Professional Documents

Culture Documents

1.13 Installation of New Piping On Deck

Uploaded by

Jefrey JucabanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.13 Installation of New Piping On Deck

Uploaded by

Jefrey JucabanCopyright:

Available Formats

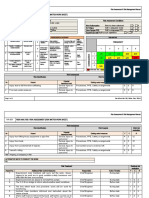

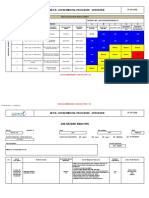

Risk Assessment & Risk Management Manual

RA 001 RISK ANALYSIS / RISK ASSESSMENT (RISK MATRIX WORK SHEET)

RISK MANAGEMENT Risk Assessment Conditions

Operation / Work activity being INSTALLATION OF NEW PIPING ON DECK

assessed: Work Authorization Work has been authorized Y N

Routine Non-routine No Fatigue Staff is adequately rested Y N

Generated by: Vessel (record the name) Office Use of proper PPE Staff is using proper PPE Y N

Code number (to be assigned by the Office): 1.16 Rev.00 Experienced staff Staff has task experience Y N

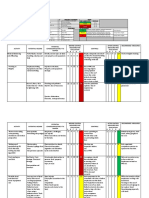

FREQUENCY CATEGORY CONSEQUENCE CATEGORY RISK MATRIX

5 Frequent - Possibility of More often than Major

repeated incidents once per voyage Human losses Major pollution / Excessive/ high cost national &

4 / fatalities Full scale response damage >$1000000 international FREQUENCY

impact

4 Probable - Possibility of Once per year

Moderate pollution/

Moderate cost or

isolated incidents Serious injury damage Considera

3 to personnel

Significant resources

(100000 – ble impact

1 2 3 4 5

commitment

1000000$)

3 Occasional- Possibility of Once per 5 Number of

Little cost or

occurring sometime years minor injuries / Little pollution / 1 L (1) L (2) L (3) M (4) M (5)

CONSEQUENCE

damage Slight

2 Medical Limited response of

($10000 – $ impact

treatment for short duration 2 L (2) M (4) M (6) M (8) H (10)

100000)

personnel

2 Remote- Not likely to Once per 10 Minimum pollution / Minimum cost /

occur years Few minor Zero 3 L (3) M (6) M (9) H (12) H (15)

1 Little or no response damage

1 Very unlikely- Practically Once per 30 injuries < $10000 impact

needed 4

impossible years or more M (4) M (8) H (12) H (16) H (20)

High=Intolerable Risk Medium=Tolerable Risk Low=Negligible Risk

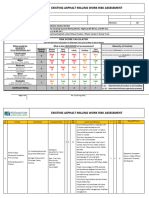

Risk Assessment

Risk Identification Risk Analysis Initial risk

evaluation

Potential

No Hazard Existing control measures F C R

hazardous event

1 Injury from tools. Serious injury to Procedures, PPE, Safety arrangements, Training 4 3 12

personnel and drills procedures, familiarization checklists

2 Injury from cutting /welding equipments. Serious injury to Procedures, PPE, Safety arrangements, Training 4 3 12

personnel and drills procedures, familiarization checklists

Page 1 of 3 Revision No: 00, Date: Dec 2016

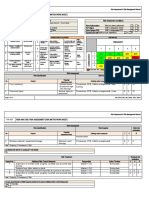

Risk Assessment & Risk Management Manual

RA 001 RISK ANALYSIS / RISK ASSESSMENT (RISK MATRIX WORK SHEET)

