Professional Documents

Culture Documents

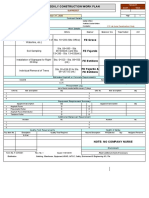

Daily Report: Réhabilitation Du Palais Présidentiel Du République Du Niger

Uploaded by

Baba YagaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Daily Report: Réhabilitation Du Palais Présidentiel Du République Du Niger

Uploaded by

Baba YagaCopyright:

Available Formats

Day : Tuesday

Date : 24-Nov-20

Hari

Daily Report Weeks : 102

Tanggal

RÉHABILITATION DU PALAIS PRÉSIDENTIEL DU RÉPUBLIQUE DU NIGER

Minggu Ke

Work Durations number of workers Volume

NO Job Description Working Hours Unit Material / Information Material

(Hours) Ind WorkersLocal Workers Tools Ind Workers

Local Workers Tools

A. EARTHWORK 0 5 0 0

a.1 Shifting and backfilling on corridor zone 1 ### s/d ### 0 0 0 0 0 m3

a.2 Manual excavation for footing corridor PoP ### s/d ### 10 0 5 0 0 m3

a.3 Backfilling area tie beam and slab on ground PoP ### s/d ### 0 0 0 0 0 m3

a.4 Excavation for footing PoP ### s/d ### 0 0 0 0 0 m3

B.1 CONCRETE FOR COLUMN 2 9 0 0

b.1.1 Casting concrete for column GF and tie beam PoP ToC -0.050 ### s/d ### 6 2 9 0 0 m3 start working for cleaning and shifting materiel

b.1.2 ### s/d ### 0 0 0 0 0

b.1.3 ### s/d ### 0 0 0 0 0

B.2 CONCRETE FOR BEAM 0 0 0 0

b.2.1 ### s/d ### 0 0 0 0 0 m3

b.2.2 ### s/d ### 0 0 0 0 0

b.2.3 ### s/d ### 0 0 0 0 0

B.3 CONCRETE FOR SLAB/FLOOR PLATE 0 0 0 0

b.3.1 ### s/d ### 0 0 0 0 0 m3

b.3.2 ### s/d ### 0 0 0 0 0

b.3.3 ### s/d ### 0 0 0 0 0

C.1 FORMWORK FOR COLUMN 12 4 0 0

c.1.1 Workshop ### s/d ### 10 3 0 0 0 m2

c.1.2 Fabrication on site ### s/d ### 10 4 0 0 0 m2

c.1.3 Install and dihutter formwork for column GF PoP ### s/d ### 10 0 4 0 0 m2

c.1.4 Install and dishutter formwork column GF and FF PoP, pedest ### s/d ### 12 5 0 0 0 m2

c.1.5 Install formwork for pedestal column PoP ### s/d ### 0 0 0 0 0 m2

C.2 FORMWORK FOR BEAM 11 8 0 0

c.2.1 Install and dishutter formwork for beam PoP ToC -0.050 ### s/d ### 0 0 0 0 0 m2

c.2.2 Instal formwork beam and slab PoP ToC +5.250 (zone 4A) ### s/d ### 15 0 8 0 0 m2

c.2.3 Install formwork for beam and slab Roof PoP ToC +10.800 ### s/d ### 13 5 0 0 0 m2

c.2.4 Instal formwork beam and slab PoP ToC +5.250 ### s/d ### 10 6 0 0 0 m2

c.2.5 Dishutter formwork beam and slab corridor on zone 1 ToC -0. ### s/d ### 0 0 0 0 0 m2

C.3 FORMWORK FOR SLAB 0 5 0 0

c.3.1 Install formwork slab on ground PoP ToC -0.050 ### s/d ### 0 0 0 0 0 m2

c.3.2 Joint and setting formwork for doom HoS ToC +6.350 ### s/d ### 0 0 0 0 0 m2

c.3.3 Dishutter formwork ring beam and slab FF PoP ToC +5.250 ### s/d ### 10 0 5 0 0 m2

c.3.4 Dishutter formwork ring beam and slab post control type 1 on ### s/d ### 0 0 0 0 0 m2

c.3.5 Install formwork for beam and slab HoS ToC -0.050 (garden a ### s/d ### 0 0 0 0 0 m2

D.1 REBAR FOR COLUMN 5 5 0 0

d.1.1 Fabrication Rebar ### s/d ### 12 5 1 0 0 kg

d.1.2 Install rebar footing and pedestal PoP ### s/d ### 0 0 0 0 0 kg

d.1.3 Prefabrication rebar for column and lintel beam ### s/d ### 12 0 0 0 0 kg

d.1.4 Erection and install rebar column GF PoP ### s/d ### 10 0 4 0 0 kg sims

d.1.5 Install rebar for column GF PoP (prefab) ### s/d ### 0 0 0 0 0 kg

D.2 REBAR FOR BEAM 5 0 0 0

d.2.1 Install rebar for ring beam and slab PoP ToC +10.800 ### s/d ### 0 0 0 0 0 kg

d.2.2 Install rebar for beam FF PoP ToC +5.250 ### s/d ### 12 5 0 0 0 kg

d.2.3 ### s/d ### 0 0 0 0 0 kg

D.3 REBAR FOR SLAB 0 15 0 0

d.3.1 Install rebar for slab on ground PoP ### s/d ### 0 0 0 0 0 kg

d.3.2 Install rebar beam and slab first floor PoP ToC +5.250 (zone 2 ### s/d ### 10 0 7 0 0 kg sims

d.3.3 Install rebar slab first floor PoP ToC +5.250 (zone 4a) ### s/d ### 15 0 8 0 0 kg sims

E. Masonry 4 47 0 0

e.1 Install brick for GF PoP ### s/d ### 9 0 11 0 0 m2 sirius

e.2 Install brick for window and corridor area ballroom ### s/d ### 11 0 20 0 0 m2 sirius

e.3 Fabrication brique ### s/d ### 9 0 6 0 0 pcs sirius

e.4 Install brick for paraphet roof ballroom ToC +9.600 ### s/d ### 0 0 0 0 0 m2

e.5 Install brick for expose stair PoP ### s/d ### 12 4 0 0 0 m2

e.6 Install brick for GF PoP ### s/d ### 12 0 10 0 0 m2 wala group

e.7 Install brick for paraphet roof post control type 2 unit 1 ### s/d ### 0 0 0 0 0 m'

F. Plastering 0 4 0 0

f.1 Finishing wall with stuccofiller on HoS ### s/d ### 0 0 0 0 0 m2

f.2 Install head of plaster on ballroom ### s/d ### 0 0 0 0 0 m'

f.3 Plastering wall of ballroom ### s/d ### 10 0 3 0 0 m2 sirius

f.4 Plastering for paraphet roof PoP ToC +10.800 ### s/d ### 10 0 1 0 0 m2 wala group

f.5 ### s/d ### 0 0 0 0 0 m2

G. Baja 0 0 0 0

g.1 ### s/d ### 0 0 0 0 0 kg

g.2 ### s/d ### 0 0 0 0 0 kg

g.3 ### s/d ### 0 0 0 0 0 kg

g.4 ### s/d ### 0 0 0 0 0 kg

g.5 ### s/d ### 0 0 0 0 0 kg

H. Anti-Thermite 0 0 0 0

h.1 ### s/d ### 0 0 0 0 0 m2

h.2 ### s/d ### 0 0 0 0 0

h.3 ### s/d ### 0 0 0 0 0

h.4 ### s/d ### 0 0 0 0 0

h.5 ### s/d ### 0 0 0 0 0

I. Waterproofing Sub Structure 0 0 0 0

i.1 ### s/d ### 0 0 0 0 0 m2

i.2 ### s/d ### 0 0 0 0 0

i.3 ### s/d ### 0 0 0 0 0

i.4 ### s/d ### 0 0 0 0 0

i.5 ### s/d ### 0 0 0 0 0

J. Waterproofing Wet Area 0 0 0 0

j.1 ### s/d ### 0 0 0 0 0

j.2 ### s/d ### 0 0 0 0 0

j.3 ### s/d ### 0 0 0 0 0

j.4 ### s/d ### 0 0 0 0 0

j.5 ### s/d ### 0 0 0 0 0

K Lain-Lain 36 18 0 0 ls

k.1 Storing ### s/d ### -7 2 0 0 0 ls 2 shift

k.2 MEP Crew ### s/d ### 10 1 0 0 0 ls

k.3 SHE Crew ### s/d ### 10 4 4 0 0 ls

k.4 Surveyor Crew ### s/d ### 10 2 0 0 0 ls

k.5 Scaffolder ### s/d ### 10 1 0 0 0 ls

k.6 Canteen Crew and office boy ### s/d ### 10 2 0 0 0 ls

k.7 Driver and Operator ### s/d ### 12 3 5 0 0 ls

k.8 Warehouse assistant ### s/d ### 10 1 0 0 0 ls

k.9 Laboratory quality control assistant ### s/d ### 10 1 0 0 0 ls

k.10 Equipment assistant ### s/d ### 12 0 1 0 0 ls

k.11 Foreman ### s/d ### 10 1 0 0 0 ls

k.12 Leave or sick ### s/d ### 8 6 3 0 0 ls

k.13 Shifting materiel for metal structure ### s/d ### 0 0 0 0 0 ls

k.14 Fabrication door and windows SVB ### s/d ### 0 0 0 0 0 set

k.15 levelling land for LC tie beam corridor PoP ### s/d ### 0 0 0 0 0 m2

k.16 Fabrication of concrete deck ### s/d ### 10 1 0 0 0 ls

k.17 Cleaning and shifting materiel ### s/d ### 0 0 0 0 0 ls

k.18 Install a frame celling in SVB ### s/d ### 9 0 5 0 0 m2 aigle royal

k.19 Install mockarabieh in Ballroom ### s/d ### 10 3 0 0 0 m2 Valasindo

k.20 Removing doors and windows from safe house ### s/d ### 0 0 0 0 0 m3

k.21 Install metal structure and metal roof in the ballroom ### s/d ### 10 8 0 0 0 kg Valasindo

k.22 Finishing and expose column and beam ### s/d ### 0 0 0 0 0 ls

25

L Alat

l.1 Excavator ### s/d ### 10 1 0

l.2 Trailler Truck ### s/d ### 9 0 0

l.3 Compactor ### s/d ### 10 1 0

l.4 Bob Cat ### s/d ### 0 0 0 bobcat off

l.5 Fiori ### s/d ### 10 2 0

l.6 Rough Terrain Crane ### s/d ### 10 1 0

l.7 Concrete Vibrator ### s/d ### 10 3 0

l.8 Bar Bending ### s/d ### 10 1 0

l.9 Bar Cutter ### s/d ### 10 1 0

l.10 Flat Bed Truck ### s/d ### 10 1 0

l.11 Circle Cutter ### s/d ### 10 4 0

l.12 Welding Machine ### s/d ### 10 4 0

l.13 Stamper ### s/d ### 10 1 0

l.14 Compressor ### s/d ### 10 1 0

l.15 Tile Cutter ### s/d ### 10 2 0

l.16 Seaming Roofing Machine ### s/d ### 10 2 0

l.17 Hand Bor ### s/d ### 10 6 0

Indonesia Local

n

Workers Workers ###

Temperature (Celcius) Amount of Working Hours Overtime (hours) Management Staff TOTAL

75 120

ENG 7 HC / GA 7

23 - 36° C 10 0 195 SPV 9 SHE 4

SURVEYOR 4 KOM 6

Notes : Maitre Douvrage Entrepreneur Dibuat Oleh,

Chef de Department Technique Chef de De Department D'ingenierie

NIAMEY NYALA PT. WIJAYA KARYA (Persero) Tbk.

Day : Sunday

Date : 1-Nov-20

Hari

Daily Report Weeks : 98

Tanggal

RÉHABILITATION DU PALAIS PRÉSIDENTIEL DU RÉPUBLIQUE DU NIGER

Minggu Ke

Work Durations number of workers Volume

NO Job Description Working Hours Unit Material / Information Material

(Hours) Ind WorkersLocal Workers Tools Ind Workers

Local Workers Tools

A. EARTHWORK 0 5 0 0

a.1 Shifting and backfilling on corridor zone 1 ### s/d ### 0 0 0 0 0 m3

a.2 Backfilling area corridor on zone 1 ### s/d ### 0 0 0 0 0 m3

a.3 Backfilling area beam PoP ### s/d ### 10 0 5 0 0 m3 levelliing until below slab on ground and castin

a.4 Levelling land for lc tie beam HoS ### s/d ### 0 0 0 0 0

B.1 CONCRETE FOR COLUMN 0 0 0 0

b.1.1 ### s/d ### 0 0 0 0 0 m3

b.1.2 ### s/d ### 0 0 0 0 0

b.1.3 ### s/d ### 0 0 0 0 0

B.2 CONCRETE FOR BEAM 2 8 0 0

b.2.1 Casting concrete for column GF PoP ### s/d ### 2 2 8 0 0 m3

b.2.2 ### s/d ### 0 0 0 0 0

b.2.3 ### s/d ### 0 0 0 0 0

B.3 CONCRETE FOR SLAB/FLOOR PLATE 0 0 0 0

b.3.1 ### s/d ### 0 0 0 0 0 m3

b.3.2 ### s/d ### 0 0 0 0 0

b.3.3 ### s/d ### 0 0 0 0 0

C.1 FORMWORK FOR COLUMN 6 6 0 0

c.1.1 Workshop ### s/d ### 10 1 0 0 0 m2

c.1.2 Fabrication on site ### s/d ### 10 1 0 0 0 m2

c.1.3 Install and dihutter formwork for column GF PoP ### s/d ### 10 0 6 0 0 m2 sims

c.1.4 Install and dishutter formwork column GF and FF PoP ### s/d ### 10 4 0 0 0 m2

