Professional Documents

Culture Documents

RA-GL-HAL-PPS-406 (Environment)

Uploaded by

BalasubramanianCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RA-GL-HAL-PPS-406 (Environment)

Uploaded by

BalasubramanianCopyright:

Available Formats

RISK ASSESSMENT

Title: HALLIBURTON MANAGEMENT SYSTEM

PPS - Environment DOCUMENT NUMBER:

REGION: FUNCTION/PSL:

Global Pipeline & Process Services

RA-GL-HAL-PPS-406

OWNER: APPROVED BY: REVISION BY: REV. DATE: REV. NO: PAGE:

PPS Product Manager GPASQM Robert Davidson 23 AUG 2019 2.0 1 of 4

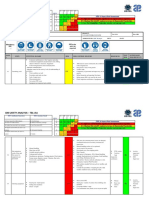

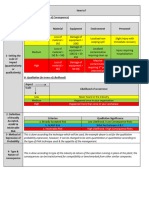

RISK ANALYSIS MATRIX

Potential Consequences Probability Rating

Hazard Personal B E

Descriptive Equipment Environmental A C D F

Severity Illness/ Reasonably Extremely

Word Loss(s) (Any incident that…) Frequent Occasional Remote Impossible

Category Injury Probable Improbable

Fatal or

Potentially harms or adversely affects the general public and has the

permanent

I Catastrophic

disabling injury or

>$1,000,000 potential for widespread public concern of Halliburton operations. 1 1 1 2 3 3

Can have serious economic liability on the operation.

illness

$200,000

Severe Injury or Potentially harms or adversely affects trained employees and the

II Critical

illness

to

environment. Requires specialised expertise or resources for correction. 1 1 2 3 3 3

$1,000,000

>$10,000

Minor Injury or Presents limited harm to the environment and requires general expertise

III Marginal

Illness

to

and resources for correction 2 2 3 3 3 3

$200,000

Presents limited harm to the environment and requires minor corrective

IV Negligible No Injury or Illness <$10,000

actions (CPI). 3 3 3 3 3 3

PROBABILITY RATING RISK PRIORITY CODE (RPC)

LEVEL DESCRIPTION CODE ACTION REQUIRED

JOB INFORMATION AND SUPERVISORY COMPLIANCE SIGNATURE A. FREQUENT: Likely to occur repeatedly 1. HIGH RISK: Imperative to suppress

during activity/operation. risk to lower level.

CLIENT JOB DETAILS LOCATION

B. REASONABLY PROBABLE: Likely to 2. MEDIUM RISK: Operations may

occur several times. require waiver endorsed by

C. OCCASIONAL: Likely to occur management.

SUPERVISOR / ENGINEER RESPONSIBLE FOR REVIEWING THE RISK ASSESSMENT WITH HIS CREW sometime. 3. OPERATION PERMISSIBLE:

D. REMOTE: Not likely but possible. Note: Risk priority code of less than 3 is

NAME (PRINT) SIGNATURE JOB POSITION DATE E. EXTREMELY IMPROBABLE: NOT ACCEPTABLE for hazards that target

Probability of occurrence cannot be personnel

distinguished from zero.

NOTE :

The supervisor will review the Risk Assessment, making additions and amendments as

necessary. The supervisor should initial the acceptable residual Risk column for each task. The

remainder of the HPPS crew should sign the Pipeline Toolbox Talk Checklist FO-GL-HAL-PPS-

403 to acknowledge that they have been involved in the risk assessment review of the job.

TARGETS: P – PEOPLE E – EQUIPMENT ENV – ENVIRONMENTAL DT – DOWNTIME M – MATERIALS

RISK ASSESSMENT

Title: HALLIBURTON MANAGEMENT SYSTEM

PPS - Environment DOCUMENT NUMBER:

REGION: FUNCTION/PSL:

Global Pipeline & Process Services

RA-GL-HAL-PPS-406

OWNER: APPROVED BY: REVISION BY: REV. DATE: REV. NO: PAGE:

PPS Product Manager GPASQM Robert Davidson 23 AUG 2019 2.0 2 of 4

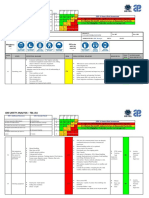

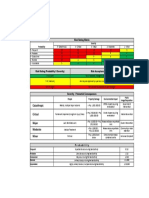

INITIAL RISK RESIDUAL RISK

Remarks RISK REDUCTION CONTROL MEASURES

ALL PERSONNEL HAVE THE AUTHORITY AND RESPONSIBILITY TO Note 1: Personnel need to be aware of and have completed all mandatory

HSE training and taken precautions against, the following hazards

STOP A JOB IF THEY ARE CONCERNED ABOUT THE SAFETY OF P which may be applicable to all steps of the task. P

THE S

R Manual Handling / Working at Height / Dropped Objects

S

R A

C

T O O

E E C

A B B

OPERATION. V

A R Note 2: Personnel need to wear the appropriate PPE for the task at all times V

A

R E

R E E P P

HAZARD EFFECT G B P B

R R C T

I C Note 3: All relevant permits to be in place prior to an operation commencing. I

E I I A

ENVIRONMENTAL ASPECT T

L

T

L

B

T I I

& IMPACT Y Y L

T Note 4: Hold a Toolbox Talk and Risk Assessment Review T

E

TASK HAZARD Y Y

Note 5. Adherence to all QHSE Policies, Standards and Procedures (Gold,

Silver, Life Rules and CFA).

Ensure that all crew read, understand and comply with the Risk

Reduction Control measures, Notes 1 to 5 above

All personnel to be trained and competent in the work task being

performed

Dropped Objects Carry out on-site review of risk assessment and sign off as acceptable.

Working at Height Barrier off worksite with tape/chain and warning signs as/if required.

Proximity to other Tannoy / loudspeaker / radio announcements to be made and clear all

work parties non- essential personnel from job site as/if required

Poor work location Raise awareness of adjacent work to all relevant parties

Slips, Trips and Personnel Injury / Assess floor, deck, ladder, scaffold conditions for grip.

Falls Fatality P Assess deck weight limitations and area for positioning equipment.

General I E 3

Operational Control Damage to Plant / E I D 2 Only certified lifting equipment to be used.

Poor Equipment Env Tools/equipment, i.e. spanners with the potential to fall to be secured by

Communication Environmental impact restraining device to appropriate location with e.g. lanyard, rope

Severe weather Certified scaffold, kick boards and ladders to be used when accessing

(high winds, heat, areas at height.

humidity etc.) Maintain 3 points of contact when accessing ladders (e.g. do not hand

Use of Tools carry tools up ladders)

Lifting and Housting Maintain good housekeeping standards throughout the job

Clean up any spills immediately and follow safety data sheets at all times

Store waste material in a secure container or use a suitable cover on the

ground when working on grating or open hatches.

Discuss with client to arrange any alterations to plant / worksite

TARGETS: P – PEOPLE E – EQUIPMENT ENV – ENVIRONMENTAL DT – DOWNTIME M – MATERIALS

RISK ASSESSMENT

Title:

HALLIBURTON MANAGEMENT SYSTEM

PPS - Environment DOCUMENT NUMBER:

REGION: FUNCTION/PSL:

Global Pipeline & Process Services

RA-GL-HAL-PPS-406

OWNER: APPROVED BY: REVISION BY: REV. DATE: REV. NO: PAGE:

PPS Product Manager GPASQM Robert Davidson 23 AUG 2019 2.0 3 of 4

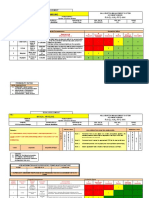

INITIAL RISK RESIDUAL RISK

TASK HAZARD HAZARD EFFECT

RISK REDUCTION CONTROL MEASURES

ENVIRONMENTAL ASPECT & T S P R S P R A

IMPACT

Where possible tie into installation/site shut down systems

Isolate the system once the announcement is made

Make sure the valves opened to the system are in closed position

GPA or any Panic Make sure no other personnel enters into the restricted area

Equipment not P

other Equipment and plant If it is known that there is a planned alarm drill, ensure personnel are

isolated E II B 1 II D 3

emergency damage aware and prepared

alarm Follow up to the muster point

Personnel to remain calm and follow Emergency procedure

Halliburton supervisor to make sure that all the personnel attended to the

muster point location

Over filling of fuel Personal injury P II C 2 Highlight chemicals in crew TBT II D 3

tanks, drums and Chemical burns Env Level indicators on fuel tanks.

containers/tanks. Damage to Auto cut off fuel filling nozzle.