Risk Assessment

Risk Identification Risk Analysis Initial risk

evaluation

Potential

No Hazard Existing control measures F C R

hazardous event

3 Burning. Serious injury to Procedures, PPE, Safety arrangements, Training 3 4 12

personnel and drills procedures, familiarization checklists

4 Ignition. Fire / Explosion Procedures, PPE, Safety arrangements, Training 3 4 12

and drills procedures, familiarization checklists

5 Fatigue. Serious injury to Procedures, PPE, Safety arrangements, Training 3 3 9

personnel and drills procedures, familiarization checklists,

Forms for watchkeeping arrangements, Hours of

Work/Rest

Note F: Frequency, C: Consequence, R: Risk

ALTERNATIVE WAYS TO CONDUCT THE WORK

NIL

Risk Treatment Residual risk

evaluation

Hazard No. Additional Risk Control Measures Responsible Action Timeline F C R

1 Brief crew. Master/ Chief Engineer Before task 2 3 6

2 The good condition of equipment and especially the safety 1 3 3

Master/ Chief Engineer Before task

devises to be asserted.

3 Hot work to take place as per procedures outlined in Safety 1 4 4

Manual. In addition, the fire pump will run, fire hoses will be

Master/ Chief Engineer During task

connected ready for use and portable extinguishers will be in

place.

4 Hot work to take place as per procedures outlined in Safety 1 3 3

Manual in addition the fire pump will run , fire hoses will be

Master/ Chief Engineer During task

connected ready for use and portable extinguishers will be in

place.

5 Taking into account ship's trading area the job should be Master/ Chief Engineer Before task 1 3 3

Page 2 of 3 Revision No: 00, Date: Dec 2016

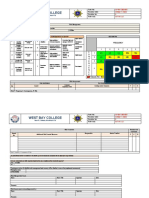

Risk Assessment & Risk Management Manual

RA 001 RISK ANALYSIS / RISK ASSESSMENT (RISK MATRIX WORK SHEET)

scheduled with a manner not to interfere neither the ship's

itinerary nor the proper resting of the crew involved to this job.

Note F: Frequency, C: Consequence, R: Risk

Are any amendments to SSMM required (related to the above Additional Risk Control Measures)?

Yes Describe:

No

Contingency plans (to facilitate safe management and recovery of the situation in case of any unplanned occurrences)

Emergency case Contingency Plans

EXPLOSION, SERIOUS REFER TO COMPANY’S EMERGENCY RESPONSE PROCEDURES

INJURY (EXPLOSION, SERIOUS INJURY) AND THE COMPANY SHOULD BE

CONTACTED.

Risk Management Team

Name Rank / Title Signature Date

Remarks:

Risk Assessment reviewed/approved by:

Name Rank / Title Signature Date

G.MYLONAS CEO

S.DAFERMOS DPA

Remarks:

Page 3 of 3 Revision No: 00, Date: Dec 2016

You might also like

- 1.17 Winch Brake TestDocument4 pages1.17 Winch Brake TestJefrey JucabanNo ratings yet

- 1.16 Visual Inspection of FPTDocument3 pages1.16 Visual Inspection of FPTJefrey JucabanNo ratings yet

- 1.8 Assembling of Fire LineDocument3 pages1.8 Assembling of Fire LineJefrey JucabanNo ratings yet

- 1.12 Installation of Anodes in W.B.T.Document5 pages1.12 Installation of Anodes in W.B.T.Jefrey JucabanNo ratings yet

- 1.15 Visual Inspection of AptDocument3 pages1.15 Visual Inspection of AptJefrey JucabanNo ratings yet

- 1.10 Hot Work On Main Deck PlatingDocument3 pages1.10 Hot Work On Main Deck PlatingJefrey JucabanNo ratings yet

- 1.9 Ballast Line Repairs Crew Exposure To Chemical MaterialsDocument3 pages1.9 Ballast Line Repairs Crew Exposure To Chemical MaterialsJefrey JucabanNo ratings yet

- 1.14 Routine Maintenance On Deck in Hot Climate (Sun Light Exposure)Document4 pages1.14 Routine Maintenance On Deck in Hot Climate (Sun Light Exposure)Jefrey JucabanNo ratings yet