c.1.5 ### s/d ### 0 0 0 0 0 m2

C.2 FORMWORK FOR BEAM 11 0 0 0

c.2.1 Dishutter formwork beam PoP ToC -0.050 ### s/d ### 0 0 0 0 0 m2

c.2.2 Install formwork for beam and slab corridor on zone 1 ToC -0 ### s/d ### 0 0 0 0 0 m2

c.2.3 Install formwork for beam and slab Roof PoP ### s/d ### 10 11 0 0 0 m2

c.2.4 Install formwork for beam PoP ToC -0.050 ### s/d ### 0 0 0 0 0 m2

c.2.5 ### s/d ### 0 0 0 0 0 m2

C.3 FORMWORK FOR SLAB 0 3 0 0

c.3.1 Dishutter formwork ring beam and slab first floor PoP ### s/d ### 10 0 3 0 0 m2

c.3.2 ### s/d ### 0 0 0 0 0 m2

c.3.3 ### s/d ### 0 0 0 0 0 m2

c.3.4 ### s/d ### 0 0 0 0 0 m2

c.3.5 ### s/d ### 0 0 0 0 0 m2

D.1 REBAR FOR COLUMN 5 0 0 0

d.1.1 Fabrication Rebar ### s/d ### 0 0 0 0 0 kg

d.1.2 Prefabrication and erection rebar for column PoP ### s/d ### 10 5 0 0 0 kg

d.1.3 ### s/d ### 0 0 0 0 0 kg

d.1.4 ### s/d ### 0 0 0 0 0 kg

d.1.5 ### s/d ### 0 0 0 0 0 kg

D.2 REBAR FOR BEAM 0 8 0 0

d.2.1 Install rebar beam FF PoP ToC +5.250 ### s/d ### 0 0 0 0 0 kg

d.2.2 Install rebar beam FF PoP ToC +5.250 ### s/d ### 10 0 8 0 0 kg sims

d.2.3 ### s/d ### 0 0 0 0 0 kg

D.3 REBAR FOR SLAB 0 0 0 0

d.3.1 Install rebar for doom HoS ToC +6.350 ### s/d ### 0 0 0 0 0 kg

d.3.2 Install rebar slab corridor on zone 1 ToC -0.050 ### s/d ### 0 0 0 0 0 kg

d.3.3 Install rebar slab on ground PoP ToC -0.050 ### s/d ### 0 0 0 0 0 kg

E. Masonry 0 14 0 0

e.1 Install brick for window and corridor area ballroom ### s/d ### 0 0 0 0 0 m2

e.2 Install brick for window and corridor area ballroom ### s/d ### 9 0 8 0 0 m2 sirius

e.3 Fabrication brique ### s/d ### 0 0 6 0 0 pcs sirius

e.4 Install brick for paraphet roof ballroom ToC +9.600 ### s/d ### 0 0 0 0 0 m2

e.5 Shifting brique ### s/d ### 0 0 0 0 0 m2

e.6 Install brick for window and corridor area ballroom ### s/d ### 0 0 0 0 0 m2

e.7 Install brick for paraphet roof post control type 2 unit 1 ### s/d ### 0 0 0 0 0 m'

F. Plastering 2 0 0 0

f.1 Finishing wall with stuccofiller on HoS ### s/d ### 0 0 0 0 0 m2

f.2 Install head of plaster on ballroom ### s/d ### 10 2 0 0 0 m2

f.3 Plastering wall of ballroom ### s/d ### 0 0 0 0 0 m2

f.4 Install head of screed roof HoS ToC +6.350 ### s/d ### 0 0 0 0 0 m'

f.5 Plastering wall for post control type 1 unit 1 ### s/d ### 0 0 0 0 0 m'

G. Baja 0 0 0 0

g.1 ### s/d ### 0 0 0 0 0 kg

g.2 ### s/d ### 0 0 0 0 0 kg

g.3 ### s/d ### 0 0 0 0 0 kg

g.4 ### s/d ### 0 0 0 0 0 kg

g.5 ### s/d ### 0 0 0 0 0 kg

H. Anti-Thermite 0 0 0 0

h.1 ### s/d ### 0 0 0 0 0 m2

h.2 ### s/d ### 0 0 0 0 0

h.3 ### s/d ### 0 0 0 0 0

h.4 ### s/d ### 0 0 0 0 0

h.5 ### s/d ### 0 0 0 0 0

I. Waterproofing Sub Structure 0 0 0 0

i.1 ### s/d ### 0 0 0 0 0 m2

i.2 ### s/d ### 0 0 0 0 0

i.3 ### s/d ### 0 0 0 0 0

i.4 ### s/d ### 0 0 0 0 0

i.5 ### s/d ### 0 0 0 0 0

J. Waterproofing Wet Area 0 0 0 0

j.1 ### s/d ### 0 0 0 0 0

j.2 ### s/d ### 0 0 0 0 0

j.3 ### s/d ### 0 0 0 0 0

j.4 ### s/d ### 0 0 0 0 0

j.5 ### s/d ### 0 0 0 0 0

K Lain-Lain 14 8 0 0 ls

k.1 Storing ### s/d ### 10 1 0 0 0 ls

k.2 MEP Crew ### s/d ### 10 1 0 0 0 ls

k.3 SHE Crew ### s/d ### 10 3 5 0 0 ls

k.4 Surveyor Crew ### s/d ### 10 0 0 0 0 ls

k.5 Scaffolder ### s/d ### 10 1 0 0 0 ls

k.6 Canteen Crew and office boy ### s/d ### 10 2 0 0 0 ls

k.7 Driver and Operator ### s/d ### 10 0 2 0 0 ls

k.8 Warehouse assistant ### s/d ### 10 1 0 0 0 ls

k.9 Laboratory quality control assistant ### s/d ### 0 0 0 0 0 ls

k.10 Equipment assistant ### s/d ### 10 0 1 0 0 ls

k.11 Foreman ### s/d ### 10 1 0 0 0 ls

k.12 Leave or sick ### s/d ### 8 0 0 0 0 ls

k.13 Shifting materiel for metal structure ### s/d ### 0 0 0 0 0 ls

k.14 Fabrication door and windows SVB ### s/d ### 0 0 0 0 0 set

k.15 levelling land for LC tie beam corridor PoP ### s/d ### 0 0 0 0 0 m2

k.16 Fabrication of concrete deck ### s/d ### 10 1 0 0 0 ls

k.17 Cleaning and shifting materiel ### s/d ### 0 0 0 0 0 ls

k.18 Repair and made a new pallet ### s/d ### 0 0 0 0 0 m2

k.19 Install rebar and formwork for column pratice and lintel beam ### s/d ### 0 0 0 0 0 m2

k.20 Grouting a column metal structure of a roof ballroom ### s/d ### 0 0 0 0 0 m3

k.21 Install metal structure for foor balrrom ### s/d ### 10 3 0 0 0 kg Valasindo

k.22 Finishing and expose column and beam ### s/d ### 0 0 0 0 0 ls

25

L Alat

l.1 Excavator ### s/d ### 10 1 0

l.2 Trailler Truck ### s/d ### 9 0 0

l.3 Compactor ### s/d ### 10 1 0

l.4 Bob Cat ### s/d ### 10 1 0

l.5 Fiori ### s/d ### 10 2 0

l.6 Rough Terrain Crane ### s/d ### 10 1 0

l.7 Concrete Vibrator ### s/d ### 10 3 0

l.8 Bar Bending ### s/d ### 10 1 0

l.9 Bar Cutter ### s/d ### 10 1 0

l.10 Flat Bed Truck ### s/d ### 10 1 0

l.11 Circle Cutter ### s/d ### 10 4 0

l.12 Welding Machine ### s/d ### 10 4 0

l.13 Stamper ### s/d ### 10 1 0

l.14 Compressor ### s/d ### 10 1 0

l.15 Tile Cutter ### s/d ### 10 2 0

l.16 Seaming Roofing Machine ### s/d ### 10 2 0

l.17 Hand Bor ### s/d ### 10 6 0

Indonesia Local

n

Workers Workers ###

Temperature (Celcius) Amount of Working Hours Overtime (hours) Management Staff TOTAL

40 52

ENG 7 HC / GA 7

26 - 35° C 10 0 92 SPV 9 SHE 4

SURVEYOR 4 KOM 6

Notes : Maitre Douvrage Entrepreneur Dibuat Oleh,

Chef de Department Technique Chef de De Department D'ingenierie

NIAMEY NYALA PT. WIJAYA KARYA (Persero) Tbk.

Day : Monday

Date : 2-Nov-20

Hari

Daily Report Weeks : 99

Tanggal

RÉHABILITATION DU PALAIS PRÉSIDENTIEL DU RÉPUBLIQUE DU NIGER

Minggu Ke

Work Durations number of workers Volume

NO Job Description Working Hours Unit Material / Information Material

(Hours) Ind WorkersLocal Workers Tools Ind Workers

Local Workers Tools

A. EARTHWORK 0 4 0 0

a.1 Shifting and backfilling on corridor zone 1 ### s/d ### 0 0 0 0 0 m3

a.2 Backfilling area tie beam on corridor zone 1 ### s/d ### 0 0 0 0 0 m3

a.3 Backfilling area tie beam and slab on ground PoP ### s/d ### 12 0 4 0 0 m3 5 person finish at 17.00 ; 2 person cleaning roof

a.4 ### s/d ### 0 0 0 0 0

B.1 CONCRETE FOR COLUMN 0 0 0 0

b.1.1 ### s/d ### 0 0 0 0 0 m3

b.1.2 ### s/d ### 0 0 0 0 0

b.1.3 ### s/d ### 0 0 0 0 0

B.2 CONCRETE FOR BEAM 0 0 0 0

b.2.1 ### s/d ### 0 0 0 0 0 m3

b.2.2 ### s/d ### 0 0 0 0 0

b.2.3 ### s/d ### 0 0 0 0 0

B.3 CONCRETE FOR SLAB/FLOOR PLATE 2 9 0 0

b.3.1 Casting concrete for ring beam and slab roof PoP ### s/d ### 8 2 9 0 0 m3 start working for dishutter formwork, cleaning a

b.3.2 ### s/d ### 0 0 0 0 0

b.3.3 ### s/d ### 0 0 0 0 0

C.1 FORMWORK FOR COLUMN 13 10 0 0

c.1.1 Workshop ### s/d ### 12 3 0 0 0 m2

c.1.2 Fabrication on site ### s/d ### 10 4 0 0 0 m2

c.1.3 Install and dihutter formwork for column GF PoP ### s/d ### 12 0 8 0 0 m2 sims

c.1.4 Install and dishutter formwork column GF and FF PoP ### s/d ### 10 6 2 0 0 m2

c.1.5 Install formwork for pedestal column PoP ### s/d ### 0 0 0 0 0 m2

C.2 FORMWORK FOR BEAM 12 2 0 0

c.2.1 Install and dishutter formwork for beam PoP ToC -0.050 ### s/d ### 10 0 2 0 0 m2 sims

c.2.2 Install formwork for beam HoS ToC -2.200 ### s/d ### 0 0 0 0 0 m2

c.2.3 Install formwork for beam and slab Roof PoP ToC +10.800 ### s/d ### 12 12 0 0 0 m2

c.2.4 Install formwork for beam PoP ToC -0.050 ### s/d ### 0 0 0 0 0 m2

c.2.5 Dishutter formwork beam and slab corridor on zone 1 ToC -0. ### s/d ### 0 0 0 0 0 m2

C.3 FORMWORK FOR SLAB 0 5 0 0

c.3.1 Install formwork slab on ground PoP ToC -0.050 ### s/d ### 10 0 0 0 0 m2

c.3.2 Joint and setting formwork for doom HoS ToC +6.350 ### s/d ### 0 0 0 0 0 m2

c.3.3 Dishutter formwork ring beam and slab FF PoP ToC +5.250 ### s/d ### 10 0 5 0 0 m2

c.3.4 Dishutter formwork ring beam and slab post control type 1 on ### s/d ### 0 0 0 0 0 m2

c.3.5 Install formwork for beam and slab HoS ToC -0.050 (garden a ### s/d ### 0 0 0 0 0 m2

D.1 REBAR FOR COLUMN 11 4 0 0

d.1.1 Fabrication Rebar ### s/d ### 10 6 0 0 0 kg

d.1.2 Prefabrication and erection rebar for column PoP ### s/d ### 12 5 0 0 0 kg

d.1.3 Manual erection for rebar column corridor on zone 1 ### s/d ### 0 0 0 0 0 kg

d.1.4 Install rebar for pedestal column PoP ### s/d ### 0 0 0 0 0 kg

d.1.5 Install rebar for column GF PoP (prefab) ### s/d ### 10 0 4 0 0 kg sims

D.2 REBAR FOR BEAM 1 0 0 0

d.2.1 Install rebar for beam FF PoP ToC +5.250 ### s/d ### 10 1 0 0 0 kg

d.2.2 Install rebar for tie beam HoS ToC -2.200 ### s/d ### 0 0 0 0 0 kg

d.2.3 ### s/d ### 0 0 0 0 0 kg

D.3 REBAR FOR SLAB 0 12 0 0

d.3.1 Install rebar for doom HoS ToC +6.350 ### s/d ### 0 0 0 0 0 kg

d.3.2 Install rebar slab ground floor PoP ToC -0.050 ### s/d ### 0 0 0 0 0 kg

d.3.3 Install rebar for slab FF PoP ToC +5.250 ### s/d ### 10 0 12 0 0 kg sims

E. Masonry 0 36 0 0

e.1 Install brick for window and corridor area ballroom ### s/d ### 10 0 9 0 0 m2 wala group

e.2 Install brick for window and corridor area ballroom ### s/d ### 11 0 18 0 0 m2 sirius

e.3 Fabrication brique ### s/d ### 9 0 9 0 0 pcs sirius

e.4 Install brick for paraphet roof ballroom ToC +9.600 ### s/d ### 0 0 0 0 0 m2

e.5 Shifting brique ### s/d ### 0 0 0 0 0 m2

e.6 Install brick for window and corridor area ballroom ### s/d ### 0 0 0 0 0 m2

e.7 Install brick for paraphet roof post control type 2 unit 1 ### s/d ### 0 0 0 0 0 m'

