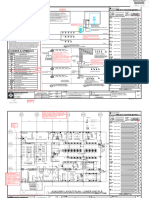

SUMMARY OF HYDRAULIC CALCULATION FIRE PREVENTION DEPARTMENT

PROJECT DESCRIPTION & SCOPE OF WORK FIRE FIGHTING SYSTEM DESIGN GENERAL NOTES GENERAL DIRECTORATE OF CIVIL DEFENCE

CLEAN AGENT FIRE EXTINGUISHING SYSTEM MINISTRY OF INTERIOR, STATE OF QATAR

GENERAL DESCRIPTIONS: 1. ALL DIMENSIONS ARE IN MILLIMETERS AND LEVELS ARE IN METERS UNLESS NOTED OTHERWISE. FF DESIGN CRITERIA FOR CLEAN AGENT FIRE EXTINGUISHING SYSTEMS

>> AUTOMATIC FIRE SUPPRESSION SYSTEM AREA PROTECTED

2. CLEAN AGENT FIRE SUPPRESSION SYSTEM MUST COMPLY WITH NFPA 2001 & 72 AND

THE PROPOSED PROJECT IS A 66/11kV PSS4 SUBSTATION LOCATED IN INDUSTRIAL AREA . KAHRAMAA FIRE SAFETY REQUIREMENT.

REFERENCE:

CRITERIA VALUE UNIT STD. / CODE / CHAPTER

● SPRINKLER SYSTEM PUMP ROOM 3. SYMBOLS USED ARE AS PER NFPA 170 SECTION / TABLE / FIGURE

WITH ANCILLARY BUILDING SUCH AS FIRE PUMP ROOM AND FIRE WATER TANK YARD. 4. THE FINAL LOCATIONS/POSITIONING AND NUMBER OF FIRE ALARM SYSTEM DEVICES ARE SUBJECT TO CHANGE,

● PRE-ACTION SYSTEM _________________ AS PER SITE CONDITIONS. EXTINGUISHING AGENT: HFC-227ea N/A

5. ALL SYSTEM DEVICES AND EQUIPMENT TO BE INSTALLED AS PER NFPA 2001 & 72 AND MANUFACTURER'S REQUIREMENTS

NUMBER OF STOREYS: ● DELUGE WATER SPRAY FIXED SYSTEM POWER TRANSFORMER & AUX. TRANS. & RECOMMENDATIONS. DISCHARGE TIME: 10 Seconds

NFPA-2001,KM SPECIFICATION

● FOAM SYSTEM _________________ 6. ALL CABLING TO COMPLY WITH NFPA 70.

66/11 kV- SUBSTATION BASEMENT, GROUND & ROOF FLOOR STOREY BUILDING 7. THE BACKUP BATTERY SHALL MAINTAIN THE SYSTEM IN NORMAL WORKING CONDITION FOR AT LEAST 24 HOURS. DESIGN CONCENTRATION: 7 %

● CLEAN AGENT SUPPRESSION SYSTEM IT SHALL BE CAPABLE OF SUPPLYING THE FULL EMERGENCY EVACUATION ALARM LOAD FOR AT LEAST 0.5 HOURS.

8. ADDITIONAL DETECTORS SHALL BE PROVIDED IN CASE IF IT IS REQUIRED AS PER SITE CONDITION.

DESIGN TEMPERATURE: 21 °C

9. MANUAL RELEASE STATIONS, ABORT SWITCHES, STATUS INDICATORS TO BE INSTALLED AT SWITCH LEVEL

● FIXED AEROSOL FIRE EXTINGUISHER SYSTEM _________________ NOT LESS THAN 1.07M AND NOT MORE THAN 1.22M ABOVE FFL ACCORDING TO NFPA72.

DESCRIPTION OF EACH LEVELS

10. AUDIBLE & VISUAL ALARMS TO BE INSTALLED 2.25M ABOVE FFL. UNLESS OTHERWISE NOTED.

SUMMARY OF AREAS SERVED BY CLEAN AGENT

● KITCHEN HOOD SUPPRESSION SYSTEM _________________ 11. END OF LINE RESISTORS TO BE INSTALLED ON THE WALL AT 1.4M ABOVE FFL.

1. BASEMENT LEVEL - ELECTRICAL CABLES ON FLOOR & ELECTRICAL CABLE TRAYS. 12. WARNING FLASH LIGHT ARE PROVIDED AT ALL DOORS WHICH ARE PROTECTED BY CLEAN AGENT EXTINGUISHING SYSTEM. ROOM INFORMATION ROOM NAMES

13. MINIMUM DESIGN CONCENTRATION TO BE USED IS 7.0%.

14. WARNING/CAUTION SIGN BOARD SHALL BE PROVIDED OUTSIDE THE PROTECTED AREA. FLOOR LEVEL CONTROL & RELAY PANEL ROOM LV AC/DC PANEL ROOM

2. GROUND LEVEL - 15. FOR EFFECTIVE TOTAL FLOODING OF FM200 CLEAN AGENT EXTINGUISHING SYSTEM,

DESIGN CONCENTRATION IS TO BE ATTAINED AT DISCHARGE & AGENT IS TO BE MAINTAINED FOR 10 MINUTES HOLD TIME. GRID LINE REFERENCE 3 TO 4 / A TO 1 1 TO 3 / F TO I

16. HAZARD VOLUME TO BE AIR TIGHT. SUPPLY & RETURN AIR PATHS IS TO CLOSED AT FIRST STAGE ALARM.

17. ALL MANUAL RELEASE STATIONS SHALL BE HOUSED WITH WEATHER PROOF ENCLOSURE SHEET REFERENCE 11 OF 26 13 OF 26

IF INSTALLED IN AREAS OPEN TO ATMOSPHERE.

