Professional Documents

Culture Documents

Foundation Packages - COMBISLAB - Rhodes Avenue School

Uploaded by

Faraz HussainOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Foundation Packages - COMBISLAB - Rhodes Avenue School

Uploaded by

Faraz HussainCopyright:

Available Formats

CASE STUDY

COMBISLAB

Raft foundations and flooring system for schools

Work type Project Brief Key issues/

COMBISLAB requirements

COMBISLAB, by Roger Bullivant

Main Contractor

Limited (RBL) was the specified T The site formed part of an

engineered solution on the site of existing school and it was

a challenging refurbishment and essential to ensure everything

Client continued to function normally

redevelopment of an existing school.

Haringey Council RBL was commissioned to design while work was carried out.

Access was restricted to

Location and install the foundation and flooring

entrances away from normal

system with minimal disturbance and

Rhodes Avenue Primary site access routes for reasons

impact on the school’s operations, and

School, Wood Green, with the aim of minimising building costs

of public safety. To ensure site

London within a restricted construction period.

deliveries did not coincide

with school starting and

finishing times, RBL worked

to a strict schedule of times to

avoid congestion.

T As well as school restrictions,

matters were further

complicated on site by

poor ground conditions.

Desiccated clay subsoils

presented the need for the

creation of a heave void due

to the influence of adjacent

trees, and required the use

of mini piling rigs due to

restricted access on site. The

school continued to operate

throughout the duration

of the works, which also

required stringent control of

plant, labour and material

movements.

ROGER BULLIVANT LIMITED R

T. 0845 838 1801 www.roger-bullivant.co.uk

COMBISLAB

Key issues/ Solution A collapsible and removable falsework

requirements soffit support system was installed

• The site was firstly excavated by to create a 300mm void; a sacrificial

T The foundation and floor slabs the main contractor to formation plywood deck was placed over to form

were designed to minimise level which was 475mm below the raft foundation and flooring system,

excavation, limit the amount edge shuttering and reinforcement

structural slab level. The formation

of time on site and reduce the placed and the raft poured. The raft

was compacted to test the

need for large items of plant was 300mm thick with upstands to the

surface for soft spots and then a perimeter totalling all 480m2.

on site, particularly when working platform of 50 to 60mm

working near operational

of concrete was applied to seal On removal of the soffit support system,

classrooms.

the surface suitable for RBL’s mini the void around the perimeter of the

piling rigs. This also provided a slab was protected with ground support

T A high-bay single-storey steel

platform from which to form the systems, during backfilling.

framed and brick clad building

suspended COMBISLAB.

with heavy concentrated loads

Work on site took six weeks in total; two

and perimeter line loads was

• A mini piling rig weighing just weeks SFA piling and four weeks for the

proposed by the architects

2.5Tonnes was used to install 78 creation of the COMBISLAB.

and engineers.

No. 300mm piles to depths up to

11m using sectional flight augers

(SFA). Piles were sleeved above

formation level by 500mm in order

to build the pile head into the soffit

of the suspended raft.

Main advantages of COMBISLAB

• Can be ground bearing or suspended for heave protection or landfill gas ventilation

• Pile positions can be flexible to avoid obstructions in the ground

• Can be installed with ground treatment systems as well as piled systems, depending on ground conditions

• Suitable for large commercial, schools, hotels and residential developments

• Load sharing systems with settlement mitigation piles can apply to limit differential settlement where high

concentrated loads exist

• Minimal excavation is required which is useful on contaminated sites where disposal of arisings can be costly

• Construction is rapid, minimising site overheads

• Limited handovers between groundwork trades speeds up process

• Cost-effective solutions for most site conditions, designed and installed by one company

R Roger Bullivant Ltd. Head Office, Walton Road, Drakelow, Burton-on-Trent, Staffordshire DE15 9UA

T. 0845 838 1801 F. 01283 517 704 E. marketing@roger-bullivant.co.uk www.roger-bullivant.co.uk

You might also like

- CASE STUDY: COMBISLAB FOUNDATION OVERCOMES CONTAMINATION AND HEAVEDocument2 pagesCASE STUDY: COMBISLAB FOUNDATION OVERCOMES CONTAMINATION AND HEAVEFaraz HussainNo ratings yet

- June-July 2022 PressDocument40 pagesJune-July 2022 Pressdara o riordainNo ratings yet

- Dynamic Compaction and Dynamic Replacement1Document4 pagesDynamic Compaction and Dynamic Replacement1Nicoleta Maria IliesNo ratings yet