F. Plastering 4 2 0 0

f.1 Finishing wall with stuccofiller on HoS ### s/d ### 10 0 2 0 0 m2 sirius

f.2 Install head of plaster on ballroom ### s/d ### 10 4 0 0 0 m2

f.3 Plastering wall of ballroom ### s/d ### 0 0 0 0 0 m2

f.4 Install head of screed roof HoS ToC +6.350 ### s/d ### 0 0 0 0 0 m'

f.5 Plastering wall for post control type 1 unit 1 ### s/d ### 0 0 0 0 0 m'

G. Baja 0 0 0 0

g.1 ### s/d ### 0 0 0 0 0 kg

g.2 ### s/d ### 0 0 0 0 0 kg

g.3 ### s/d ### 0 0 0 0 0 kg

g.4 ### s/d ### 0 0 0 0 0 kg

g.5 ### s/d ### 0 0 0 0 0 kg

H. Anti-Thermite 0 0 0 0

h.1 ### s/d ### 0 0 0 0 0 m2

h.2 ### s/d ### 0 0 0 0 0

h.3 ### s/d ### 0 0 0 0 0

h.4 ### s/d ### 0 0 0 0 0

h.5 ### s/d ### 0 0 0 0 0

I. Waterproofing Sub Structure 0 0 0 0

i.1 ### s/d ### 0 0 0 0 0 m2

i.2 ### s/d ### 0 0 0 0 0

i.3 ### s/d ### 0 0 0 0 0

i.4 ### s/d ### 0 0 0 0 0

i.5 ### s/d ### 0 0 0 0 0

J. Waterproofing Wet Area 0 0 0 0

j.1 ### s/d ### 0 0 0 0 0

j.2 ### s/d ### 0 0 0 0 0

j.3 ### s/d ### 0 0 0 0 0

j.4 ### s/d ### 0 0 0 0 0

j.5 ### s/d ### 0 0 0 0 0

K Lain-Lain 33 26 0 0 ls

k.1 Storing ### s/d ### 12 1 0 0 0 ls

k.2 MEP Crew ### s/d ### 10 2 0 0 0 ls

k.3 SHE Crew ### s/d ### 10 4 4 0 0 ls

k.4 Surveyor Crew ### s/d ### 10 2 0 0 0 ls

k.5 Scaffolder ### s/d ### 10 1 0 0 0 ls

k.6 Canteen Crew and office boy ### s/d ### 10 2 0 0 0 ls

k.7 Driver and Operator ### s/d ### 15 3 5 0 0 ls

k.8 Warehouse assistant ### s/d ### 10 1 0 0 0 ls

k.9 Laboratory quality control assistant ### s/d ### 10 1 0 0 0 ls

k.10 Equipment assistant ### s/d ### 12 0 1 0 0 ls

k.11 Foreman ### s/d ### 10 0 0 0 0 ls

k.12 Leave or sick ### s/d ### 8 3 7 0 0 ls

k.13 Shifting materiel for metal structure ### s/d ### 0 0 0 0 0 ls

k.14 Fabrication door and windows SVB ### s/d ### 0 0 0 0 0 set

k.15 levelling land for LC tie beam corridor PoP ### s/d ### 0 0 0 0 0 m2

k.16 Fabrication of concrete deck ### s/d ### 0 0 0 0 0 ls

k.17 Cleaning and shifting materiel ### s/d ### 10 0 6 0 0 ls

k.18 Fabrication and install window alumunium ### s/d ### 9 0 2 0 0 m2 aigle royal

k.19 Ansembling mockarabieh ### s/d ### 10 4 0 0 0 m2 Valasindo

k.20 Removing doors and windows from safe house ### s/d ### 10 0 1 0 0 m3

k.21 Install metal roof for ballroom ### s/d ### 10 8 0 0 0 kg Valasindo

k.22 Finishing and expose column and beam ### s/d ### 10 1 0 0 0 ls

25

L Alat

l.1 Excavator ### s/d ### 10 1 0

l.2 Trailler Truck ### s/d ### 9 0 0

l.3 Compactor ### s/d ### 10 1 0

l.4 Bob Cat ### s/d ### 10 1 0

l.5 Fiori ### s/d ### 10 2 0

l.6 Rough Terrain Crane ### s/d ### 10 1 0

l.7 Concrete Vibrator ### s/d ### 10 3 0

l.8 Bar Bending ### s/d ### 10 1 0

l.9 Bar Cutter ### s/d ### 10 1 0

l.10 Flat Bed Truck ### s/d ### 10 1 0

l.11 Circle Cutter ### s/d ### 10 4 0

l.12 Welding Machine ### s/d ### 10 4 0

l.13 Stamper ### s/d ### 10 1 0

l.14 Compressor ### s/d ### 10 1 0

l.15 Tile Cutter ### s/d ### 10 2 0

l.16 Seaming Roofing Machine ### s/d ### 10 2 0

l.17 Hand Bor ### s/d ### 10 6 0

Indonesia Local

n

Workers Workers ###

Temperature (Celcius) Amount of Working Hours Overtime (hours) Management Staff TOTAL

76 110

ENG 7 HC / GA 7

23 - 37° C 10 0 186 SPV 9 SHE 4

SURVEYOR 4 KOM 6

Notes : Maitre Douvrage Entrepreneur Dibuat Oleh,

Chef de Department Technique Chef de De Department D'ingenierie

NIAMEY NYALA PT. WIJAYA KARYA (Persero) Tbk.

Day : Tuesday

Date : 3-Nov-20

Hari

Daily Report Weeks : 99

Tanggal

RÉHABILITATION DU PALAIS PRÉSIDENTIEL DU RÉPUBLIQUE DU NIGER

Minggu Ke

Work Durations number of workers Volume

NO Job Description Working Hours Unit Material / Information Material

(Hours) Ind WorkersLocal Workers Tools Ind Workers

Local Workers Tools

A. EARTHWORK 0 4 0 0

a.1 Shifting and backfilling on corridor zone 1 ### s/d ### 0 0 0 0 0 m3

a.2 Backfilling area tie beam on corridor zone 1 ### s/d ### 0 0 0 0 0 m3

a.3 Backfilling area tie beam and slab on ground PoP ### s/d ### 10 0 4 0 0 m3

a.4 ### s/d ### 0 0 0 0 0

B.1 CONCRETE FOR COLUMN 0 0 0 0

b.1.1 ### s/d ### 0 0 0 0 0 m3

b.1.2 ### s/d ### 0 0 0 0 0

b.1.3 ### s/d ### 0 0 0 0 0

B.2 CONCRETE FOR BEAM 0 0 0 0

b.2.1 ### s/d ### 0 0 0 0 0 m3

b.2.2 ### s/d ### 0 0 0 0 0

b.2.3 ### s/d ### 0 0 0 0 0

B.3 CONCRETE FOR SLAB/FLOOR PLATE 1 9 0 0

b.3.1 Casting concrete for column GF and slab PoP ToC -0.050 ### s/d ### 6 1 9 0 0 m3 start working for dishutter formwork, cleaning a

b.3.2 ### s/d ### 0 0 0 0 0

b.3.3 ### s/d ### 0 0 0 0 0

C.1 FORMWORK FOR COLUMN 12 8 0 0

c.1.1 Workshop ### s/d ### 12 3 0 0 0 m2

c.1.2 Fabrication on site ### s/d ### 10 3 0 0 0 m2

c.1.3 Install and dihutter formwork for column GF PoP ### s/d ### 12 0 8 0 0 m2 sims

c.1.4 Install and dishutter formwork column GF and FF PoP ### s/d ### 10 6 0 0 0 m2

c.1.5 Install formwork for pedestal column PoP ### s/d ### 0 0 0 0 0 m2

C.2 FORMWORK FOR BEAM 13 2 0 0

c.2.1 Install and dishutter formwork for beam PoP ToC -0.050 ### s/d ### 10 0 2 0 0 m2 sims

c.2.2 Install formwork for beam HoS ToC -2.200 ### s/d ### 0 0 0 0 0 m2

c.2.3 Install formwork for beam and slab Roof PoP ToC +10.800 ### s/d ### 12 13 0 0 0 m2

c.2.4 Install formwork for beam PoP ToC -0.050 ### s/d ### 0 0 0 0 0 m2

c.2.5 Dishutter formwork beam and slab corridor on zone 1 ToC -0. ### s/d ### 0 0 0 0 0 m2

C.3 FORMWORK FOR SLAB 0 5 0 0

c.3.1 Install formwork slab on ground PoP ToC -0.050 ### s/d ### 10 0 0 0 0 m2

c.3.2 Joint and setting formwork for doom HoS ToC +6.350 ### s/d ### 0 0 0 0 0 m2

c.3.3 Dishutter formwork ring beam and slab FF PoP ToC +5.250 ### s/d ### 10 0 5 0 0 m2

c.3.4 Dishutter formwork ring beam and slab post control type 1 on ### s/d ### 0 0 0 0 0 m2

c.3.5 Install formwork for beam and slab HoS ToC -0.050 (garden a ### s/d ### 0 0 0 0 0 m2

D.1 REBAR FOR COLUMN 11 6 0 0

d.1.1 Fabrication Rebar ### s/d ### 10 6 0 0 0 kg

d.1.2 Prefabrication and erection rebar for column PoP ### s/d ### 12 5 0 0 0 kg

d.1.3 Prefabrication rebar for column and lintel beam ### s/d ### 12 0 2 0 0 kg

d.1.4 Install rebar for pedestal column PoP ### s/d ### 0 0 0 0 0 kg

d.1.5 Install rebar for column GF PoP (prefab) ### s/d ### 10 0 4 0 0 kg sims

D.2 REBAR FOR BEAM 2 6 0 0

d.2.1 Install rebar for beam roof PoP ToC +10.800 ### s/d ### 10 2 6 0 0 kg sims

d.2.2 Install rebar for tie beam HoS ToC -2.200 ### s/d ### 0 0 0 0 0 kg

d.2.3 ### s/d ### 0 0 0 0 0 kg

D.3 REBAR FOR SLAB 0 6 0 0

d.3.1 Install rebar for doom HoS ToC +6.350 ### s/d ### 0 0 0 0 0 kg

d.3.2 Install rebar slab ground floor PoP ToC -0.050 ### s/d ### 0 0 0 0 0 kg

d.3.3 Install rebar for slab roof PoP ToC +10.800 ### s/d ### 10 0 6 0 0 kg sims

E. Masonry 0 37 0 0

e.1 Install brick for window and corridor area ballroom ### s/d ### 10 0 9 0 0 m2 wala group

e.2 Install brick for window and corridor area ballroom ### s/d ### 11 0 19 0 0 m2 sirius

e.3 Fabrication brique ### s/d ### 9 0 9 0 0 pcs sirius

e.4 Install brick for paraphet roof ballroom ToC +9.600 ### s/d ### 0 0 0 0 0 m2

e.5 Shifting brique ### s/d ### 0 0 0 0 0 m2

e.6 Install brick for window and corridor area ballroom ### s/d ### 0 0 0 0 0 m2

e.7 Install brick for paraphet roof post control type 2 unit 1 ### s/d ### 0 0 0 0 0 m'

F. Plastering 4 6 0 0

f.1 Finishing wall with stuccofiller on HoS ### s/d ### 10 0 6 0 0 m2 sirius

f.2 Install head of plaster on ballroom ### s/d ### 10 4 0 0 0 m2

f.3 Plastering wall of ballroom ### s/d ### 0 0 0 0 0 m2

f.4 Install head of screed roof HoS ToC +6.350 ### s/d ### 0 0 0 0 0 m'

f.5 Plastering wall for post control type 1 unit 1 ### s/d ### 0 0 0 0 0 m'

