Professional Documents

Culture Documents

Base Plate A3

Uploaded by

kheang mengOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Base Plate A3

Uploaded by

kheang mengCopyright:

Available Formats

Project

Address

Execution class

Report EXC2

EN 1090-2

GRAITEC INNOVATION Designed by Date

www.graitec.com Verified by Date

17 Burospace 91572 Bièvres Revision A Drawing

Base Plate Report

Maximum Work Ratio 71.42 % Passed

Table of Contents

1 Joint description..................................................................................................................... 3

2 Load combinations description............................................................................................. 4

3 Design Assumptions............................................................................................................... 4

4 Holes distances conditions..................................................................................................... 5

4.1 Minimum distance conditions for round holes ............................................................................5

4.2 Maximum distance for steel without improved atmospheric corrosion resistance..................... 5

5 Compression verifications..................................................................................................... 6

5.1 Compression resistance of the column.........................................................................................6

5.2 Compression verification of the column base..............................................................................6

6 Anchor Verifications............................................................................................................. 7

6.1 Anchor bolt shear verification......................................................................................................8

6.2 Anchor bolt combined shear-tension verification........................................................................9

6.3 Summary - Individual anchor bolt verifications..........................................................................9

7 Stiffeners verifications......................................................................................................... 10

8 Tension verifications............................................................................................................ 10

9 Shear verifications.............................................................................................................. 11

9.1 Shear force resistance.................................................................................................................11

9.2 Column web panel in shear........................................................................................................11

9.3 Shear verification of the bolt rows.............................................................................................11

10 T-Stub method..................................................................................................................... 11

11 Weld verifications............................................................................................................... 12

12 Rotational Stiffness.............................................................................................................. 12

13 Warning and error messages.............................................................................................. 12

14 Summary.............................................................................................................................. 12

Advance Design Steel Connection 2024 Page 1 of 12

Project: Date: 12-02-2023

Advance Design Steel Connection 2024 Page 2 of 12

Project: Date: 12-02-2023

1 Joint description

Column HN496x199x9x14 (Section Class 1)

Material: S235 (EN 10025-2)

Dimensions Characteristics

Anchors dimensions and properties

Anchor shear area Mechanical properties:

Anchor length Class 4.6

Diameter (Ribbed bar)

Nut Height

Nut Width

Washer Thickness

Base Plate

Material: S235 (EN 10025-2)

Section Dimensions

Height

Width

Thickness

Holes diameter

Concrete

Length

Width

Height

Advance Design Steel Connection 2024 Page 3 of 12

Project: Date: 12-02-2023

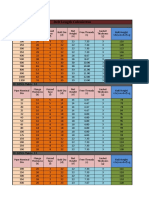

2 Load combinations description

Comb. Load Combination Description V M N

Index Envelope Type (kN) (kN⋅m) (kN)

Forces Max

5 52.82 0 -105.63

Max(Vz; My; Sqrt(N^2+Vz^2)); Min(N; My)

Forces Min

6 15.93 0 -40.06

Max(N); Min(Vz)

Maximum Efforts 52.82 0 -40.06

Minimum Efforts 15.93 0 -105.63

The forces are defined in the member's local axis

3 Design Assumptions

Design standards

EN 1993-1-1 Design of Steel Structures. General Rules and Rules for Buildings

EN 1993-1-8 Design of Steel Structures. Design of Joints

EN 1992-1-1 Design of Concrete Structures. General Rules and Rules for Buildings

EN 1993-1 National Annex: United Kingdom National Annex.

Units

Dimensions: mm Area: mm²

Forces: kN Inertia modulus: cm³

Bending moments: kN⋅m Inertia Moment: cm⁴

Stresses: MPa Rotational Stiffness: kN⋅m/rad

Angles: °

Anchors

The shear plane passes through the threaded part of the anchor.

T-Stub Failure Method: Method 2

T-stub method - tensioned zone limit: automatic determination

Approximate value for the transformation parameter, according to Table 5.4 (EN 1993-1-8):

Anchor tension reduction factor, according to EN 1090:

Poor bond conditions are considered.

Safety Coefficients

Structural steel Structural concrete:

- for bolts/anchors, welds, plates in bearing

Advance Design Steel Connection 2024 Page 4 of 12

Project: Date: 12-02-2023

- for cross-sections in tension to fracture

- for reinforcing steel (EN 1992-1-1)

Corrosion conditions

EN 10025, the steel is used unprotected (without improved atmospheric corrosion resistance).

