Professional Documents

Culture Documents

1.17 Winch Brake Test

Uploaded by

Jefrey JucabanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.17 Winch Brake Test

Uploaded by

Jefrey JucabanCopyright:

Available Formats

Risk Assessment & Risk Management Manual

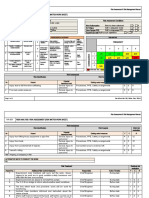

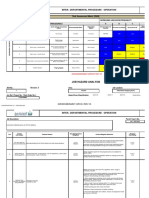

RA 001 RISK ANALYSIS / RISK ASSESSMENT (RISK MATRIX WORK SHEET)

RISK MANAGEMENT Risk Assessment Conditions

Operation / Work activity being WINCH BRAKE TEST

assessed: Work Authorization Work has been authorized Y N

Routine Non-routine No Fatigue Staff is adequately rested Y N

Generated by: Vessel (record the name) Office Use of proper PPE Staff is using proper PPE Y N

Code number (to be assigned by the Office): 1.13 Rev.00 Experienced staff Staff has task experience Y N

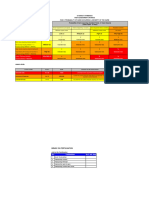

FREQUENCY CATEGORY CONSEQUENCE CATEGORY RISK MATRIX

5 Frequent - Possibility of More often than Major

repeated incidents once per voyage Human losses Major pollution / Excessive/ high cost national &

4 / fatalities Full scale response damage >$1000000 international FREQUENCY

impact

4 Probable - Possibility of Once per year

Moderate pollution/

Moderate cost or

isolated incidents Serious injury damage Considera

3 to personnel

Significant resources

(100000 – ble impact

1 2 3 4 5

commitment

1000000$)

3 Occasional- Possibility of Once per 5 Number of

Little cost or

occurring sometime years minor injuries / Little pollution / 1 L (1) L (2) L (3) M (4) M (5)

CONSEQUENCE

damage Slight

2 Medical Limited response of

($10000 – $ impact

treatment for short duration 2 L (2) M(4) M(6) M(8) H(10)

100000)

personnel

2 Remote- Not likely to Once per 10 Minimum pollution / Minimum cost /

occur years Few minor Zero 3 L(3) M(6) M(9) H(12) H(15)

1 Little or no response damage

1 Very unlikely- Practically Once per 30 injuries < $10000 impact

needed 4

impossible years or more M(4) M(8) H(12) H(16) H(20)

High=Intolerable Risk Medium=Tolerable Risk Low=Negligible Risk

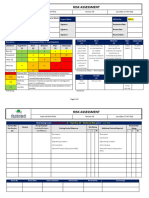

Risk Assessment

Risk Identification Risk Analysis Initial risk

evaluation

Potential

No Hazard Existing control measures F C R

hazardous event

1 Verifying/proving that the brakes hold the correct load. Operational cost Procedures 3 3 9

2 Injury of ships personnel. Serious injury to Procedures, PPE, Safety arrangements, Training 3 3 9

personnel and drills procedures, familiarization checklists

3 Adverse weather/sea condition. Operational cost Procedures, PPE, Safety arrangements 3 3 9

Page 1 of 4 Revision No: 00, Date: Dec 2016

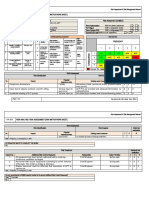

Risk Assessment & Risk Management Manual

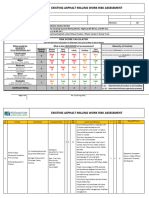

RA 001 RISK ANALYSIS / RISK ASSESSMENT (RISK MATRIX WORK SHEET)

Risk Assessment

Risk Identification Risk Analysis Initial risk

evaluation

Potential

No Hazard Existing control measures F C R

hazardous event

4 Inadequate coordination/supervision / communication. - Serious injury Procedures, PPE, Safety arrangements, Training 4 3 12

to personnel and drills procedures, familiarization checklists

- Moderate cost

or damage

5 Lifting/transferring heavy objects. Serious injury to Procedures, PPE, Safety arrangements 3 3 9

personnel

Note F: Frequency, C: Consequence, R: Risk

ALTERNATIVE WAYS TO CONDUCT THE WORK

NIL

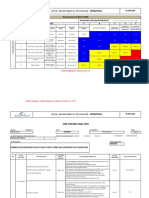

Risk Treatment Residual risk

evaluation

Hazard No. Additional Risk Control Measures Responsible Action Timeline F C R

1 A. The hydraulic jack for the testing to be fastened on to the Personnel in charge of the During the work 1 3 3

drum’s split flange in such a way so that the acting force to be work

as much tangential to the drum as possible for the whole

duration of the test, especially during brake’s rendering.