G. Baja 0 0 0 0

g.1 ### s/d ### 0 0 0 0 0 kg

g.2 ### s/d ### 0 0 0 0 0 kg

g.3 ### s/d ### 0 0 0 0 0 kg

g.4 ### s/d ### 0 0 0 0 0 kg

g.5 ### s/d ### 0 0 0 0 0 kg

H. Anti-Thermite 0 0 0 0

h.1 ### s/d ### 0 0 0 0 0 m2

h.2 ### s/d ### 0 0 0 0 0

h.3 ### s/d ### 0 0 0 0 0

h.4 ### s/d ### 0 0 0 0 0

h.5 ### s/d ### 0 0 0 0 0

I. Waterproofing Sub Structure 0 0 0 0

i.1 ### s/d ### 0 0 0 0 0 m2

i.2 ### s/d ### 0 0 0 0 0

i.3 ### s/d ### 0 0 0 0 0

i.4 ### s/d ### 0 0 0 0 0

i.5 ### s/d ### 0 0 0 0 0

J. Waterproofing Wet Area 0 0 0 0

j.1 ### s/d ### 0 0 0 0 0

j.2 ### s/d ### 0 0 0 0 0

j.3 ### s/d ### 0 0 0 0 0

j.4 ### s/d ### 0 0 0 0 0

j.5 ### s/d ### 0 0 0 0 0

K Lain-Lain 33 25 0 0 ls

k.1 Storing ### s/d ### 12 1 0 0 0 ls

k.2 MEP Crew ### s/d ### 10 2 0 0 0 ls

k.3 SHE Crew ### s/d ### 10 4 4 0 0 ls

k.4 Surveyor Crew ### s/d ### 10 2 0 0 0 ls

k.5 Scaffolder ### s/d ### 10 1 0 0 0 ls

k.6 Canteen Crew and office boy ### s/d ### 10 2 0 0 0 ls

k.7 Driver and Operator ### s/d ### 15 3 5 0 0 ls

k.8 Warehouse assistant ### s/d ### 10 1 0 0 0 ls

k.9 Laboratory quality control assistant ### s/d ### 10 1 0 0 0 ls

k.10 Equipment assistant ### s/d ### 12 0 1 0 0 ls

k.11 Foreman ### s/d ### 10 1 0 0 0 ls

k.12 Leave or sick ### s/d ### 8 2 7 0 0 ls

k.13 Shifting materiel for metal structure ### s/d ### 0 0 0 0 0 ls

k.14 Fabrication door and windows SVB ### s/d ### 0 0 0 0 0 set

k.15 levelling land for LC tie beam corridor PoP ### s/d ### 0 0 0 0 0 m2

k.16 Fabrication of concrete deck ### s/d ### 10 1 0 0 0 ls

k.17 Cleaning and shifting materiel ### s/d ### 10 0 6 0 0 ls

k.18 Fabrication and install window alumunium ### s/d ### 9 0 2 0 0 m2 aigle royal

k.19 Ansembling mockarabieh ### s/d ### 10 4 0 0 0 m2 Valasindo

k.20 Removing doors and windows from safe house ### s/d ### 0 0 0 0 0 m3

k.21 Install metal roof for ballroom ### s/d ### 10 8 0 0 0 kg Valasindo

k.22 Finishing and expose column and beam ### s/d ### 0 0 0 0 0 ls

25

L Alat

l.1 Excavator ### s/d ### 10 1 0

l.2 Trailler Truck ### s/d ### 9 0 0

l.3 Compactor ### s/d ### 10 1 0

l.4 Bob Cat ### s/d ### 10 1 0

l.5 Fiori ### s/d ### 10 2 0

l.6 Rough Terrain Crane ### s/d ### 10 1 0

l.7 Concrete Vibrator ### s/d ### 10 3 0

l.8 Bar Bending ### s/d ### 10 1 0

l.9 Bar Cutter ### s/d ### 10 1 0

l.10 Flat Bed Truck ### s/d ### 10 1 0

l.11 Circle Cutter ### s/d ### 10 4 0

l.12 Welding Machine ### s/d ### 10 4 0

l.13 Stamper ### s/d ### 10 1 0

l.14 Compressor ### s/d ### 10 1 0

l.15 Tile Cutter ### s/d ### 10 2 0

l.16 Seaming Roofing Machine ### s/d ### 10 2 0

l.17 Hand Bor ### s/d ### 10 6 0

Indonesia Local

n

Workers Workers ###

Temperature (Celcius) Amount of Working Hours Overtime (hours) Management Staff TOTAL

76 114

ENG 7 HC / GA 7

23 - 37° C 10 0 190 SPV 9 SHE 4

SURVEYOR 4 KOM 6

Notes : Maitre Douvrage Entrepreneur Dibuat Oleh,

Chef de Department Technique Chef de De Department D'ingenierie

NIAMEY NYALA PT. WIJAYA KARYA (Persero) Tbk.

Day : Wednesday

Date : 4-Nov-20

Hari

Daily Report Weeks : 99

Tanggal

RÉHABILITATION DU PALAIS PRÉSIDENTIEL DU RÉPUBLIQUE DU NIGER

Minggu Ke

Work Durations number of workers Volume

NO Job Description Working Hours Unit Material / Information Material

(Hours) Ind WorkersLocal Workers Tools Ind Workers

Local Workers Tools

A. EARTHWORK 0 6 0 0

a.1 Shifting and backfilling on corridor zone 1 ### s/d ### 0 0 0 0 0 m3

a.2 Backfilling area tie beam on corridor zone 1 ### s/d ### 0 0 0 0 0 m3

a.3 Backfilling area tie beam and slab on ground PoP ### s/d ### 12 0 6 0 0 m3

a.4 ### s/d ### 0 0 0 0 0

B.1 CONCRETE FOR COLUMN 0 0 0 0

b.1.1 ### s/d ### 0 0 0 0 0 m3

b.1.2 ### s/d ### 0 0 0 0 0

b.1.3 ### s/d ### 0 0 0 0 0

B.2 CONCRETE FOR BEAM 0 0 0 0

b.2.1 ### s/d ### 0 0 0 0 0 m3

b.2.2 ### s/d ### 0 0 0 0 0

b.2.3 ### s/d ### 0 0 0 0 0

B.3 CONCRETE FOR SLAB/FLOOR PLATE 1 9 0 0

b.3.1 Casting concrete for column GF and beam and slab PoP ToC + ### s/d ### 7 1 9 0 0 m3 start working for dishutter formwork, cleaning a

b.3.2 ### s/d ### 0 0 0 0 0

b.3.3 ### s/d ### 0 0 0 0 0

C.1 FORMWORK FOR COLUMN 13 8 0 0

c.1.1 Workshop ### s/d ### 12 3 0 0 0 m2

c.1.2 Fabrication on site ### s/d ### 10 4 0 0 0 m2

c.1.3 Install and dihutter formwork for column GF PoP ### s/d ### 12 0 8 0 0 m2 sims

c.1.4 Install and dishutter formwork column GF and FF PoP ### s/d ### 10 6 0 0 0 m2

c.1.5 Install formwork for pedestal column PoP ### s/d ### 0 0 0 0 0 m2

C.2 FORMWORK FOR BEAM 13 2 0 0

c.2.1 Install and dishutter formwork for beam PoP ToC -0.050 ### s/d ### 10 0 2 0 0 m2 sims

c.2.2 Install formwork for beam HoS ToC -2.200 ### s/d ### 0 0 0 0 0 m2

c.2.3 Install formwork for beam and slab Roof PoP ToC +10.800 ### s/d ### 12 4 0 0 0 m2

c.2.4 Instal formwork beam and slab PoP ToC +5.250 ### s/d ### 12 9 0 0 0 m2

c.2.5 Dishutter formwork beam and slab corridor on zone 1 ToC -0. ### s/d ### 0 0 0 0 0 m2

C.3 FORMWORK FOR SLAB 0 5 0 0

c.3.1 Install formwork slab on ground PoP ToC -0.050 ### s/d ### 10 0 0 0 0 m2

c.3.2 Joint and setting formwork for doom HoS ToC +6.350 ### s/d ### 0 0 0 0 0 m2

c.3.3 Dishutter formwork ring beam and slab FF PoP ToC +5.250 ### s/d ### 10 0 5 0 0 m2

c.3.4 Dishutter formwork ring beam and slab post control type 1 on ### s/d ### 0 0 0 0 0 m2

c.3.5 Install formwork for beam and slab HoS ToC -0.050 (garden a ### s/d ### 0 0 0 0 0 m2

D.1 REBAR FOR COLUMN 11 6 0 0

d.1.1 Fabrication Rebar ### s/d ### 10 6 0 0 0 kg

d.1.2 Prefabrication and erection rebar for column PoP ### s/d ### 12 5 0 0 0 kg

d.1.3 Prefabrication rebar for column and lintel beam ### s/d ### 12 0 2 0 0 kg

d.1.4 Install rebar for pedestal column PoP ### s/d ### 0 0 0 0 0 kg

d.1.5 Install rebar for column GF PoP (prefab) ### s/d ### 10 0 4 0 0 kg sims

D.2 REBAR FOR BEAM 2 6 0 0

d.2.1 Install rebar for beam roof PoP ToC +10.800 ### s/d ### 10 2 6 0 0 kg sims

d.2.2 Install rebar for tie beam HoS ToC -2.200 ### s/d ### 0 0 0 0 0 kg

d.2.3 ### s/d ### 0 0 0 0 0 kg

D.3 REBAR FOR SLAB 0 6 0 0

d.3.1 Install rebar for doom HoS ToC +6.350 ### s/d ### 0 0 0 0 0 kg

d.3.2 Install rebar slab ground floor PoP ToC -0.050 ### s/d ### 0 0 0 0 0 kg

d.3.3 Install rebar for slab roof PoP ToC +10.800 ### s/d ### 10 0 6 0 0 kg sims

E. Masonry 0 43 0 0

e.1 Install brick for window and corridor area ballroom ### s/d ### 10 0 9 0 0 m2 wala group

e.2 Install brick for window and corridor area ballroom ### s/d ### 11 0 25 0 0 m2 sirius

e.3 Fabrication brique ### s/d ### 9 0 9 0 0 pcs sirius

e.4 Install brick for paraphet roof ballroom ToC +9.600 ### s/d ### 0 0 0 0 0 m2

e.5 Shifting brique ### s/d ### 0 0 0 0 0 m2

e.6 Install brick for window and corridor area ballroom ### s/d ### 0 0 0 0 0 m2

e.7 Install brick for paraphet roof post control type 2 unit 1 ### s/d ### 0 0 0 0 0 m'

F. Plastering 4 6 0 0

f.1 Finishing wall with stuccofiller on HoS ### s/d ### 10 0 6 0 0 m2 sirius

f.2 Install head of plaster on ballroom ### s/d ### 10 4 0 0 0 m2

f.3 Plastering wall of ballroom ### s/d ### 0 0 0 0 0 m2

f.4 Install head of screed roof HoS ToC +6.350 ### s/d ### 0 0 0 0 0 m'

f.5 Plastering wall for post control type 1 unit 1 ### s/d ### 0 0 0 0 0 m'

G. Baja 0 0 0 0

g.1 ### s/d ### 0 0 0 0 0 kg

g.2 ### s/d ### 0 0 0 0 0 kg

g.3 ### s/d ### 0 0 0 0 0 kg

g.4 ### s/d ### 0 0 0 0 0 kg

g.5 ### s/d ### 0 0 0 0 0 kg

H. Anti-Thermite 0 0 0 0

h.1 ### s/d ### 0 0 0 0 0 m2

h.2 ### s/d ### 0 0 0 0 0

h.3 ### s/d ### 0 0 0 0 0

h.4 ### s/d ### 0 0 0 0 0

h.5 ### s/d ### 0 0 0 0 0

I. Waterproofing Sub Structure 0 0 0 0

i.1 ### s/d ### 0 0 0 0 0 m2

i.2 ### s/d ### 0 0 0 0 0

i.3 ### s/d ### 0 0 0 0 0

i.4 ### s/d ### 0 0 0 0 0

i.5 ### s/d ### 0 0 0 0 0

J. Waterproofing Wet Area 0 0 0 0

j.1 ### s/d ### 0 0 0 0 0

j.2 ### s/d ### 0 0 0 0 0

j.3 ### s/d ### 0 0 0 0 0

j.4 ### s/d ### 0 0 0 0 0

j.5 ### s/d ### 0 0 0 0 0

K Lain-Lain 32 23 0 0 ls

k.1 Storing ### s/d ### 12 1 0 0 0 ls

k.2 MEP Crew ### s/d ### 10 2 0 0 0 ls

k.3 SHE Crew ### s/d ### 10 4 4 0 0 ls

k.4 Surveyor Crew ### s/d ### 10 2 0 0 0 ls

k.5 Scaffolder ### s/d ### 10 1 0 0 0 ls

k.6 Canteen Crew and office boy ### s/d ### 10 2 0 0 0 ls

k.7 Driver and Operator ### s/d ### 15 3 5 0 0 ls

k.8 Warehouse assistant ### s/d ### 10 1 0 0 0 ls

k.9 Laboratory quality control assistant ### s/d ### 10 1 0 0 0 ls

k.10 Equipment assistant ### s/d ### 12 0 1 0 0 ls

k.11 Foreman ### s/d ### 10 1 0 0 0 ls

k.12 Leave or sick ### s/d ### 8 1 5 0 0 ls

k.13 Shifting materiel for metal structure ### s/d ### 0 0 0 0 0 ls

k.14 Fabrication door and windows SVB ### s/d ### 0 0 0 0 0 set

k.15 levelling land for LC tie beam corridor PoP ### s/d ### 0 0 0 0 0 m2

k.16 Fabrication of concrete deck ### s/d ### 10 1 0 0 0 ls

k.17 Cleaning and shifting materiel ### s/d ### 10 0 6 0 0 ls

k.18 Fabrication and install window alumunium ### s/d ### 9 0 2 0 0 m2 aigle royal

k.19 Ansembling mockarabieh ### s/d ### 10 4 0 0 0 m2 Valasindo

k.20 Removing doors and windows from safe house ### s/d ### 0 0 0 0 0 m3

k.21 Install metal roof for ballroom ### s/d ### 10 8 0 0 0 kg Valasindo

k.22 Finishing and expose column and beam ### s/d ### 0 0 0 0 0 ls

25

L Alat

l.1 Excavator ### s/d ### 10 1 0

l.2 Trailler Truck ### s/d ### 9 0 0

l.3 Compactor ### s/d ### 10 1 0

l.4 Bob Cat ### s/d ### 10 1 0

l.5 Fiori ### s/d ### 10 2 0

l.6 Rough Terrain Crane ### s/d ### 10 1 0

l.7 Concrete Vibrator ### s/d ### 10 3 0

l.8 Bar Bending ### s/d ### 10 1 0

l.9 Bar Cutter ### s/d ### 10 1 0

l.10 Flat Bed Truck ### s/d ### 10 1 0

l.11 Circle Cutter ### s/d ### 10 4 0

l.12 Welding Machine ### s/d ### 10 4 0

l.13 Stamper ### s/d ### 10 1 0

l.14 Compressor ### s/d ### 10 1 0

l.15 Tile Cutter ### s/d ### 10 2 0

l.16 Seaming Roofing Machine ### s/d ### 10 2 0

l.17 Hand Bor ### s/d ### 10 6 0

Indonesia Local

n

Workers Workers ###

Temperature (Celcius) Amount of Working Hours Overtime (hours) Management Staff TOTAL

76 120

ENG 7 HC / GA 7

23 - 38° C 10 0 196 SPV 9 SHE 4

SURVEYOR 4 KOM 6

Notes : Maitre Douvrage Entrepreneur Dibuat Oleh,

Chef de Department Technique Chef de De Department D'ingenierie

NIAMEY NYALA PT. WIJAYA KARYA (Persero) Tbk.