Conventions

Tension is considered positive (compression is considered negative).

Bending moment is considered positive if clockwise (in above

elevation).

Strong axis of the profile is considered "y-y" and weak axis "z-z".

Application domain:

The joint members are I or H construction steel profiles.

4 Holes distances conditions

Next, "Right" holes and "Left" holes refer to the joint part to which the holes belong (e.g. right plate).

4.1 Minimum distance conditions for round holes

Minimum holes edge distance on load direction (round holes)

EN 1993-1-8, Table 3.3

Right holes Passed

Minimum holes edge distance perpendicular on load direction (round holes)

EN 1993-1-8, Table 3.3

Right holes Passed

Minimum spacing between the centers of 2 holes, measured on the direction of the load

EN 1993-1-8, Table 3.3

Right holes Passed

Minimum spacing between the centers of 2 holes, measured perpendicular on the direction of the load

EN 1993-1-8, Table 3.3

Right holes Passed

4.2 Maximum distance for steel without improved atmospheric corrosion resistance

Note: Steel conforming to EN 10025-5*.

No verification of spacing between anchor bolt-rows (perpendicular on the load direction) is done.

* Verification to avoid local buckling and to prevent corrosion

Advance Design Steel Connection 2024 Page 5 of 12

Project: Date: 12-02-2023

5 Compression verifications

5.1 Compression resistance of the column

Column cross section design bending moment resistance reduced if necessary, to allow for shear force. Its

formula is shown below.

The column profile is class 1, so the moment resistance of the section is calculated using the plastic

modulus:

EN1993-1-1. 6.2.5

The Design Combined Compression Resistance of the Column Flange and the Adjacent Compression Zone

of the Column Web:

EN 1993-1-8, 6.2.6.7

5.2 Compression verification of the column base

Check relation:

Combination: [5]: Forces Max

Concrete compression resistance force under column base( 2 flanges+web )

EN 1992-1-1, 3.1.6(1)

+ 3.1.7(3)

For determining the compression resistance under the column base, an additional bearing width needs to

be determined:

EN 1993-1-8, 6.2.5(4)

Compression resistance of concrete under column flange

Advance Design Steel Connection 2024 Page 6 of 12

Project: Date: 12-02-2023

The design bearing resistance under the base plate will be calculated considering the loaded area equal

with the maximum design distribution area having a similar shape.

EN 1993-1-8, 6.2.6.9

Effective bearing area

Calculation of the bearing pressure zone width

The bearing pressure zone exceeds the plate length:

EN 1993-1-8, 6.2.5(3)

c - available space outside the flange measured in the direction of the corresponding distance

Calculation of the bearing pressure zone length

EN 1993-1-8, 6.2.5(3)

Replacing the values of effective dimensions, the design bearing resistance becomes:

EN 1992-1-1, 6.7 (3)

Compression resistance of concrete under column web

EN 1992-1-1, 6.7 (3)

Replacing the values of effective dimensions, the design bearing resistance of the web becomes:

Resistance of the spread footing in axial compression

EN 1993-1-8, 6.2.8.2 (1)

Work Ratio: 14.6 % Passed

6 Anchor Verifications

Anchor-bolt dimensions and mechanical properties

Diameter: (Ribbed bar)

Dimensions:

Advance Design Steel Connection 2024 Page 7 of 12

Project: Date: 12-02-2023

Mechanical properties:

Class 4.6

Tensile stress area :

Anchor dimension conditions (EN1992-1-1 recommendations)

Length is determined starting from equivalent anchorage length (according to paragraph 8.4, EN 1992-1-

1):

EN 1992-1-1, 8.4.4 (2)

where

EN 1992-1-1, Table 8.2

EN 1992-1-1, 8.4.3 (8.3)

where

EN 1992-1-1, 8.4.2

where:

Replacing the above values, basic required anchorage length becomes:

EN 1992-1-1, 8.4.3 (2)

Next, we'll use the real anchorage length:

Minimum mandrel diameter

Minimum recommended mandrel diameter is (according to Table 8.1N, EN 1992-1-1):

Minimum anchorage length (l2)

WARNING: The length past the end of the bend is smaller than 5 diameters of the anchor

(Figure 8.1, EN 1992-1-1)!

Minimum recommended length is:

Verification is not required.