Leaking fuel pipes. environment. Vigilance during filling operations.

Damaged hoses (unintended Regular maintenance/ inspection of fuel lines.

Spill of chemicals discharge to ground Install bunding/drip trays where required.

Fuel tank split or sea) Pre-start checks.

Environmental

Spill kits

precautions

Appropriate PPE.

Barrier creams to be available.

Emergency shower.

SDS / COSHH (if applicable) available for precautionary measures to be

taken.

Spillages to be cleaned up immediately.

Use of PON 15 C compliant chemicals used.(if applicable)

TARGETS: P – PEOPLE E – EQUIPMENT ENV – ENVIRONMENTAL DT – DOWNTIME M – MATERIALS

RISK ASSESSMENT

Title:

HALLIBURTON MANAGEMENT SYSTEM

PPS - Environment DOCUMENT NUMBER:

REGION: FUNCTION/PSL:

Global Pipeline & Process Services

RA-GL-HAL-PPS-406

OWNER: APPROVED BY: REVISION BY: REV. DATE: REV. NO: PAGE:

PPS Product Manager GPASQM Robert Davidson 23 AUG 2019 2.0 4 of 4

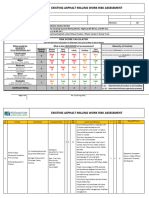

INITIAL RISK RESIDUAL RISK

TASK HAZARD HAZARD EFFECT

RISK REDUCTION CONTROL MEASURES

ENVIRONMENTAL ASPECT & T S P R S P R A

IMPACT

REVIEW THE RISK ASSESSMENT AND IDENTIFY ANY ADDITIONAL HAZARDS & CONTROL MEASURES IN THIS SECTION FOR THE SPECIFIC TASK TO BE CARRIED OUT.

THE HAZARD CHECKLIST BELOW CAN BE USED AS A PROMPT.

HAZARD CHECKLIST

1. CHEMICALS 5. CONFINED SPACES 9. SLIPS, TRIPS, FALLS 13. MECHANICAL LIFTING 17. STORED ENERGY 21. LIGHTING 25. RADIATION

2. ASPHYXIANTS 6. EXCAVATIONS 10. MANUAL HANDLING 14. OPERATION OF VEHICLES 18. IGNITION SOURCES 22. HOT/COLD SURFACE 26. SIMOPS

3. DROWNING 7. HEIGHT 11. INCORRECT POSTURE 15. HAND TOOLS 19. EXPLOSION 23. NOISE 27. WEATHER

4. BIOLOGICAL AGENTS 8. DROPPED OBJECTS 12. USE OF EQUIPMENT 16. PRESSURE 20. ELECTRICITY 24. VIBRATION 28. RELEASE TO ENVIRONMENT

TARGETS: P – PEOPLE E – EQUIPMENT ENV – ENVIRONMENTAL DT – DOWNTIME M – MATERIALS

You might also like

- 004-JSA Manual WeldingDocument6 pages004-JSA Manual WeldingMoaatazz NouisriNo ratings yet

- Risk Assessment For BridgeDocument31 pagesRisk Assessment For BridgeMariam Mousa100% (2)

- RA For ExcavationDocument7 pagesRA For ExcavationpoovazhaganNo ratings yet

- RISK ASSESSMENT CONTROL SHEET j80Document21 pagesRISK ASSESSMENT CONTROL SHEET j80SaberNo ratings yet

- Risk Assessment For Sheet PilingDocument33 pagesRisk Assessment For Sheet Pilingsajin75% (24)

- 005-JSA X-Ray & Gamma Ray RadiographyDocument7 pages005-JSA X-Ray & Gamma Ray RadiographyMoaatazz NouisriNo ratings yet

- RA - Fire Alarm SystemDocument12 pagesRA - Fire Alarm Systemvelangi rajuNo ratings yet

- JSA - RA 000-Water ProofingDocument5 pagesJSA - RA 000-Water ProofingNAGARJUNA100% (1)