B. Special attention must be paid so that the holding bolts to Personnel in charge of the During the work

well tightened and that the jack’s extension is perpendicularly work

placed on to a robust foundation at upper deck in order to avoid

accidental release of the jack under the applied force.

C. After proper installation of the test kit a long hydraulic pipe is Personnel in charge of the During the work

to be utilized between the jack and the pump, allowing the pump work

and the operator to maintain a distance of at least 5 meters from

the winch.

D. Suitable mark is to be added to the winch screw in order to Personnel in charge of the On work completion

be made clear to the crew the exact degree of brake tightening. work

Page 2 of 4 Revision No: 00, Date: Dec 2016

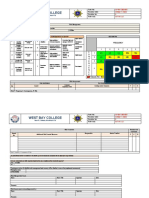

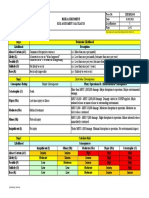

Risk Assessment & Risk Management Manual

RA 001 RISK ANALYSIS / RISK ASSESSMENT (RISK MATRIX WORK SHEET)

E. In case that the required brake capacity is not achieved then Personnel in charge of the During the work

the test is to be repeated. work

2 A. Except involved personnel, all other personnel should be in Safety Officer During the work 1 3 3

safe distance. To this extent a full restriction of the surrounding

area using coloured tape and sufficient number of “Keep Away-

Winch Brake Test In Progress” signs notifying crew of the test

are to be placed in the vicinity.

B. Ensure that the working area is clean from any slippery C/O Prior to work

material and free of any obstruction.

3 The work should be carried out only in good weather and sea C/O Prior to the work 1 3 3

condition.

4 A. A work planning/safety meeting should be carried out with the Master Prior to the work 1 3 3

participation of all involved personnel with the aim of discussing,

amongst others: (a) job procedure; (b) tool transferring

arrangements; (c) lifting arrangements; (d) safety

procedures/work permits; (e) individual work responsibilities; (f)

means of communication.

B. The Chief Officer should be in charge supervising the job. C/O During the work

C. Bridge OOW should be informed of the C/O Prior to the work

commencement/completion of the work.

5 The lifting/transferring/securing procedure to be applied should C/O Prior to the work 1 3 3

be properly planned and communicated to the involved

personnel.

Note F: Frequency, C: Consequence, R: Risk

Page 3 of 4 Revision No: 00, Date: Dec 2016

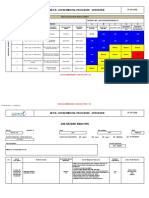

Risk Assessment & Risk Management Manual

RA 001 RISK ANALYSIS / RISK ASSESSMENT (RISK MATRIX WORK SHEET)

Are any amendments to SSMM required (related to the above Additional Risk Control Measures)?

Yes Describe:

No

Contingency plans (to facilitate safe management and recovery of the situation in case of any unplanned occurrences)

Emergency case Contingency Plans

SERIOUS INJURY REFER TO COMPANY’S EMERGENCY RESPONSE PROCEDURES (SERIOUS

INJURY) AND THE COMPANY SHOULD BE CONTACTED.

Risk Management Team

Name Rank / Title Signature Date

Remarks:

Risk Assessment reviewed/approved by:

Name Rank / Title Signature Date

G.MYLONAS CEO

S.DAFERMOS DPA

Remarks:

Page 4 of 4 Revision No: 00, Date: Dec 2016

You might also like

- 1.16 Visual Inspection of FPTDocument3 pages1.16 Visual Inspection of FPTJefrey JucabanNo ratings yet

- 1.13 Installation of New Piping On DeckDocument3 pages1.13 Installation of New Piping On DeckJefrey JucabanNo ratings yet

- 1.8 Assembling of Fire LineDocument3 pages1.8 Assembling of Fire LineJefrey JucabanNo ratings yet

- 1.15 Visual Inspection of AptDocument3 pages1.15 Visual Inspection of AptJefrey JucabanNo ratings yet