6.1 Anchor bolt shear verification

Check relation:

Advance Design Steel Connection 2024 Page 8 of 12

Project: Date: 12-02-2023

Combination: [5]: Forces Max

Bearing resistance of an anchor bolt

EN 1993-1-8, 3.6.1, table 3.4

EN 1993-1-8, 3.6.1, table 3.4

EN 1993-1-8, 3.6.1, table 3.4

EN 1993-1-8, 3.6.1, table 3.4

Work Ratio: 71.42 % Passed

6.2 Anchor bolt combined shear-tension verification

Verification is not required.

6.3 Summary - Individual anchor bolt verifications

Table is presented for the most solicited anchor.

Tension Verification Shear Shear and Tension

Verification Verification

Combination

- [5]: Forces Max -

Force - 13.2 kN -

Resistance - 18.49 kN -

Work Ratio - 71.42% -

Verification - Passed -

Advance Design Steel Connection 2024 Page 9 of 12

Project: Date: 12-02-2023

7 Stiffeners verifications

Verification not necessary!

8 Tension verifications

Verification is not necessary.

Advance Design Steel Connection 2024 Page 10 of 12

Project: Date: 12-02-2023

9 Shear verifications

9.1 Shear force resistance

Check relation:

Combination: [5]: Forces Max

Design friction resistance between base plate and grout layer / concrete

Friction coefficient (special grout) is:

Design bearing resistance of an anchor-bolt (previously calculated):

Replacing the above values, check relation becomes:

Work Ratio: 50 % Passed

9.2 Column web panel in shear

Check relation:

For an unstiffened column web panel, EN 1993-1-8 6.2.6.1(2):

Work Ratio: 8.25 % Passed

9.3 Shear verification of the bolt rows

Check relation:

Combination: [5]: Forces Max

n1 - number of bolts that are not required to resist tension; EN 1993-1-8 6.2.2 (2a)

n2 - number of bolts that are also required to resist tension; EN 1993-1-8 6.2.2 (2b)

EN 1993-1-8 6.2.2 (2)

Work Ratio: 71.42 % Passed

10 T-Stub method

T-stub method is not applied due to pinned assumption of base plate.

Verification is not necessary.

Advance Design Steel Connection 2024 Page 11 of 12

Project: Date: 12-02-2023

11 Weld verifications

Verification is not necessary.

12 Rotational Stiffness

The base plate joint is assumed "pinned". No rotational stiffness is determined.

13 Warning and error messages

Type Description

No bending moment exists. Equivalent T-stub method cannot be applied. Bolt-rows

Warning resistance, moment resistance and rotational stiffness results are not available

Load cases: 5, 6

There are no tensioned anchors/bolts. Anchor/bolt rows resistance, moment resistance

Warning and rotational stiffness results are not calculated.

Load cases: 5, 6

No bending moment detected. Results from weld verification with simplified method

(4.5.3.3) are inconsistent. Please choose directional method (4.5.3.2) for welds

Error

design!

Load cases: 5, 6

14 Summary

Verification Combination Effort Resistance Work Ratio Status

Anchor bolt shear [5]: Forces Max 13.2 kN 18.49 kN 71.42 % Passed

Shear of the anchor bolt

[5]: Forces Max 52.82 kN 73.95 kN 71.42 % Passed

rows

Shear [5]: Forces Max 52.82 kN 105.64 kN 50 % Passed

Column base plate in

[5]: Forces Max -105.63 kN 723.62 kN 14.6 % Passed

compression

Column web panel in

[5]: Forces Max 52.82 kN 640.02 kN 8.25 % Passed

shear

Maximum Work Ratio: 71.42 % Passed

Advance Design Steel Connection 2024 Page 12 of 12

You might also like

- Wind As Per 875-2015Document33 pagesWind As Per 875-2015V.m. RajanNo ratings yet

- Graitec Beam ReportDocument46 pagesGraitec Beam ReportChanel CuteNo ratings yet

- Foundation 1 Design ReportDocument5 pagesFoundation 1 Design Reportyug draciNo ratings yet

- Stub ColumnDocument4 pagesStub ColumnCHRISTOPHER EKIRAPANo ratings yet

- Truss-EC3 DesignDocument57 pagesTruss-EC3 Designshaff85No ratings yet

- Structural Design Report For High Lift Pump StationDocument195 pagesStructural Design Report For High Lift Pump StationEphrem GalNo ratings yet

