Professional Documents

Culture Documents

1.12 Installation of Anodes in W.B.T.

Uploaded by

Jefrey JucabanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.12 Installation of Anodes in W.B.T.

Uploaded by

Jefrey JucabanCopyright:

Available Formats

Risk Assessment & Risk Management Manual

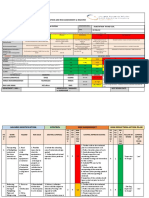

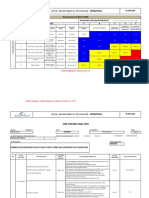

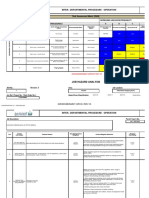

RA 001 RISK ANALYSIS / RISK ASSESSMENT (RISK MATRIX WORK SHEET)

RISK MANAGEMENT Risk Assessment Conditions

Operation / Work activity being INSTALLATION OF ANODES IN W.B.T.

assessed: Work Authorization Work has been authorized Y N

Routine Non-routine No Fatigue Staff is adequately rested Y N

Generated by: Vessel (record the name) Office Use of proper PPE Staff is using proper PPE Y N

Code number (to be assigned by the Office): 1.12 Rev.00 Experienced staff Staff has task experience Y N

FREQUENCY CATEGORY CONSEQUENCE CATEGORY RISK MATRIX

5 Frequent - Possibility of More often than Major

repeated incidents once per voyage Human losses Major pollution / Excessive/ high cost national &

4 / fatalities Full scale response damage >$1000000 international FREQUENCY

impact

4 Probable - Possibility of Once per year

Moderate pollution/

Moderate cost or

isolated incidents Serious injury damage Considera

3 to personnel

Significant resources

(100000 – ble impact

1 2 3 4 5

commitment

1000000$)

3 Occasional- Possibility of Once per 5 Number of

Little cost or

occurring sometime years minor injuries / Little pollution / 1 L (1) L (2) L (3) M (4) M (5)

CONSEQUENCE

damage Slight

2 Medical Limited response of

($10000 – $ impact

treatment for short duration 2 L (2) M (4) M (6) M (8) H (10)

100000)

personnel

2 Remote- Not likely to Once per 10 Minimum pollution / Minimum cost /

occur years Few minor Zero 3 L (3) M (6) M (9) H (12) H (15)

1 Little or no response damage

1 Very unlikely- Practically Once per 30 injuries < $10000 impact

needed 4

impossible years or more M (4) M (8) H (12) H (16) H (20)

High=Intolerable Risk Medium=Tolerable Risk Low=Negligible Risk

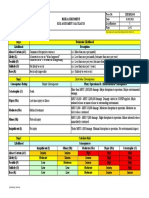

Risk Assessment

Risk Identification Risk Analysis Initial risk

evaluation

Potential

No Hazard Existing control measures F C R

hazardous event

1 Slippery surface. Serious injury to Procedures, PPE, Safety arrangements 4 3 12

personnel

2 Working at a height. Serious injury to Procedures, PPE, Safety arrangements 4 3 12

personnel

Page 1 of 5 Revision No: 00, Date: Dec 2016

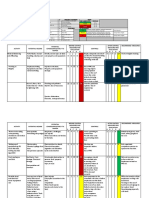

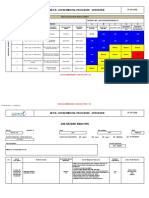

Risk Assessment & Risk Management Manual

RA 001 RISK ANALYSIS / RISK ASSESSMENT (RISK MATRIX WORK SHEET)

Risk Assessment

Risk Identification Risk Analysis Initial risk

evaluation

Potential

No Hazard Existing control measures F C R

hazardous event

3 Lack of oxygen, possible exposure to hazardous Human loss Procedures, PPE, Safety arrangements, Regular 3 4 12

gases. checks on ventilation, Drills

4 Inadequate ventilation. Human loss Procedures, PPE, Safety arrangements 3 4 12

5 Inadequate illumination. Serious injury to Procedures, PPE, Safety arrangements 4 2 8

personnel

6 Adverse weather/sea condition. - Serious injury Procedures, PPE, Safety arrangements 4 3 12

to personnel

- Moderate cost

or damage

7 Inadequate coordination/supervision/communication. - Serious injury Procedures, PPE, Safety arrangements, crew 4 3 12

to personnel familiarisation

- Moderate cost

or damage

8 Lifting/transferring heavy objects (anodes). Human loss Procedures, PPE, Safety arrangements 3 4 12

9 High temperature/humidity in the working area. Serious injury to Procedures, PPE, Safety arrangements 3 3 9

personnel

Note F: Frequency, C: Consequence, R: Risk

ALTERNATIVE WAYS TO CONDUCT THE WORK

NIL

Page 2 of 5 Revision No: 00, Date: Dec 2016

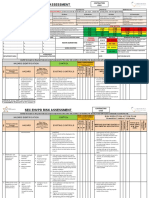

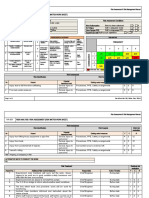

Risk Assessment & Risk Management Manual

RA 001 RISK ANALYSIS / RISK ASSESSMENT (RISK MATRIX WORK SHEET)