- Behavior of Structures With BasementsDocument13 pagesBehavior of Structures With BasementsAlly TNo ratings yet

- Glasgow Library Facade OverhaulDocument9 pagesGlasgow Library Facade OverhaulSubhishasri A K VNo ratings yet

- Glasgow University Library ReferenceDocument9 pagesGlasgow University Library ReferenceSubhishasri A K VNo ratings yet

- Case study: Foundations for new academy schoolDocument2 pagesCase study: Foundations for new academy schoolFaraz HussainNo ratings yet

- 4 Design and Construction of The Millennium Dome, UKDocument5 pages4 Design and Construction of The Millennium Dome, UKDiannisa Rachmawati100% (2)

- Deep Soil Mixing in Sabkha Soils For Foundation Support in United Arab EmiratesDocument15 pagesDeep Soil Mixing in Sabkha Soils For Foundation Support in United Arab EmiratesLale ÖnerNo ratings yet

- TOCIEJ-15-310Document10 pagesTOCIEJ-15-310DownNo ratings yet

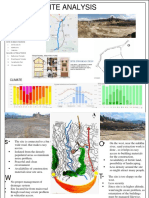

- Site AnalysisDocument1 pageSite Analysisbijaya neupaneNo ratings yet

- Bahrain International Airport: Remote Aircraft ApronsDocument2 pagesBahrain International Airport: Remote Aircraft ApronsRaymanNo ratings yet

- Basement ExcavationDocument4 pagesBasement ExcavationAnonymous U6pIEKQghNo ratings yet

- Foundation Packages - Pre-Cast Piles & Beams - Hagley RoadDocument2 pagesFoundation Packages - Pre-Cast Piles & Beams - Hagley RoadFaraz HussainNo ratings yet

- NotesDocument2 pagesNotesArslaan AlamNo ratings yet

- Application of Deep Foundation: (Yash Prabhat Priadarshi) (17-11-050)Document45 pagesApplication of Deep Foundation: (Yash Prabhat Priadarshi) (17-11-050)Yash PrabhatNo ratings yet

- 2008-quality-control-in-the-construction-of-reinforced-concrete-buildings-in-dar-es-salaamDocument7 pages2008-quality-control-in-the-construction-of-reinforced-concrete-buildings-in-dar-es-salaamArchibold KganyagoNo ratings yet

- Ground Treatment/Improvement Ground Treatment/Improvement: Materials Existing orDocument8 pagesGround Treatment/Improvement Ground Treatment/Improvement: Materials Existing orShahzada PhookNo ratings yet

- Basement General Illustration With Case ExamplesDocument109 pagesBasement General Illustration With Case Examplesronan1984No ratings yet

- Educational Facilities PlanningDocument29 pagesEducational Facilities PlanningRolando AlbertoNo ratings yet

- The Effects of Polycom On The Permeability of Compacted Clay Landfill Liners Conf - PaperDocument6 pagesThe Effects of Polycom On The Permeability of Compacted Clay Landfill Liners Conf - PaperChristopher TanjungNo ratings yet

- Rehabilitate RSU Complex and Buildings in RomblonDocument1 pageRehabilitate RSU Complex and Buildings in RomblonL.J. IlaganNo ratings yet

- S1 Perbaikan Tanah - Chapter Preloading Lecture HandoutDocument42 pagesS1 Perbaikan Tanah - Chapter Preloading Lecture HandoutsakuNo ratings yet

- Flexiarch: From Concept To Practical Applications: Beng, MSC, PHD BSC, PHD, Ceng, Fistructe Btech, Mtech, Mphil BengDocument6 pagesFlexiarch: From Concept To Practical Applications: Beng, MSC, PHD BSC, PHD, Ceng, Fistructe Btech, Mtech, Mphil BengFicior ConstantinNo ratings yet

- Chapter 4 Soil ImprovementDocument35 pagesChapter 4 Soil Improvementsyamsey16No ratings yet

- Construction Defects: DefinitionDocument12 pagesConstruction Defects: Definitionzoya mariamNo ratings yet

- Cost Effective Geotechnical Solutions For Roads and Factories Over Soft GroundDocument9 pagesCost Effective Geotechnical Solutions For Roads and Factories Over Soft GroundHanumantha Rao BNo ratings yet

- Hot Climate Double Facades A Focus On Solar AvoidanceDocument47 pagesHot Climate Double Facades A Focus On Solar AvoidanceMohamedNo ratings yet

- Construction Today MagazineDocument1 pageConstruction Today MagazineSchofield MediaNo ratings yet