Day : Thursday

Date : 5-Nov-20

Hari

Daily Report Weeks : 99

Tanggal

RÉHABILITATION DU PALAIS PRÉSIDENTIEL DU RÉPUBLIQUE DU NIGER

Minggu Ke

Work Durations number of workers Volume

NO Job Description Working Hours Unit Material / Information Material

(Hours) Ind WorkersLocal Workers Tools Ind Workers

Local Workers Tools

A. EARTHWORK 0 2 0 0

a.1 Shifting and backfilling on corridor zone 1 ### s/d ### 0 0 0 0 0 m3

a.2 Backfilling area tie beam on corridor zone 1 ### s/d ### 0 0 0 0 0 m3

a.3 Backfilling area tie beam and slab on ground PoP ### s/d ### 12 0 2 0 0 m3

a.4 ### s/d ### 0 0 0 0 0

B.1 CONCRETE FOR COLUMN 2 8 0 0

b.1.1 Casting concrete for column GF ### s/d ### 4 2 8 0 0 m3 start working for dishutter formwork, cleaning a

b.1.2 ### s/d ### 0 0 0 0 0

b.1.3 ### s/d ### 0 0 0 0 0

B.2 CONCRETE FOR BEAM 0 0 0 0

b.2.1 ### s/d ### 0 0 0 0 0 m3

b.2.2 ### s/d ### 0 0 0 0 0

b.2.3 ### s/d ### 0 0 0 0 0

B.3 CONCRETE FOR SLAB/FLOOR PLATE 0 0 0 0

b.3.1 ### s/d ### 0 0 0 0 0 m3

b.3.2 ### s/d ### 0 0 0 0 0

b.3.3 ### s/d ### 0 0 0 0 0

C.1 FORMWORK FOR COLUMN 13 8 0 0

c.1.1 Workshop ### s/d ### 10 3 0 0 0 m2

c.1.2 Fabrication on site ### s/d ### 10 4 0 0 0 m2

c.1.3 Install and dihutter formwork for column GF PoP ### s/d ### 12 0 8 0 0 m2 sims

c.1.4 Install and dishutter formwork column GF and FF PoP ### s/d ### 10 6 0 0 0 m2

c.1.5 Install formwork for pedestal column PoP ### s/d ### 0 0 0 0 0 m2

C.2 FORMWORK FOR BEAM 13 0 0 0

c.2.1 Install and dishutter formwork for beam PoP ToC -0.050 ### s/d ### 0 0 0 0 0 m2

c.2.2 Install formwork for beam HoS ToC -2.200 ### s/d ### 0 0 0 0 0 m2

c.2.3 Install formwork for beam and slab Roof PoP ToC +10.800 ### s/d ### 10 4 0 0 0 m2

c.2.4 Instal formwork beam and slab PoP ToC +5.250 ### s/d ### 10 9 0 0 0 m2

c.2.5 Dishutter formwork beam and slab corridor on zone 1 ToC -0. ### s/d ### 0 0 0 0 0 m2

C.3 FORMWORK FOR SLAB 0 5 0 0

c.3.1 Install formwork slab on ground PoP ToC -0.050 ### s/d ### 10 0 0 0 0 m2

c.3.2 Joint and setting formwork for doom HoS ToC +6.350 ### s/d ### 0 0 0 0 0 m2

c.3.3 Dishutter formwork ring beam and slab FF PoP ToC +5.250 ### s/d ### 10 0 5 0 0 m2

c.3.4 Dishutter formwork ring beam and slab post control type 1 on ### s/d ### 0 0 0 0 0 m2

c.3.5 Install formwork for beam and slab HoS ToC -0.050 (garden a ### s/d ### 0 0 0 0 0 m2

D.1 REBAR FOR COLUMN 11 6 0 0

d.1.1 Fabrication Rebar ### s/d ### 10 6 0 0 0 kg

d.1.2 Prefabrication and erection rebar for column PoP ### s/d ### 10 5 0 0 0 kg

d.1.3 Prefabrication rebar for column and lintel beam ### s/d ### 10 0 2 0 0 kg

d.1.4 Install rebar for pedestal column PoP ### s/d ### 0 0 0 0 0 kg

d.1.5 Install rebar for column GF PoP (prefab) ### s/d ### 10 0 4 0 0 kg sims

D.2 REBAR FOR BEAM 2 6 0 0

d.2.1 Install rebar for beam roof PoP ToC +10.800 ### s/d ### 10 2 6 0 0 kg sims

d.2.2 Install rebar for tie beam HoS ToC -2.200 ### s/d ### 0 0 0 0 0 kg

d.2.3 ### s/d ### 0 0 0 0 0 kg

D.3 REBAR FOR SLAB 0 7 0 0

d.3.1 Install rebar for doom HoS ToC +6.350 ### s/d ### 0 0 0 0 0 kg

d.3.2 Install rebar slab ground floor PoP ToC -0.050 ### s/d ### 0 0 0 0 0 kg

d.3.3 Install rebar for slab roof PoP ToC +10.800 ### s/d ### 10 0 7 0 0 kg sims

E. Masonry 0 41 0 0

e.1 Install brick for window and corridor area ballroom ### s/d ### 10 0 8 0 0 m2 wala group

e.2 Install brick for window and corridor area ballroom ### s/d ### 11 0 24 0 0 m2 sirius

e.3 Fabrication brique ### s/d ### 9 0 9 0 0 pcs sirius

e.4 Install brick for paraphet roof ballroom ToC +9.600 ### s/d ### 0 0 0 0 0 m2

e.5 Shifting brique ### s/d ### 0 0 0 0 0 m2

e.6 Install brick for window and corridor area ballroom ### s/d ### 0 0 0 0 0 m2

e.7 Install brick for paraphet roof post control type 2 unit 1 ### s/d ### 0 0 0 0 0 m'

F. Plastering 4 7 0 0

f.1 Finishing wall with stuccofiller on HoS ### s/d ### 10 0 7 0 0 m2 sirius

f.2 Install head of plaster on ballroom ### s/d ### 10 4 0 0 0 m2

f.3 Plastering wall of ballroom ### s/d ### 0 0 0 0 0 m2

f.4 Install head of screed roof HoS ToC +6.350 ### s/d ### 0 0 0 0 0 m'

f.5 Plastering wall for post control type 1 unit 1 ### s/d ### 0 0 0 0 0 m'

G. Baja 0 0 0 0

g.1 ### s/d ### 0 0 0 0 0 kg

g.2 ### s/d ### 0 0 0 0 0 kg

g.3 ### s/d ### 0 0 0 0 0 kg

g.4 ### s/d ### 0 0 0 0 0 kg

g.5 ### s/d ### 0 0 0 0 0 kg

H. Anti-Thermite 0 0 0 0

h.1 ### s/d ### 0 0 0 0 0 m2

h.2 ### s/d ### 0 0 0 0 0

h.3 ### s/d ### 0 0 0 0 0

h.4 ### s/d ### 0 0 0 0 0

h.5 ### s/d ### 0 0 0 0 0

I. Waterproofing Sub Structure 0 0 0 0

i.1 ### s/d ### 0 0 0 0 0 m2

i.2 ### s/d ### 0 0 0 0 0

i.3 ### s/d ### 0 0 0 0 0

i.4 ### s/d ### 0 0 0 0 0

i.5 ### s/d ### 0 0 0 0 0

J. Waterproofing Wet Area 0 0 0 0

j.1 ### s/d ### 0 0 0 0 0

j.2 ### s/d ### 0 0 0 0 0

j.3 ### s/d ### 0 0 0 0 0

j.4 ### s/d ### 0 0 0 0 0

j.5 ### s/d ### 0 0 0 0 0

K Lain-Lain 31 21 0 0 ls

k.1 Storing ### s/d ### 12 1 0 0 0 ls

k.2 MEP Crew ### s/d ### 10 2 0 0 0 ls

k.3 SHE Crew ### s/d ### 10 4 4 0 0 ls

k.4 Surveyor Crew ### s/d ### 10 2 0 0 0 ls

k.5 Scaffolder ### s/d ### 10 1 0 0 0 ls

k.6 Canteen Crew and office boy ### s/d ### 10 2 0 0 0 ls

k.7 Driver and Operator ### s/d ### 12 3 5 0 0 ls

k.8 Warehouse assistant ### s/d ### 10 1 0 0 0 ls

k.9 Laboratory quality control assistant ### s/d ### 10 1 0 0 0 ls

k.10 Equipment assistant ### s/d ### 12 0 1 0 0 ls

k.11 Foreman ### s/d ### 10 1 0 0 0 ls

k.12 Leave or sick ### s/d ### 8 0 7 0 0 ls

k.13 Shifting materiel for metal structure ### s/d ### 0 0 0 0 0 ls

k.14 Fabrication door and windows SVB ### s/d ### 0 0 0 0 0 set

k.15 levelling land for LC tie beam corridor PoP ### s/d ### 0 0 0 0 0 m2

k.16 Fabrication of concrete deck ### s/d ### 10 1 0 0 0 ls

k.17 Cleaning and shifting materiel ### s/d ### 10 0 2 0 0 ls

k.18 Fabrication and install window alumunium ### s/d ### 9 0 2 0 0 m2 aigle royal

k.19 Ansembling mockarabieh ### s/d ### 10 4 0 0 0 m2 Valasindo

k.20 Removing doors and windows from safe house ### s/d ### 0 0 0 0 0 m3

k.21 Install metal roof for ballroom ### s/d ### 10 8 0 0 0 kg Valasindo

k.22 Finishing and expose column and beam ### s/d ### 0 0 0 0 0 ls

25

L Alat

l.1 Excavator ### s/d ### 10 1 0

l.2 Trailler Truck ### s/d ### 9 0 0

l.3 Compactor ### s/d ### 10 1 0

l.4 Bob Cat ### s/d ### 10 1 0

l.5 Fiori ### s/d ### 10 2 0

l.6 Rough Terrain Crane ### s/d ### 10 1 0

l.7 Concrete Vibrator ### s/d ### 10 3 0

l.8 Bar Bending ### s/d ### 10 1 0

l.9 Bar Cutter ### s/d ### 10 1 0

l.10 Flat Bed Truck ### s/d ### 10 1 0

l.11 Circle Cutter ### s/d ### 10 4 0

l.12 Welding Machine ### s/d ### 10 4 0

l.13 Stamper ### s/d ### 10 1 0

l.14 Compressor ### s/d ### 10 1 0

l.15 Tile Cutter ### s/d ### 10 2 0

l.16 Seaming Roofing Machine ### s/d ### 10 2 0

l.17 Hand Bor ### s/d ### 10 6 0

Indonesia Local

n

Workers Workers ###

Temperature (Celcius) Amount of Working Hours Overtime (hours) Management Staff TOTAL

76 111

ENG 7 HC / GA 7

23 - 38° C 10 0 187 SPV 9 SHE 4

SURVEYOR 4 KOM 6

Notes : Maitre Douvrage Entrepreneur Dibuat Oleh,

Chef de Department Technique Chef de De Department D'ingenierie

NIAMEY NYALA PT. WIJAYA KARYA (Persero) Tbk.

Day : Friday

Date : 6-Nov-20

Hari

Daily Report Weeks : 99

Tanggal

RÉHABILITATION DU PALAIS PRÉSIDENTIEL DU RÉPUBLIQUE DU NIGER

Minggu Ke

Work Durations number of workers Volume

NO Job Description Working Hours Unit Material / Information Material

(Hours) Ind WorkersLocal Workers Tools Ind Workers

Local Workers Tools

A. EARTHWORK 0 2 0 0

a.1 Shifting and backfilling on corridor zone 1 ### s/d ### 0 0 0 0 0 m3

a.2 Backfilling area tie beam on corridor zone 1 ### s/d ### 0 0 0 0 0 m3

a.3 Backfilling area tie beam and slab on ground PoP ### s/d ### 12 0 2 0 0 m3

a.4 ### s/d ### 0 0 0 0 0

B.1 CONCRETE FOR COLUMN 2 8 0 0

b.1.1 Casting concrete for column GF PoP and screed roof HoS ToC ### s/d ### -16 2 8 0 0 m3 Preparing for working with night shift 15.00 - 0

b.1.2 ### s/d ### 0 0 0 0 0

b.1.3 ### s/d ### 0 0 0 0 0

B.2 CONCRETE FOR BEAM 0 0 0 0

b.2.1 ### s/d ### 0 0 0 0 0 m3

b.2.2 ### s/d ### 0 0 0 0 0

b.2.3 ### s/d ### 0 0 0 0 0

B.3 CONCRETE FOR SLAB/FLOOR PLATE 0 0 0 0

b.3.1 ### s/d ### 0 0 0 0 0 m3

b.3.2 ### s/d ### 0 0 0 0 0

b.3.3 ### s/d ### 0 0 0 0 0

C.1 FORMWORK FOR COLUMN 13 11 0 0

c.1.1 Workshop ### s/d ### 10 3 0 0 0 m2

c.1.2 Fabrication on site ### s/d ### 10 4 0 0 0 m2

c.1.3 Install and dihutter formwork for column GF PoP ### s/d ### 13 0 11 0 0 m2 sims

c.1.4 Install and dishutter formwork column GF and FF PoP ### s/d ### 10 6 0 0 0 m2

c.1.5 Install formwork for pedestal column PoP ### s/d ### 0 0 0 0 0 m2

C.2 FORMWORK FOR BEAM 13 0 0 0

c.2.1 Install and dishutter formwork for beam PoP ToC -0.050 ### s/d ### 0 0 0 0 0 m2

c.2.2 Install formwork for beam HoS ToC -2.200 ### s/d ### 0 0 0 0 0 m2

c.2.3 Install formwork for beam and slab Roof PoP ToC +10.800 ### s/d ### 10 4 0 0 0 m2

c.2.4 Instal formwork beam and slab PoP ToC +5.250 ### s/d ### 10 9 0 0 0 m2

c.2.5 Dishutter formwork beam and slab corridor on zone 1 ToC -0. ### s/d ### 0 0 0 0 0 m2