- 1.12 Installation of Anodes in W.B.T.Document5 pages1.12 Installation of Anodes in W.B.T.Jefrey JucabanNo ratings yet

- 1.9 Ballast Line Repairs Crew Exposure To Chemical MaterialsDocument3 pages1.9 Ballast Line Repairs Crew Exposure To Chemical MaterialsJefrey JucabanNo ratings yet

- 1.14 Routine Maintenance On Deck in Hot Climate (Sun Light Exposure)Document4 pages1.14 Routine Maintenance On Deck in Hot Climate (Sun Light Exposure)Jefrey JucabanNo ratings yet

- 1.10 Hot Work On Main Deck PlatingDocument3 pages1.10 Hot Work On Main Deck PlatingJefrey JucabanNo ratings yet

- RA 001 Risk Analysis - Risk AssessementDocument2 pagesRA 001 Risk Analysis - Risk AssessementJoshua Guerrero CaloyongNo ratings yet

- Olifantsvlei: General Site Operations - Flame CuttingDocument4 pagesOlifantsvlei: General Site Operations - Flame CuttinggrantNo ratings yet

- RISK ASSESSMENT FOR 11 KV Auto Recloser Installation Updated 31-08-2019Document10 pagesRISK ASSESSMENT FOR 11 KV Auto Recloser Installation Updated 31-08-2019Musthafa ShaikNo ratings yet

- Project Risk Index for HIRADocument12 pagesProject Risk Index for HIRAKamesh A100% (1)

- RA-GL-HAL-PPS-444 (Manual Handling)Document7 pagesRA-GL-HAL-PPS-444 (Manual Handling)BalasubramanianNo ratings yet

- Perlin IDocument544 pagesPerlin IbalasubramaniamNo ratings yet

- Risk Assessment For Installation of BMS M Tower PDFDocument15 pagesRisk Assessment For Installation of BMS M Tower PDFAndrew HivNo ratings yet

- Road ReinstatementDocument4 pagesRoad ReinstatementBishop Ojonuguwa AmehNo ratings yet

- Monsoon SeasonDocument4 pagesMonsoon SeasonSARFARAJ AHMADNo ratings yet

- RA-GL-HAL-PPS-445 (Working at Height)Document5 pagesRA-GL-HAL-PPS-445 (Working at Height)BalasubramanianNo ratings yet

- Risk Assessment (Installation of Cables & Wires)Document6 pagesRisk Assessment (Installation of Cables & Wires)michael acosta100% (3)

- Ra-Me-02 - Fire Fighting SystemDocument13 pagesRa-Me-02 - Fire Fighting Systemasamrat582No ratings yet

- Risk Assessment 2 PDFDocument15 pagesRisk Assessment 2 PDFarunNo ratings yet

- Hemp R&BDocument139 pagesHemp R&BBalasubramaniamkamarajNo ratings yet

- UploadDocument7 pagesUploadAlif algifariNo ratings yet

- 20161104-NW SHEF RA Boxing of Swordfish wings (1)Document4 pages20161104-NW SHEF RA Boxing of Swordfish wings (1)mark.wilsonNo ratings yet

- 29-JHA For Removal of Wooden PalletDocument4 pages29-JHA For Removal of Wooden PalletPradip Kumar ShaNo ratings yet

- Fahm-Electrical JhaDocument6 pagesFahm-Electrical Jhaindiasingapore9No ratings yet

- ISK Valuation Atrix: Exposure Factor Level 1 Level 2 Level 3 Level 4Document1 pageISK Valuation Atrix: Exposure Factor Level 1 Level 2 Level 3 Level 4dnmuleNo ratings yet

- 27.JHA For Collection and Disposal of Used Air Filter and Electronic WasteDocument4 pages27.JHA For Collection and Disposal of Used Air Filter and Electronic WastePradip Kumar ShaNo ratings yet

- Inter - Departmental Procedure Operation: IP-OPS-066Document10 pagesInter - Departmental Procedure Operation: IP-OPS-066AnuradheNo ratings yet

- Approved Risk Assessment & Risk RegisterDocument53 pagesApproved Risk Assessment & Risk RegisterAhmed RedaNo ratings yet

- RA For Snake BiteDocument5 pagesRA For Snake Biteshamroz khan100% (1)