Risk Treatment Residual risk

evaluation

Hazard No. Additional Risk Control Measures Responsible Action Timeline F C R

1 Ensure that the working area is clean from mud, water or any C/O Prior to work 2 3 6

other slippery material and free of any obstruction.

2 Any staging to be used should be properly secured. C/O Prior to/during the work 1 2 2

3 At least one member of the work team in the tank should wear a C/O During the work 2 3 6

personal multi-gas detection instrument.

4 Adequate ventilation should be ensured by the use of a portable C/O Prior to/during the work 2 3 6

water-driven fan and flexible air-duct.

5 A. Adequate illumination should be ensured by the use of C/O During the work 1 3 3

portable gastight/Ex lights.

B. Pneumatic gastight turbo lamps or gastight cap lamps to be C/O During the work

used to provide illumination in the area.

6 A. The work should be carried out only in good weather and C/O Prior to the work 2 3 6

sea condition.

B. Weather conditions-forecast to be monitored and in case of OOW During the work

deterioration the Master/Chief Officer should be advised.

7 A. A work planning/safety meeting should be carried out with the Master Prior to the work 1 3 3

participation of all involved personnel with the aim of discussing,

amongst others: (a) job procedure; (b) tool transferring

arrangements; (c) lifting arrangements; (d) safety

procedures/work permits; (e) individual work responsibilities; (f)

means of communication.

B. The Chief Officer should be in charge supervising the job. C/O During the work

C. Bridge OOW should be informed of the C/O Prior to the work

commencement/completion of the work.

D. During the work any operation of the ballast hydraulic valves C/O Prior to/during thework

should be prohibited and a relevant WARNING should be

posted in the CCR.

E. All walkie-talkies to be used should be in good operational C/O Prior to the work

condition and fully charged.

Page 3 of 5 Revision No: 00, Date: Dec 2016

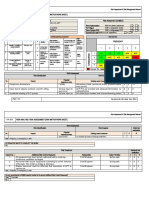

Risk Assessment & Risk Management Manual

RA 001 RISK ANALYSIS / RISK ASSESSMENT (RISK MATRIX WORK SHEET)

8 A. The lifting/transferring/securing procedure to be applied C/O Prior to the work 2 3 6

should be properly planned and communicated to the involved

personnel.

B. Adequate manpower should be ensured for the C/O During the work

transferring/lifting of the anodes.

C. During lifting heavy objects (anodes), all personnel should C/O During the work

keep clear from the “dangerous zone.

D. During lowering/transferring tools in the tank from the tank C/O During the work

hatch, it should be ensured that nobody is underneath.

9 A. Adequate work rest periods should be provided and C/O During the work 1 3 3

precautions against dehydration should be taken.

B. Any involved personnel showing signs of fatigue should be C/O During the work

released from duty and replaced at once.

Note F: Frequency, C: Consequence, R: Risk

Are any amendments to SSMM required (related to the above Additional Risk Control Measures)?

Yes Describe:

No

Contingency plans (to facilitate safe management and recovery of the situation in case of any unplanned occurrences)

Emergency case Contingency Plans

RESCUE FROM REFER TO COMPANY’S EMERGENCY RESPONSE PROCEDURES (RESCUE

ENCLOSED SPACE, FROM ENCLOSED SPACE, SERIOUS INJURY) AND THE COMPANY SHOULD

SERIOUS INJURY BE CONTACTED.