- 8-28-2023 6-54-40 AmDocument2 pages8-28-2023 6-54-40 AmCHRISTOPHER EKIRAPANo ratings yet

- ETAG 001-C Ancoraggi Metallici in CalcestruzzoDocument32 pagesETAG 001-C Ancoraggi Metallici in CalcestruzzoNiccolò PassariniNo ratings yet

- Design Load Combinations for Eurocode 2Document24 pagesDesign Load Combinations for Eurocode 2Tai Pham100% (1)

- Do It Yourself 1Document63 pagesDo It Yourself 1Nguyen Duc CuongNo ratings yet

- Wind Load SheetDocument32 pagesWind Load SheetNishan GajurelNo ratings yet

- ArcelorMittal Composite Bridge Predesign ReportDocument4 pagesArcelorMittal Composite Bridge Predesign ReportIoana Codrea OrtelecanNo ratings yet

- Design of A Notched Section at The End of A BeamDocument5 pagesDesign of A Notched Section at The End of A BeamBobaru MariusNo ratings yet

- Test Beam ReportDocument35 pagesTest Beam Reportkheang mengNo ratings yet

- Africa Tower Design ReportDocument15 pagesAfrica Tower Design ReporttahaelnourNo ratings yet

- Reduced Stress Method for Steel StructuresDocument8 pagesReduced Stress Method for Steel StructureselleesseNo ratings yet

- Pipeline Cathodic Protection Design - Compress PDFDocument20 pagesPipeline Cathodic Protection Design - Compress PDFBadi100% (1)

- Design Calculations For 3WH36 Composit Steel Deck-1 MMDocument5 pagesDesign Calculations For 3WH36 Composit Steel Deck-1 MMmohanNo ratings yet

- ETABS RC Slab Design PDFDocument29 pagesETABS RC Slab Design PDFLim Wee BengNo ratings yet

- NCCI: Design of A Notched Section at The End of A BeamDocument5 pagesNCCI: Design of A Notched Section at The End of A BeamhapsinteNo ratings yet

- OffCon Beta CanadaDocument11 pagesOffCon Beta CanadaHelmiNo ratings yet

- Punching Shear Strength of Flat Slabs: Critical Review of Eurocode 2 and Fib Model Code 2010 Design ProvisionsDocument35 pagesPunching Shear Strength of Flat Slabs: Critical Review of Eurocode 2 and Fib Model Code 2010 Design Provisionstekla gom-lua groupNo ratings yet

- Structural Calculation For Steel Chassis of Cladding Between Floors (Part.5) Building-BDocument60 pagesStructural Calculation For Steel Chassis of Cladding Between Floors (Part.5) Building-Bنصر عبدالسلامNo ratings yet

- Installation - Typical 3.3m.precast Concrete Beam Design (EN1992)Document5 pagesInstallation - Typical 3.3m.precast Concrete Beam Design (EN1992)zms msswiNo ratings yet

- Diseño de Anclajes en HormigonDocument32 pagesDiseño de Anclajes en HormigonnagenolNo ratings yet

- Design Example of Reinforce Concrete BeamsDocument60 pagesDesign Example of Reinforce Concrete BeamsMario FrankistaNo ratings yet

- AWS3 Technical Design for IEC 64100-2 ComplianceDocument57 pagesAWS3 Technical Design for IEC 64100-2 ComplianceĐặng Tấn PhátNo ratings yet

- Landing Beam Design Cal.Document4 pagesLanding Beam Design Cal.Saurabh PandeyNo ratings yet

- Calculations XavierDocument35 pagesCalculations XavierAlexo NgendaNo ratings yet

- Designing Concrete Structures:: Reinforced Rectangular Concrete Column Interaction Diagram ExampleDocument16 pagesDesigning Concrete Structures:: Reinforced Rectangular Concrete Column Interaction Diagram ExampleDiego Alberto Espitia RojasNo ratings yet

- Crack Width Check BS5400 4Document5 pagesCrack Width Check BS5400 4saravanan4286100% (1)

- Design calculations for low head vertical slide gateDocument12 pagesDesign calculations for low head vertical slide gatesuranga dadallage100% (1)

- FINAL - SKILLS - Design of Built-Up Columns - V3Document41 pagesFINAL - SKILLS - Design of Built-Up Columns - V3johnautodidacteNo ratings yet