- Jha RebarsDocument7 pagesJha RebarsJaycee QuinNo ratings yet

- Job Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentDocument4 pagesJob Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentMoaatazz NouisriNo ratings yet

- ISK Valuation Atrix: Exposure Factor Level 1 Level 2 Level 3 Level 4Document1 pageISK Valuation Atrix: Exposure Factor Level 1 Level 2 Level 3 Level 4dnmuleNo ratings yet

- DRRM-H Planning With SampleDocument51 pagesDRRM-H Planning With SampleHerbert Dumaoal92% (25)

- Risk AssessmentDocument5 pagesRisk Assessmentsudeesh kumar100% (1)

- Risk Assessment of Cable Tray InstallationDocument10 pagesRisk Assessment of Cable Tray Installationfayaz fayazhotmail.comNo ratings yet

- 003-JSA Pipe Loading and OffloadingDocument8 pages003-JSA Pipe Loading and OffloadingMoaatazz NouisriNo ratings yet

- Marine Ecosystem Restoration and Biodiversity OffsetDocument10 pagesMarine Ecosystem Restoration and Biodiversity OffsetMiriam TorresNo ratings yet

- #404 Emergency Fire Pump Maintenance (Revised)Document4 pages#404 Emergency Fire Pump Maintenance (Revised)Tolias EgwNo ratings yet

- 10 JSA - Cable Drums InstallationsDocument6 pages10 JSA - Cable Drums Installationssyed khaja misbhuddinNo ratings yet

- Activity Being Assessed: Risk Assessment For Skate Park ConstructionDocument9 pagesActivity Being Assessed: Risk Assessment For Skate Park ConstructionTerence Tsam0% (1)

- 04 JSA - Welding WorksDocument6 pages04 JSA - Welding Workssyed khaja misbhuddinNo ratings yet

- 1-Risk Assessment For Hot Work ParmitDocument4 pages1-Risk Assessment For Hot Work Parmitsudeesh kumarNo ratings yet

- YR7 Revision Sheet - Working ScietificallyDocument6 pagesYR7 Revision Sheet - Working ScietificallyNisha zehra100% (1)

- Rail Generic Risk Assessments V8 2014Document10 pagesRail Generic Risk Assessments V8 2014SbitNo ratings yet

- Final Exam in DRRR 2020Document4 pagesFinal Exam in DRRR 2020Ryan San LuisNo ratings yet

- On Disaster Readiness & Risk Reduction - First Quarter: Table of Specification For A 50 - Item TestDocument4 pagesOn Disaster Readiness & Risk Reduction - First Quarter: Table of Specification For A 50 - Item TestLiezel CauilanNo ratings yet

- DRRR Mid Term Exam 2018Document4 pagesDRRR Mid Term Exam 2018Ryan Negad100% (27)

- Jsa Trial Run of DGDocument3 pagesJsa Trial Run of DGDwitikrushna RoutNo ratings yet

- Unified Schools of The Archdiocese of Lipa: Table of Specification For A 40 - Item TestDocument4 pagesUnified Schools of The Archdiocese of Lipa: Table of Specification For A 40 - Item TestJohn Kevin NocheNo ratings yet

- RA GL HAL PPS 404 (Dewatering)Document6 pagesRA GL HAL PPS 404 (Dewatering)BalasubramanianNo ratings yet

- RA-GL-HAL-PPS-442 (Air Pigging)Document5 pagesRA-GL-HAL-PPS-442 (Air Pigging)BalasubramanianNo ratings yet

- RA-GL-HAL-PPS-444 (Manual Handling)Document7 pagesRA-GL-HAL-PPS-444 (Manual Handling)BalasubramanianNo ratings yet

- RA-GL-HAL-PPS-445 (Working at Height)Document5 pagesRA-GL-HAL-PPS-445 (Working at Height)BalasubramanianNo ratings yet

- 01 JSA - Material ShiftingDocument5 pages01 JSA - Material Shiftingsyed khaja misbhuddinNo ratings yet

- IRON ORE Risk AssessmentDocument5 pagesIRON ORE Risk AssessmentMamunNo ratings yet