- 014 - Manual HandlingDocument4 pages014 - Manual HandlingPrem ChristianNo ratings yet

- 030 - Moving Machineries in Site PremisesDocument6 pages030 - Moving Machineries in Site PremisesPrem ChristianNo ratings yet

- Hira For DemolitionDocument3 pagesHira For DemolitionMokka SamaiyalNo ratings yet

- Baseline Risk Assessment and Risk Matrix (An Example)Document8 pagesBaseline Risk Assessment and Risk Matrix (An Example)Victor75% (4)

- HVAC Risk AssesmentDocument8 pagesHVAC Risk Assesmentaaktgt MepNo ratings yet

- Jha - Wheel & Tire Removal and Repair ActivityDocument7 pagesJha - Wheel & Tire Removal and Repair ActivityPradip Kumar ShaNo ratings yet

- Revised JHA HDDDocument12 pagesRevised JHA HDDHariharan RajaramanNo ratings yet

- Working On HeightsDocument5 pagesWorking On HeightsgrantNo ratings yet

- RA Existing Asphalt Milling WorksDocument8 pagesRA Existing Asphalt Milling WorksSolimanNo ratings yet

- QP Guideline For Hazid Review: Doc File No.: GDL-S-040 R1 Page 22 of 27 Custodian Dept: STDocument1 pageQP Guideline For Hazid Review: Doc File No.: GDL-S-040 R1 Page 22 of 27 Custodian Dept: STsanjayNo ratings yet

- Risk Assessment For Sheet PilingDocument33 pagesRisk Assessment For Sheet Pilingsajin75% (24)

- 038 - Working On Mobile Elevating Work PlatformDocument4 pages038 - Working On Mobile Elevating Work PlatformPrem ChristianNo ratings yet

- 010 - Scaffolding (Erection & Dismantling)Document6 pages010 - Scaffolding (Erection & Dismantling)Prem ChristianNo ratings yet

- Determine Consequence People ConsequenceDocument1 pageDetermine Consequence People ConsequenceAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- H PSAF RAINALDI Process Safety PDFDocument12 pagesH PSAF RAINALDI Process Safety PDFanton100% (1)

- HIRARC On Fertilisation - SI - 2022Document6 pagesHIRARC On Fertilisation - SI - 2022noor khairaniNo ratings yet

- Risk Assessment P3 Permanent Power Provision at IthraDocument2 pagesRisk Assessment P3 Permanent Power Provision at Ithraghazi4uNo ratings yet

- JSA - RA 000-Water ProofingDocument5 pagesJSA - RA 000-Water ProofingNAGARJUNA100% (1)

- SOM 1.1 A Risk Assessment Matrix - Flowchart Rev 0Document1 pageSOM 1.1 A Risk Assessment Matrix - Flowchart Rev 0Amit BhadauriaNo ratings yet

- Hazard identification, risk assessment and control formDocument1 pageHazard identification, risk assessment and control formmyn maliQue100% (1)

- ChagTerms TBRA - Fuel Delivery To VSL - SampleDocument21 pagesChagTerms TBRA - Fuel Delivery To VSL - SampleshannonNo ratings yet

- Demobilization and Demolition Activies of Porta Cabins and Containers For Laydown AreaDocument10 pagesDemobilization and Demolition Activies of Porta Cabins and Containers For Laydown AreaNasrullahNo ratings yet

- Safety at OffshoreDocument51 pagesSafety at OffshoreRavi Kant TripathiNo ratings yet

- HIRARC On Harvesting - SI - 2022Document11 pagesHIRARC On Harvesting - SI - 2022noor khairaniNo ratings yet

- FT4596 1Document1 pageFT4596 1angelaNo ratings yet

- JSA - Bar Cutting, GrindingDocument3 pagesJSA - Bar Cutting, GrindingNisith Sahoo100% (1)

- OHS-PR-09-03-F02 HIRA - 004 Soil Investigation For Plain AreaDocument6 pagesOHS-PR-09-03-F02 HIRA - 004 Soil Investigation For Plain AreaJaafar LagayanNo ratings yet

- RA Site EstablishmentDocument4 pagesRA Site EstablishmentAndrewNo ratings yet

- 3 Keys To Achieve Consistent Profit From Stock Market by Adam KhooDocument60 pages3 Keys To Achieve Consistent Profit From Stock Market by Adam KhooSau Fei100% (6)