- RA 001 Risk Analysis - Risk AssessementDocument2 pagesRA 001 Risk Analysis - Risk AssessementJoshua Guerrero CaloyongNo ratings yet

- Olifantsvlei: General Site Operations - Flame CuttingDocument4 pagesOlifantsvlei: General Site Operations - Flame CuttinggrantNo ratings yet

- RISK ASSESSMENT FOR 11 KV Auto Recloser Installation Updated 31-08-2019Document10 pagesRISK ASSESSMENT FOR 11 KV Auto Recloser Installation Updated 31-08-2019Musthafa ShaikNo ratings yet

- Perlin IDocument544 pagesPerlin IbalasubramaniamNo ratings yet

- Project Risk Index for HIRADocument12 pagesProject Risk Index for HIRAKamesh A100% (1)

- RA-GL-HAL-PPS-444 (Manual Handling)Document7 pagesRA-GL-HAL-PPS-444 (Manual Handling)BalasubramanianNo ratings yet

- Risk Assessment For Installation of BMS M Tower PDFDocument15 pagesRisk Assessment For Installation of BMS M Tower PDFAndrew HivNo ratings yet

- RA-GL-HAL-PPS-445 (Working at Height)Document5 pagesRA-GL-HAL-PPS-445 (Working at Height)BalasubramanianNo ratings yet

- Ra-Me-02 - Fire Fighting SystemDocument13 pagesRa-Me-02 - Fire Fighting Systemasamrat582No ratings yet

- Risk Assessment 2 PDFDocument15 pagesRisk Assessment 2 PDFarunNo ratings yet

- HVAC Risk AssesmentDocument8 pagesHVAC Risk Assesmentaaktgt MepNo ratings yet

- Monsoon SeasonDocument4 pagesMonsoon SeasonSARFARAJ AHMADNo ratings yet

- Hemp R&BDocument139 pagesHemp R&BBalasubramaniamkamarajNo ratings yet

- Approved Risk Assessment & Risk RegisterDocument53 pagesApproved Risk Assessment & Risk RegisterAhmed RedaNo ratings yet

- ISK Valuation Atrix: Exposure Factor Level 1 Level 2 Level 3 Level 4Document1 pageISK Valuation Atrix: Exposure Factor Level 1 Level 2 Level 3 Level 4dnmuleNo ratings yet

- Hira For DemolitionDocument3 pagesHira For DemolitionMokka SamaiyalNo ratings yet

- 29-JHA For Removal of Wooden PalletDocument4 pages29-JHA For Removal of Wooden PalletPradip Kumar ShaNo ratings yet

- Road ReinstatementDocument4 pagesRoad ReinstatementBishop Ojonuguwa AmehNo ratings yet

- UploadDocument7 pagesUploadAlif algifariNo ratings yet

- SOM 1.1 A Risk Assessment Matrix - Flowchart Rev 0Document1 pageSOM 1.1 A Risk Assessment Matrix - Flowchart Rev 0Amit BhadauriaNo ratings yet

- Fahm-Electrical JhaDocument6 pagesFahm-Electrical Jhaindiasingapore9No ratings yet

- 030 - Moving Machineries in Site PremisesDocument6 pages030 - Moving Machineries in Site PremisesPrem ChristianNo ratings yet

- 27.JHA For Collection and Disposal of Used Air Filter and Electronic WasteDocument4 pages27.JHA For Collection and Disposal of Used Air Filter and Electronic WastePradip Kumar ShaNo ratings yet

- 20161104-NW SHEF RA Boxing of Swordfish wings (1)Document4 pages20161104-NW SHEF RA Boxing of Swordfish wings (1)mark.wilsonNo ratings yet

- 014 - Manual HandlingDocument4 pages014 - Manual HandlingPrem ChristianNo ratings yet

- QP Guideline For Hazid Review: Doc File No.: GDL-S-040 R1 Page 22 of 27 Custodian Dept: STDocument1 pageQP Guideline For Hazid Review: Doc File No.: GDL-S-040 R1 Page 22 of 27 Custodian Dept: STsanjayNo ratings yet