- Requirements For Overhead Cranes Rails: Annex 1Document21 pagesRequirements For Overhead Cranes Rails: Annex 1Fuad KhoirulNo ratings yet

- Evo Design S.R.L.: Calculation SheetDocument1 pageEvo Design S.R.L.: Calculation SheetPK PKNo ratings yet

- 0 1 Reinforced Concrete EC2 Definitions and Details p1-5Document6 pages0 1 Reinforced Concrete EC2 Definitions and Details p1-5VijayNo ratings yet

- Analysis and Design of Members For TensionDocument84 pagesAnalysis and Design of Members For TensionicpertacortaNo ratings yet

- Analyses On Reinforced Concrete Cross SectionsDocument35 pagesAnalyses On Reinforced Concrete Cross SectionsnavaleriNo ratings yet

- CoP (IPE 160 Joint)Document3 pagesCoP (IPE 160 Joint)BanditAkosNo ratings yet

- Uncracked Concrete DesignDocument15 pagesUncracked Concrete Designmohamad jbaraNo ratings yet

- Foundation 1 Design ReportDocument6 pagesFoundation 1 Design ReportDinesh RajaNo ratings yet

- Design Manual To EC2Document39 pagesDesign Manual To EC2Tomas MerkeviciusNo ratings yet

- 8.anchor Design Methodology (P10-13)Document4 pages8.anchor Design Methodology (P10-13)jamesstewartNo ratings yet

- Concrete: Input DataDocument4 pagesConcrete: Input DataARYANo ratings yet

- Presentacion SMIE FibrasDocument55 pagesPresentacion SMIE FibrasVladimir RodríguezNo ratings yet

- Slab Design CombinedDocument28 pagesSlab Design CombinedEr. Rajendra Acharaya0% (1)

- Technical Comment - Wall Formwork - CommentsDocument19 pagesTechnical Comment - Wall Formwork - CommentsYazan AmlehNo ratings yet

- Numerical Weld Modeling - A Method For Calculating Weld-Induced Residual StressesDocument12 pagesNumerical Weld Modeling - A Method For Calculating Weld-Induced Residual StressesSwarupendra BhattacharyyaNo ratings yet

- Two Way Flat Plate Concrete Floor Slab Design Detailing - CSA23.3 14 PDFDocument67 pagesTwo Way Flat Plate Concrete Floor Slab Design Detailing - CSA23.3 14 PDFJGFUYGKIUGUNo ratings yet

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceFrom EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Fatigue Design: International Series on the Strength and Fracture of Materials and StructuresFrom EverandFatigue Design: International Series on the Strength and Fracture of Materials and StructuresNo ratings yet

- Earthquake Resistant Design of Buildings 2020: A Comparative Study of Old and Revised Provisions in Indian Seismic CodesDocument14 pagesEarthquake Resistant Design of Buildings 2020: A Comparative Study of Old and Revised Provisions in Indian Seismic CodesFazilat Mohammad ZaidiNo ratings yet

- Rafter ReportDocument2 pagesRafter Reportmengkheang31071999No ratings yet

- Beam-Column Connection 4B ReportDocument15 pagesBeam-Column Connection 4B Reportkheang mengNo ratings yet

- Footfall AnalysisDocument32 pagesFootfall Analysiskheang mengNo ratings yet

- 2-Wind Load Calculation Monoslop RoofDocument4 pages2-Wind Load Calculation Monoslop Roofkheang mengNo ratings yet

- Learn LUSAS SimplyDocument2 pagesLearn LUSAS Simplykheang mengNo ratings yet

- Steel Hauch Connection A4Document15 pagesSteel Hauch Connection A4kheang mengNo ratings yet

- Test1 DrawingDocument1 pageTest1 Drawingkheang mengNo ratings yet

- FTDoc5 ndc03Document2 pagesFTDoc5 ndc03kheang mengNo ratings yet

- Asphaltic Plug JointDocument8 pagesAsphaltic Plug Jointkheang mengNo ratings yet

- The Structural EngineerDocument44 pagesThe Structural Engineerkheang meng100% (2)

- Double Block and Bleed Valves DesignDocument16 pagesDouble Block and Bleed Valves DesignUncircleDecoderNo ratings yet

- Assignment#1: Construction Materials and Testing, LabDocument7 pagesAssignment#1: Construction Materials and Testing, LabMarvin Lloyd Gonzales TriaNo ratings yet