3. FIRST LEVEL - ROOM AREA (M²) 244.79 94.55

18. ALL LOW PRESSURE SWITCH SIGNALS SHALL BE CLUBBED TOGETHER AND SEND AS A COMMON SIGNAL

TO THE EXTINGUISHING CONTROL PANEL.

ROOM / FLOOR HEIGHT (M) 4.55 4.55

4. ROOF LEVEL - MEP SERVICE EQUIPMENTS 19. CLEAN AGENT PRESSURE OPERATING SWITCHES SENT THE SIGNALS ACROSS TO FSCP PANEL AND

ALSO TO FIRE ALARM CONTROL PANEL. ROOM / FLOOR VOLUME (M³) 1113.81 430.21

20. THE LOCATION OF EXTINGUISHER SHOWN ON THE DRAWING MAY SLIGHTLY VARY AS PER SITE CONDITION.

MATERIALS ENTRY 21. FIRE EXTINGUISHER IS DESIGNED AS PER THE GUIDE LINES MENTIONED IN NFPA 10,KM SPECIFICATION AND QCDD. ESTIMATED CAPACITY (KG) 705.5 274.5

ANCILLARY BUILDING - FIRE PUMP ROOM & GUARD ROOM SPRINKLER

DIMENSIONS AREA (COMBUSTIBLE OR (ACCESSIBLE OR 22. FIRE EXTINGUISHER SHALL BE MOUNTED ON WALLS AND THE TOP SURFACE NOT MORE THAN 1.5MTS.

(YES / NO)

NON-COMBUSTIBLE) NON-ACCESSIBLE) EACH OF THIS LOCATIONS ON THE WALL SHALL BE MARK "FIRE POINT"IN ENGLISH & ARABIC. NO. OF CYLINDERS &

23. FIRE SHELTER SHALL BE CONNECTED TO THE ROAD/SIDE WALK. CAPACITY PER CYLINDER(KG)

4 / 93.5 & 3 / 110.5 3 / 91.5 APPROVING AUTHORITY

BUILDING CLASSIFICATION : PREVIOUS QCD PLAN APPROVAL REF. NOS.:

<400MM HEIGHT - - - - PS NUMBER : N/2019/0002807 PREVIOUS PS NUMBER :

(HABITABLE HEIGHT)

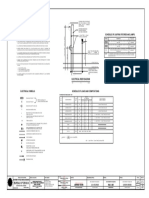

FF DESIGN CRITERIA FOR WATER SPRAY FIXED SYSTEMS

HIGH-RISE BUILDING (28m) FSD/PS/N/M/R ___________________ >400MM - <800MM - - - - DELUGE WATER SPRAY SYSTEM

HEIGHT

EQUIPMENT PROTECTED: 40MVA POWER TRANSFORMER SHEET REFERENCE / DRAWING NUMBER: SHEET 20 OF 31 / FF-401 CONSULTANT'S ENDORSEMENT

1. ALL DIMENSION ARE IN (MM) MILLIMETER UNLESS OTHERWISE SPECIFIED.

MID-RISE BUILDING (>15m - <28m) N/A FLOOR LEVEL: GROUND FLOOR SPECIFIED AREA OF OPERATION: 40MVA TRANSFORMER -3

- - - - 2. ALL ABOVE GROUND PIPING TO BE SUPPORTED PROPERLY.

LOW-RISE BUILDING (<15m) >800MM HEIGHT I ILAYARAJA NEDUNCHEZIAN NEDUNCHEZIAN AMECHANICAL ENGINEER WITH

3. ALL UNDERGROUND PIPING TO BE PROVIDED IN THE RCC TRENCH (RCC TRENCH BY OTHERS). DELUGE VALVE TAGGING: DV-4 MOST REMOTE

N/A 4. ALL EXTERNAL PIPES WILL BE SEAMLESS SCH.40 ASTM A53, GRADE-B;

UPDA REGISTRATION NO. 14191 AS GRADE "A" BEING THE CONSULTANT HEREBY

REMOTEST NOZZLES ELEVATION DIFFERENCE FROM PUMP SUCTION(M): 4.265 MOST DEMAND

HOT DIPPED GALVANIZE AND RED POWDER COATED. CERTIFY THAT THE FIREFIGHTING SYSTEM SHOWN ON THESE PLANS HAS BEEN

5. ALL INTERNAL PIPES WILL BE SEAMLESS SCH.40 ASTM A53, GRADE-B; TYPE OS SPRINKLER SYSTEM: DESIGNED IN ACCORDANCE WITH THE PROVISIONS OF NFPA

HOT DIPPED GALVANIZE AND RED PAINTED. 10,13,14,15,20,101,170,2001 and 5000 AND LOCAL FIRE SAFETY CODES OR

REFERENCE:

6. PIPES & FITTINGS THREADED UPTO Ø50 mm & GROOVED/WELDED FROM Ø65 mm & ABOVE. CRITERIA VALUE UNIT STD. / CODE / CHAPTER

7. FIRE PROTECTION SYSTEM DESIGN AS PER GUIDE LINES MENTIONED IN SECTION / TABLE / FIGURE

STANDARDS BEING IMPOSED BY QATAR CIVIL DEFENSE.