- Why Brick Bat Coba Is Not WaterproofingDocument2 pagesWhy Brick Bat Coba Is Not WaterproofingpankajmandloiNo ratings yet

- Comparative study on methods for foundations in collapsible soilsDocument28 pagesComparative study on methods for foundations in collapsible soilsskumar_93691No ratings yet

- Slope and Site Stabilization (Article) Author Crow Wing CountyDocument5 pagesSlope and Site Stabilization (Article) Author Crow Wing CountyAmr AlawdiNo ratings yet

- 3 Dynamic ReplacementDocument2 pages3 Dynamic ReplacementAmw Mohamed AmwNo ratings yet

- Building With Straw Bales A Practical Manual For S... - (Contents)Document10 pagesBuilding With Straw Bales A Practical Manual For S... - (Contents)Yuchen WuNo ratings yet

- Chapter1 Week2Document7 pagesChapter1 Week2Mohammad NaimNo ratings yet

- EarthworkDocument54 pagesEarthworkNurul AmiraNo ratings yet

- 4 Design and Construction of The Millennium Dome, UKDocument4 pages4 Design and Construction of The Millennium Dome, UKTarun SebastianNo ratings yet

- Poster DefectsinconstructionDocument11 pagesPoster DefectsinconstructionniluNo ratings yet

- Dynamic Compaction and Replacement TechniquesDocument4 pagesDynamic Compaction and Replacement Techniquescepi herdiyanNo ratings yet

- Construction Defects: Causes and RemediesDocument11 pagesConstruction Defects: Causes and RemediesniluNo ratings yet

- Hot Climate Double Facades - A Focus On Solar AvoidanceDocument47 pagesHot Climate Double Facades - A Focus On Solar AvoidanceRodrigo Carlos FritschNo ratings yet

- 12 - The Edge - Does IBS Really Reduce Construction CostDocument2 pages12 - The Edge - Does IBS Really Reduce Construction CostKung FooNo ratings yet

- Advantages of Precast Concrete ConstructionDocument12 pagesAdvantages of Precast Concrete Constructionvalerie samarNo ratings yet

- Lime N1Document10 pagesLime N1Abbas AyadNo ratings yet

- Strength Parameters of Various Soils With AdmixtureDocument4 pagesStrength Parameters of Various Soils With AdmixtureSaksham KumarNo ratings yet

- Case Histories of Pile Foundations in Bombay RegionDocument7 pagesCase Histories of Pile Foundations in Bombay RegionRaghu PrasanthNo ratings yet

- GEOBAMTILE Presentation 25 Oct 2019 PDFDocument64 pagesGEOBAMTILE Presentation 25 Oct 2019 PDFsal harun100% (1)

- Engineers Ireland: Piled Embankments - Recent Experiences in IrelandDocument9 pagesEngineers Ireland: Piled Embankments - Recent Experiences in Irelandsandycastle100% (1)

- A Study On The NeedDocument4 pagesA Study On The NeedlohitsnNo ratings yet

- The Precast Advantage: Quality, Value, Permanence: BriefDocument1 pageThe Precast Advantage: Quality, Value, Permanence: BriefEmille CarabeoNo ratings yet

- Build Over Guide: Who Do I Contact?Document2 pagesBuild Over Guide: Who Do I Contact?Barrasons Engineers TeamNo ratings yet

- Pages from 104_NZGS_Dec2022-FinalDocument3 pagesPages from 104_NZGS_Dec2022-FinalilamaranNo ratings yet

- CLC International Brochure - EnglishDocument4 pagesCLC International Brochure - EnglishAishwarya KumarNo ratings yet

- 2019 Dufaylite - Clayboard BrochureDocument9 pages2019 Dufaylite - Clayboard Brochurecolinbooth91No ratings yet

- (Moyes, Etal 2005) Piled Raft Design Process For A High-Rise Building On The Gold Coast, AustraliaDocument9 pages(Moyes, Etal 2005) Piled Raft Design Process For A High-Rise Building On The Gold Coast, AustraliaHarrison StamoudisNo ratings yet

- Journal 1Document13 pagesJournal 1009 Dhanush Gowtham HNo ratings yet

- Application of Micro Tunneling Technique To Rectify Tilted Structures Constructed On Cohesive SoilDocument9 pagesApplication of Micro Tunneling Technique To Rectify Tilted Structures Constructed On Cohesive SoilMohamed EidNo ratings yet