Page 4 of 5 Revision No: 00, Date: Dec 2016

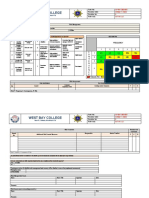

Risk Assessment & Risk Management Manual

RA 001 RISK ANALYSIS / RISK ASSESSMENT (RISK MATRIX WORK SHEET)

Risk Management Team

Name Rank / Title Signature Date

Remarks:

Risk Assessment reviewed/approved by:

Name Rank / Title Signature Date

G.MYLONAS CEO

S.DAFERMOS DPA

Remarks:

Page 5 of 5 Revision No: 00, Date: Dec 2016

You might also like

- Baseline Risk Assessment and Risk Matrix (An Example)Document8 pagesBaseline Risk Assessment and Risk Matrix (An Example)Victor75% (4)

- UG RA 003 - Test Pit Markings and Asphalt CuttingDocument6 pagesUG RA 003 - Test Pit Markings and Asphalt CuttingshamshuddinNo ratings yet

- Risk Assessment 2 PDFDocument15 pagesRisk Assessment 2 PDFarunNo ratings yet

- UG RA 009 - Light Materials and Equipment Loading and UnloadingDocument6 pagesUG RA 009 - Light Materials and Equipment Loading and Unloadingshamshuddin100% (1)

- Electrical Panel MaintenanceDocument3 pagesElectrical Panel MaintenanceNdi Mvogo100% (1)

- Personality Disorders: Paranoid, Schizoid & SchizotypalDocument7 pagesPersonality Disorders: Paranoid, Schizoid & SchizotypalKodhai NarayananNo ratings yet

- UG RA 004 - Test Pit Manual ExcavationDocument5 pagesUG RA 004 - Test Pit Manual ExcavationshamshuddinNo ratings yet

- 014 - Manual HandlingDocument4 pages014 - Manual HandlingPrem ChristianNo ratings yet

- RISK ASSESSMENT AND ANALYSISDocument6 pagesRISK ASSESSMENT AND ANALYSISabhinav dj50% (2)

- HIRA - Fixed Scaffold and Wall BreakingDocument6 pagesHIRA - Fixed Scaffold and Wall BreakingSujan Augustin100% (2)

- HVAC Risk AssesmentDocument8 pagesHVAC Risk Assesmentaaktgt MepNo ratings yet

- Risk Assessment (Installation of Cables & Wires)Document6 pagesRisk Assessment (Installation of Cables & Wires)michael acosta100% (3)

- Project Risk Index for HIRADocument12 pagesProject Risk Index for HIRAKamesh A100% (1)

- UG RA 006 - Installation of Road BarricadesDocument4 pagesUG RA 006 - Installation of Road BarricadesshamshuddinNo ratings yet

- RA For Snake BiteDocument5 pagesRA For Snake Biteshamroz khan100% (1)

- Revised JHA HDDDocument12 pagesRevised JHA HDDHariharan RajaramanNo ratings yet

- Risk Assessment For Sheet PilingDocument33 pagesRisk Assessment For Sheet Pilingsajin75% (24)

- Psychological AssessmentDocument46 pagesPsychological Assessmentyubarajbro9104No ratings yet

- UG RA 005 - Thermal Integrity and Resistivity TestingDocument6 pagesUG RA 005 - Thermal Integrity and Resistivity TestingshamshuddinNo ratings yet

- Fire Alarm System Risk AssessmentDocument13 pagesFire Alarm System Risk AssessmentRais BurondkarNo ratings yet

- ISK Valuation Atrix: Exposure Factor Level 1 Level 2 Level 3 Level 4Document1 pageISK Valuation Atrix: Exposure Factor Level 1 Level 2 Level 3 Level 4dnmuleNo ratings yet

- 2020 - PWC - Global Annual Report PDFDocument59 pages2020 - PWC - Global Annual Report PDFTakis IliopoulosNo ratings yet

- Risk AsseementDocument8 pagesRisk AsseementMajaga MabhenaNo ratings yet

- Ra - Traning CeneterDocument12 pagesRa - Traning CeneterRais BurondkarNo ratings yet

- UG RA 002 - Route SurveyingDocument4 pagesUG RA 002 - Route SurveyingshamshuddinNo ratings yet

- OHS-PR-09-03-F02 HIRA - 004 Soil Investigation For Plain AreaDocument6 pagesOHS-PR-09-03-F02 HIRA - 004 Soil Investigation For Plain AreaJaafar LagayanNo ratings yet

- Risk Assessment For Installation of BMS M Tower PDFDocument15 pagesRisk Assessment For Installation of BMS M Tower PDFAndrew HivNo ratings yet

- UploadDocument7 pagesUploadAlif algifariNo ratings yet

- RA 001 Risk Analysis - Risk AssessementDocument2 pagesRA 001 Risk Analysis - Risk AssessementJoshua Guerrero CaloyongNo ratings yet

- JSA - RA 000-Water ProofingDocument5 pagesJSA - RA 000-Water ProofingNAGARJUNA100% (1)

- ChagTerms TBRA - Fuel Delivery To VSL - SampleDocument21 pagesChagTerms TBRA - Fuel Delivery To VSL - SampleshannonNo ratings yet