NFPA.13,14, 15, 20, 22, KM TECHNICAL SPECIFICATION AND QCDD REQUIREMENTS. OCCUPANCY: SPECIAL INDUSTRIAL NA

8. ALL DRAIN VALVES TO BE CONNECTED TO NEAREST DRAIN PIT.

FURTHER, I CERTIFY THAT I AM FULLY AWARE AND COMMIT MYSELF RESPONSIBLE

9. ALL DIMENSION INDICATED IN DRAWING SHALL BE VERIFIED AT SITE BEFORE FABRICATION.

HAZARD CLASSIFICATION: ORDINARY NA TO THIS PROJECT AND ALL THE CONDITIONS PRESCRIBED UNDER THE EXISTING

SYSTEM ACTUATION VALVE: DELUGE VALVE NA LAW NO.19 OF 2005, THE LAW REGULATING THE PRACTICE OF ENGINEERING

PROFESSION IN THE STATE OF QATAR.

EQUIPMENT/HAZARD TO BE NA

POWER TRANSFORMER

PROTECTED:

AFFIXED IS MY SIGNATURE TO ATTEST WITH THE ABOVE UNDERTAKINGS.

DESIGN AREA / NET SURFACE AREA 140 M²

DESIGN DENSITY: 10.2 LPM / M²

TYPE OF WATER SPRAY NOZZLE: OPEN SPRAY NOZZLE NFPA-15,KM SPECIFICATION

LIST OF FIREFIGHTING DRAWINGS FIREFIGHTING / LEGEND INFORMATION DESIGN CRITERIA'S NUMBER OF DESIGN NOZZLES: 40 Nos.

NOZZLE K-FACTOR: 20 LPM / (BAR)½

CLEAN AGENT FIRE SUPPRESSION SYSTEM

MIN. PRESSURE PER NOZZLE: 2.1 BAR ILAYARAJA NEDUNCHEZIAN NEDUNCHEZIAN

CLEAN AGENT SYSTEM IS SPECIFICALLY DESIGNED AND INSTALLED IN C & R ROOM & LV AC/DC ROOM,

ALARM SYSTEM IN THE SPECIFIED ROOMS IS AN INTEGRAL PART OF CLEAN AGENT SYSTEM.

Po Box: 5171

LEGEND MIN. FLOW PER NOZZLE: 28.98 LPM

CLEAN AGENT DESIGN, FLOW CALCULATION, RATINGS AND PERFORMANCE SPECIFICATIONS Tel +974: 44191777

Dry Powder Fire Extinguisher ARE BASED ON NFPA-2001 STANDARD FOR CLEAN AGENT FIRE SUPPRESSION SYSTEM. SIZE OF DELUGE VALVE: 100 MM Fax +974: 44433873

Carbon Dioxide Fire Extinguisher Fire brigade inlet PRODUCTS SPECIFIED AND USED IN THIS PROJECT ARE UL LISTED, FM APPROVED AND DETECTION EQUIPMENT: WET PILOT SPRINKLER - 93 C°

4x 2 1/2" Inlet (male) COMPLY WITH NFPA-2001 STANDARD; KM SPECIFICATION & QCDD REQUIREMENT. HYDRAULIC FLOW

Wheeled 50kg Dry Powder Mobile FE CALCULATION SOFTWARE CPY4.02 USED IS DEDICATED FOR SIEMENS SINORIX CLEAN AGENT WATER DURATION: 20 MINUTES UPDA REG. NO. / Grade : 14191 / "A" QATAR ID NO. : 27835624113

FIRE SUPPRESSION SYSTEMS.

Trolley Type

Deluge valve THE CLEAN AGENT FIRE SUPPRESSION SYSTEM FOR THE SUBSTATION ARE COMPRISE OF:- VALIDITY : 24/01/2023 VALIDITY : 21/05/2022

Wheeled FF DESIGN CRITERIA FOR WATER SPRAY FIXED SYSTEMS

100ltrs Mobile Foam FE Non-return valve 1. (1) DEDICATED 2-ZONE FIRE EXTINGUISHING CONTROL PANEL (FECP) ASSEMBLY.

Trolley Type 2. FIELD INITIATING DEVICES LIKE: (SMOKE DETECTOR/ MANUAL RELEASE) EQUIPMENT PROTECTED: 1000kVA AUX. TRANSFORMER SHEET REFERENCE / DRAWING NUMBER: SHEET 24 OF 31 / FF-405

DCV Drip check valve

3. FIELD INDICATING DEVICES LIKE: (BELL; SOUNDER; STROBE & CAUTION LIGHT.

FLOOR LEVEL: GROUND FLOOR SPECIFIED AREA OF OPERATION: 1000kVA AUX.TRANSFORMER -2

7 2 01 7

Flow direction 3/2-way valve 4. ABORT SWITCH TO HOLD TIMER/DISCHARGE OF AGENT. 197

5. CLEAN AGENT CYLINDER & CYLINDER VALVE ASSEMBLY FILLED WITH HFC-227ea GAS. DELUGE VALVE TAGGING: DV-6 MOST REMOTE

DP Diesel engine driven fire pump Filter with throttle disc 3.5 mm

6. SOLENOID TYPE ACTUATOR ASSEMBLY WITH MECHANICAL MANUAL LEVER. REMOTEST NOZZLES ELEVATION DIFFERENCE FROM PUMP SUCTION(M): 1.255 MOST DEMAND Yea