- OECD Working Paper Discusses Social Media Use by GovernmentsDocument72 pagesOECD Working Paper Discusses Social Media Use by GovernmentsAnibal MartinNo ratings yet

- Oxy 2006 10KDocument138 pagesOxy 2006 10Kbmichaud758No ratings yet

- Sop Guidelines OpcenDocument17 pagesSop Guidelines OpcenJessie Bhong LegartoNo ratings yet

- Introduction to Business Finance ConceptsDocument7 pagesIntroduction to Business Finance ConceptsMich ValenciaNo ratings yet

- Tutorialanswer All QuestionsDocument2,619 pagesTutorialanswer All QuestionsVolcanBlack100% (1)

- CA Inter FM-ECO Chapter 6 Key ConceptsDocument23 pagesCA Inter FM-ECO Chapter 6 Key ConceptsAejaz MohamedNo ratings yet

- Nebosh Igc2 Exam Questions - IhsecDocument1 pageNebosh Igc2 Exam Questions - IhsecMohammad Gita89% (28)

- Behavioral Finance - Investor StyleDocument15 pagesBehavioral Finance - Investor StyleCarmen BejarNo ratings yet

- Nature of financial attest auditsDocument59 pagesNature of financial attest audits40B Sushil UrkudeNo ratings yet

- Risk Assessment Plan OutlineDocument5 pagesRisk Assessment Plan Outlinemarwan omarNo ratings yet

- Theme1 StarbucksCoffe CaseStudyDocument2 pagesTheme1 StarbucksCoffe CaseStudyYannis A. PollalisNo ratings yet

- Cold Facts Buyers Guide (2017) PDFDocument41 pagesCold Facts Buyers Guide (2017) PDFBinh Thanh LeNo ratings yet

- UNEP POPS BATBEP GUID POPs 03 202106.enDocument38 pagesUNEP POPS BATBEP GUID POPs 03 202106.enIngrid GuimarãesNo ratings yet

- BC Core BehaviourDocument6 pagesBC Core BehaviourNura PaglaNo ratings yet

- Systems Engineering Management PlanDocument26 pagesSystems Engineering Management PlanAndile CeleNo ratings yet

- Simulation Using PromodelDocument707 pagesSimulation Using PromodelMujaddid Fahmy100% (1)

- Raid Log TemplateDocument5 pagesRaid Log TemplateAmy HullNo ratings yet

- Strategic, Tactical and Operational Decisions in Multi-national LogisticsDocument34 pagesStrategic, Tactical and Operational Decisions in Multi-national LogisticsLaimi MutikishaNo ratings yet

- SA7 - Investment and Finance Specialist Advanced: SyllabusDocument5 pagesSA7 - Investment and Finance Specialist Advanced: SyllabusRANJAN THOMASNo ratings yet

- Responding To The Growing Threat of Human-Operated Ransomware AttacksDocument13 pagesResponding To The Growing Threat of Human-Operated Ransomware AttacksAmita Singh RajputNo ratings yet

- Operations Excellence: The Key to Sustained Business PerformanceDocument8 pagesOperations Excellence: The Key to Sustained Business PerformancePrathap SankarNo ratings yet

- Assessing Risk of Violence in a Patient with Auditory HallucinationsDocument17 pagesAssessing Risk of Violence in a Patient with Auditory HallucinationsIrrisse SisonNo ratings yet

- Baker (Pp. 308-328)Document22 pagesBaker (Pp. 308-328)SofíaNo ratings yet

- Ch 1 risk questions definedDocument2 pagesCh 1 risk questions definedAbdulkadir Hassan mohamedNo ratings yet

- Pivot Candle TradingDocument11 pagesPivot Candle Tradingjavamate100% (7)

- Chapter 03 Hull Hedging Strategies Using FuturesDocument18 pagesChapter 03 Hull Hedging Strategies Using FuturesJobayer Islam TunanNo ratings yet

- CH 18 Financial RegulationDocument7 pagesCH 18 Financial RegulationAd QasimNo ratings yet

- Comparison of Mutual Funds With Other Investment Options FINALSDocument51 pagesComparison of Mutual Funds With Other Investment Options FINALSankitNo ratings yet

- The Story of Statistics in Geotechnical EngineeringDocument24 pagesThe Story of Statistics in Geotechnical EngineeringfakeNo ratings yet