- A Practical Guide To The NEC4 Engineering and Cons... - (2 Tables of Client's Project Manager's Supervisor's Contractor's Senio... )Document38 pagesA Practical Guide To The NEC4 Engineering and Cons... - (2 Tables of Client's Project Manager's Supervisor's Contractor's Senio... )Faraz HussainNo ratings yet

- Case study: Foundations for new academy schoolDocument2 pagesCase study: Foundations for new academy schoolFaraz HussainNo ratings yet

- Ground Improvement and Piling: Mai N Cont Ract orDocument2 pagesGround Improvement and Piling: Mai N Cont Ract orFaraz HussainNo ratings yet

- 01 - Midlands Office Contacts 2017Document1 page01 - Midlands Office Contacts 2017Faraz HussainNo ratings yet

- مجموعة أحزاب وأوراد الشيخ الأكبر إبن عربيDocument367 pagesمجموعة أحزاب وأوراد الشيخ الأكبر إبن عربيEbu Eba100% (1)

- 57 Chandos Street (Existing and Proposed Plans) 04.02.2020 PDFDocument1 page57 Chandos Street (Existing and Proposed Plans) 04.02.2020 PDFFaraz HussainNo ratings yet

- Hizb Fath Al Basaair EnglishDocument3 pagesHizb Fath Al Basaair EnglishFaraz HussainNo ratings yet

- Foundation Packages - Pre-Cast Piles & Beams - Hagley RoadDocument2 pagesFoundation Packages - Pre-Cast Piles & Beams - Hagley RoadFaraz HussainNo ratings yet

- Wazifa Ash ShadhiliyyaDocument23 pagesWazifa Ash ShadhiliyyaFaraz HussainNo ratings yet

- RC Wall DesignDocument30 pagesRC Wall DesignFaraz HussainNo ratings yet

- Tosun Baba Farewell LetterDocument1 pageTosun Baba Farewell LetterFaraz HussainNo ratings yet

- Northridge SymposiumDocument38 pagesNorthridge SymposiumFaraz HussainNo ratings yet

- HydrostaticDocument9 pagesHydrostaticRezza AdityaNo ratings yet

- HydrostaticDocument9 pagesHydrostaticRezza AdityaNo ratings yet

- Cross Newsletter 54Document9 pagesCross Newsletter 54Faraz HussainNo ratings yet

- Site preparation and plate bearing tests for compacted fillDocument1 pageSite preparation and plate bearing tests for compacted fillFaraz HussainNo ratings yet

- Standard Detail Drawings (Civils) PDFDocument62 pagesStandard Detail Drawings (Civils) PDFMaram Al-MasriNo ratings yet

- MenuDocument2 pagesMenuFaraz HussainNo ratings yet

- Breastfeeding With Thrush: Signs and Symptoms For The MotherDocument2 pagesBreastfeeding With Thrush: Signs and Symptoms For The MotherFaraz HussainNo ratings yet

- Training Request and Tracking: Business Management System FormDocument1 pageTraining Request and Tracking: Business Management System FormFaraz HussainNo ratings yet

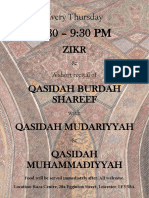

- Every Thursday: & A Short Recital ofDocument1 pageEvery Thursday: & A Short Recital ofFaraz HussainNo ratings yet

- ﲓﺣﺮﻟا ﻦﲪﺮﻟا ﷲ ﻢﺴ� Every Thursday: & A Short Recital ofDocument1 pageﲓﺣﺮﻟا ﻦﲪﺮﻟا ﷲ ﻢﺴ� Every Thursday: & A Short Recital ofFaraz HussainNo ratings yet

- Zikr Poster2 PDFDocument1 pageZikr Poster2 PDFFaraz HussainNo ratings yet

- World of Roof TechnologyDocument87 pagesWorld of Roof TechnologyjustinadoiNo ratings yet

- ("Error":"Only 1 Parallel Operations Allowed","Extensions": ("Code":"Parallellimitexceeded","Status":400) )Document1 page("Error":"Only 1 Parallel Operations Allowed","Extensions": ("Code":"Parallellimitexceeded","Status":400) )Faraz HussainNo ratings yet

- JUNE Monthly Prayer TimesDocument1 pageJUNE Monthly Prayer TimesFaraz HussainNo ratings yet

- Padstones Bearing Lengths MM) Max Fac Reaction F Under BearingDocument19 pagesPadstones Bearing Lengths MM) Max Fac Reaction F Under BearingFaraz HussainNo ratings yet

