Professional Documents

Culture Documents

Graitec Beam Report

Uploaded by

Chanel CuteOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Graitec Beam Report

Uploaded by

Chanel CuteCopyright:

Available Formats

Project

Address

Report

GRAITEC INNOVATION Designed by Date

www.graitec.com Verified by Date

17 Burospace 91572 Bièvres Revision 0 Drawing

Reinforced concrete beam

Table of Contents

1 Geometry description.............................................................................................................. 2

2 Loads and combinations......................................................................................................... 2

3 Global assumptions................................................................................................................. 3

3.1 Localisation...................................................................................................................................3

3.2 Units..............................................................................................................................................4

3.3 Materials........................................................................................................................................4

4 Creep coefficient...................................................................................................................... 5

5 Fire resistance minimum conditions...................................................................................... 6

6 Internal forces......................................................................................................................... 6

6.1 Envelope of ULS combinations....................................................................................................8

6.2 Envelope of SLS combinations.....................................................................................................8

7 Longitudinal reinforcement................................................................................................... 9

7.1 Detailed calculation.....................................................................................................................11

8 Transversal reinforcement................................................................................................... 22

8.1 Transversal reinforcement global assumptions...........................................................................22

8.2 Detailed calculation.....................................................................................................................24

8.3 Minimal constructive dispositions..............................................................................................26

9 Stresses verification............................................................................................................... 27

9.1 Envelope of SLS-CRQ combinations.........................................................................................27

9.2 Envelope of SLS-FRQ combinations..........................................................................................27

9.3 Envelope of SLS-QP combinations............................................................................................28

10 Crack width check................................................................................................................. 33

11 Anchorage calculation.......................................................................................................... 37

12 Support strut verification..................................................................................................... 38

12.1 Support strut stresses verification...............................................................................................38

12.2 Sliding reinforcement verification..............................................................................................40

13 Support reactions.................................................................................................................. 42

14 Deflections.............................................................................................................................. 42

15 Bill of materials..................................................................................................................... 45

RC Beam Designer 2018 Page 1 of 46

Project: Date: 03-23-2023

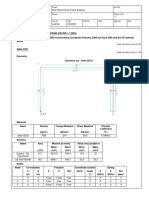

1 Geometry description

Span: 1

Span: 2

Span: 3

Span: 4

Length

Width of the beam web

Total height of the beam

Width of the left support

Width of the right support

2 Loads and combinations

Load cases description

Title

1 Dead loads 1 - - - 1.1 1.35 0.9 1

2 Live loads 1 0.7 0.5 0.3 1.5 1.5 0 0

Uniform linear loads

Load Span Case ID f x L h'

(kN/m) (mm)

1 1 1 5.00 0 29200 -

2 1 2 3.00 0 29200 -

RC Beam Designer 2018 Page 2 of 46

Project: Date: 03-23-2023

Combinations description

ID Combination Code Type

101 1x[1 G] ECELUSTR ULS

102 1.35x[1 G] ECELUSTR ULS

103 1x[1 G]+1.5x[2 Q] ECELUSTR ULS

104 1.35x[1 G]+1.5x[2 Q] ECELUSTR ULS

105 1x[1 G] ECELSCQ SLS

106 1x[1 G]+1x[2 Q] ECELSCQ SLS

107 1x[1 G] ECELSFQ SLS

108 1x[1 G]+0.5x[2 Q] ECELSFQ SLS

109 1x[1 G] ECELSQP SLS

110 1x[1 G]+0.3x[2 Q] ECELSQP SLS

3 Global assumptions

Concrete design calculation: EN1992-1-1 / EN1992-1-2.

Loadings and combinations: EN1990 / EN1991.

Longitudinal reinforcement design: EN1992-1-1 / 6.1 - 'Limit reduced moment' method

Transversal reinforcement design: Standard method (EN1992-1-1, 6.2.2 / 6.2.3).

Concrete: No concrete with silica fume

No high performance concrete

Reinforcement diagram: Bilinear stress-strain diagram

Seismic dispositions: No seismic dispositions.

Fire resistance: R 60

Self weight: Self weight considered without compression flanges.

Calculation section type: T-section design.

3.1 Localisation

Localisation France

Element name Main beam

Element ID

Position Beam no 1 Level no. 1

Drawing -

Level 0.00 m NGF

Coordinates X₁ = 0.00 m; Y₁ = 0.00 m; Z₁ = 0.00 m

X₂ = 29.20 m; Y₂ = 0.00 m; Z₂ = 0.00 m

RC Beam Designer 2018 Page 3 of 46

Project: Date: 03-23-2023

3.2 Units

Lengths mm

Forces kN

Moments kN⋅m

Stresses MPa (N/mm²)

Angles °

Reinforcement areas cm²

Crack Width mm

All the lengths are linked to the "Small lengths" unit from the GUI.

3.3 Materials

Concrete quality Span 1

(EN1992-1-1 / 3.1) Concrete class: C30/37

Span 2

Concrete class: C30/37

Span 3

Concrete class: C30/37

Span 4

Concrete class: C30/37

ULS :

ULSA:

RC Beam Designer 2018 Page 4 of 46

Project: Date: 03-23-2023

Steel grade Span 1

(EN1992-1-1 / Section 3 / Annex C) Logitudinal steel class: B390A

Transversal steel class: B235A

Span 2

Logitudinal steel class: B390A

Transversal steel class: B235A

Span 3

Logitudinal steel class: B390A

Transversal steel class: B235A

Span 4

Logitudinal steel class: B390A

Transversal steel class: B235A

Ductility class: A

Horizontal plastic branch

k = 1.05

ULS:

ULSA:

Concrete covers

Top Bottom Lateral

Cover Cover Cover

(mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm)

30 25 14 30 25 14 30 25 14

Minimal cover value for durability (4.4.1.2 (5))

Execution tolerance (4.4.1.1 2(P))

Security tolerance (4.4.1.2 (6))

Reduction for stainless steel (4.4.1.2 (7))

Reduction for supplementary protection (4.4.1.2 (8))

4 Creep coefficient

The creep coefficient calculation is done according to Annex B of EN1992-1-1.

Relative Humidity

Time at initial loading (in days)

Coefficient to describe the development

of creep with time after loading

RC Beam Designer 2018 Page 5 of 46

Project: Date: 03-23-2023

Span 1 & 2 & 3 & 4

Notional size of the member in mm

(B.6)

Humidity influence (B.3b)

Influence of concrete resistance (B.4)

Age of loading t₀, considering the effect

of the cement type (B.9), in days

Influence of concrete maturity (B.5)

Long term creep coefficient (B.2)

Creep coefficient (B.1)

5 Fire resistance minimum conditions

Fire resistance class R60

Span 1

Minimum width verification Passed

Minimum concrete cover Passed

Span 2

Minimum width verification Passed

Minimum concrete cover Passed

Span 3

Minimum width verification Passed

Minimum concrete cover Passed

Span 4

Minimum width verification Passed

Minimum concrete cover Passed

6 Internal forces

Synthetic values table

Span - Section Abscissa Face

(m) (kN⋅m) (kN⋅m) (kN⋅m) (kN⋅m) (kN) (kN⋅m)

1 - Left support 0.00 Top -11.52 -8.26 -7.03 -6.54 47.47 0.00

Bottom 7.30 5.25 4.52 4.23 0.00 0.00

1 - Right support 7.00 Top -70.17 -50.44 -43.52 -40.75 0.00 0.00

Bottom 0.00 0.00 0.00 0.00 -67.79 0.00

1 - MInf 2.94 Top 0.00 0.00 0.00 0.00 0.11 0.00

Bottom 76.79 55.05 46.84 43.55 -2.72 0.00

1 - VMax 7.00 Top -70.17 -50.44 -43.52 -40.75 0.00 0.00

Bottom 0.00 0.00 0.00 0.00 -67.79 0.00

RC Beam Designer 2018 Page 6 of 46

Project: Date: 03-23-2023

Span - Section Abscissa Face

(m) (kN⋅m) (kN⋅m) (kN⋅m) (kN⋅m) (kN) (kN⋅m)