- BUNKERING Risk AssessmentDocument3 pagesBUNKERING Risk Assessmentobikaka333No ratings yet

- Civil Works - Building Painting WorksDocument3 pagesCivil Works - Building Painting Worksfairoos aliNo ratings yet

- On Disaster Readiness & Risk Reduction - Third QuarterDocument5 pagesOn Disaster Readiness & Risk Reduction - Third QuarterMaricar Tan ArtuzNo ratings yet

- RA Existing Asphalt Milling WorksDocument8 pagesRA Existing Asphalt Milling WorksSolimanNo ratings yet

- Eepsp Ra Swro 003 - 00aDocument9 pagesEepsp Ra Swro 003 - 00afayaz5233No ratings yet

- Final Exam in DRRR 2020Document4 pagesFinal Exam in DRRR 2020ryan erwin san luisNo ratings yet

- MKT-PK3-01-01 Identifikasi, Penilaian & Pengendalian RisikoDocument3 pagesMKT-PK3-01-01 Identifikasi, Penilaian & Pengendalian RisikoDania RachmawatiNo ratings yet

- (Hari 8) Risk MatriksDocument1 page(Hari 8) Risk MatrikslubangjarumNo ratings yet

- Hira For DemolitionDocument3 pagesHira For DemolitionMokka SamaiyalNo ratings yet

- 004-RA-Installation of Steel Structure by Using CraneDocument11 pages004-RA-Installation of Steel Structure by Using Cranehussein aliNo ratings yet

- Defining Risk CriteriaDocument1 pageDefining Risk CriteriaheropokerusNo ratings yet

- RA 002forklift OperationsDocument9 pagesRA 002forklift Operationsamrismail2012No ratings yet

- Biis-Sf-03-Risk Assessment Form-GeneratorDocument3 pagesBiis-Sf-03-Risk Assessment Form-GeneratorBIIS QAQC Babu SivaNo ratings yet

- Catasthropic Critical Major Moderate Minor: Severity ProbabilityDocument1 pageCatasthropic Critical Major Moderate Minor: Severity ProbabilityArjay LauretaNo ratings yet

- IMSP 6.1.2 Risk MatrixDocument12 pagesIMSP 6.1.2 Risk MatrixMichael RujuwaNo ratings yet

- RA Site EstablishmentDocument4 pagesRA Site EstablishmentAndrewNo ratings yet

- Finance Risk Assessment of CCSU ProjectDocument10 pagesFinance Risk Assessment of CCSU ProjectNavya RaturiNo ratings yet

- Db Shr 010 전사 안전보건방침Document2 pagesDb Shr 010 전사 안전보건방침Tigor GurningNo ratings yet

- KP Incident Log Hva 3.0!6!2020 TemplateDocument23 pagesKP Incident Log Hva 3.0!6!2020 TemplaterubertusedyNo ratings yet

- Emergency Response Plan GuideDocument12 pagesEmergency Response Plan GuideDave DohaNo ratings yet

- Risk RegisterDocument3 pagesRisk Registerjojomalik2010No ratings yet

- HSE Severity TableDocument1 pageHSE Severity TableMohamed HadjkacemNo ratings yet

- 1.12 Installation of Anodes in W.B.T.Document5 pages1.12 Installation of Anodes in W.B.T.Jefrey JucabanNo ratings yet

- Env Aspects-Impact Register ExampleDocument8 pagesEnv Aspects-Impact Register ExampleBryanNo ratings yet

- 1.15 Visual Inspection of AptDocument3 pages1.15 Visual Inspection of AptJefrey JucabanNo ratings yet

- IM-08-B EHS Risk Assessment DC WorkDocument4 pagesIM-08-B EHS Risk Assessment DC WorkAndrés PacompíaNo ratings yet

- Turn Down the Heat: Climate Extremes, Regional Impacts, and the Case for ResilienceFrom EverandTurn Down the Heat: Climate Extremes, Regional Impacts, and the Case for ResilienceNo ratings yet

- LEPTOSPIRADocument31 pagesLEPTOSPIRADinar NastitiNo ratings yet

- Effect of Childhood Adversity On Brain Dopamine Function in Adulthood !Document2 pagesEffect of Childhood Adversity On Brain Dopamine Function in Adulthood !Aaron AdamsNo ratings yet