- Maslach Burnout Toolkit For Medical Personnel Intro SheetDocument1 pageMaslach Burnout Toolkit For Medical Personnel Intro SheetMyint ZuNo ratings yet

- 6.) Metod Statement For Tie End ConnectionDocument13 pages6.) Metod Statement For Tie End Connectionsandeep reshmaNo ratings yet

- Research Methodology MCQ 180629120038 PDFDocument95 pagesResearch Methodology MCQ 180629120038 PDFbmk2k450% (2)

- Demobilization and Demolition Activies of Porta Cabins and Containers For Laydown AreaDocument10 pagesDemobilization and Demolition Activies of Porta Cabins and Containers For Laydown AreaNasrullahNo ratings yet

- Dehradun Distributor RetailersDocument238 pagesDehradun Distributor RetailersAmit DesaiNo ratings yet

- 29-JHA For Removal of Wooden PalletDocument4 pages29-JHA For Removal of Wooden PalletPradip Kumar ShaNo ratings yet

- Employees ActivitiesDocument2 pagesEmployees ActivitiesLovely De CastroNo ratings yet

- 1.8 Assembling of Fire LineDocument3 pages1.8 Assembling of Fire LineJefrey JucabanNo ratings yet

- 1.15 Visual Inspection of AptDocument3 pages1.15 Visual Inspection of AptJefrey JucabanNo ratings yet

- 1.16 Visual Inspection of FPTDocument3 pages1.16 Visual Inspection of FPTJefrey JucabanNo ratings yet

- 1.13 Installation of New Piping On DeckDocument3 pages1.13 Installation of New Piping On DeckJefrey JucabanNo ratings yet

- 1.17 Winch Brake TestDocument4 pages1.17 Winch Brake TestJefrey JucabanNo ratings yet

- 1.10 Hot Work On Main Deck PlatingDocument3 pages1.10 Hot Work On Main Deck PlatingJefrey JucabanNo ratings yet

- 1.9 Ballast Line Repairs Crew Exposure To Chemical MaterialsDocument3 pages1.9 Ballast Line Repairs Crew Exposure To Chemical MaterialsJefrey JucabanNo ratings yet

- 1.14 Routine Maintenance On Deck in Hot Climate (Sun Light Exposure)Document4 pages1.14 Routine Maintenance On Deck in Hot Climate (Sun Light Exposure)Jefrey JucabanNo ratings yet

- Olifantsvlei: General Site Operations - Flame CuttingDocument4 pagesOlifantsvlei: General Site Operations - Flame CuttinggrantNo ratings yet

- RISK ASSESSMENT FOR 11 KV Auto Recloser Installation Updated 31-08-2019Document10 pagesRISK ASSESSMENT FOR 11 KV Auto Recloser Installation Updated 31-08-2019Musthafa ShaikNo ratings yet

- RA-GL-HAL-PPS-444 (Manual Handling)Document7 pagesRA-GL-HAL-PPS-444 (Manual Handling)BalasubramanianNo ratings yet

- RA-GL-HAL-PPS-445 (Working at Height)Document5 pagesRA-GL-HAL-PPS-445 (Working at Height)BalasubramanianNo ratings yet

- Road ReinstatementDocument4 pagesRoad ReinstatementBishop Ojonuguwa AmehNo ratings yet

- Monsoon SeasonDocument4 pagesMonsoon SeasonSARFARAJ AHMADNo ratings yet

- Fahm-Electrical JhaDocument6 pagesFahm-Electrical Jhaindiasingapore9No ratings yet

- Approved Risk Assessment & Risk RegisterDocument53 pagesApproved Risk Assessment & Risk RegisterAhmed RedaNo ratings yet

- 27.JHA For Collection and Disposal of Used Air Filter and Electronic WasteDocument4 pages27.JHA For Collection and Disposal of Used Air Filter and Electronic WastePradip Kumar ShaNo ratings yet

- Inter - Departmental Procedure Operation: IP-OPS-066Document10 pagesInter - Departmental Procedure Operation: IP-OPS-066AnuradheNo ratings yet

- Hemp R&BDocument139 pagesHemp R&BBalasubramaniamkamarajNo ratings yet

- QP Guideline For Hazid Review: Doc File No.: GDL-S-040 R1 Page 22 of 27 Custodian Dept: STDocument1 pageQP Guideline For Hazid Review: Doc File No.: GDL-S-040 R1 Page 22 of 27 Custodian Dept: STsanjayNo ratings yet