EP Electric motor driven fire pump MG Alarm gong 7. CYLINDER PRESSURE SUPERVISORY (FOR MONITORING) rs

8. PRESSURE SWITCH ASSEMBLY. TYPE OS SPRINKLER SYSTEM:

JP Jockey pump General symbolic for drainage

9. NETWORK PIPING; DISCHARGE HOSES; DISCHARGE NOZZLES; RELATED ANCILLARIES. REFERENCE:

Gate valve M Manual release box DELUGE WATER SPRAY SYSTEM CRITERIA VALUE UNIT STD. / CODE / CHAPTER

Water spray systems are used to protect the main transformer and are usually applied

SECTION / TABLE / FIGURE P.O. Box : 5171, Doha, State of Qatar:

Ball valve Upright Sprinkler

to special fire protection problems beyond the capability of a standard sprinkler system. OCCUPANCY: SPECIAL INDUSTRIAL NA

They are specifically designed for fire control, extinguishment, prevention, or exposure

Tel. : 44191700,44191777, Fax. : +974 44433873

Globe valve Release sprinkler

protection. These systems typically require that the water be applied rapidly to all HAZARD CLASSIFICATION: ORDINARY NA

Check valve Spray nozzle protected surfaces at the same time, an objective that might not be possible with E-mail. : mail@qdcqatar.net

closed nozzles. SYSTEM ACTUATION VALVE: DELUGE VALVE NA

Check valve with orifice Test valve K...

In addition, to protect specific surfaces, the use of special nozzles with directional EQUIPMENT/HAZARD TO BE

discharge is employed. The placement of these nozzles to provide proper coverage is PROTECTED:

AUX. TRANSFORMER NA HEAD OF OFFICE SIGNATURE

Pressure gauge stopvalve Pressure gauge, glycerinefilled

for pressure switch, often in conflict with the required placement to ensure prompt operation where automatic

detached handwheel PS Pressure switch nozzles are used. Thus, the standard contemplates that open nozzles will normally be DESIGN AREA / NET SURFACE AREA 22 M² UPDA REG. NO. / GRADE : L/20 QATAR ID NO. : 140202

employed and that a separate detection system will be used to actuate the system.

Nozzles are generally position to cover and wet the entire surface area of transformer DESIGN DENSITY: 10.2 LPM / M²

Air vent valve Pressure transmitter

body and its appurtenances.

VALIDITY : 27/01/2022 COMPANY REG. GRADE "A"

PRV

Pressure relief valve LI Level indicator TYPE OF WATER SPRAY NOZZLE: OPEN SPRAY NOZZLE NFPA-15,KM SPECIFICATION

SPRINKLER SYSTEM

DPRV

THE ENTIRE FIRE-FIGHTING PUMP ROOM IS PROTECTED BY AUTOMATIC SPRINKLER SYSTEM DESIGNED NUMBER OF DESIGN NOZZLES: 11 Nos.

Deluge pressure relief valve LS Level switch

AS PER NFPA 13, 2010 EDITION. THE SYSTEM IS PROVIDED WITH THE HEAT ACTUATED GLASS BULB

NOZZLE K-FACTOR: 20 LPM / (BAR)½ 6 RE ISSUED FOR QCDD APPROVAL 02/01/2022 RM IR IR

Strainer FS Flow switch TYPE SPRINKLERS OS&Y GATE VALVE CONNECTED TO THE MAIN DELIVERY LINE. THE SYSTEM IS ALWAYS

PRESSURIZED. IN CASE OF FIRE, DUE TO INCREASE IN TEMPERATURE, THE GLASS BULB RUPTURE RE ISSUED FOR QCDD APPROVAL

Silencer, outlet with mesh VS Valve supervisory switch FOLLOWING WATER FLOW THROUGH ALL SPRINKLERS THAT ARE OPEN DUE TO HEAT AND ALARM ACTIVATED

MIN. PRESSURE PER NOZZLE: 2.1 BAR 5 25/11/2021 RM IR IR

THROUGH WATER FLOW ALARM SWITCH. THE WATER FROM THE MAIN HEADER WILL START FLOWING

THROUGH THE SYSTEM. THE DROP OF MAIN DELIVERY LINE PRESSURE WILL ACTIVATE THE PUMPS AND

MIN. FLOW PER NOZZLE: 28.98 LPM

4 RE ISSUED FOR QCDD APPROVAL 18/10/2021 RM IR IR

Float switch

CONTINUOUS PRESSURIZED WATER WILL BE SUPPLIED TO THE SPRINKLER SYSTEM. SIZE OF DELUGE VALVE: 50 MM

Water flow meter

3 RE ISSUED FOR QCDD APPROVAL 23/05/2021 RM IR IR

Heat detector

FM

THE FIRE FIGHTING PUMP ROOM IS PROVIDED WITH SEPARATE ZONAL CONTROL STATION, WHICH

R/F-1

INCLUDES (1) SUPERVISORY SWITCH (OS&Y GATE VALVE), WATER FLOW SWITCH AND INTEGRATED TEST DETECTION EQUIPMENT: WET PILOT SPRINKLER - 93 C°

CUM DRAIN VALVE. THE FLOW SWITCH WILL SEND THE SIGNAL OF SPRINKLER SYSTEM ACTUATED. 2 RE ISSUED FOR QCDD APPROVAL 04/03/2021 RM IR MP