- Working On HeightsDocument5 pagesWorking On HeightsgrantNo ratings yet

- 05. HIRA-Shaft Cable Tray N Cable InstallationDocument2 pages05. HIRA-Shaft Cable Tray N Cable InstallationDivakar DhandeNo ratings yet

- RA Site EstablishmentDocument4 pagesRA Site EstablishmentAndrewNo ratings yet

- 038 - Working On Mobile Elevating Work PlatformDocument4 pages038 - Working On Mobile Elevating Work PlatformPrem ChristianNo ratings yet

- Risk AsseementDocument8 pagesRisk AsseementMajaga MabhenaNo ratings yet

- Inter - Departmental Procedure Operation: IP-OPS-066Document10 pagesInter - Departmental Procedure Operation: IP-OPS-066AnuradheNo ratings yet

- #410 Heavy LiftDocument3 pages#410 Heavy LiftTolias EgwNo ratings yet

- Risk Assessment For Sheet PilingDocument33 pagesRisk Assessment For Sheet Pilingsajin75% (24)

- AKRON RISK ASSESSMENT FOR HOT WORK IN FRESH WATER TANKDocument7 pagesAKRON RISK ASSESSMENT FOR HOT WORK IN FRESH WATER TANKTolias EgwNo ratings yet

- JSA - RA 000-Water ProofingDocument5 pagesJSA - RA 000-Water ProofingNAGARJUNA100% (1)

- Risk Assessment (Installation of Cables & Wires)Document6 pagesRisk Assessment (Installation of Cables & Wires)michael acosta100% (3)

- #106 Embarkation or Disembarkation Via LaunchesDocument4 pages#106 Embarkation or Disembarkation Via LaunchesTolias EgwNo ratings yet

- UG RA 006 - Installation of Road BarricadesDocument4 pagesUG RA 006 - Installation of Road BarricadesshamshuddinNo ratings yet

- UG RA 004 - Test Pit Manual ExcavationDocument5 pagesUG RA 004 - Test Pit Manual ExcavationshamshuddinNo ratings yet

- UG RA 003 - Test Pit Markings and Asphalt CuttingDocument6 pagesUG RA 003 - Test Pit Markings and Asphalt CuttingshamshuddinNo ratings yet

- RA Existing Asphalt Milling WorksDocument8 pagesRA Existing Asphalt Milling WorksSolimanNo ratings yet

- 010 - Scaffolding (Erection & Dismantling)Document6 pages010 - Scaffolding (Erection & Dismantling)Prem ChristianNo ratings yet

- HIRA - Fixed Scaffold and Wall BreakingDocument6 pagesHIRA - Fixed Scaffold and Wall BreakingSujan Augustin100% (2)

- Jha - Wheel & Tire Removal and Repair ActivityDocument7 pagesJha - Wheel & Tire Removal and Repair ActivityPradip Kumar ShaNo ratings yet

- Determine Consequence People ConsequenceDocument1 pageDetermine Consequence People ConsequenceAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Baseline Risk Assessment and Risk Matrix (An Example)Document8 pagesBaseline Risk Assessment and Risk Matrix (An Example)Victor75% (4)

- UG RA 009 - Light Materials and Equipment Loading and UnloadingDocument6 pagesUG RA 009 - Light Materials and Equipment Loading and Unloadingshamshuddin100% (1)

- ChagTerms TBRA - Fuel Delivery To VSL - SampleDocument21 pagesChagTerms TBRA - Fuel Delivery To VSL - SampleshannonNo ratings yet

- FT4596 1Document1 pageFT4596 1angelaNo ratings yet

- Electrical Panel MaintenanceDocument3 pagesElectrical Panel MaintenanceNdi Mvogo100% (1)

- Country Presentation MaldivesDocument11 pagesCountry Presentation MaldivesEndah PutriNo ratings yet