C.3 FORMWORK FOR SLAB 0 5 0 0

c.3.1 Install formwork slab on ground PoP ToC -0.050 ### s/d ### 10 0 0 0 0 m2

c.3.2 Joint and setting formwork for doom HoS ToC +6.350 ### s/d ### 0 0 0 0 0 m2

c.3.3 Dishutter formwork ring beam and slab FF PoP ToC +5.250 ### s/d ### 10 0 5 0 0 m2

c.3.4 Dishutter formwork ring beam and slab post control type 1 on ### s/d ### 0 0 0 0 0 m2

c.3.5 Install formwork for beam and slab HoS ToC -0.050 (garden a ### s/d ### 0 0 0 0 0 m2

D.1 REBAR FOR COLUMN 11 6 0 0

d.1.1 Fabrication Rebar ### s/d ### 10 6 0 0 0 kg

d.1.2 Prefabrication and erection rebar for column PoP ### s/d ### 10 5 0 0 0 kg

d.1.3 Prefabrication rebar for column and lintel beam ### s/d ### 10 0 2 0 0 kg

d.1.4 Install rebar for pedestal column PoP ### s/d ### 0 0 0 0 0 kg

d.1.5 Install rebar for column GF PoP (prefab) ### s/d ### 10 0 4 0 0 kg sims

D.2 REBAR FOR BEAM 2 6 0 0

d.2.1 Install rebar for beam roof PoP ToC +10.800 ### s/d ### 10 2 6 0 0 kg sims

d.2.2 Install rebar for tie beam HoS ToC -2.200 ### s/d ### 0 0 0 0 0 kg

d.2.3 ### s/d ### 0 0 0 0 0 kg

D.3 REBAR FOR SLAB 0 7 0 0

d.3.1 Install rebar for doom HoS ToC +6.350 ### s/d ### 0 0 0 0 0 kg

d.3.2 Install rebar slab ground floor PoP ToC -0.050 ### s/d ### 0 0 0 0 0 kg

d.3.3 Install rebar for slab roof PoP ToC +10.800 ### s/d ### 10 0 7 0 0 kg sims

E. Masonry 0 41 0 0

e.1 Install brick for window and corridor area ballroom ### s/d ### 10 0 8 0 0 m2 wala group

e.2 Install brick for window and corridor area ballroom ### s/d ### 11 0 24 0 0 m2 sirius

e.3 Fabrication brique ### s/d ### 9 0 9 0 0 pcs sirius

e.4 Install brick for paraphet roof ballroom ToC +9.600 ### s/d ### 0 0 0 0 0 m2

e.5 Shifting brique ### s/d ### 0 0 0 0 0 m2

e.6 Install brick for window and corridor area ballroom ### s/d ### 0 0 0 0 0 m2

e.7 Install brick for paraphet roof post control type 2 unit 1 ### s/d ### 0 0 0 0 0 m'

F. Plastering 4 6 0 0

f.1 Finishing wall with stuccofiller on HoS ### s/d ### 10 0 6 0 0 m2 sirius

f.2 Install head of plaster on ballroom ### s/d ### 10 4 0 0 0 m2

f.3 Plastering wall of ballroom ### s/d ### 0 0 0 0 0 m2

f.4 Install head of screed roof HoS ToC +6.350 ### s/d ### 0 0 0 0 0 m'

f.5 Plastering wall for post control type 1 unit 1 ### s/d ### 0 0 0 0 0 m'

G. Baja 0 0 0 0

g.1 ### s/d ### 0 0 0 0 0 kg

g.2 ### s/d ### 0 0 0 0 0 kg

g.3 ### s/d ### 0 0 0 0 0 kg

g.4 ### s/d ### 0 0 0 0 0 kg

g.5 ### s/d ### 0 0 0 0 0 kg

H. Anti-Thermite 0 0 0 0

h.1 ### s/d ### 0 0 0 0 0 m2

h.2 ### s/d ### 0 0 0 0 0

h.3 ### s/d ### 0 0 0 0 0

h.4 ### s/d ### 0 0 0 0 0

h.5 ### s/d ### 0 0 0 0 0

I. Waterproofing Sub Structure 0 0 0 0

i.1 ### s/d ### 0 0 0 0 0 m2

i.2 ### s/d ### 0 0 0 0 0

i.3 ### s/d ### 0 0 0 0 0

i.4 ### s/d ### 0 0 0 0 0

i.5 ### s/d ### 0 0 0 0 0

J. Waterproofing Wet Area 0 0 0 0

j.1 ### s/d ### 0 0 0 0 0

j.2 ### s/d ### 0 0 0 0 0

j.3 ### s/d ### 0 0 0 0 0

j.4 ### s/d ### 0 0 0 0 0

j.5 ### s/d ### 0 0 0 0 0

K Lain-Lain 31 21 0 0 ls

k.1 Storing ### s/d ### 12 1 0 0 0 ls

k.2 MEP Crew ### s/d ### 10 2 0 0 0 ls

k.3 SHE Crew ### s/d ### 10 4 4 0 0 ls

k.4 Surveyor Crew ### s/d ### 10 2 0 0 0 ls

k.5 Scaffolder ### s/d ### 10 1 0 0 0 ls

k.6 Canteen Crew and office boy ### s/d ### 10 2 0 0 0 ls

k.7 Driver and Operator ### s/d ### 12 3 5 0 0 ls

k.8 Warehouse assistant ### s/d ### 10 1 0 0 0 ls

k.9 Laboratory quality control assistant ### s/d ### 10 1 0 0 0 ls

k.10 Equipment assistant ### s/d ### 12 0 1 0 0 ls

k.11 Foreman ### s/d ### 10 1 0 0 0 ls

k.12 Leave or sick ### s/d ### 8 0 7 0 0 ls

k.13 Shifting materiel for metal structure ### s/d ### 0 0 0 0 0 ls

k.14 Fabrication door and windows SVB ### s/d ### 0 0 0 0 0 set

k.15 levelling land for LC tie beam corridor PoP ### s/d ### 0 0 0 0 0 m2

k.16 Fabrication of concrete deck ### s/d ### 10 1 0 0 0 ls

k.17 Cleaning and shifting materiel ### s/d ### 10 0 2 0 0 ls

k.18 Fabrication and install window alumunium ### s/d ### 9 0 2 0 0 m2 aigle royal

k.19 Repair and installing doors in SVB and HoS ### s/d ### 10 4 0 0 0 m2 Valasindo

k.20 Removing doors and windows from safe house ### s/d ### 0 0 0 0 0 m3

k.21 Install metal structure for roof of ballroom ### s/d ### 10 8 0 0 0 kg Valasindo

k.22 Finishing and expose column and beam ### s/d ### 0 0 0 0 0 ls

25

L Alat

l.1 Excavator ### s/d ### 10 1 0

l.2 Trailler Truck ### s/d ### 9 0 0

l.3 Compactor ### s/d ### 10 1 0

l.4 Bob Cat ### s/d ### 10 1 0

l.5 Fiori ### s/d ### 10 2 0

l.6 Rough Terrain Crane ### s/d ### 10 1 0

l.7 Concrete Vibrator ### s/d ### 10 3 0

l.8 Bar Bending ### s/d ### 10 1 0

l.9 Bar Cutter ### s/d ### 10 1 0

l.10 Flat Bed Truck ### s/d ### 10 1 0

l.11 Circle Cutter ### s/d ### 10 4 0

l.12 Welding Machine ### s/d ### 10 4 0

l.13 Stamper ### s/d ### 10 1 0

l.14 Compressor ### s/d ### 10 1 0

l.15 Tile Cutter ### s/d ### 10 2 0

l.16 Seaming Roofing Machine ### s/d ### 10 2 0

l.17 Hand Bor ### s/d ### 10 6 0

Indonesia Local

n

Workers Workers ###

Temperature (Celcius) Amount of Working Hours Overtime (hours) Management Staff TOTAL

76 113

ENG 7 HC / GA 7

23 - 38° C 10 0 189 SPV 9 SHE 4

SURVEYOR 4 KOM 6

Notes : Maitre Douvrage Entrepreneur Dibuat Oleh,

Chef de Department Technique Chef de De Department D'ingenierie

NIAMEY NYALA PT. WIJAYA KARYA (Persero) Tbk.

Day : Saturday

Date : 7-Nov-20

Hari

Daily Report Weeks : 99

Tanggal

RÉHABILITATION DU PALAIS PRÉSIDENTIEL DU RÉPUBLIQUE DU NIGER

Minggu Ke

Work Durations number of workers Volume

NO Job Description Working Hours Unit Material / Information Material

(Hours) Ind WorkersLocal Workers Tools Ind Workers

Local Workers Tools

A. EARTHWORK 0 2 0 0

a.1 Shifting and backfilling on corridor zone 1 ### s/d ### 0 0 0 0 0 m3

a.2 Backfilling area tie beam on corridor zone 1 ### s/d ### 0 0 0 0 0 m3

a.3 Backfilling area tie beam and slab on ground PoP ### s/d ### 12 0 2 0 0 m3

a.4 ### s/d ### 0 0 0 0 0

B.1 CONCRETE FOR COLUMN 2 8 0 0

b.1.1 Casting concrete for column GF, lc tie beam and footing, rin ### s/d ### -6 2 8 0 0 m3 concrete team working for night shift 15.00 - 00

b.1.2 ### s/d ### 0 0 0 0 0

b.1.3 ### s/d ### 0 0 0 0 0

B.2 CONCRETE FOR BEAM 0 0 0 0

b.2.1 ### s/d ### 0 0 0 0 0 m3

b.2.2 ### s/d ### 0 0 0 0 0

b.2.3 ### s/d ### 0 0 0 0 0

B.3 CONCRETE FOR SLAB/FLOOR PLATE 0 0 0 0

b.3.1 ### s/d ### 0 0 0 0 0 m3

b.3.2 ### s/d ### 0 0 0 0 0

b.3.3 ### s/d ### 0 0 0 0 0

C.1 FORMWORK FOR COLUMN 13 10 0 0

c.1.1 Workshop ### s/d ### 10 3 0 0 0 m2

c.1.2 Fabrication on site ### s/d ### 10 4 0 0 0 m2

c.1.3 Install and dihutter formwork for column GF PoP ### s/d ### 16 0 10 0 0 m2 sims

c.1.4 Install and dishutter formwork column GF and FF PoP ### s/d ### 10 6 0 0 0 m2

c.1.5 Install formwork for pedestal column PoP ### s/d ### 0 0 0 0 0 m2

C.2 FORMWORK FOR BEAM 13 0 0 0

c.2.1 Install and dishutter formwork for beam PoP ToC -0.050 ### s/d ### 0 0 0 0 0 m2

c.2.2 Install formwork for beam HoS ToC -2.200 ### s/d ### 0 0 0 0 0 m2

c.2.3 Install formwork for beam and slab Roof PoP ToC +10.800 ### s/d ### 10 4 0 0 0 m2

c.2.4 Instal formwork beam and slab PoP ToC +5.250 ### s/d ### 10 9 0 0 0 m2

c.2.5 Dishutter formwork beam and slab corridor on zone 1 ToC -0. ### s/d ### 0 0 0 0 0 m2

C.3 FORMWORK FOR SLAB 0 5 0 0

c.3.1 Install formwork slab on ground PoP ToC -0.050 ### s/d ### 10 0 0 0 0 m2

c.3.2 Joint and setting formwork for doom HoS ToC +6.350 ### s/d ### 0 0 0 0 0 m2

c.3.3 Dishutter formwork ring beam and slab FF PoP ToC +5.250 ### s/d ### 10 0 5 0 0 m2

c.3.4 Dishutter formwork ring beam and slab post control type 1 on ### s/d ### 0 0 0 0 0 m2

c.3.5 Install formwork for beam and slab HoS ToC -0.050 (garden a ### s/d ### 0 0 0 0 0 m2

D.1 REBAR FOR COLUMN 11 6 0 0

d.1.1 Fabrication Rebar ### s/d ### 10 6 0 0 0 kg

d.1.2 Prefabrication and erection rebar for column PoP ### s/d ### 10 5 0 0 0 kg

d.1.3 Prefabrication rebar for column and lintel beam ### s/d ### 10 0 2 0 0 kg

d.1.4 Install rebar for pedestal column PoP ### s/d ### 0 0 0 0 0 kg

d.1.5 Install rebar for column GF PoP (prefab) ### s/d ### 10 0 4 0 0 kg sims

D.2 REBAR FOR BEAM 2 3 0 0

d.2.1 Install rebar for beam FF PoP ToC +5.250 ### s/d ### 10 2 3 0 0 kg sims

d.2.2 Install rebar for tie beam HoS ToC -2.200 ### s/d ### 0 0 0 0 0 kg

d.2.3 ### s/d ### 0 0 0 0 0 kg

D.3 REBAR FOR SLAB 0 0 0 0

d.3.1 Install rebar for doom HoS ToC +6.350 ### s/d ### 0 0 0 0 0 kg

d.3.2 Install rebar slab ground floor PoP ToC -0.050 ### s/d ### 0 0 0 0 0 kg

d.3.3 Install rebar for slab roof PoP ToC +10.800 ### s/d ### 0 0 0 0 0 kg

E. Masonry 0 41 0 0

e.1 Install brick for window and corridor area ballroom ### s/d ### 10 0 8 0 0 m2 wala group

e.2 Install brick for window and corridor area ballroom ### s/d ### 11 0 24 0 0 m2 sirius

e.3 Fabrication brique ### s/d ### 9 0 9 0 0 pcs sirius

e.4 Install brick for paraphet roof ballroom ToC +9.600 ### s/d ### 0 0 0 0 0 m2

e.5 Shifting brique ### s/d ### 0 0 0 0 0 m2

e.6 Install brick for window and corridor area ballroom ### s/d ### 0 0 0 0 0 m2

e.7 Install brick for paraphet roof post control type 2 unit 1 ### s/d ### 0 0 0 0 0 m'