WATER DURATION: 20 MINUTES

FIRE ALARM CONTROL PANEL FIRE EXTINGUISHING CONTROL PANEL

1 RE ISSUED FOR QCDD APPROVAL 14/01/2021 RM IR MP

SUMMARY OF HYDRAULIC CALCULATION 0 ISSUED FOR QCDD APPROVAL 28/12/2020 RM IR MP

P-2

OPTICAL SMOKE DETECTOR PS

1

PRESSURE SWITCH

SEQUENCE OF OPERATION FILE NAME / REFERENCE LOCATION OF AREA SIMULATED TYPE OF SYSTEM SIMULATED

CALCULATION CALCULATION

REV. DESCRIPTION DATE DRAWN CHECKED APPROVED

FLOW (GPM/LPM) PRESSURE (PSI/kPa)

CONTACT PRESSURE GAUGE DELUGE WATER SPRAY SYSTEM GROUND FLOOR

PRESSURE SWITCH INCLUDED CA MANUEL RELEASE PUSH BUTTON F-C001/40MVA.P.TRANS POWER TRANSFORMER-3 OPEN SPRAY NOZZLE 415.85 / 1574 78.30 / 540.00 CLIENT / OWNER

1. AT NORMAL CONDITION, MAIN SUPPLY VALVE AND MAIN DRAIN VALVE ARE CLOSED.

1

PRIMING LINE IS PRESSURIZED, KEEPING THE DELUGE VALVE DIAPHRAGM CLOSED.

GROUND FLOOR

2. IF FIRE ACTIVATES THE WET PILOT SPRINKLERS, WATER FROM DIAPHRAGM CHAMBER F-C001/AUX.TRANS AUX. TRANSFORMER-2 OPEN SPRAY NOZZLE 85.86 / 325 36.83 / 254.00

HORN/FLASH LIGHT IS RELEASED.

CA 1 1 3. WATER IS RELEASED FROM DIAPHRAGM CHAMBER FASTER THAN IT CAN BE REPLACED GROUND FLOOR

BY RESTRICTION LINE IN THE AUTOMATIC SHUT-OFF VALVE. F-C001/SPRINKLER FIRE PUMP ROOM SPRINKLER 126.55 / 479 28.85 / 199.00

4. RAPID PRESSURE DROP IN THE DIAPHRAGM CHAMBER ALLOWS DIAPHRAGM TO OPEN,

ALLOWING WATER TO ENTER THE SYSTEM.

ALARM BELL

1 V 5. WATER FLOWS INTO THE ALARM TRIM AND ACTIVATES THE WATER FLOW PRESSURE

ALARM SWITCH TO TRIGGER THE FIRE ALARM. THE AUTOMATIC DRAIN VALVE IS CLOSED.

6. WATER PASSES THROUGH THE TRIM TO THE AUTOMATIC SHUT-OFF VALVE TO PREVENT THE

STATUS INDICATOR DIAPHRAGM CHAMBER FROM BECOMING RE-PRESSURIZED.

2

DK

WITH AUTO / MANUAL SWITCH 7. WATER WILL SPRAY OUT THE MAIN SPRINKLER SYSTEM THROUGH THE NOZZLES.

8. AFTER FIRE IS UNDER CONTROL, VALVE IS MANUALLY CLOSED TO CUT OFF THE WATER

SUPPLY.THE DIAPHRAGM CHAMBER SUPPLY VALVES ALSO CLOSED.

EOL 9. THEN, THE MAIN DRAIN AND ALL SYSTEM DRAINS ARE OPENED TO DRAIN THE SYSTEM. FIRE PUMP & FIRE WATER TANK

RE 10. AFTER WATER CEASES TO DISCHARGE, CLOSE THE AUXILIARY DRAINS. KEEP THE MAIN

DRAIN OPEN. PROJECT TITLE

11. RESET THE WET PILOT ACTUATION SYSTEM, BY REPLACING ANY OPERATED PILOT

SPRINKLERS.

12. OPEN THE DIAPHRAGM CHAMBER SUPPLY VALVE SO THE DIAPHRAGM CHAMBER CAN

BEGIN TO FULL PRESSURE.

13. THE DIAPHRAGM CHAMBER WILL COMPLETELY CLOSE ONCE THE CHAMBER RETURNS TO

FULL PRESSURE.

14. FINALLY, SLOWLY OPEN THE MAIN SUPPLY VALVE AND CLOSE THE MAIN DRAIN ONCE WATER MOTOR

BEGINS TO DISCHARGE FROM THE DRAIN. UNIT CAPACITY TOTAL HEAD DESCRIPTION

EQUIPMENT LOCATION

CLEAN AGENT FIRE SUPPRESSION SYSTEM TAG (GPM) (bars) (TYPE)

HP VOLTS PHASE HZ

I. AUTOMATIC OPERATION

A. ACTUATION OF 1ST DETECTOR WITHIN THE SYSTEM WILL: ELECTRIC GND - FIRE HORIZONTAL

EFP 75 415 3 50 750 8.2

1. ILLUMINATE "ALARM" LAMP ON THE CONTROL PANEL. FIRE PUMP PUMP ROOM SPLIT CASE

AREA OF STATEMENT ABBREVIATION 2. ACTIVATE ALARM BELL INSIDE THE ROOM. (1st STAGE) DIESEL ENGINE GND - FIRE HORIZONTAL

3. SEND PRE-ALARM SIGNAL TO FACP. DFP

FIRE PUMP

115 230 1 50 750 8.2

PUMP ROOM SPLIT CASE

4. SEND SIGNAL TO CLOSE ASSOCIATED FIRE DAMPER OR SHUT DOWN HVAC.

Z ZONE E ENCLOSURE JOCKEY GND - FIRE VERTICAL

B. ACTUATION OF 2ND DETECTOR WITHIN THE SYSTEM WILL: JP 2 415 3 50 15 8.7

PUMP PUMP ROOM MULTISTAGE

D DETECTOR N NOZZLE 1. ILLUMINATE "PRE-DISCHARGE" INDICATOR ON THE FSCP.