- 2019 Symposium - Anchorage Zone DesignDocument96 pages2019 Symposium - Anchorage Zone DesignHYUN SUNG KimNo ratings yet

- Yorfk ZF 180 To 300Document7 pagesYorfk ZF 180 To 300Martin BourgonNo ratings yet

- Bolt Torque CalculationDocument3 pagesBolt Torque Calculationshazan100% (1)

- Petroleum Development Oman Construction/Commissioning Punch ListDocument5 pagesPetroleum Development Oman Construction/Commissioning Punch ListMuthu KumaranNo ratings yet

- Bolt Length Calculation: IS 6392-Table 11Document3 pagesBolt Length Calculation: IS 6392-Table 11sumit_b123No ratings yet

- An Introduction To Thermosetting Plastics, Its Manufacturing Processes and ApplicationsDocument2 pagesAn Introduction To Thermosetting Plastics, Its Manufacturing Processes and ApplicationsvijayakumarNo ratings yet

- MC - 17 Apr 2018Document46 pagesMC - 17 Apr 2018maizansofiaNo ratings yet

- Programme of Works 2008-2009Document189 pagesProgramme of Works 2008-2009rbr100% (2)

- Bamboo As A Sustainable And Versatile Building MaterialDocument17 pagesBamboo As A Sustainable And Versatile Building Materialmegha projectsNo ratings yet

- Al Waha Marbles Factory LLC-4Document25 pagesAl Waha Marbles Factory LLC-4october87No ratings yet

- Earthquake Loads NSCP 2015Document10 pagesEarthquake Loads NSCP 2015Franklyn Genove33% (3)

- Rashtrapati Bhavan's History and ArchitectureDocument34 pagesRashtrapati Bhavan's History and ArchitecturePrerna AggarwalNo ratings yet

- Reinforced Concrete Beam: Tank SupportDocument3 pagesReinforced Concrete Beam: Tank SupportMatiur Rahman BasumNo ratings yet

- Data Point Summary For Building Management SystemDocument3 pagesData Point Summary For Building Management SystemBasil Oguaka100% (1)

- Electrical Engineer ResumeDocument5 pagesElectrical Engineer ResumeTitus ThankachanNo ratings yet

- Hyundai R140W-9 Hydraulic SystemDocument33 pagesHyundai R140W-9 Hydraulic SystemHai VanNo ratings yet

- Climate Cold-2 ...Document14 pagesClimate Cold-2 ...Pooja K A NaikNo ratings yet

- 300.4 Speciality ProductsDocument8 pages300.4 Speciality ProductsHassan GDOURANo ratings yet

- Cylindrical Shell Type StructureDocument12 pagesCylindrical Shell Type StructureSneha NairNo ratings yet

- Electrical Installation and Maintainance: CapsletDocument6 pagesElectrical Installation and Maintainance: CapsletGERRYNo ratings yet

- PD Sheet - M3, M6, M10, M15 Series Plate Heat Exchanger - enDocument8 pagesPD Sheet - M3, M6, M10, M15 Series Plate Heat Exchanger - enJulio Alberto Guerrero EnriquezNo ratings yet

- Quarter 2 Plumbing Activity Sheet Conversions Symbols TestsDocument10 pagesQuarter 2 Plumbing Activity Sheet Conversions Symbols TestsjunielNo ratings yet

- Kerite Engineering Catalog PDFDocument20 pagesKerite Engineering Catalog PDFTIAGO3045No ratings yet

- Torsion Assignments Prep Sheets - 2023Document2 pagesTorsion Assignments Prep Sheets - 2023Mwizukanji NakambaNo ratings yet

- Digital Museum - General Information and Description of The Project and Architect - PRESS RELEASEDocument3 pagesDigital Museum - General Information and Description of The Project and Architect - PRESS RELEASEClaudiu IonescuNo ratings yet

- F1472 1479757-1Document5 pagesF1472 1479757-1Thaweekarn Changthong100% (1)

- Pipe SpecificationsDocument5 pagesPipe Specificationsbabar.muetNo ratings yet

- PCAB List of Licensed Contractors For CFY 2016-2017 As of 08 Sep 2016 PDFDocument531 pagesPCAB List of Licensed Contractors For CFY 2016-2017 As of 08 Sep 2016 PDFMenkar Construction Supplies TradingNo ratings yet