1 - wk Max 0.70 Top -0.93 -0.67 -0.44 -0.41 36.12 0.00

Bottom 36.56 26.26 22.57 21.10 0.00 0.00

1 - Max Concrete Stress 2.87 Top 0.00 0.00 0.00 0.00 1.04 0.00

Bottom 76.76 55.04 46.85 43.58 -1.90 0.00

1 - Max Steel Stress 2.87 Top 0.00 0.00 0.00 0.00 1.04 0.00

Bottom 76.76 55.04 46.85 43.58 -1.90 0.00

1 - Max Deflection 0.00 Top -11.52 -8.26 -7.03 -6.54 47.47 0.00

Bottom 7.30 5.25 4.52 4.23 0.00 0.00

2 - Left support 0.00 Top -71.10 -51.12 -44.15 -41.36 61.60 0.00

Bottom 0.00 0.00 0.00 0.00 0.00 0.00

2 - Right support 7.00 Top -51.14 -36.47 -30.09 -27.54 0.00 0.00

Bottom 0.00 0.00 0.00 0.00 -56.16 0.00

2 - MInf 3.71 Top 0.00 0.00 0.00 0.00 2.50 0.00

Bottom 51.83 36.85 29.88 27.10 -2.84 0.00

2 - VMax 0.00 Top -71.10 -51.12 -44.15 -41.36 61.60 0.00

Bottom 0.00 0.00 0.00 0.00 0.00 0.00

2 - wk Max 0.00 Top -71.10 -51.12 -44.15 -41.36 61.60 0.00

Bottom 0.00 0.00 0.00 0.00 0.00 0.00

2 - Max Concrete Stress 0.00 Top -71.10 -51.12 -44.15 -41.36 61.60 0.00

Bottom 0.00 0.00 0.00 0.00 0.00 0.00

2 - Max Steel Stress 0.00 Top -71.10 -51.12 -44.15 -41.36 61.60 0.00

Bottom 0.00 0.00 0.00 0.00 0.00 0.00

2 - Max Deflection 0.00 Top -71.10 -51.12 -44.15 -41.36 61.60 0.00

Bottom 0.00 0.00 0.00 0.00 0.00 0.00

3 - Left support 0.00 Top -51.14 -36.47 -30.09 -27.54 56.16 0.00

Bottom 0.00 0.00 0.00 0.00 0.00 0.00

3 - Right support 7.00 Top -71.10 -51.12 -44.15 -41.36 0.00 0.00

Bottom 0.00 0.00 0.00 0.00 -61.60 0.00

3 - MInf 3.29 Top 0.00 0.00 0.00 0.00 2.84 0.00

Bottom 51.83 36.85 29.88 27.10 -2.50 0.00

3 - VMax 7.00 Top -71.10 -51.12 -44.15 -41.36 0.00 0.00

Bottom 0.00 0.00 0.00 0.00 -61.60 0.00

3 - wk Max 7.00 Top -71.10 -51.12 -44.15 -41.36 0.00 0.00

Bottom 0.00 0.00 0.00 0.00 -61.60 0.00

3 - Max Concrete Stress 7.00 Top -71.10 -51.12 -44.15 -41.36 0.00 0.00

Bottom 0.00 0.00 0.00 0.00 -61.60 0.00

3 - Max Steel Stress 7.00 Top -71.10 -51.12 -44.15 -41.36 0.00 0.00

Bottom 0.00 0.00 0.00 0.00 -61.60 0.00

3 - Max Deflection 0.00 Top -51.14 -36.47 -30.09 -27.54 56.16 0.00

Bottom 0.00 0.00 0.00 0.00 0.00 0.00

4 - Left support 0.00 Top -70.17 -50.44 -43.52 -40.75 67.79 0.00

Bottom 0.00 0.00 0.00 0.00 0.00 0.00

4 - Right support 7.00 Top -11.52 -8.26 -7.03 -6.54 0.00 0.00

Bottom 7.30 5.25 4.52 4.23 -47.47 0.00

4 - MInf 4.06 Top 0.00 0.00 0.00 0.00 2.72 0.00

Bottom 76.79 55.05 46.84 43.55 -0.11 0.00

RC Beam Designer 2018 Page 7 of 46

Project: Date: 03-23-2023

Span - Section Abscissa Face

(m) (kN⋅m) (kN⋅m) (kN⋅m) (kN⋅m) (kN) (kN⋅m)

4 - VMax 0.00 Top -70.17 -50.44 -43.52 -40.75 67.79 0.00

Bottom 0.00 0.00 0.00 0.00 0.00 0.00

4 - wk Max 6.30 Top -0.93 -0.67 -0.44 -0.41 0.00 0.00

Bottom 36.56 26.26 22.57 21.10 -36.12 0.00

4 - Max Concrete Stress 4.13 Top 0.00 0.00 0.00 0.00 1.90 0.00

Bottom 76.76 55.04 46.85 43.58 -1.04 0.00

4 - Max Steel Stress 4.13 Top 0.00 0.00 0.00 0.00 1.90 0.00

Bottom 76.76 55.04 46.85 43.58 -1.04 0.00

4 - Max Deflection 0.00 Top -70.17 -50.44 -43.52 -40.75 67.79 0.00

Bottom 0.00 0.00 0.00 0.00 0.00 0.00

6.1 Envelope of ULS combinations

6.2 Envelope of SLS combinations

RC Beam Designer 2018 Page 8 of 46

Project: Date: 03-23-2023

7 Longitudinal reinforcement

Reinforcement is calculated considering a design bending moment which is different than the bending

moment from actions, according to article 9.2.1.3, figure 9.2, from EN1992-1-1.

Longitudinal reinforcement

Position Bending moments Reinforcement

Span - Section Abscissa Comb Face WR Theo Real Min

(mm) (kN⋅m) (kN⋅m) (cm²) (cm²) (cm²)

1 - Left support 0 104 Top 11.52 46.41 24.82 % 2.55 3.07 2.55

RC Beam Designer 2018 Page 9 of 46

Project: Date: 03-23-2023

Longitudinal reinforcement

Position Bending moments Reinforcement

Span - Section Abscissa Comb Face WR Theo Real Min

(mm) (kN⋅m) (kN⋅m) (cm²) (cm²) (cm²)

1 - Right support 7000 104 Top 70.17 90.10 77.88 % 4.85 6.16 2.55

1 - MInf 2940 104 Bottom -76.79 91.68 83.76 % 5.33 6.28 2.55

1 - wk Max 700 104 Bottom -43.79 43.47 100.74 % 2.99 3.14 2.55

1 - Max Deflection 0 104 Top 11.52 46.41 24.82 % 2.55 3.07 2.55

2 - Left support 0 104 Top 71.10 90.26 78.77 % 4.92 6.16 2.55

2 - Right support 7000 104 Top 51.14 66.79 76.57 % 3.51 4.52 2.55

2 - MInf 3710 104 Bottom -51.83 59.82 86.64 % 3.55 4.02 2.55

2 - VMax 0 104 Top 71.10 90.26 78.77 % 4.92 6.16 2.55

2 - wk Max 0 104 Top 71.10 90.26 78.77 % 4.92 6.16 2.55

2 - Max Concrete Stress 0 104 Top 71.10 90.26 78.77 % 4.92 6.16 2.55

2 - Max Steel Stress 0 104 Top 71.10 90.26 78.77 % 4.92 6.16 2.55

2 - Max Deflection 0 104 Top 71.10 90.26 78.77 % 4.92 6.16 2.55

3 - Left support 0 104 Top 51.14 66.79 76.57 % 3.51 4.52 2.55

3 - Right support 7000 104 Top 71.10 90.26 78.77 % 4.92 6.16 2.55

3 - MInf 3290 104 Bottom -51.83 59.82 86.64 % 3.55 4.02 2.55

3 - wk Max 7000 104 Top 71.10 90.26 78.77 % 4.92 6.16 2.55

3 - Max Concrete Stress 7000 104 Top 71.10 90.26 78.77 % 4.92 6.16 2.55

3 - Max Steel Stress 7000 104 Top 71.10 90.26 78.77 % 4.92 6.16 2.55

3 - Max Deflection 0 104 Top 51.14 66.79 76.57 % 3.51 4.52 2.55

4 - Left support 0 104 Top 70.17 90.10 77.88 % 4.85 6.16 2.55

4 - Right support 7000 104 Top 11.52 46.41 24.82 % 2.55 3.07 2.55

4 - MInf 4060 104 Bottom -76.79 91.68 83.76 % 5.33 6.28 2.55

4 - VMax 0 104 Top 70.17 90.10 77.88 % 4.85 6.16 2.55

4 - wk Max 6300 104 Bottom -43.79 43.47 100.74 % 2.99 3.14 2.55

4 - Max Deflection 0 104 Top 70.17 90.10 77.88 % 4.85 6.16 2.55

Real longitudinal reinforcement

Span Position Family Reinforcement

Bottom 1 4 × ø10 + 4 × ø10 (6.28 cm²)

1

Top 1 4 × ø8 (2.01 cm²)

Bottom 1 4 × ø8 + 4 × ø8 (4.02 cm²)

2

Top 1 4 × ø8 (2.01 cm²)

Bottom 1 4 × ø8 + 4 × ø8 (4.02 cm²)

3

Top 1 4 × ø8 (2.01 cm²)

Bottom 1 4 × ø10 + 4 × ø10 (6.28 cm²)

4

Top 1 4 × ø8 (2.01 cm²)

Real longitudinal reinforcement over supports

Support Family Reinforcement

1 1 4 × ø10 (3.14 cm²)

2 1 4 × ø14 (6.16 cm²)

3 1 4 × ø12 (4.52 cm²)

4 1 4 × ø14 (6.16 cm²)

5 1 4 × ø10 (3.14 cm²)

RC Beam Designer 2018 Page 10 of 46

Project: Date: 03-23-2023

The value of the effective height (d) is defined automatically according to the real reinforcement in place.