2. ACTIVATE HORN STROBES (VISUAL & AUDIO ALARMS) INSIDE & OUTSIDE THE ROOM.

FSCP FIRE SUPPRESSION CONTROL PANEL PS PIPE SUPPORT 3. ENABLE PRE-DISCHARGE TIME DELAY (60 SEC.). LOCATION : INDUSTRIAL AREA PIN : 81050420

4. ENABLED SYSTEM ABORT SEQUENCE.

FACP FIRE ALARM CONTROL PANEL FFL FINISHED FLOOR LEVEL. STREET :

FIRE WATER TANK

AREA : 5500.00 m² PLOT :

IRM IMPULSE RELEASE MODULE EL ELEVATION. C. AFTER PRE-SET TIME DELAY SEQUENCE, THE FOLLOWING SHALL OCCUR:

TYPE OF NO. OF EFFECTIVE

1. ACTUATE CIRCUIT TO RELEASE HFC 227 AGENT TO THE AFFECTED AREA. LOCATION EFFECTIVE DURATION DRAWING TITLE:

CHM CONTROL HEAD MONITOR FWL FINISHED WALKWAY LEVEL. CONSTRUCTION COMPARTMENTS CAPACITY

2. ILLUMINATE "RELEASE" INDICATOR ON THE FSCP.

20 MINUTES.

RP RELAY PANEL FRL FINISHED ROAD LEVEL. 3. SEND RELEASE SIGNAL TO FACP. GROUND FLOOR GALVANIZED STEEL & BOLTED 30.00 CU. M EACH

2 NOS. (AS PER KAHRAMAA

(BESIDE PUMP ROOM) SECTIONAL WITH LINER (60.00 CU. M TOTAL)

REQUIREMENTS)

II. MANUAL OPERATION

POCH PRESSURE OPERATED CONTROL HEAD FGL FINISH GROUND LEVEL.

A. ACTIVATION OF MANUAL RELEASE STATION SHALL:

1. ALL OPERATION OF B & C AS DESCRIBED ABOVE EXCEPT TIME DELAY AND ABORT FUNCTION.

LPS LOW PRESSURE SWITCH RI REMOTE INDICATOR B. ACTIVATION OF MANUAL RELEASE ON THE CYLINDER VALVE SHALL:

BOTTOM OF SLEEVE

1. ALL OPERATION OF B & C AS DESCRIBED ABOVE EXCEPT TIME DELAY AND ABORT FUNCTION. DELUGE WATER SYSTEM GENERAL NOTES & LEGENDS

BOS SLC SIGNALING LINE CERCUIT

III. ABORT OPERATION COVER PAGE

A. IF ABORT SWITCH IS ACTIVATED WITHIN PRE-DISCHARGE PERIOD, THE FOLLOWING SHALL OCCUR;

1. ABORT INDICATION ON THE FSCP.

2. RELEASE OF AGENT IS HELD IF ABORT SWITCH IS PRESSED CONTENTIOUSLY.

3. AGENT WILL RELEASE IF ABORT SWITCH IS DEACTIVATED & COUNT DOWN IS COMPLETED.

REVISION NO.: 6 QCDD DWG NO. : FF-000 SHEET NO. : 01 OF 31

DATE : 02/01/2022 SCALE : NTS

You might also like

- Isx15 CM2250 4022234Document1 pageIsx15 CM2250 4022234Josuu Garcia100% (7)

- Api 6a PDFDocument42 pagesApi 6a PDFremyshazwan100% (6)

- Renovation Plan for Unit 27A at 99 Battery PlaceDocument30 pagesRenovation Plan for Unit 27A at 99 Battery Placeart cafeNo ratings yet

- Isx15 CM2250 4022234Document1 pageIsx15 CM2250 4022234Omar HernándezNo ratings yet

- X15 Cm2350 X116B - Performance Series Wiring DiagramDocument1 pageX15 Cm2350 X116B - Performance Series Wiring DiagramVeterano del Camino100% (3)

- Hydraulic EngineeringDocument8 pagesHydraulic Engineeringcharan__No ratings yet

- Mv-01 Project DetailsDocument1 pageMv-01 Project DetailsriyazNo ratings yet

- Project Description Fire Safety Provisions Occupant Load CalculationsDocument1 pageProject Description Fire Safety Provisions Occupant Load CalculationsAbid AyubNo ratings yet

- Cover PagDocument1 pageCover Pagwael hassanNo ratings yet

- Fire prevention system sequence of operationDocument1 pageFire prevention system sequence of operationmuthazirNo ratings yet

- 1245 F A0 0001Document1 page1245 F A0 0001Eugene Francis CastroNo ratings yet

- Qatar Fire Safety Guidelines for Residential ApartmentsDocument122 pagesQatar Fire Safety Guidelines for Residential ApartmentsNirupan Kumar100% (1)