- Jha - Wheel & Tire Removal and Repair ActivityDocument7 pagesJha - Wheel & Tire Removal and Repair ActivityPradip Kumar ShaNo ratings yet

- RA Site EstablishmentDocument4 pagesRA Site EstablishmentAndrewNo ratings yet

- Ra-Me-02 - Fire Fighting SystemDocument13 pagesRa-Me-02 - Fire Fighting Systemasamrat582No ratings yet

- 20161104-NW SHEF RA Boxing of Swordfish wings (1)Document4 pages20161104-NW SHEF RA Boxing of Swordfish wings (1)mark.wilsonNo ratings yet

- 030 - Moving Machineries in Site PremisesDocument6 pages030 - Moving Machineries in Site PremisesPrem ChristianNo ratings yet

- Risk Assessment Manhole CleaningDocument9 pagesRisk Assessment Manhole CleaningShah MuzzamilNo ratings yet

- 05. HIRA-Shaft Cable Tray N Cable InstallationDocument2 pages05. HIRA-Shaft Cable Tray N Cable InstallationDivakar DhandeNo ratings yet

- Perlin IDocument544 pagesPerlin IbalasubramaniamNo ratings yet

- Determine Consequence People ConsequenceDocument1 pageDetermine Consequence People ConsequenceAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- WRITTEN REPORT Guidance and CounselingDocument5 pagesWRITTEN REPORT Guidance and CounselingJohairah MolantaNo ratings yet

- Hilti Firestop Submittal - Balamand UniversityDocument32 pagesHilti Firestop Submittal - Balamand UniversitybasbousrNo ratings yet

- 2019 Clinical Performance of Direct Anterior Composite Restorations A Systematic Literature Review and Critical AppraisalDocument19 pages2019 Clinical Performance of Direct Anterior Composite Restorations A Systematic Literature Review and Critical Appraisalmaroun ghalebNo ratings yet

- Seminar ReportDocument31 pagesSeminar ReportBitNo ratings yet

- PSY632 Assign Solution 1Document3 pagesPSY632 Assign Solution 1safoora ilyasNo ratings yet

- Courses Offered in NursingDocument7 pagesCourses Offered in NursingNorhanie AliNo ratings yet

- Kahel: Dishwashing Liquid From Orange PeelingsDocument16 pagesKahel: Dishwashing Liquid From Orange PeelingsRussel AloceljaNo ratings yet

- ARH Report Format Adolescent Reproductive Health (ARH) Action PlanDocument3 pagesARH Report Format Adolescent Reproductive Health (ARH) Action PlanRona Ellein GaloNo ratings yet

- Adult AdhdDocument10 pagesAdult AdhdJose SilvaNo ratings yet

- Is.4544.2000 0Document17 pagesIs.4544.2000 0Davorin IvićNo ratings yet

- Assessing The Nose and SinusesDocument5 pagesAssessing The Nose and SinusesYudi TrigunaNo ratings yet

- Comparative Efficacy of Amoxicillin Clavulanate and Clindamycin in Management of Resistant Orofacial Infection. Randomized Clinical TrialDocument7 pagesComparative Efficacy of Amoxicillin Clavulanate and Clindamycin in Management of Resistant Orofacial Infection. Randomized Clinical TrialInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Demographic segmentation of illegal drug addictionDocument6 pagesDemographic segmentation of illegal drug addictionALLIA LOPEZNo ratings yet

- Tataamalan HIRARC 2020Document42 pagesTataamalan HIRARC 2020Khaty JahNo ratings yet

- 1 - Woodbine DRF BetsDocument19 pages1 - Woodbine DRF BetsCristian HernandezNo ratings yet

- DSE Biology - Structured Questions on Human GrowthDocument6 pagesDSE Biology - Structured Questions on Human GrowthEmily LiNo ratings yet

- Final Health Assessment Study GuideDocument11 pagesFinal Health Assessment Study Guideflynnc1No ratings yet

- Psychological Theories of Crime ChartDocument1 pagePsychological Theories of Crime ChartTayyaba HafeezNo ratings yet

- Attention, Distraction, and Cognitive Control Under LoadDocument7 pagesAttention, Distraction, and Cognitive Control Under LoadJosé GresalNo ratings yet

- Open Chest WoundDocument17 pagesOpen Chest WoundDael GerongNo ratings yet

- Dialog Patient AdmissionDocument3 pagesDialog Patient AdmissionYunita TriscaNo ratings yet

- Coping Mechanism of Grade 12 Students of Birbira High School On The Face-To-FaceDocument25 pagesCoping Mechanism of Grade 12 Students of Birbira High School On The Face-To-FaceaiyahnuevaNo ratings yet