7.1 Detailed calculation

Span T 1.1, Section MInf, Abscissa 2940 mm, (Bottom bars)

Combination ULS 104 : 1.35x[1 G]+1.5x[2 Q]

Design bending moment

Reduced moment value

Reduced moment limit

Compressed reinforcement is not

required

Neutral axis

Inner lever arm

Steel stress in tension

Tension reinforcement area

The minimal and maximal percentages of longitudinal reinforcement in the beam are defined by the article

9.2.1.1 from EN1992-1-1 :

Minimal percentage (9.1N)

Bending moment resistance

Bending moment verification

Work Ratio 83.76 % (Passed)

RC Beam Designer 2018 Page 11 of 46

Project: Date: 03-23-2023

Span T 1.1, Section Right support, Abscissa 7000 mm, (Top bars)

Combination ULS 104 : 1.35x[1 G]+1.5x[2 Q]

Design bending moment

Reduced moment value

Reduced moment limit

Compressed reinforcement is not

required

Neutral axis

Inner lever arm

Steel stress in tension

Tension reinforcement area

The minimal and maximal percentages of longitudinal reinforcement in the beam are defined by the article

9.2.1.1 from EN1992-1-1 :

Minimal percentage (9.1N)

Bending moment resistance

Bending moment verification

Work Ratio 77.88 % (Passed)

RC Beam Designer 2018 Page 12 of 46

Project: Date: 03-23-2023

Span T 1.1, Section Left support, Abscissa 0 mm, (Top bars)

Combination ULS 104 : 1.35x[1 G]+1.5x[2 Q]

Design bending moment

Reduced moment value

Reduced moment limit

Compressed reinforcement is not

required

Neutral axis

Inner lever arm

Steel stress in tension

Tension reinforcement area

The minimal and maximal percentages of longitudinal reinforcement in the beam are defined by the article

9.2.1.1 from EN1992-1-1 :

Minimal percentage (9.1N)

Bending moment resistance

Bending moment verification

Work Ratio 24.82 % (Passed)

RC Beam Designer 2018 Page 13 of 46

Project: Date: 03-23-2023

Span T 1.2, Section MInf, Abscissa 3710 mm, (Bottom bars)

Combination ULS 104 : 1.35x[1 G]+1.5x[2 Q]

Design bending moment

Reduced moment value

Reduced moment limit

Compressed reinforcement is not

required

Neutral axis

Inner lever arm

Steel stress in tension

Tension reinforcement area

The minimal and maximal percentages of longitudinal reinforcement in the beam are defined by the article

9.2.1.1 from EN1992-1-1 :

Minimal percentage (9.1N)

Bending moment resistance

Bending moment verification

Work Ratio 86.64 % (Passed)

RC Beam Designer 2018 Page 14 of 46

Project: Date: 03-23-2023

Span T 1.2, Section Right support, Abscissa 7000 mm, (Top bars)

Combination ULS 104 : 1.35x[1 G]+1.5x[2 Q]

Design bending moment

Reduced moment value

Reduced moment limit

Compressed reinforcement is not

required

Neutral axis

Inner lever arm

Steel stress in tension

Tension reinforcement area

The minimal and maximal percentages of longitudinal reinforcement in the beam are defined by the article

9.2.1.1 from EN1992-1-1 :

Minimal percentage (9.1N)

Bending moment resistance

Bending moment verification

Work Ratio 76.57 % (Passed)

RC Beam Designer 2018 Page 15 of 46

Project: Date: 03-23-2023

Span T 1.2, Section Left support, Abscissa 0 mm, (Top bars)

Combination ULS 104 : 1.35x[1 G]+1.5x[2 Q]

Design bending moment

Reduced moment value

Reduced moment limit

Compressed reinforcement is not

required

Neutral axis

Inner lever arm

Steel stress in tension

Tension reinforcement area

The minimal and maximal percentages of longitudinal reinforcement in the beam are defined by the article

9.2.1.1 from EN1992-1-1 :

Minimal percentage (9.1N)

Bending moment resistance

Bending moment verification

Work Ratio 78.77 % (Passed)

RC Beam Designer 2018 Page 16 of 46

Project: Date: 03-23-2023

Span T 1.3, Section MInf, Abscissa 3290 mm, (Bottom bars)

Combination ULS 104 : 1.35x[1 G]+1.5x[2 Q]

Design bending moment

Reduced moment value

Reduced moment limit

Compressed reinforcement is not

required

Neutral axis

Inner lever arm

Steel stress in tension

Tension reinforcement area

The minimal and maximal percentages of longitudinal reinforcement in the beam are defined by the article

9.2.1.1 from EN1992-1-1 :

Minimal percentage (9.1N)

Bending moment resistance

Bending moment verification

Work Ratio 86.64 % (Passed)

RC Beam Designer 2018 Page 17 of 46

Project: Date: 03-23-2023

Span T 1.3, Section Right support, Abscissa 7000 mm, (Top bars)

Combination ULS 104 : 1.35x[1 G]+1.5x[2 Q]

Design bending moment

Reduced moment value

Reduced moment limit

Compressed reinforcement is not

required

Neutral axis

Inner lever arm

Steel stress in tension

Tension reinforcement area

The minimal and maximal percentages of longitudinal reinforcement in the beam are defined by the article

9.2.1.1 from EN1992-1-1 :

Minimal percentage (9.1N)

Bending moment resistance

Bending moment verification

Work Ratio 78.77 % (Passed)

RC Beam Designer 2018 Page 18 of 46

Project: Date: 03-23-2023

Span T 1.3, Section Left support, Abscissa 0 mm, (Top bars)

Combination ULS 104 : 1.35x[1 G]+1.5x[2 Q]

Design bending moment

Reduced moment value

Reduced moment limit

Compressed reinforcement is not

required

Neutral axis

Inner lever arm

Steel stress in tension

Tension reinforcement area

The minimal and maximal percentages of longitudinal reinforcement in the beam are defined by the article

9.2.1.1 from EN1992-1-1 :

Minimal percentage (9.1N)

Bending moment resistance

Bending moment verification

Work Ratio 76.57 % (Passed)

RC Beam Designer 2018 Page 19 of 46

Project: Date: 03-23-2023

Span T 1.4, Section MInf, Abscissa 4060 mm, (Bottom bars)

Combination ULS 104 : 1.35x[1 G]+1.5x[2 Q]

Design bending moment

Reduced moment value

Reduced moment limit

Compressed reinforcement is not

required

Neutral axis

Inner lever arm

Steel stress in tension

Tension reinforcement area

The minimal and maximal percentages of longitudinal reinforcement in the beam are defined by the article

9.2.1.1 from EN1992-1-1 :

Minimal percentage (9.1N)

Bending moment resistance

Bending moment verification

Work Ratio 83.76 % (Passed)

RC Beam Designer 2018 Page 20 of 46

Project: Date: 03-23-2023

Span T 1.4, Section Right support, Abscissa 7000 mm, (Top bars)

Combination ULS 104 : 1.35x[1 G]+1.5x[2 Q]

Design bending moment

Reduced moment value

Reduced moment limit

Compressed reinforcement is not

required

Neutral axis

Inner lever arm

Steel stress in tension

Tension reinforcement area

The minimal and maximal percentages of longitudinal reinforcement in the beam are defined by the article

9.2.1.1 from EN1992-1-1 :

Minimal percentage (9.1N)

Bending moment resistance

Bending moment verification

Work Ratio 24.82 % (Passed)

RC Beam Designer 2018 Page 21 of 46

Project: Date: 03-23-2023

Span T 1.4, Section Left support, Abscissa 0 mm, (Top bars)

Combination ULS 104 : 1.35x[1 G]+1.5x[2 Q]

Design bending moment

Reduced moment value

Reduced moment limit

Compressed reinforcement is not

required

Neutral axis

Inner lever arm

Steel stress in tension

Tension reinforcement area

The minimal and maximal percentages of longitudinal reinforcement in the beam are defined by the article

9.2.1.1 from EN1992-1-1 :

Minimal percentage (9.1N)

Bending moment resistance

Bending moment verification

Work Ratio 77.88 % (Passed)

8 Transversal reinforcement

8.1 Transversal reinforcement global assumptions

The transversal reinforcement calculation is done according to article 6.2 of EN1992-1-1.

No direct transmission for shear force.

Calculation is done according to elementary length z(cot Ɵ) according to 6.2.3(5) from EN 1992-1-1.

RC Beam Designer 2018 Page 22 of 46

Project: Date: 03-23-2023

Transversal reinforcement

Span - Section Abscissa WR

(mm) (kN) (cm²/m) (kN)