- Qatar Fire Safety Guidelines for Residential ApartmentsDocument122 pagesQatar Fire Safety Guidelines for Residential ApartmentsAbdul Jamal100% (1)

- Auxiliary drawing (CCTV AND DATA) for sample projectDocument3 pagesAuxiliary drawing (CCTV AND DATA) for sample projectengrpaulppangilinanNo ratings yet

- Aq 211105 001Document1 pageAq 211105 001Qudsi NayazNo ratings yet

- Summary of Hydraulic Calculation: Area ProtectedDocument10 pagesSummary of Hydraulic Calculation: Area ProtectedsalesNo ratings yet

- Pages From All Drawings - Bid SetDocument2 pagesPages From All Drawings - Bid SetbilalNo ratings yet

- CM00-CS03-CEG-ARC-DWG-030001-COVER PAGE (Life Safety)Document1 pageCM00-CS03-CEG-ARC-DWG-030001-COVER PAGE (Life Safety)AjmeerNo ratings yet

- Basement Ventilation (003) - ModelDocument1 pageBasement Ventilation (003) - ModelUri BabaNo ratings yet

- FP-01 Front PageDocument1 pageFP-01 Front PageBerlin Andrew SionNo ratings yet

- Demolition Notes General Notes General Notes: Creative Structures ServicesDocument1 pageDemolition Notes General Notes General Notes: Creative Structures ServicesHanif KhanNo ratings yet

- Ugc 01 Geo SCP 1100 002 ADocument1 pageUgc 01 Geo SCP 1100 002 AAlhad PanwalkarNo ratings yet

- Mechanical Abbreviations and Symbols: Project Number: 629 - 247637Document30 pagesMechanical Abbreviations and Symbols: Project Number: 629 - 247637phlxuNo ratings yet

- Cs B Final Report Valero SunrayDocument11 pagesCs B Final Report Valero Sunrayjmz mtzNo ratings yet

- Humidification ShowersDocument1 pageHumidification ShowersRifai IndraswariNo ratings yet

- General specifications and legends for mechanical drawingsDocument1 pageGeneral specifications and legends for mechanical drawingsinno de los santosNo ratings yet

- Va CadDocument4 pagesVa Cadrov1976No ratings yet

- M 02Document1 pageM 02prokjongNo ratings yet

- Owner Manual - MonarchDocument4 pagesOwner Manual - MonarchYoyon HaryonoNo ratings yet

- Notes Legends ECSDocument1 pageNotes Legends ECSAmando GonzalesNo ratings yet

- Aq 211101 001Document1 pageAq 211101 001Qudsi NayazNo ratings yet

- Egyptian Natural Gas Holding Company: REV Date Description Check BY ApprovedDocument14 pagesEgyptian Natural Gas Holding Company: REV Date Description Check BY ApprovedOmar KhaledNo ratings yet

- Fire Protection Bid SetDocument7 pagesFire Protection Bid SetMaxwellNo ratings yet

- SMD-PE-FF-91-001-01 Fire Protection System Philosophy (Indoor and Outdoor)Document17 pagesSMD-PE-FF-91-001-01 Fire Protection System Philosophy (Indoor and Outdoor)Yaser AhmadNo ratings yet

- 2015 0526 DWG Fire DDSetDocument16 pages2015 0526 DWG Fire DDSetnadiruuzaman sizanNo ratings yet

- Typical Standard Lift Station - WWSTypicalStandardLiftStation PDFDocument13 pagesTypical Standard Lift Station - WWSTypicalStandardLiftStation PDFTahirJabbarNo ratings yet

- Sheet 02 of 03Document1 pageSheet 02 of 03AHMED TAHERNo ratings yet

- SA320Document1 pageSA320RoshNo ratings yet

- Kfss 1: Deyu CaiDocument1 pageKfss 1: Deyu CaiSKYLERNo ratings yet

- Overhead service entrance 230V 1Ø 2W 60Hz with weatherheadDocument1 pageOverhead service entrance 230V 1Ø 2W 60Hz with weatherheadrafael nazaretaNo ratings yet

- M-0.1 - Mechanical SpecificationsDocument1 pageM-0.1 - Mechanical SpecificationsAbdellatif AlhNo ratings yet

- Disclosure To Promote The Right To InformationDocument36 pagesDisclosure To Promote The Right To InformationInnovative Safety MarinesNo ratings yet

- Plumbing Permit Drawings PDFDocument3 pagesPlumbing Permit Drawings PDFJeremy BoyceNo ratings yet

- Deepak Pandey logs into engineering project files on 8/31Document1 pageDeepak Pandey logs into engineering project files on 8/31அம்ரு சாந்திவேலுNo ratings yet

- RFII-MRI - 5.6 K-Factor - Non Magnetic SprinklerDocument4 pagesRFII-MRI - 5.6 K-Factor - Non Magnetic SprinklerValentin A.No ratings yet

- Va250 16 B 0621 005 PDFDocument52 pagesVa250 16 B 0621 005 PDFkishoreNo ratings yet

- Inert Gas Generators: Design Practices Fired Heaters Subsection L Exxon EngineeringDocument5 pagesInert Gas Generators: Design Practices Fired Heaters Subsection L Exxon EngineeringFRANKLIN REVILLANo ratings yet

- Normal SparesDocument1 pageNormal SparesPrabuNo ratings yet

- Dol 0000 Ppi 00001 - Z19Document1 pageDol 0000 Ppi 00001 - Z19ywahyudiNo ratings yet