F. Plastering 4 6 0 0

f.1 Finishing wall with stuccofiller on HoS ### s/d ### 10 0 6 0 0 m2 sirius

f.2 Install head of plaster on ballroom ### s/d ### 10 4 0 0 0 m2

f.3 Plastering wall of ballroom ### s/d ### 0 0 0 0 0 m2

f.4 Install head of screed roof HoS ToC +6.350 ### s/d ### 0 0 0 0 0 m'

f.5 Plastering wall for post control type 1 unit 1 ### s/d ### 0 0 0 0 0 m'

G. Baja 0 0 0 0

g.1 ### s/d ### 0 0 0 0 0 kg

g.2 ### s/d ### 0 0 0 0 0 kg

g.3 ### s/d ### 0 0 0 0 0 kg

g.4 ### s/d ### 0 0 0 0 0 kg

g.5 ### s/d ### 0 0 0 0 0 kg

H. Anti-Thermite 0 0 0 0

h.1 ### s/d ### 0 0 0 0 0 m2

h.2 ### s/d ### 0 0 0 0 0

h.3 ### s/d ### 0 0 0 0 0

h.4 ### s/d ### 0 0 0 0 0

h.5 ### s/d ### 0 0 0 0 0

I. Waterproofing Sub Structure 0 0 0 0

i.1 ### s/d ### 0 0 0 0 0 m2

i.2 ### s/d ### 0 0 0 0 0

i.3 ### s/d ### 0 0 0 0 0

i.4 ### s/d ### 0 0 0 0 0

i.5 ### s/d ### 0 0 0 0 0

J. Waterproofing Wet Area 0 0 0 0

j.1 ### s/d ### 0 0 0 0 0

j.2 ### s/d ### 0 0 0 0 0

j.3 ### s/d ### 0 0 0 0 0

j.4 ### s/d ### 0 0 0 0 0

j.5 ### s/d ### 0 0 0 0 0

K Lain-Lain 31 21 0 0 ls

k.1 Storing ### s/d ### 12 1 0 0 0 ls

k.2 MEP Crew ### s/d ### 10 2 0 0 0 ls

k.3 SHE Crew ### s/d ### 10 4 4 0 0 ls

k.4 Surveyor Crew ### s/d ### 10 2 0 0 0 ls

k.5 Scaffolder ### s/d ### 10 1 0 0 0 ls

k.6 Canteen Crew and office boy ### s/d ### 10 2 0 0 0 ls

k.7 Driver and Operator ### s/d ### 12 3 5 0 0 ls

k.8 Warehouse assistant ### s/d ### 10 1 0 0 0 ls

k.9 Laboratory quality control assistant ### s/d ### 10 1 0 0 0 ls

k.10 Equipment assistant ### s/d ### 12 0 1 0 0 ls

k.11 Foreman ### s/d ### 10 1 0 0 0 ls

k.12 Leave or sick ### s/d ### 8 0 7 0 0 ls

k.13 Shifting materiel for metal structure ### s/d ### 0 0 0 0 0 ls

k.14 Fabrication door and windows SVB ### s/d ### 0 0 0 0 0 set

k.15 levelling land for LC tie beam corridor PoP ### s/d ### 0 0 0 0 0 m2

k.16 Fabrication of concrete deck ### s/d ### 10 1 0 0 0 ls

k.17 Cleaning and shifting materiel ### s/d ### 10 0 2 0 0 ls

k.18 Fabrication and install window alumunium ### s/d ### 9 0 2 0 0 m2 aigle royal

k.19 Repair and installing doors in SVB and HoS ### s/d ### 10 4 0 0 0 m2 Valasindo

k.20 Removing doors and windows from safe house ### s/d ### 0 0 0 0 0 m3

k.21 Install metal structure for roof of ballroom ### s/d ### 10 8 0 0 0 kg Valasindo

k.22 Finishing and expose column and beam ### s/d ### 0 0 0 0 0 ls

25

L Alat

l.1 Excavator ### s/d ### 10 1 0

l.2 Trailler Truck ### s/d ### 9 0 0

l.3 Compactor ### s/d ### 10 1 0

l.4 Bob Cat ### s/d ### 10 1 0

l.5 Fiori ### s/d ### 10 2 0

l.6 Rough Terrain Crane ### s/d ### 10 1 0

l.7 Concrete Vibrator ### s/d ### 10 3 0

l.8 Bar Bending ### s/d ### 10 1 0

l.9 Bar Cutter ### s/d ### 10 1 0

l.10 Flat Bed Truck ### s/d ### 10 1 0

l.11 Circle Cutter ### s/d ### 10 4 0

l.12 Welding Machine ### s/d ### 10 4 0

l.13 Stamper ### s/d ### 10 1 0

l.14 Compressor ### s/d ### 10 1 0

l.15 Tile Cutter ### s/d ### 10 2 0

l.16 Seaming Roofing Machine ### s/d ### 10 2 0

l.17 Hand Bor ### s/d ### 10 6 0

Indonesia Local

n

Workers Workers ###

Temperature (Celcius) Amount of Working Hours Overtime (hours) Management Staff TOTAL

76 102

ENG 7 HC / GA 7

23 - 38° C 10 0 178 SPV 9 SHE 4

SURVEYOR 4 KOM 6

Notes : Maitre Douvrage Entrepreneur Dibuat Oleh,

Chef de Department Technique Chef de De Department D'ingenierie

NIAMEY NYALA PT. WIJAYA KARYA (Persero) Tbk.

Day : Sunday

Date : 8-Nov-20

Hari

Daily Report Weeks : 99

Tanggal

RÉHABILITATION DU PALAIS PRÉSIDENTIEL DU RÉPUBLIQUE DU NIGER

Minggu Ke

Work Durations number of workers Volume

NO Job Description Working Hours Unit Material / Information Material

(Hours) Ind WorkersLocal Workers Tools Ind Workers

Local Workers Tools

A. EARTHWORK 0 0 0 0

a.1 Shifting and backfilling on corridor zone 1 ### s/d ### 0 0 0 0 0 m3

a.2 Backfilling area corridor on zone 1 ### s/d ### 0 0 0 0 0 m3

a.3 Backfilling area beam PoP ### s/d ### 0 0 0 0 0 m3

a.4 Levelling land for lc tie beam HoS ### s/d ### 0 0 0 0 0

B.1 CONCRETE FOR COLUMN 0 0 0 0

b.1.1 ### s/d ### 0 0 0 0 0 m3

b.1.2 ### s/d ### 0 0 0 0 0

b.1.3 ### s/d ### 0 0 0 0 0

B.2 CONCRETE FOR BEAM 0 0 0 0

b.2.1 ### s/d ### 0 0 0 0 0 m3

b.2.2 ### s/d ### 0 0 0 0 0

b.2.3 ### s/d ### 0 0 0 0 0

B.3 CONCRETE FOR SLAB/FLOOR PLATE 0 0 0 0

b.3.1 ### s/d ### 0 0 0 0 0 m3

b.3.2 ### s/d ### 0 0 0 0 0

b.3.3 ### s/d ### 0 0 0 0 0

C.1 FORMWORK FOR COLUMN 6 4 0 0

c.1.1 Workshop ### s/d ### 0 0 0 0 0 m2

c.1.2 Fabrication on site ### s/d ### 10 2 0 0 0 m2

c.1.3 Install and dihutter formwork for column GF PoP ### s/d ### 10 0 4 0 0 m2 sims

c.1.4 Install and dishutter formwork column GF and FF PoP ### s/d ### 10 4 0 0 0 m2

c.1.5 ### s/d ### 0 0 0 0 0 m2

C.2 FORMWORK FOR BEAM 6 0 0 0

c.2.1 Dishutter formwork beam PoP ToC -0.050 ### s/d ### 0 0 0 0 0 m2

c.2.2 Install formwork for beam and slab corridor on zone 1 ToC -0 ### s/d ### 0 0 0 0 0 m2

c.2.3 Install formwork for beam and slab Roof PoP ### s/d ### 10 6 0 0 0 m2

c.2.4 Install formwork for beam PoP ToC -0.050 ### s/d ### 0 0 0 0 0 m2

c.2.5 ### s/d ### 0 0 0 0 0 m2

C.3 FORMWORK FOR SLAB 5 3 0 0

c.3.1 Dishutter formwork ring beam and slab first floor PoP ### s/d ### 10 0 3 0 0 m2

c.3.2 Install formwork slab FF PoP ### s/d ### 10 5 0 0 0 m2

c.3.3 ### s/d ### 0 0 0 0 0 m2

c.3.4 ### s/d ### 0 0 0 0 0 m2

c.3.5 ### s/d ### 0 0 0 0 0 m2

D.1 REBAR FOR COLUMN 11 0 0 0

d.1.1 Fabrication Rebar ### s/d ### 10 5 0 0 0 kg

d.1.2 Install rebar footing and pedestal column PoP ### s/d ### 10 6 0 0 0 kg

d.1.3 ### s/d ### 0 0 0 0 0 kg

d.1.4 ### s/d ### 0 0 0 0 0 kg

d.1.5 ### s/d ### 0 0 0 0 0 kg

D.2 REBAR FOR BEAM 0 8 0 0

d.2.1 Install rebar tie beam GF PoP ToC -0.050 ### s/d ### 10 0 3 0 0 kg sims

d.2.2 Install rebar beam FF PoP ToC +5.250 ### s/d ### 10 0 5 0 0 kg sims

d.2.3 ### s/d ### 0 0 0 0 0 kg

D.3 REBAR FOR SLAB 0 0 0 0

d.3.1 Install rebar for doom HoS ToC +6.350 ### s/d ### 0 0 0 0 0 kg

d.3.2 Install rebar slab corridor on zone 1 ToC -0.050 ### s/d ### 0 0 0 0 0 kg

d.3.3 Install rebar slab on ground PoP ToC -0.050 ### s/d ### 0 0 0 0 0 kg

E. Masonry 0 22 0 0

e.1 Install brick for window and corridor area ballroom ### s/d ### 10 0 8 0 0 m2 wala group

e.2 Install brick for window and corridor area ballroom ### s/d ### 9 0 8 0 0 m2 sirius

e.3 Fabrication brique ### s/d ### 0 0 6 0 0 pcs sirius

e.4 Install brick for paraphet roof ballroom ToC +9.600 ### s/d ### 0 0 0 0 0 m2

e.5 Shifting brique ### s/d ### 0 0 0 0 0 m2

e.6 Install brick for window and corridor area ballroom ### s/d ### 0 0 0 0 0 m2

e.7 Install brick for paraphet roof post control type 2 unit 1 ### s/d ### 0 0 0 0 0 m'

F. Plastering 4 0 0 0

f.1 Finishing wall with stuccofiller on HoS ### s/d ### 0 0 0 0 0 m2

f.2 Install head of plaster on ballroom ### s/d ### 10 4 0 0 0 m2

f.3 Plastering wall of ballroom ### s/d ### 0 0 0 0 0 m2

f.4 Install head of screed roof HoS ToC +6.350 ### s/d ### 0 0 0 0 0 m'

f.5 Plastering wall for post control type 1 unit 1 ### s/d ### 0 0 0 0 0 m'

G. Baja 0 0 0 0

g.1 ### s/d ### 0 0 0 0 0 kg

g.2 ### s/d ### 0 0 0 0 0 kg

g.3 ### s/d ### 0 0 0 0 0 kg

g.4 ### s/d ### 0 0 0 0 0 kg

g.5 ### s/d ### 0 0 0 0 0 kg

H. Anti-Thermite 0 0 0 0

h.1 ### s/d ### 0 0 0 0 0 m2

h.2 ### s/d ### 0 0 0 0 0

h.3 ### s/d ### 0 0 0 0 0

h.4 ### s/d ### 0 0 0 0 0

h.5 ### s/d ### 0 0 0 0 0

I. Waterproofing Sub Structure 0 0 0 0

i.1 ### s/d ### 0 0 0 0 0 m2

i.2 ### s/d ### 0 0 0 0 0

i.3 ### s/d ### 0 0 0 0 0

i.4 ### s/d ### 0 0 0 0 0

i.5 ### s/d ### 0 0 0 0 0

J. Waterproofing Wet Area 0 0 0 0

j.1 ### s/d ### 0 0 0 0 0

j.2 ### s/d ### 0 0 0 0 0

j.3 ### s/d ### 0 0 0 0 0

j.4 ### s/d ### 0 0 0 0 0

j.5 ### s/d ### 0 0 0 0 0

K Lain-Lain 15 8 0 0 ls

k.1 Storing ### s/d ### 10 1 0 0 0 ls

k.2 MEP Crew ### s/d ### 10 1 0 0 0 ls

k.3 SHE Crew ### s/d ### 10 3 5 0 0 ls

k.4 Surveyor Crew ### s/d ### 10 0 0 0 0 ls

k.5 Scaffolder ### s/d ### 10 1 0 0 0 ls

k.6 Canteen Crew and office boy ### s/d ### 10 2 0 0 0 ls

k.7 Driver and Operator ### s/d ### 10 0 2 0 0 ls

k.8 Warehouse assistant ### s/d ### 10 1 0 0 0 ls

k.9 Laboratory quality control assistant ### s/d ### 0 0 0 0 0 ls

k.10 Equipment assistant ### s/d ### 10 0 1 0 0 ls

k.11 Foreman ### s/d ### 10 1 0 0 0 ls

k.12 Leave or sick ### s/d ### 8 0 0 0 0 ls

k.13 Shifting materiel for metal structure ### s/d ### 0 0 0 0 0 ls

k.14 Fabrication door and windows SVB ### s/d ### 0 0 0 0 0 set

k.15 levelling land for LC tie beam corridor PoP ### s/d ### 0 0 0 0 0 m2

k.16 Fabrication of concrete deck ### s/d ### 10 1 0 0 0 ls

k.17 Cleaning and shifting materiel ### s/d ### 0 0 0 0 0 ls

k.18 Repair and made a new pallet ### s/d ### 0 0 0 0 0 m2

k.19 Install rebar and formwork for column pratice and lintel beam ### s/d ### 0 0 0 0 0 m2

k.20 Grouting a column metal structure of a roof ballroom ### s/d ### 0 0 0 0 0 m3

k.21 Install metal structure for foor balrrom ### s/d ### 10 3 0 0 0 kg Valasindo

k.22 Finishing and expose column and beam ### s/d ### 10 1 0 0 0 ls

25

L Alat

l.1 Excavator ### s/d ### 10 1 0

l.2 Trailler Truck ### s/d ### 9 0 0

l.3 Compactor ### s/d ### 10 1 0

l.4 Bob Cat ### s/d ### 10 1 0

l.5 Fiori ### s/d ### 10 2 0

l.6 Rough Terrain Crane ### s/d ### 10 1 0

l.7 Concrete Vibrator ### s/d ### 10 3 0

l.8 Bar Bending ### s/d ### 10 1 0

l.9 Bar Cutter ### s/d ### 10 1 0

l.10 Flat Bed Truck ### s/d ### 10 1 0

l.11 Circle Cutter ### s/d ### 10 4 0

l.12 Welding Machine ### s/d ### 10 4 0

l.13 Stamper ### s/d ### 10 1 0

l.14 Compressor ### s/d ### 10 1 0

l.15 Tile Cutter ### s/d ### 10 2 0

l.16 Seaming Roofing Machine ### s/d ### 10 2 0

l.17 Hand Bor ### s/d ### 10 6 0

Indonesia Local

n

Workers Workers ###

Temperature (Celcius) Amount of Working Hours Overtime (hours) Management Staff TOTAL