1 - Left support 0 40.66 55.34 627.26 5.59 5.59 6.70 55.96 72.66 %

1 - Right support 7000 60.98 55.34 627.26 7.54 5.59 8.38 69.56 87.65 %

1 - MInf 2940 2.72 60.81 627.26 5.59 5.59 6.70 55.22 4.93 %

1 - VMax 7000 60.98 55.34 627.26 7.54 5.59 8.38 69.56 87.65 %

1 - wk Max 700 33.85 55.34 627.26 5.59 5.59 6.70 55.96 60.49 %

1 - Max Concrete Stress 2870 2.72 60.81 627.26 5.59 5.59 6.70 55.22 4.93 %

1 - Max Steel Stress 2870 2.72 60.81 627.26 5.59 5.59 6.70 55.22 4.93 %

1 - Max Deflection 0 40.66 55.34 627.26 5.59 5.59 6.70 55.96 72.66 %

2 - Left support 0 54.79 55.34 627.26 5.59 5.59 6.70 55.65 98.45 %

2 - Right support 7000 49.34 55.34 627.26 5.59 5.59 6.70 55.78 88.47 %

2 - MInf 3710 1.67 55.34 627.26 5.59 5.59 8.62 71.31 2.34 %

2 - VMax 0 54.79 55.34 627.26 5.59 5.59 6.70 55.65 98.45 %

2 - wk Max 0 54.79 55.34 627.26 5.59 5.59 6.70 55.65 98.45 %

2 - Max Concrete Stress 0 54.79 55.34 627.26 5.59 5.59 6.70 55.65 98.45 %

2 - Max Steel Stress 0 54.79 55.34 627.26 5.59 5.59 6.70 55.65 98.45 %

2 - Max Deflection 0 54.79 55.34 627.26 5.59 5.59 6.70 55.65 98.45 %

3 - Left support 0 49.34 55.34 627.26 5.59 5.59 6.70 55.78 88.47 %

3 - Right support 7000 54.79 55.34 627.26 5.59 5.59 6.70 55.65 98.45 %

3 - MInf 3290 3.32 55.34 627.26 5.59 5.59 8.62 71.31 4.66 %

3 - VMax 7000 54.79 55.34 627.26 5.59 5.59 6.70 55.65 98.45 %

3 - wk Max 7000 54.79 55.34 627.26 5.59 5.59 6.70 55.65 98.45 %

3 - Max Concrete Stress 7000 54.79 55.34 627.26 5.59 5.59 6.70 55.65 98.45 %

3 - Max Steel Stress 7000 54.79 55.34 627.26 5.59 5.59 6.70 55.65 98.45 %

3 - Max Deflection 0 49.34 55.34 627.26 5.59 5.59 6.70 55.78 88.47 %

4 - Left support 0 60.98 55.34 627.26 7.54 5.59 8.38 69.56 87.65 %

4 - Right support 7000 40.66 55.34 627.26 5.59 5.59 6.70 55.96 72.66 %

4 - MInf 4060 2.72 60.81 627.26 5.59 5.59 6.70 55.22 4.93 %

4 - VMax 0 60.98 55.34 627.26 7.54 5.59 8.38 69.56 87.65 %

4 - wk Max 6300 33.85 55.34 627.26 5.59 5.59 6.70 55.96 60.49 %

4 - Max Concrete Stress 4130 2.72 60.81 627.26 5.59 5.59 6.70 55.22 4.93 %

4 - Max Steel Stress 4130 2.72 60.81 627.26 5.59 5.59 6.70 55.22 4.93 %

4 - Max Deflection 0 60.98 55.34 627.26 7.54 5.59 8.38 69.56 87.65 %

Real transversal reinforcement

Span Pack Reinforcement

1 11 × ø8 / 300 mm

2 1 × ø8 / 240 mm

1

3 9 × ø8 / 300 mm

4 2 × ø8 / 240 mm

1 10 × ø8 / 300 mm

2 2 3 × ø8 / 233 mm

3 10 × ø8 / 300 mm

1 10 × ø8 / 300 mm

3

2 3 × ø8 / 233 mm

RC Beam Designer 2018 Page 23 of 46

Project: Date: 03-23-2023

3 3 10 × ø8 / 300 mm

1 2 × ø8 / 240 mm

2 9 × ø8 / 300 mm

4

3 1 × ø8 / 240 mm

4 11 × ø8 / 300 mm

8.2 Detailed calculation

The shear verification and dimensioning of the shear reinforcement is done according to article 6.2 of

EN1992-1-1

Span T 1.1, Section VMax, Abscissa 7000 mm

Combination 104 : 1.35x[1 G]+1.5x[2 Q]

Span T 1.4, Section VMax, Abscissa 0 mm

RC Beam Designer 2018 Page 24 of 46

Project: Date: 03-23-2023

Combination 104 : 1.35x[1 G]+1.5x[2 Q]

Reduced design shear force

Strut angle

Inner lever arm

(6.2.2 (1))

Factor taking account the effective

height

Longitudinal reinforcement ratio, (6.2.2

(1))

Minimal resistant shear force (6.3N)

Design value for the shear resistance

(6.2.a) & (6.2.b)

Coefficient taking account of the state

of the stress in the compression chord

Strength reduction factor for concrete

cracked in shear (6.6N)

Design value of the maximum shear

force (6.9)

Concrete cross section satisfies the

crushing condition

Theoretical shear reinforcement area

(6.8)

Real shear reinforcement area

Design value for the shear resistance

with real value of shear reinforcement,

expression (6.8)

Shear force verification

Work Ratio 87.65 % (Passed)

Span T 1.2, Section VMax, Abscissa 0 mm

Combination 104 : 1.35x[1 G]+1.5x[2 Q]

Span T 1.3, Section VMax, Abscissa 7000 mm

RC Beam Designer 2018 Page 25 of 46

Project: Date: 03-23-2023

Combination 104 : 1.35x[1 G]+1.5x[2 Q]

Reduced design shear force

Strut angle

Inner lever arm

(6.2.2 (1))

Factor taking account the effective

height

Longitudinal reinforcement ratio, (6.2.2

(1))

Minimal resistant shear force (6.3N)

Design value for the shear resistance

(6.2.a) & (6.2.b)

Coefficient taking account of the state

of the stress in the compression chord

Strength reduction factor for concrete

cracked in shear (6.6N)

Design value of the maximum shear

force (6.9)

Theoretical shear reinforcement area

(6.8)

Real shear reinforcement area

Design value for the shear resistance

with real value of shear reinforcement,

expression (6.8)

Shear force verification

Work Ratio 98.45 % (Passed)

8.3 Minimal constructive dispositions

The minimal transversal reinforcement is defined according to 9.2.2 from NF EN1992-1-1 .

RC Beam Designer 2018 Page 26 of 46

Project: Date: 03-23-2023

Minimal percentage

Minimal transversal reinforcement area

The maximum spacing is calculated according to 9.2.2 from EN 1992-1-1 and 5.13 from EN 1998-1-1 .

Maximum spacing at the ends of the

beam

Maximum spacing throughout the

length of the beam

9 Stresses verification

9.1 Envelope of SLS-CRQ combinations

Concrete compressive stress

Reinforcement tension stress

9.2 Envelope of SLS-FRQ combinations

Concrete compressive stress

RC Beam Designer 2018 Page 27 of 46

Project: Date: 03-23-2023

Reinforcement tension stress

9.3 Envelope of SLS-QP combinations

Concrete compressive stress

Reinforcement tension stress

RC Beam Designer 2018 Page 28 of 46

Project: Date: 03-23-2023

Synthetic values table

Stresses verification

Span - Section Abscissa Envelope Stresses (MPa)

Type

(mm) WR WR

CRQ 2.91 17.71 1.07 3.56 % 64.32 20.61 %

1 - Left Support 0 FRQ 2.91 19.67 0.86 2.88 % 54.91 17.60 %

QP 3.39 20.64 0.78 2.61 % 51.14 16.39 %

CRQ 2.93 17.85 5.40 18.00 % 203.16 65.11 %

1 - Right Support 7000 FRQ 2.93 19.72 4.48 14.94 % 176.05 56.43 %

QP 3.39 20.64 4.12 13.75 % 165.19 52.94 %

CRQ 2.89 17.60 6.20 20.66 % 219.89 70.48 %

1 - MInf 2940 FRQ 2.89 19.62 5.08 16.93 % 188.11 60.29 %

QP 3.39 20.64 4.64 15.47 % 175.37 56.21 %

CRQ 2.93 17.85 5.40 18.00 % 203.16 65.11 %

1 - VMax 7000 FRQ 2.93 19.72 4.48 14.94 % 176.05 56.43 %

QP 3.39 20.64 4.12 13.75 % 165.19 52.94 %

CRQ 2.70 16.43 3.36 11.18 % 200.28 64.19 %

1 - wk Max 700 FRQ 2.70 19.67 2.74 9.14 % 172.67 55.34 %

QP 3.39 20.64 2.50 8.35 % 161.60 51.80 %

CRQ 2.89 17.61 6.20 20.65 % 219.85 70.46 %

1 - Max Conc Stress 2870 FRQ 2.89 19.63 5.08 16.93 % 188.17 60.31 %

QP 3.39 20.64 4.64 15.48 % 175.48 56.24 %

CRQ 2.89 17.61 6.20 20.65 % 219.85 70.46 %

1 - Max Steel Stress 2870 FRQ 2.89 19.63 5.08 16.93 % 188.17 60.31 %

QP 3.39 20.64 4.64 15.48 % 175.48 56.24 %

CRQ 2.91 17.71 1.07 3.56 % 64.32 20.61 %

1 - Max Deflection 0 FRQ 2.91 19.67 0.86 2.88 % 54.91 17.60 %

QP 3.39 20.64 0.78 2.61 % 51.14 16.39 %

CRQ 2.93 17.87 5.51 18.37 % 205.99 66.02 %

2 - Left Support 0 FRQ 2.93 19.72 4.58 15.28 % 178.69 57.27 %

QP 3.39 20.64 4.22 14.07 % 167.75 53.77 %

CRQ 2.80 17.08 4.46 14.86 % 196.49 62.98 %

2 - Right Support 7000 FRQ 2.80 19.41 3.49 11.65 % 162.97 52.23 %

RC Beam Designer 2018 Page 29 of 46

Project: Date: 03-23-2023

Stresses verification

Span - Section Abscissa Envelope Stresses (MPa)