- RA612003001P0A1Document1 pageRA612003001P0A1Muhammad AbrarNo ratings yet

- PDF cm2880 Wiring Diagram en - CompressDocument1 pagePDF cm2880 Wiring Diagram en - CompressTaller Automotriz GLNo ratings yet

- Miami Inn 2.0Document4 pagesMiami Inn 2.0construdico serviceNo ratings yet

- LS-101 - Rev. 01Document1 pageLS-101 - Rev. 01david901221No ratings yet

- Clint Over Prodotti ENG-GREEK 2018 WDocument2 pagesClint Over Prodotti ENG-GREEK 2018 WlibegradNo ratings yet

- M-2 - Lower Ground FLR AC & Vent Equipt LayoutDocument1 pageM-2 - Lower Ground FLR AC & Vent Equipt LayoutJennifer AmionNo ratings yet

- Gas Detection Layout For EnquiryDocument1 pageGas Detection Layout For EnquiryShanmugamoorthyNo ratings yet

- Sop & Jsa For Pipe LeakageDocument1 pageSop & Jsa For Pipe LeakageSoumya ChatterjeeNo ratings yet

- PHC Satrod Layout PlanDocument1 pagePHC Satrod Layout PlanOnlyyJ XtraNo ratings yet

- QCD-FS-G.Annex Rev2015 PDFDocument1 pageQCD-FS-G.Annex Rev2015 PDFvhin84No ratings yet

- Annex 02Document12 pagesAnnex 02rukshan jayasingheNo ratings yet

- Understand The NEC Rules For Back Up Power SystemDocument45 pagesUnderstand The NEC Rules For Back Up Power SystemJun Rey DasigNo ratings yet

- Fact-Data: ManufacturerDocument2 pagesFact-Data: Manufacturersandrapat45No ratings yet

- METAL PUTTY TECHNICAL DATA SHEETDocument2 pagesMETAL PUTTY TECHNICAL DATA SHEETabdullahNo ratings yet

- Cross Regulator EstimateDocument6 pagesCross Regulator EstimateIrfan ShaNo ratings yet

- Tyco HV Cable and Arresters Ans InsulatorDocument104 pagesTyco HV Cable and Arresters Ans InsulatorRazvan MaresNo ratings yet

- CMV Fracture Toughness ArticleDocument10 pagesCMV Fracture Toughness ArticleFlo RenceNo ratings yet

- Thermal Properties of ConcreteDocument8 pagesThermal Properties of ConcreteS Praveenkumar100% (1)

- Mini ProjectDocument58 pagesMini ProjectDeepak Varma50% (2)

- VAUTID ASW 143 Engl 041016Document1 pageVAUTID ASW 143 Engl 041016rusf123No ratings yet

- Technical Specification for Match-It Outdoor UnitsDocument4 pagesTechnical Specification for Match-It Outdoor UnitsNaye JuárezNo ratings yet

- Ib Tutorial 4 (12 13) Sem 2Document5 pagesIb Tutorial 4 (12 13) Sem 2omarnasriNo ratings yet

- Design File Type RUBDocument116 pagesDesign File Type RUBAbilaash VNo ratings yet

- Fundiciones Nardo Presentation LetterDocument2 pagesFundiciones Nardo Presentation LetterEnrique PGNo ratings yet

- METAL CASTING GUIDEDocument18 pagesMETAL CASTING GUIDEvelavansuNo ratings yet

- Brochure - Luffa Cylindrica Fiber As An Additive in Concrete MIxtureDocument2 pagesBrochure - Luffa Cylindrica Fiber As An Additive in Concrete MIxtureRhizyl Jhane EstrellaNo ratings yet

- CE032 FINAL ReformattedDocument11 pagesCE032 FINAL ReformattedElakkiya KarthicNo ratings yet

- IntroductionDocument24 pagesIntroductionDexter JasmaNo ratings yet

- Insulation Material Glass WoolDocument16 pagesInsulation Material Glass WoolAtiq_2909No ratings yet

- Structure Material Details & WeightDocument2 pagesStructure Material Details & WeightRahul SahaNo ratings yet

- 01-15-14 Concrete Damaged Plasticity ModelDocument13 pages01-15-14 Concrete Damaged Plasticity ModelatchzytNo ratings yet

- Fluid Flow Measurement Theory and TypesDocument4 pagesFluid Flow Measurement Theory and TypesJoshua ReynoldsNo ratings yet

- Acoustical Design Materials Concert HallsDocument30 pagesAcoustical Design Materials Concert HallsAyesha AnnNo ratings yet

- Catalogo Küpper PDFDocument70 pagesCatalogo Küpper PDFguiller_vasquezNo ratings yet

- Section A: 2.1. Sling Design Load and SelectionDocument30 pagesSection A: 2.1. Sling Design Load and SelectionThomas StephenNo ratings yet

- Transeals Identifying Hydraulic SealsDocument28 pagesTranseals Identifying Hydraulic Sealsvikram_007No ratings yet

- Tarifa PVP IluminacionDocument16 pagesTarifa PVP IluminaciongesticorslNo ratings yet

- 41.is25 - General Guidance On Shielding Requirements For Medical X-Ray Diagnostic RoomsDocument2 pages41.is25 - General Guidance On Shielding Requirements For Medical X-Ray Diagnostic RoomsMuzri MuhammoodNo ratings yet

- Midterm 112Document3 pagesMidterm 112demplelugoNo ratings yet