- Anticoagulant ReversalDocument4 pagesAnticoagulant Reversalapi-647779956No ratings yet

- Cellular Regulation-BreastDocument41 pagesCellular Regulation-BreastMegan TurnerNo ratings yet

- SjmoDocument24 pagesSjmoapi-528183036No ratings yet

- S-48B Ultrasonic Liposuction Equipment User ManualDocument11 pagesS-48B Ultrasonic Liposuction Equipment User ManualmoparlatinoNo ratings yet

- B Relative Risk and Odds Ratios ExamplesDocument8 pagesB Relative Risk and Odds Ratios ExamplesJing CruzNo ratings yet

- Complement Cascade NotesDocument6 pagesComplement Cascade NotesAndrienne Valen de BelenNo ratings yet

- Cerumen ImpactionDocument9 pagesCerumen Impactionnnennachidera2002No ratings yet

- Live music reduces pediatric distressDocument5 pagesLive music reduces pediatric distressandreaNo ratings yet

- Materi Pencegahan PlabsiDocument51 pagesMateri Pencegahan PlabsiAnonymous HXyd4E100% (1)

- Western Mindanao State University College of NursingDocument3 pagesWestern Mindanao State University College of NursingDarina Shumei MustaphaNo ratings yet

- 182 P - Leech Therapy - An Introduction - Matt IsaacDocument182 pages182 P - Leech Therapy - An Introduction - Matt IsaacKatyi Gyula100% (1)

- Saran prasarana kepatuhan pada anemia aplastikDocument1 pageSaran prasarana kepatuhan pada anemia aplastikAlika Nigandiva41No ratings yet

- Cna Practice ExamDocument4 pagesCna Practice ExamJennifer Venfield83% (12)

- Measures of Public Health Impact in EpidemiologyDocument30 pagesMeasures of Public Health Impact in EpidemiologyHanifHarySNo ratings yet

- Vázquez Justo2017 PDFDocument194 pagesVázquez Justo2017 PDFCristinaNo ratings yet

- The Dangers of Cigarette SmokingDocument6 pagesThe Dangers of Cigarette SmokingEdelmar BenosaNo ratings yet

- CDC - AV Fistula Graft Can Decannulation Observations ATDocument2 pagesCDC - AV Fistula Graft Can Decannulation Observations ATDewi Ratna SariNo ratings yet

- DanielDocument1 pageDanielapi-547109595No ratings yet

- Child Growth. Growth Disorders UpdateDocument57 pagesChild Growth. Growth Disorders UpdateShahpoor Ahmad ShirzadaNo ratings yet

- Histologi KelinciDocument7 pagesHistologi Kelinciummu0% (2)

- Patient Case PresentationDocument26 pagesPatient Case PresentationKathleen B BaldadoNo ratings yet

- OPERATING ROOM TEACHING PLANDocument7 pagesOPERATING ROOM TEACHING PLANjohnhenryv100% (2)

- Oral & Maxillofacial Surgery Medical Emergencies GuideDocument7 pagesOral & Maxillofacial Surgery Medical Emergencies GuidedrpnnreddyNo ratings yet

- Leopold's Maneuver ResearchDocument4 pagesLeopold's Maneuver ResearchCarl Andre ReyesNo ratings yet

- International Journal of Pharmaceutical Science Invention (IJPSI)Document6 pagesInternational Journal of Pharmaceutical Science Invention (IJPSI)inventionjournalsNo ratings yet

- SpermDocument1 pageSpermEve Karen PobleteNo ratings yet

- Drugs and Substance AbuseDocument4 pagesDrugs and Substance Abusevaibhavch2904No ratings yet

- PSEQ1Document11 pagesPSEQ1Vane GANo ratings yet

- GTN Ointment Relieves Chronic Anal FissuresDocument8 pagesGTN Ointment Relieves Chronic Anal FissuresAndrew SuryaNo ratings yet