Type

(mm) WR WR

QP 3.39 20.64 3.12 10.40 % 149.53 47.93 %

CRQ 2.76 16.80 4.93 16.44 % 223.77 71.72 %

2 - MInf 3710 FRQ 2.76 19.29 3.80 12.66 % 182.58 58.52 %

QP 3.39 20.64 3.36 11.20 % 166.07 53.23 %

CRQ 2.93 17.87 5.51 18.37 % 205.99 66.02 %

2 - VMax 0 FRQ 2.93 19.72 4.58 15.28 % 178.69 57.27 %

QP 3.39 20.64 4.22 14.07 % 167.75 53.77 %

CRQ 2.93 17.87 5.51 18.37 % 205.99 66.02 %

2 - wk Max 0 FRQ 2.93 19.72 4.58 15.28 % 178.69 57.27 %

QP 3.39 20.64 4.22 14.07 % 167.75 53.77 %

CRQ 2.93 17.87 5.51 18.37 % 205.99 66.02 %

2 - Max Conc Stress 0 FRQ 2.93 19.72 4.58 15.28 % 178.69 57.27 %

QP 3.39 20.64 4.22 14.07 % 167.75 53.77 %

CRQ 2.93 17.87 5.51 18.37 % 205.99 66.02 %

2 - Max Steel Stress 0 FRQ 2.93 19.72 4.58 15.28 % 178.69 57.27 %

QP 3.39 20.64 4.22 14.07 % 167.75 53.77 %

CRQ 2.93 17.87 5.51 18.37 % 205.99 66.02 %

2 - Max Deflection 0 FRQ 2.93 19.72 4.58 15.28 % 178.69 57.27 %

QP 3.39 20.64 4.22 14.07 % 167.75 53.77 %

CRQ 2.80 17.08 4.46 14.86 % 196.49 62.98 %

3 - Left Support 0 FRQ 2.80 19.41 3.49 11.65 % 162.97 52.23 %

QP 3.39 20.64 3.12 10.40 % 149.53 47.93 %

CRQ 2.93 17.87 5.51 18.37 % 205.99 66.02 %

3 - Right Support 7000 FRQ 2.93 19.72 4.58 15.28 % 178.69 57.27 %

QP 3.39 20.64 4.22 14.07 % 167.75 53.77 %

CRQ 2.76 16.80 4.93 16.44 % 223.77 71.72 %

3 - MInf 3290 FRQ 2.76 19.29 3.80 12.66 % 182.58 58.52 %

QP 3.39 20.64 3.36 11.20 % 166.07 53.23 %

CRQ 2.93 17.87 5.51 18.37 % 205.99 66.02 %

3 - VMax 7000 FRQ 2.93 19.72 4.58 15.28 % 178.69 57.27 %

QP 3.39 20.64 4.22 14.07 % 167.75 53.77 %

CRQ 2.93 17.87 5.51 18.37 % 205.99 66.02 %

3 - wk Max 7000 FRQ 2.93 19.72 4.58 15.28 % 178.69 57.27 %

QP 3.39 20.64 4.22 14.07 % 167.75 53.77 %

CRQ 2.93 17.87 5.51 18.37 % 205.99 66.02 %

3 - Max Conc Stress 7000 FRQ 2.93 19.72 4.58 15.28 % 178.69 57.27 %

QP 3.39 20.64 4.22 14.07 % 167.75 53.77 %

CRQ 2.93 17.87 5.51 18.37 % 205.99 66.02 %

3 - Max Steel Stress 7000 FRQ 2.93 19.72 4.58 15.28 % 178.69 57.27 %

QP 3.39 20.64 4.22 14.07 % 167.75 53.77 %

CRQ 2.80 17.08 4.46 14.86 % 196.49 62.98 %

3 - Max Deflection 0 FRQ 2.80 19.41 3.49 11.65 % 162.97 52.23 %

QP 3.39 20.64 3.12 10.40 % 149.53 47.93 %

CRQ 2.93 17.85 5.40 18.00 % 203.16 65.11 %

RC Beam Designer 2018 Page 30 of 46

Project: Date: 03-23-2023

Stresses verification

Span - Section Abscissa Envelope Stresses (MPa)

Type

(mm) WR WR

4 - Left Support 0 FRQ 2.93 19.72 4.48 14.94 % 176.05 56.43 %

QP 3.39 20.64 4.12 13.75 % 165.19 52.94 %

CRQ 2.91 17.71 1.07 3.56 % 64.32 20.61 %

4 - Right Support 7000 FRQ 2.91 19.67 0.86 2.88 % 54.91 17.60 %

QP 3.39 20.64 0.78 2.61 % 51.14 16.39 %

CRQ 2.89 17.60 6.20 20.66 % 219.89 70.48 %

4 - MInf 4060 FRQ 2.89 19.62 5.08 16.93 % 188.11 60.29 %

QP 3.39 20.64 4.64 15.47 % 175.37 56.21 %

CRQ 2.93 17.85 5.40 18.00 % 203.16 65.11 %

4 - VMax 0 FRQ 2.93 19.72 4.48 14.94 % 176.05 56.43 %

QP 3.39 20.64 4.12 13.75 % 165.19 52.94 %

CRQ 2.70 16.43 3.36 11.18 % 200.28 64.19 %

4 - wk Max 6300 FRQ 2.70 19.67 2.74 9.14 % 172.67 55.34 %

QP 3.39 20.64 2.50 8.35 % 161.60 51.80 %

CRQ 2.89 17.61 6.20 20.65 % 219.85 70.46 %

4 - Max Conc Stress 4130 FRQ 2.89 19.63 5.08 16.93 % 188.17 60.31 %

QP 3.39 20.64 4.64 15.48 % 175.48 56.24 %

CRQ 2.89 17.61 6.20 20.65 % 219.85 70.46 %

4 - Max Steel Stress 4130 FRQ 2.89 19.63 5.08 16.93 % 188.17 60.31 %

QP 3.39 20.64 4.64 15.48 % 175.48 56.24 %

CRQ 2.93 17.85 5.40 18.00 % 203.16 65.11 %

4 - Max Deflection 0 FRQ 2.93 19.72 4.48 14.94 % 176.05 56.43 %

QP 3.39 20.64 4.12 13.75 % 165.19 52.94 %

Span T 1.1, Section Max Steel Stress, Abscissa 2870 mm

Combination Envelope of SLS QP combinations

Span T 1.4, Section Max Steel Stress, Abscissa 4130 mm

RC Beam Designer 2018 Page 31 of 46

Project: Date: 03-23-2023

Combination Envelope of SLS QP combinations

SLS bending moment

Tensioned reinforcement area

Compressed reinforcement area

Equivalence coefficient for long term

loads

Height of compressed concrete

The moment of inertia

Reinforcement tension stress

Concrete compression stress

Concrete tension stress

Span T 1.2, Section Max Steel Stress, Abscissa 0 mm

Combination Envelope of SLS QP combinations

Span T 1.3, Section Max Steel Stress, Abscissa 7000 mm

Combination Envelope of SLS QP combinations

SLS bending moment

Tensioned reinforcement area

Compressed reinforcement area

Equivalence coefficient for long term

loads

Height of compressed concrete

The moment of inertia

Reinforcement tension stress

Reinforcement compression stress

Concrete compression stress

Concrete tension stress

RC Beam Designer 2018 Page 32 of 46

Project: Date: 03-23-2023

10 Crack width check

Crack width verification

Span - Section Abscissa Section WR

(mm) Position (mm) (mm) (mm) (‰) (mm) (mm)

1 - Left support 0 Top 0.044 0.028 289 0.15 0.044 0.400 11.07 %

1 - Right support 7000 Top 0.115 0.000 232 0.50 0.115 0.400 28.70 %

1 - MInf 2940 Bottom 0.000 0.100 190 0.53 0.100 0.400 25.03 %

1 - VMax 7000 Bottom 0.115 0.000 0 0.00 0.115 0.400 28.70 %

1 - wk Max 700 Bottom 0.003 0.138 284 0.48 0.138 0.400 34.47 %

1 - Max Concrete Stress 2870 Bottom 0.000 0.100 190 0.53 0.100 0.400 25.06 %

1 - Max Steel Stress 2870 Bottom 0.000 0.100 190 0.53 0.100 0.400 25.06 %

1 - Max Deflection 0 Top 0.044 0.028 289 0.15 0.044 0.400 11.07 %

2 - Left support 0 Top 0.116 0.000 231 0.50 0.116 0.400 29.11 %

2 - Right support 7000 Top 0.116 0.000 258 0.45 0.116 0.400 28.98 %

2 - MInf 3710 Bottom 0.000 0.111 222 0.50 0.111 0.400 27.65 %

2 - VMax 0 Top 0.116 0.000 231 0.50 0.116 0.400 29.11 %

2 - wk Max 0 Top 0.116 0.000 231 0.50 0.116 0.400 29.11 %

2 - Max Concrete Stress 0 Top 0.116 0.000 231 0.50 0.116 0.400 29.11 %

2 - Max Steel Stress 0 Top 0.116 0.000 231 0.50 0.116 0.400 29.11 %

2 - Max Deflection 0 Top 0.116 0.000 231 0.50 0.116 0.400 29.11 %

3 - Left support 0 Top 0.116 0.000 258 0.45 0.116 0.400 28.98 %

3 - Right support 7000 Top 0.116 0.000 231 0.50 0.116 0.400 29.11 %

3 - MInf 3290 Bottom 0.000 0.111 222 0.50 0.111 0.400 27.65 %

3 - VMax 7000 Bottom 0.116 0.000 0 0.00 0.116 0.400 29.11 %

3 - wk Max 7000 Top 0.116 0.000 231 0.50 0.116 0.400 29.11 %

3 - Max Concrete Stress 7000 Top 0.116 0.000 231 0.50 0.116 0.400 29.11 %

3 - Max Steel Stress 7000 Top 0.116 0.000 231 0.50 0.116 0.400 29.11 %

3 - Max Deflection 0 Top 0.116 0.000 258 0.45 0.116 0.400 28.98 %

4 - Left support 0 Top 0.115 0.000 232 0.50 0.115 0.400 28.70 %

4 - Right support 7000 Top 0.044 0.028 289 0.15 0.044 0.400 11.07 %

4 - MInf 4060 Bottom 0.000 0.100 190 0.53 0.100 0.400 25.03 %

4 - VMax 0 Top 0.115 0.000 232 0.50 0.115 0.400 28.70 %

4 - wk Max 6300 Bottom 0.003 0.138 284 0.48 0.138 0.400 34.47 %

4 - Max Concrete Stress 4130 Bottom 0.000 0.100 190 0.53 0.100 0.400 25.06 %

4 - Max Steel Stress 4130 Bottom 0.000 0.100 190 0.53 0.100 0.400 25.06 %

4 - Max Deflection 0 Top 0.115 0.000 232 0.50 0.115 0.400 28.70 %

RC Beam Designer 2018 Page 33 of 46

Project: Date: 03-23-2023

The crack opening calculation is done according to EN 1992-1-1, 7.3.4 (1).