47 45

ENG 7 HC / GA 7

25 - 36° C 10 0 92 SPV 9 SHE 4

SURVEYOR 4 KOM 6

Notes : Maitre Douvrage Entrepreneur Dibuat Oleh,

Chef de Department Technique Chef de De Department D'ingenierie

NIAMEY NYALA PT. WIJAYA KARYA (Persero) Tbk.

Day : Monday

Date : 9-Nov-20

Hari

Daily Report Weeks : 100

Tanggal

RÉHABILITATION DU PALAIS PRÉSIDENTIEL DU RÉPUBLIQUE DU NIGER

Minggu Ke

Work Durations number of workers Volume

NO Job Description Working Hours Unit Material / Information Material

(Hours) Ind WorkersLocal Workers Tools Ind Workers

Local Workers Tools

A. EARTHWORK 0 0 0 0

a.1 Shifting and backfilling on corridor zone 1 ### s/d ### 0 0 0 0 0 m3

a.2 Backfilling area tie beam on corridor zone 1 ### s/d ### 0 0 0 0 0 m3

a.3 Backfilling area tie beam and slab on ground PoP ### s/d ### 0 0 0 0 0 m3

a.4 Excavation for footing PoP ### s/d ### 10 0 0 0 0 m3

B.1 CONCRETE FOR COLUMN 2 8 0 0

b.1.1 Casting concrete for column GF, footing PoP, screed roof HoS ### s/d ### -13 2 8 0 0 m3 concrete team working for night shift 15.00 - 00

b.1.2 ### s/d ### 0 0 0 0 0

b.1.3 ### s/d ### 0 0 0 0 0

B.2 CONCRETE FOR BEAM 0 0 0 0

b.2.1 ### s/d ### 0 0 0 0 0 m3

b.2.2 ### s/d ### 0 0 0 0 0

b.2.3 ### s/d ### 0 0 0 0 0

B.3 CONCRETE FOR SLAB/FLOOR PLATE 0 0 0 0

b.3.1 ### s/d ### 0 0 0 0 0 m3

b.3.2 ### s/d ### 0 0 0 0 0

b.3.3 ### s/d ### 0 0 0 0 0

C.1 FORMWORK FOR COLUMN 13 4 0 0

c.1.1 Workshop ### s/d ### 10 3 0 0 0 m2

c.1.2 Fabrication on site ### s/d ### 12 4 0 0 0 m2

c.1.3 Install and dihutter formwork for column GF PoP ### s/d ### 16 0 4 0 0 m2 sims

c.1.4 Install and dishutter formwork column GF and FF PoP ### s/d ### 12 6 0 0 0 m2

c.1.5 Install formwork for pedestal column PoP ### s/d ### 0 0 0 0 0 m2

C.2 FORMWORK FOR BEAM 12 7 0 0

c.2.1 Install and dishutter formwork for beam PoP ToC -0.050 ### s/d ### 0 0 0 0 0 m2

c.2.2 Instal formwork beam and slab PoP ToC +5.250 (zone 4A) ### s/d ### 15 0 7 0 0 m2 sims

c.2.3 Install formwork for beam and slab Roof PoP ToC +10.800 ### s/d ### 12 5 0 0 0 m2

c.2.4 Instal formwork beam and slab PoP ToC +5.250 ### s/d ### 10 7 0 0 0 m2

c.2.5 Dishutter formwork beam and slab corridor on zone 1 ToC -0. ### s/d ### 0 0 0 0 0 m2

C.3 FORMWORK FOR SLAB 0 5 0 0

c.3.1 Install formwork slab on ground PoP ToC -0.050 ### s/d ### 10 0 0 0 0 m2

c.3.2 Joint and setting formwork for doom HoS ToC +6.350 ### s/d ### 0 0 0 0 0 m2

c.3.3 Dishutter formwork ring beam and slab FF PoP ToC +5.250 ### s/d ### 10 0 5 0 0 m2

c.3.4 Dishutter formwork ring beam and slab post control type 1 on ### s/d ### 0 0 0 0 0 m2

c.3.5 Install formwork for beam and slab HoS ToC -0.050 (garden a ### s/d ### 0 0 0 0 0 m2

D.1 REBAR FOR COLUMN 11 6 0 0

d.1.1 Fabrication Rebar ### s/d ### 12 6 0 0 0 kg

d.1.2 Install rebar footing and pedestal PoP ### s/d ### 10 5 0 0 0 kg

d.1.3 Prefabrication rebar for column and lintel beam ### s/d ### 10 0 2 0 0 kg

d.1.4 Install rebar for pedestal column PoP ### s/d ### 0 0 0 0 0 kg

d.1.5 Install rebar for column GF PoP (prefab) ### s/d ### 10 0 4 0 0 kg sims

D.2 REBAR FOR BEAM 2 17 0 0

d.2.1 Install rebar for beam FF PoP ToC +5.250 ### s/d ### 10 2 5 0 0 kg sims

d.2.2 Install rebar for tie beam GF PoP ToC -0.050 ### s/d ### 10 0 12 0 0 kg sims

d.2.3 ### s/d ### 0 0 0 0 0 kg

D.3 REBAR FOR SLAB 0 0 0 0

d.3.1 Install rebar for doom HoS ToC +6.350 ### s/d ### 0 0 0 0 0 kg

d.3.2 Install rebar slab ground floor PoP ToC -0.050 ### s/d ### 0 0 0 0 0 kg

d.3.3 Install rebar for slab roof PoP ToC +10.800 ### s/d ### 0 0 0 0 0 kg

E. Masonry 0 41 0 0

e.1 Install brick for window and corridor area ballroom ### s/d ### 10 0 8 0 0 m2 wala group

e.2 Install brick for window and corridor area ballroom ### s/d ### 11 0 24 0 0 m2 sirius

e.3 Fabrication brique ### s/d ### 9 0 9 0 0 pcs sirius

e.4 Install brick for paraphet roof ballroom ToC +9.600 ### s/d ### 0 0 0 0 0 m2

e.5 Shifting brique ### s/d ### 0 0 0 0 0 m2

e.6 Install brick for window and corridor area ballroom ### s/d ### 0 0 0 0 0 m2

e.7 Install brick for paraphet roof post control type 2 unit 1 ### s/d ### 0 0 0 0 0 m'

F. Plastering 3 6 0 0

f.1 Finishing wall with stuccofiller on HoS ### s/d ### 10 0 6 0 0 m2 sirius

f.2 Install head of plaster on ballroom ### s/d ### 12 3 0 0 0 m2

f.3 Plastering wall of ballroom ### s/d ### 0 0 0 0 0 m2

f.4 Install head of screed roof HoS ToC +6.350 ### s/d ### 0 0 0 0 0 m'

f.5 Plastering wall for post control type 1 unit 1 ### s/d ### 0 0 0 0 0 m'

G. Baja 0 0 0 0

g.1 ### s/d ### 0 0 0 0 0 kg

g.2 ### s/d ### 0 0 0 0 0 kg

g.3 ### s/d ### 0 0 0 0 0 kg

g.4 ### s/d ### 0 0 0 0 0 kg

g.5 ### s/d ### 0 0 0 0 0 kg

H. Anti-Thermite 0 0 0 0

h.1 ### s/d ### 0 0 0 0 0 m2

h.2 ### s/d ### 0 0 0 0 0

h.3 ### s/d ### 0 0 0 0 0

h.4 ### s/d ### 0 0 0 0 0

h.5 ### s/d ### 0 0 0 0 0

I. Waterproofing Sub Structure 0 0 0 0

i.1 ### s/d ### 0 0 0 0 0 m2

i.2 ### s/d ### 0 0 0 0 0

i.3 ### s/d ### 0 0 0 0 0

i.4 ### s/d ### 0 0 0 0 0

i.5 ### s/d ### 0 0 0 0 0

J. Waterproofing Wet Area 0 0 0 0

j.1 ### s/d ### 0 0 0 0 0

j.2 ### s/d ### 0 0 0 0 0

j.3 ### s/d ### 0 0 0 0 0

j.4 ### s/d ### 0 0 0 0 0

j.5 ### s/d ### 0 0 0 0 0

K Lain-Lain 33 23 0 0 ls

k.1 Storing ### s/d ### 12 1 0 0 0 ls

k.2 MEP Crew ### s/d ### 10 2 0 0 0 ls

k.3 SHE Crew ### s/d ### 10 4 4 0 0 ls

k.4 Surveyor Crew ### s/d ### 10 2 0 0 0 ls

k.5 Scaffolder ### s/d ### 10 1 0 0 0 ls

k.6 Canteen Crew and office boy ### s/d ### 10 2 0 0 0 ls

k.7 Driver and Operator ### s/d ### 12 3 5 0 0 ls

k.8 Warehouse assistant ### s/d ### 10 1 0 0 0 ls

k.9 Laboratory quality control assistant ### s/d ### 10 1 0 0 0 ls

k.10 Equipment assistant ### s/d ### 12 0 1 0 0 ls

k.11 Foreman ### s/d ### 10 1 0 0 0 ls

k.12 Leave or sick ### s/d ### 8 2 6 0 0 ls

k.13 Shifting materiel for metal structure ### s/d ### 0 0 0 0 0 ls

k.14 Fabrication door and windows SVB ### s/d ### 0 0 0 0 0 set

k.15 levelling land for LC tie beam corridor PoP ### s/d ### 0 0 0 0 0 m2

k.16 Fabrication of concrete deck ### s/d ### 10 1 0 0 0 ls

k.17 Cleaning and shifting materiel ### s/d ### 10 0 5 0 0 ls

k.18 Fabrication and install window alumunium ### s/d ### 9 0 2 0 0 m2 aigle royal

k.19 Repair and installing doors in SVB and HoS ### s/d ### 10 4 0 0 0 m2 Valasindo

k.20 Removing doors and windows from safe house ### s/d ### 0 0 0 0 0 m3

k.21 Install metal structure for roof of ballroom ### s/d ### 10 8 0 0 0 kg Valasindo

k.22 Finishing and expose column and beam ### s/d ### 0 0 0 0 0 ls

25

L Alat

l.1 Excavator ### s/d ### 10 1 0

l.2 Trailler Truck ### s/d ### 9 0 0

l.3 Compactor ### s/d ### 10 1 0

l.4 Bob Cat ### s/d ### 10 1 0

l.5 Fiori ### s/d ### 10 2 0

l.6 Rough Terrain Crane ### s/d ### 10 1 0

l.7 Concrete Vibrator ### s/d ### 10 3 0

l.8 Bar Bending ### s/d ### 10 1 0

l.9 Bar Cutter ### s/d ### 10 1 0

l.10 Flat Bed Truck ### s/d ### 10 1 0

l.11 Circle Cutter ### s/d ### 10 4 0

l.12 Welding Machine ### s/d ### 10 4 0

l.13 Stamper ### s/d ### 10 1 0

l.14 Compressor ### s/d ### 10 1 0

l.15 Tile Cutter ### s/d ### 10 2 0

l.16 Seaming Roofing Machine ### s/d ### 10 2 0

l.17 Hand Bor ### s/d ### 10 6 0

Indonesia Local

n

Workers Workers ###

Temperature (Celcius) Amount of Working Hours Overtime (hours) Management Staff TOTAL

76 117

ENG 7 HC / GA 7

23 - 38° C 10 0 193 SPV 9 SHE 4

SURVEYOR 4 KOM 6

Notes : Maitre Douvrage Entrepreneur Dibuat Oleh,

Chef de Department Technique Chef de De Department D'ingenierie

NIAMEY NYALA PT. WIJAYA KARYA (Persero) Tbk.

Day : Tuesday

Date : 10-Nov-20

Hari

Daily Report Weeks : 100

Tanggal

RÉHABILITATION DU PALAIS PRÉSIDENTIEL DU RÉPUBLIQUE DU NIGER

Minggu Ke

Work Durations number of workers Volume

NO Job Description Working Hours Unit Material / Information Material

(Hours) Ind WorkersLocal Workers Tools Ind Workers

Local Workers Tools

A. EARTHWORK 0 0 0 0

a.1 Shifting and backfilling on corridor zone 1 ### s/d ### 0 0 0 0 0 m3