- 1 Laddawan JEMES Checked by Issara 13 07 21Document18 pages1 Laddawan JEMES Checked by Issara 13 07 21trader123No ratings yet

- Abstract On Face Recognition TechnologyDocument1 pageAbstract On Face Recognition TechnologyParas Pareek60% (5)

- Various Executions MA: Series Foodstuffs ExecutionDocument17 pagesVarious Executions MA: Series Foodstuffs ExecutionKyriakos MichalakiNo ratings yet

- A Peer Reviewed Research Journal On Language, Literature & Culture'sDocument8 pagesA Peer Reviewed Research Journal On Language, Literature & Culture'sTRISANGAM INTERNATIONAL REFEREED JOURNAL (TIRJ) EDITOR - MR. PRASENJIT ROYNo ratings yet

- Ministry of Health and Family Welfare Pregnancy GuidelinesDocument173 pagesMinistry of Health and Family Welfare Pregnancy GuidelinesKhushi GuptaNo ratings yet

- Case StudyDocument11 pagesCase StudyCyril CauilanNo ratings yet

- Philippine College of Science and Technology: Assignment For Module 1 Nge6 (Art Appreciation)Document1 pagePhilippine College of Science and Technology: Assignment For Module 1 Nge6 (Art Appreciation)Mark Brendon Jess VargasNo ratings yet

- Reduced Adjective ClausesDocument1 pageReduced Adjective Clausesmetoeflgrammar100% (1)

- Academic Calendar - ARUDocument5 pagesAcademic Calendar - ARUEmmanuella NnodimNo ratings yet

- Admission Notification 2024-2025Document12 pagesAdmission Notification 2024-2025jsbska88No ratings yet

- Presentation by SHIVAM SHAHDocument23 pagesPresentation by SHIVAM SHAHmikojiNo ratings yet

- ITEM ANALYSIS - MATH 9 EmeraldDocument5 pagesITEM ANALYSIS - MATH 9 EmeraldLiz Rabaya IntiaNo ratings yet

- CRE Chapter 5 (Solutions)Document8 pagesCRE Chapter 5 (Solutions)Bella HannaNo ratings yet

- CSC-160 Series Numerical Line Protection EquipmentDocument112 pagesCSC-160 Series Numerical Line Protection EquipmentMarkusKunNo ratings yet

- Astm D2777 Determinacion de La Precision y El Sesgo PDFDocument21 pagesAstm D2777 Determinacion de La Precision y El Sesgo PDFAlvaro Pérez PérezNo ratings yet

- Alexander Lowen - The Language of The Body (Physical Dynamics of Character Structure) (1958, Psychology, Freud)Document404 pagesAlexander Lowen - The Language of The Body (Physical Dynamics of Character Structure) (1958, Psychology, Freud)Barbara Kubiec75% (4)

- Geography Worksheet 1 Rural SettlementsDocument14 pagesGeography Worksheet 1 Rural SettlementsLelethuNo ratings yet

- P, PI and PID ControlDocument3 pagesP, PI and PID ControlsivaNo ratings yet

- Mechanical Properties of SolidsDocument7 pagesMechanical Properties of SolidsStudent RequestNo ratings yet

- (IMP) Ancient Indian JurisprudenceDocument28 pages(IMP) Ancient Indian JurisprudenceSuraj AgarwalNo ratings yet

- Mai 4.9 Discrete DistributionsDocument16 pagesMai 4.9 Discrete DistributionsAvatNo ratings yet

- Bump Grade Force On Wire Student-1Document3 pagesBump Grade Force On Wire Student-1Benjamin WatsonNo ratings yet

- Intro To Bifurcation TheoryDocument47 pagesIntro To Bifurcation TheoryJohn StarrettNo ratings yet

- Wre MCQDocument136 pagesWre MCQsurendranath jadhavNo ratings yet

- English Solved SP3Document6 pagesEnglish Solved SP3Prem PatelNo ratings yet

- Đề Trung Học Thực Hành Đại Học Sư Phạm 2020-2021Document8 pagesĐề Trung Học Thực Hành Đại Học Sư Phạm 2020-2021Chi Vũ LinhNo ratings yet