Span T 1.1, Section wk Max, Abscissa 700 mm, Position: bottom

Combination Envelope of SLS QP combinations

Neutral axis position

Effective tension area, surrounding the

tension reinforcement

(7.3.4(2), Fig. 7.1)

Maximum crack spacing

(7.3.4(3), 7.11)

Secant Young modulus

Short term equivalence coefficient

Difference between average strains

(7.3.4 (2))

Crack width (7.3.4 (1))

Crack width verification

Passed

Span T 1.2, Section wk Max, Abscissa 0 mm, Position: top

Combination Envelope of SLS QP combinations

Neutral axis position

Effective tension area, surrounding the

tension reinforcement

(7.3.4(2), Fig. 7.1)

RC Beam Designer 2018 Page 34 of 46

Project: Date: 03-23-2023

Maximum crack spacing

(7.3.4(3), 7.11)

Secant Young modulus

Short term equivalence coefficient

Difference between average strains

(7.3.4 (2))

Crack width (7.3.4 (1))

Crack width verification

Passed

Span T 1.3, Section wk Max, Abscissa 7000 mm, Position: top

Combination Envelope of SLS QP combinations

Neutral axis position

Effective tension area, surrounding the

tension reinforcement

(7.3.4(2), Fig. 7.1)

RC Beam Designer 2018 Page 35 of 46

Project: Date: 03-23-2023

Maximum crack spacing

(7.3.4(3), 7.11)

Secant Young modulus

Short term equivalence coefficient

Difference between average strains

(7.3.4 (2))

Crack width (7.3.4 (1))

Crack width verification

Passed

Span T 1.4, Section wk Max, Abscissa 6300 mm, Position: bottom

Combination Envelope of SLS QP combinations

Neutral axis position

Effective tension area, surrounding the

tension reinforcement

(7.3.4(2), Fig. 7.1)

Maximum crack spacing

(7.3.4(3), 7.11)

Secant Young modulus

RC Beam Designer 2018 Page 36 of 46

Project: Date: 03-23-2023

Short term equivalence coefficient

Difference between average strains

(7.3.4 (2))

Crack width (7.3.4 (1))

Crack width verification

Passed

11 Anchorage calculation

Anchorage calculation

Bar Position

mark

(kN) (mm) (MPa) (mm) (mm)

1 Start 11.07 40 140.95 116 1.00 1.00 1.00 1.00 0.98 114

End 0.00 0 0.00 0 1.00 1.00 1.00 1.00 0.98 100

2 Start 0.00 0 339.13 279 1.00 0.70 1.00 1.00 1.00 195

End 0.00 0 339.13 279 1.00 0.70 1.00 1.00 1.00 195

8 Start 0.00 0 0.00 0 0.70 0.89 1.00 1.00 0.98 100

End 0.00 0 0.00 0 0.70 0.89 1.00 1.00 0.98 100

9 Start 0.00 0 339.13 223 1.00 0.70 1.00 1.00 1.00 156

End 0.00 0 339.13 223 1.00 0.70 1.00 1.00 1.00 156

14 Start 0.00 0 0.00 0 0.70 0.89 1.00 1.00 0.98 100

End 0.00 0 0.00 0 0.70 0.89 1.00 1.00 0.98 100

15 Start 0.00 0 339.13 223 1.00 0.70 1.00 1.00 1.00 156

End 0.00 0 339.13 223 1.00 0.70 1.00 1.00 1.00 156

20 Start 0.00 0 0.00 0 1.00 1.00 1.00 1.00 0.98 100

End 11.07 40 140.95 116 1.00 1.00 1.00 1.00 0.98 114

21 Start 0.00 0 339.13 279 1.00 0.70 1.00 1.00 1.00 195

End 0.00 0 339.13 279 1.00 0.70 1.00 1.00 1.00 195

3 Start 0.00 0 275.15 323 1.00 1.00 1.00 1.00 1.00 323

End 0.00 0 339.13 398 1.00 0.70 1.00 1.00 1.00 279

4 Start 0.00 0 339.13 558 1.00 0.83 1.00 1.00 1.00 462

End 0.00 0 339.13 558 1.00 0.83 1.00 1.00 1.00 462

10 Start 0.00 0 339.13 478 1.00 0.78 1.00 1.00 1.00 370

End 0.00 0 339.13 478 1.00 0.78 1.00 1.00 1.00 370

RC Beam Designer 2018 Page 37 of 46

Project: Date: 03-23-2023

Anchorage calculation

Bar Position

mark

(kN) (mm) (MPa) (mm) (mm)

16 Start 0.00 0 339.13 558 1.00 0.83 1.00 1.00 1.00 462

End 0.00 0 339.13 558 1.00 0.83 1.00 1.00 1.00 462

22 Start 0.00 0 339.13 398 1.00 0.70 1.00 1.00 1.00 279

End 0.00 0 275.15 323 1.00 1.00 1.00 1.00 1.00 323

Anchorage calculation: anchorage at a s0.cot(teta) distance.

Anchorage calculation is done according to EN1992-1, 8.4.

12 Support strut verification

The support strut verification and dimensioning of the sliding reinforcement is done according to article 6.5

and 9.2.1.4/ 9.2.1.5 of EN 1992-1-1.

Support strut verification

Span Sliding reinforcement Support strut stress

ID Position Real Minimum θ' Work Status

(cm²) (cm²) (°) (MPa) (MPa) Ratio

1 Left 3.14 1.40 46.99 0.84 14.96 5.65 % Passed

Right 1.13 0.00 - 17.60 8.48 % Passed

2 Left 0.90 0.00 - 1.49 17.60 8.48 % Passed

Right 0.90 0.00 - 17.60 7.40 % Passed

3 Left 0.90 0.00 - 1.30 17.60 7.40 % Passed

Right 0.90 0.00 - 17.60 8.48 % Passed

4 Left 1.13 0.00 - 1.49 17.60 8.48 % Passed

Right 3.14 1.40 0.00 14.96 5.65 % Passed

12.1 Support strut stresses verification

Span T 1.1, Section Left support, Abscissa 0 mm

Envelope ULS

Stresses verification

Maximum stress which can be applied at the

edges of the node (23.4.3)

Effective support stress

Support reaction

Compressed strut width

Distance from beam bottom edge to bottom

bars on support axis

Effective width of support

Inclination angle

Stresses verification

5.65 % (Passed)

Span T 1.2, Section Left support, Abscissa 0 mm

Envelope ULS

Stresses verification

Maximum stress which can be applied at the

edges of the node (23.4.3)

RC Beam Designer 2018 Page 38 of 46

Project: Date: 03-23-2023

Effective support stress

Support reaction

Stresses verification

8.48 % (Passed)

Span T 1.3, Section Left support, Abscissa 0 mm

Envelope ULS

Stresses verification

Maximum stress which can be applied at the

edges of the node (23.4.3)

Effective support stress

Support reaction

Stresses verification

7.40 % (Passed)

Span T 1.4, Section Left support, Abscissa 0 mm

Envelope ULS

Stresses verification

Maximum stress which can be applied at the

edges of the node (23.4.3)

Effective support stress

Support reaction

Stresses verification

8.48 % (Passed)

Span T 1.1, Section Right support, Abscissa 7000 mm

Envelope ULS

Stresses verification

Maximum stress which can be applied at the

edges of the node (23.4.3)

Effective support stress

Support reaction

Stresses verification

8.48 % (Passed)

Span T 1.2, Section Right support, Abscissa 7000 mm

Envelope ULS

Stresses verification

Maximum stress which can be applied at the

edges of the node (23.4.3)

Effective support stress

Support reaction

Stresses verification

7.40 % (Passed)

Span T 1.3, Section Right support, Abscissa 7000 mm

Envelope ULS

Stresses verification

RC Beam Designer 2018 Page 39 of 46

Project: Date: 03-23-2023

Maximum stress which can be applied at the

edges of the node (23.4.3)

Effective support stress

Support reaction

Stresses verification

8.48 % (Passed)

Span T 1.4, Section Right support, Abscissa 7000 mm

Envelope ULS

Stresses verification

Maximum stress which can be applied at the

edges of the node (23.4.3)

Effective support stress

Support reaction

Compressed strut width

Distance from beam bottom edge to bottom

bars on support axis

Effective width of support

Inclination angle

Stresses verification

5.65 % (Passed)

12.2 Sliding reinforcement verification

Span T 1.1, Section Left support, Abscissa 0 mm

Envelope ULS

Reinforcement verification

Bottom longitudinal reinforcement which is

anchored in support verification

Tensile force to be anchored in support

Reinforcement verification

224.43 % (Passed)

Additional sliding reinforcement not needed

Span T 1.2, Section Left support, Abscissa 0 mm

Envelope ULS

Reinforcement verification

Bottom longitudinal reinforcement which is

anchored in support verification

Tensile force to be anchored in support

Reinforcement verification

100.00 % (Passed)

Additional sliding reinforcement not needed

Span T 1.3, Section Left support, Abscissa 0 mm

Envelope ULS

Reinforcement verification

Bottom longitudinal reinforcement which is

anchored in support verification

RC Beam Designer 2018 Page 40 of 46

Project: Date: 03-23-2023

Tensile force to be anchored in support

Reinforcement verification

100.00 % (Passed)

Additional sliding reinforcement not needed

Span T 1.4, Section Left support, Abscissa 0 mm

Envelope ULS

Reinforcement verification

Bottom longitudinal reinforcement which is

anchored in support verification

Tensile force to be anchored in support

Reinforcement verification

100.00 % (Passed)

Additional sliding reinforcement not needed

Span T 1.1, Section Right support, Abscissa 7000 mm

Envelope ULS

Reinforcement verification

Bottom longitudinal reinforcement which is

anchored in support verification

Tensile force to be anchored in support

Reinforcement verification

100.00 % (Passed)

Additional sliding reinforcement not needed

Span T 1.2, Section Right support, Abscissa 7000 mm

Envelope ULS

Reinforcement verification

Bottom longitudinal reinforcement which is

anchored in support verification

Tensile force to be anchored in support

Reinforcement verification

100.00 % (Passed)

Additional sliding reinforcement not needed

Span T 1.3, Section Right support, Abscissa 7000 mm

Envelope ULS

Reinforcement verification

Bottom longitudinal reinforcement which is

anchored in support verification

Tensile force to be anchored in support

Reinforcement verification

100.00 % (Passed)

Additional sliding reinforcement not needed

Span T 1.4, Section Right support, Abscissa 7000 mm

Envelope ULS

Reinforcement verification

Bottom longitudinal reinforcement which is

anchored in support verification

RC Beam Designer 2018 Page 41 of 46

Project: Date: 03-23-2023

Tensile force to be anchored in support

Reinforcement verification

224.43 % (Passed)

Additional sliding reinforcement not needed

13 Support reactions

Load case / combination Support 1 Support 2 Support 3 Support 4

ID Title Fz (kN) Fz (kN) Fz (kN) Fz (kN)

1 Dead loads 1 -25.91 -71.05 -59.51 -71.05

2 Live loads 1 -8.96 -24.06 -21.40 -24.06

101 1x[1 G] -25.91 -71.05 -59.51 -71.05

102 1.35x[1 G] -34.98 -95.91 -80.34 -95.91

103 1x[1 G]+1.5x[2 Q] -40.84 -109.38 -96.35 -109.38

104 1.35x[1 G]+1.5x[2 Q] -49.90 -134.25 -117.18 -134.25

105 1x[1 G] -25.91 -71.05 -59.51 -71.05

106 1x[1 G]+1x[2 Q] -35.86 -96.60 -84.07 -96.60

107 1x[1 G] -25.91 -71.05 -59.51 -71.05

108 1x[1 G]+0.5x[2 Q] -30.88 -83.83 -71.79 -83.83

109 1x[1 G] -25.91 -71.05 -59.51 -71.05

110 1x[1 G]+0.3x[2 Q] -28.89 -78.71 -66.88 -78.71

Max(ULS) -49.90 -134.25 -117.18 -134.25

Max(SLS) -35.86 -96.60 -84.07 -96.60

Load case / combination Support 5

ID Title Fz (kN)

1 Dead loads 1 -25.91

2 Live loads 1 -8.96

101 1x[1 G] -25.91

102 1.35x[1 G] -34.98

103 1x[1 G]+1.5x[2 Q] -40.84

104 1.35x[1 G]+1.5x[2 Q] -49.90

105 1x[1 G] -25.91

106 1x[1 G]+1x[2 Q] -35.86

107 1x[1 G] -25.91

108 1x[1 G]+0.5x[2 Q] -30.88

109 1x[1 G] -25.91

110 1x[1 G]+0.3x[2 Q] -28.89

Max(ULS) -49.90

Max(SLS) -35.86

14 Deflections

The deflections are calculated with the curvature integration method.

RC Beam Designer 2018 Page 42 of 46

Project: Date: 03-23-2023

The total deflection is calculated according to 7.4.3 from EN 1992-1-1.

Span 1

Distance between support axes

Modular ratio

Mean flexural tensile strength of

reinforced concrete

Modulus of elasticity of concrete

Uncracked moment of inertia

Cracked moment of inertia

Bottom reinforcement area

Top reinforcement area

Deflection calculated for the uncracked

conditions

Deflection calculated for the fully

cracked conditions

Distribution coefficient

Span 2

Distance between support axes

Modular ratio

Mean flexural tensile strength of

reinforced concrete

Modulus of elasticity of concrete

Uncracked moment of inertia

Cracked moment of inertia

Bottom reinforcement area

Top reinforcement area

Deflection calculated for the uncracked

conditions

Deflection calculated for the fully

cracked conditions

Distribution coefficient

RC Beam Designer 2018 Page 43 of 46

Project: Date: 03-23-2023

Span 3

Distance between support axes

Modular ratio

Mean flexural tensile strength of

reinforced concrete

Modulus of elasticity of concrete

Uncracked moment of inertia

Cracked moment of inertia

Bottom reinforcement area

Top reinforcement area

Deflection calculated for the uncracked

conditions

Deflection calculated for the fully

cracked conditions

Distribution coefficient

Span 4

Distance between support axes

Modular ratio

Mean flexural tensile strength of

reinforced concrete

Modulus of elasticity of concrete

Uncracked moment of inertia

Cracked moment of inertia

Bottom reinforcement area

Top reinforcement area

Deflection calculated for the uncracked

conditions

Deflection calculated for the fully

cracked conditions

Distribution coefficient

Interpolation is done between inertias in

the uncracked and fully cracked states

Total deflection

Span f Ratio Status

(mm) (mm) (%)

1 -6 mm 15 mm 41.90 % Passed

2 -3 mm 15 mm 22.92 % Passed

3 -3 mm 15 mm 22.92 % Passed

4 -6 mm 15 mm 41.90 % Passed

f Total deflection EN 1992-1-1

Total allowable deflection

The peak deflection is calculated applying the Professional Rules.

Characteristics

Span αₑ ϕ L Eᵥ E Reinf. (cm²)

(MPa) (m) (MPa) (MPa) (m⁴) (m⁴)

1 15.00 2.0 3.19 7.00 10945.52 32836.57 6.28 0.00 0.00347 0.00117

2 15.00 2.0 3.19 7.00 10945.52 32836.57 4.02 0.00 0.00336 0.00083

RC Beam Designer 2018 Page 44 of 46

Project: Date: 03-23-2023

Characteristics

Span αₑ ϕ L Eᵥ E Reinf. (cm²)

(MPa) (m) (MPa) (MPa) (m⁴) (m⁴)

3 15.00 2.0 3.19 7.00 10945.52 32836.57 4.02 0.00 0.00336 0.00083

4 15.00 2.0 3.19 7.00 10945.52 32836.57 6.28 0.00 0.00347 0.00117

Maximum bending moments

Span

(kN⋅m) (kN⋅m) (kN⋅m) (kN⋅m) (kN⋅m)

1 15.58 15.58 36.75 53.10 46.43

2 9.63 9.63 22.71 36.63 44.15

3 9.63 9.63 22.71 36.63 44.15

4 15.58 15.58 36.75 53.10 46.43

Total deflection

Span

(cm) (cm) (cm)

1 0.06 -1.617 -0.544 -0.614

2 0.00 -1.477 -0.365 -0.365

3 0.00 -1.477 -0.365 -0.365

4 0.06 -1.617 -0.544 -0.614

Initial deflection

Span

(cm) (cm) (cm) (cm) (cm) (cm)

1 0.00 -0.199 -0.067 -0.067 0.00 -0.597 -0.201 -0.201

2 0.00 -0.173 -0.043 -0.043 0.00 -0.520 -0.128 -0.128

3 0.00 -0.173 -0.043 -0.043 0.00 -0.520 -0.128 -0.128

4 0.00 -0.199 -0.067 -0.067 0.00 -0.597 -0.201 -0.201

Initial deflection

Span RH

(%) (mm) (days) (days) (cm)

1 50 188 521.207 30 28 0.188 0.000 -0.07

2 50 188 521.207 30 28 0.188 0.000 -0.04

3 50 188 521.207 30 28 0.188 0.000 -0.04

4 50 188 521.207 30 28 0.188 0.000 -0.07

Peak Deflection

Span

(cm) (cm)

1 -0.547 1.400

2 -0.322 1.400

3 -0.322 1.400

4 -0.547 1.400

15 Bill of materials

RC Beam Designer 2018 Page 45 of 46

Project: Date: 03-23-2023

Beam Dimensions

Level 1 L r b

(mm) (mm) (mm)

T 1.1 7450 500 300

T 1.2 7300 500 300

T 1.3 7300 500 300

T 1.4 7450 500 300

Beam Concrete Formwork Steel Reinf. Ratio

Level 1 Quantity Price Quantity Price Quantity Price

(m³) (€) (m²) (€) (kg) (€) (kg/m³)

T 1.1 1.12 0.00 9.10 0.00 91.34 0.00 62.73

T 1.2 1.10 0.00 9.10 0.00 68.93 0.00 42.58

T 1.3 1.10 0.00 9.10 0.00 76.67 0.00 49.65

T 1.4 1.12 0.00 9.10 0.00 69.96 0.00 43.59

Total 4.43 0.00 36.40 0.00 306.90 0.00 49.64

Total Price 0.00 €

Average Diameter: 10 mm

RC Beam Designer 2018 Page 46 of 46

You might also like

- Test Beam ReportDocument35 pagesTest Beam Reportkheang mengNo ratings yet

- Beam Design ReportDocument20 pagesBeam Design Reportkheang mengNo ratings yet

- Base Plate A3Document12 pagesBase Plate A3kheang mengNo ratings yet

- Design Calculations For 3WH36 Composit Steel Deck-1 MMDocument5 pagesDesign Calculations For 3WH36 Composit Steel Deck-1 MMmohanNo ratings yet

- Engineering Bulletin SpecimenDocument34 pagesEngineering Bulletin SpecimenNidDouNo ratings yet

- XBeam2d 2 ENDocument10 pagesXBeam2d 2 ENAlem LoajnerNo ratings yet

- OffCon Beta CanadaDocument11 pagesOffCon Beta CanadaHelmiNo ratings yet

- Investigation of a multi-cyclone dust separator efficiencyDocument59 pagesInvestigation of a multi-cyclone dust separator efficiencyAyman RiyadhNo ratings yet

- Structural Calculation For Steel Chassis of Cladding Between Floors (Part.5) Building-BDocument60 pagesStructural Calculation For Steel Chassis of Cladding Between Floors (Part.5) Building-Bنصر عبدالسلامNo ratings yet

- Structural Design Report For High Lift Pump StationDocument195 pagesStructural Design Report For High Lift Pump StationEphrem GalNo ratings yet

- BeamDocument10 pagesBeamdoggNo ratings yet

- Akcome Single-Axis Tracker Structure Calculation Report 2PDocument26 pagesAkcome Single-Axis Tracker Structure Calculation Report 2PRajaa KodadNo ratings yet

- Bsfait00 - Fa - Archive - IB - 2016 - IB - 2016 - 173 - MA WerthenDocument73 pagesBsfait00 - Fa - Archive - IB - 2016 - IB - 2016 - 173 - MA WerthenValentina DiamanteNo ratings yet

- Design Calculation of PT-SOG (LOGISTICS VINH LOC) - BASE SLAB 180.250mmDocument30 pagesDesign Calculation of PT-SOG (LOGISTICS VINH LOC) - BASE SLAB 180.250mmPhạm Tiến ĐạtNo ratings yet

- ArcelorMittal Composite Bridge Predesign ReportDocument4 pagesArcelorMittal Composite Bridge Predesign ReportIoana Codrea OrtelecanNo ratings yet

- 02 StatikaDocument14 pages02 StatikaArmin HudutiNo ratings yet

- Reinforced Concrete Beam: Graitec Innovation 17 Burospace 91572 BièvresDocument4 pagesReinforced Concrete Beam: Graitec Innovation 17 Burospace 91572 BièvresFreizerNo ratings yet

- Transformer Slab PDFDocument1 pageTransformer Slab PDFfdfsdfsNo ratings yet

- System Information Cross Sectional LoadingDocument39 pagesSystem Information Cross Sectional LoadingHasan arif KısaalioğluNo ratings yet

- Concrete: Input DataDocument4 pagesConcrete: Input DataARYANo ratings yet

- ACCROPODE™ II - Design - Table - 2012Document4 pagesACCROPODE™ II - Design - Table - 2012Tarun KawNo ratings yet

- JETIR2203560Document6 pagesJETIR2203560mahesh jangirNo ratings yet

- Design Methods For AnchoragesDocument19 pagesDesign Methods For Anchorageshitendra_gkNo ratings yet

- Culverts Design Review From ROCLA - 20211214Document7 pagesCulverts Design Review From ROCLA - 20211214Clement TakavarashaNo ratings yet

- CoP (IPE 160 Joint)Document3 pagesCoP (IPE 160 Joint)BanditAkosNo ratings yet

- RCC32R Rigorous Ribbed SlabsDocument554 pagesRCC32R Rigorous Ribbed SlabsCioabla Bogdan100% (1)

- Pipeline Cathodic Protection Design - Compress PDFDocument20 pagesPipeline Cathodic Protection Design - Compress PDFBadi100% (1)

- LOAD CALC - Concord UnitedDocument95 pagesLOAD CALC - Concord UnitedRakesh CivilianNo ratings yet

- Wind As Per 875-2015Document33 pagesWind As Per 875-2015V.m. RajanNo ratings yet

- Mat Foundation Y Dir Rebar DesignDocument4 pagesMat Foundation Y Dir Rebar DesignGaneshalingam Ramprasanna2No ratings yet

- Design Report On Approach BridgeDocument48 pagesDesign Report On Approach Bridgepremnath16No ratings yet

- CADS Bearing Pile Designer Working Platform AnalysisDocument2 pagesCADS Bearing Pile Designer Working Platform AnalysisDavidNo ratings yet

- Methodology of Die Design For HPDCDocument8 pagesMethodology of Die Design For HPDCruben6286No ratings yet

- DownloadDocument122 pagesDownloadzxc091823No ratings yet

- MainBridge - Design ReportDocument18 pagesMainBridge - Design ReportWan100% (1)

- Report BR No 80 R0 01 10 2023Document30 pagesReport BR No 80 R0 01 10 2023Saurabh PandeyNo ratings yet

- 25m Single Lane Bridge Design Calculations LatestDocument23 pages25m Single Lane Bridge Design Calculations Latestdravinonares100% (1)

- RCC32R Rigorous Ribbed SlabsDocument201 pagesRCC32R Rigorous Ribbed SlabsMohammad Twaha JaumbocusNo ratings yet

- Lessen of Steel DesignDocument34 pagesLessen of Steel DesignMohammed AdelNo ratings yet

- Chapter 3 Example Set 4Document9 pagesChapter 3 Example Set 4alaa altaeeNo ratings yet

- IS875 (Part3) - Wind Loads On Buildings and Structures - IIT Kanpur-Part 4Document7 pagesIS875 (Part3) - Wind Loads On Buildings and Structures - IIT Kanpur-Part 4Adam Michael GreenNo ratings yet

- One Storey Analysis Tedds Detailed AnalysisDocument5 pagesOne Storey Analysis Tedds Detailed AnalysisShingirai JoeNo ratings yet

- RCS2 Report TranDangKhoa 1652312Document170 pagesRCS2 Report TranDangKhoa 1652312Đặng Nhật HàoNo ratings yet

- Fire Design Example Based On European Standard ENV 1999-2 (Eurocode 9)Document27 pagesFire Design Example Based On European Standard ENV 1999-2 (Eurocode 9)CORE MaterialsNo ratings yet

- Simulation of Crack Propogation of Shackle Used in Suspension GearDocument12 pagesSimulation of Crack Propogation of Shackle Used in Suspension GearCarlos Eduardo JaenNo ratings yet

- Steel 2D Analysis & Design (EN1993)Document4 pagesSteel 2D Analysis & Design (EN1993)Truong Phuoc TriNo ratings yet

- Structural Analysis and Design of Security TowerDocument30 pagesStructural Analysis and Design of Security TowerdovermanNo ratings yet

- Strap Footing Design: ASDIP Foundation 3.2.2Document4 pagesStrap Footing Design: ASDIP Foundation 3.2.2Mainali IshuNo ratings yet

- National University of Civil Engineering Division of Construction Technology and ManagementDocument48 pagesNational University of Civil Engineering Division of Construction Technology and ManagementNguyễn Minh HiếuNo ratings yet

- Etabs 19 beam design summaryDocument1 pageEtabs 19 beam design summaryMelissa MartinezNo ratings yet

- Precast PlankDocument9 pagesPrecast PlankKalpanaNo ratings yet

- 1 Input Data: Profis Anchor 2.6.0Document6 pages1 Input Data: Profis Anchor 2.6.0Shaikh Muhammad AteeqNo ratings yet

- Munyaka BEAM 01 July 2023Document22 pagesMunyaka BEAM 01 July 2023michaelNo ratings yet

- Design of Composite GirderDocument86 pagesDesign of Composite GirderSaran KumarNo ratings yet

- Installation - Typical 3.3m.precast Concrete Beam Design (EN1992)Document5 pagesInstallation - Typical 3.3m.precast Concrete Beam Design (EN1992)zms msswiNo ratings yet

- Advanced Millimeter-wave Technologies: Antennas, Packaging and CircuitsFrom EverandAdvanced Millimeter-wave Technologies: Antennas, Packaging and CircuitsDuixian LiuNo ratings yet

- Nuclear Magnetic Resonance: Petrophysical and Logging ApplicationsFrom EverandNuclear Magnetic Resonance: Petrophysical and Logging ApplicationsRating: 5 out of 5 stars5/5 (1)