- DIN EN 1504-BasfDocument48 pagesDIN EN 1504-Basfcostinl100% (4)

- Specification For RCC Boundary KM Stone and Guard Stone 1. ScopeDocument3 pagesSpecification For RCC Boundary KM Stone and Guard Stone 1. ScopeAakash2013No ratings yet

- MECHANICS OF DEFORMABLE BODIES: FUNDAMENTALS OF STRAIN AND DEFORMATIONDocument70 pagesMECHANICS OF DEFORMABLE BODIES: FUNDAMENTALS OF STRAIN AND DEFORMATIONIan Arnold Fami100% (1)

- 3R-2D JB 15A DiodeDocument4 pages3R-2D JB 15A DiodeSuryanshu KushwahaNo ratings yet

- Arch Bridge Code-ACS-8 PDFDocument8 pagesArch Bridge Code-ACS-8 PDFshobhit mohtaNo ratings yet

- Control of Cracking Due To End Restraint: Input Parameters Symbol Unit ValueDocument1 pageControl of Cracking Due To End Restraint: Input Parameters Symbol Unit ValuedsureshcivilNo ratings yet

- Steel Sheet Piling Design ManualDocument6 pagesSteel Sheet Piling Design ManualAddrien DanielNo ratings yet

- Ambient Accoustic Ceiling Systems - Brochure A4 PDFDocument16 pagesAmbient Accoustic Ceiling Systems - Brochure A4 PDFhuychungngNo ratings yet

- JCSR FinDocument39 pagesJCSR FinvictorNo ratings yet

- Pavilion Embassy Tower EDocument20 pagesPavilion Embassy Tower EHa RuNo ratings yet

- Dan Gelbart Coursenotes2Document23 pagesDan Gelbart Coursenotes2zorkerNo ratings yet

- Halo Outdoor slmt1000 - slmt1000wDocument1 pageHalo Outdoor slmt1000 - slmt1000wFrank MoyaNo ratings yet

- Standard Power Cables for Low Voltage ApplicationsDocument5 pagesStandard Power Cables for Low Voltage Applicationsmo shNo ratings yet

- Convection Heat Transfer in a Square Copper RodDocument20 pagesConvection Heat Transfer in a Square Copper RodAashutosh GargNo ratings yet

- !indx DWG IDocument23 pages!indx DWG IAmolNo ratings yet

- Natural Convection Heat Transfer On A Vertical C 2014 International JournalDocument8 pagesNatural Convection Heat Transfer On A Vertical C 2014 International JournalAnonymous vVsidh3nNo ratings yet

- Chapter 2 ManifoldsDocument34 pagesChapter 2 ManifoldsFeras BatarsehNo ratings yet

- A07 PPTDocument55 pagesA07 PPTashutosh JhaNo ratings yet

- Bv421 Pressure Reducing ValveDocument4 pagesBv421 Pressure Reducing ValveFAIYAZ AHMEDNo ratings yet

- Bulwark Profile 23rd DecDocument138 pagesBulwark Profile 23rd DecMohanakrishnan SNo ratings yet

- Cement & Concrete Composites: Farid Debieb, Luc Courard, Said Kenai, Robert DegeimbreDocument6 pagesCement & Concrete Composites: Farid Debieb, Luc Courard, Said Kenai, Robert DegeimbreRajaa KodadNo ratings yet

- INDUSTRY GUIDE T38 Reinforced Concrete Design in Accordance With AS3600Document225 pagesINDUSTRY GUIDE T38 Reinforced Concrete Design in Accordance With AS3600Peter WestNo ratings yet

- ACI 318 08 Design of Retaining Wall With Counterfort Rev1Document4 pagesACI 318 08 Design of Retaining Wall With Counterfort Rev1Soe ThihaNo ratings yet

- PCI MNL-116-99 Structural QC Manual PDFDocument332 pagesPCI MNL-116-99 Structural QC Manual PDFJason Powell100% (1)

- Silicone Encapsulants and GelsDocument12 pagesSilicone Encapsulants and GelssundarNo ratings yet

- Beam DesignDocument3 pagesBeam DesignDeepak SahNo ratings yet

- ASHRAE Report On Pre Cooling With Indirect Evaporative CoolingDocument8 pagesASHRAE Report On Pre Cooling With Indirect Evaporative CoolingAhmad Mahrous AboulsoudNo ratings yet

- Air Cooled Package Unit with Scroll CompressorsDocument48 pagesAir Cooled Package Unit with Scroll CompressorsMUBASHIRNo ratings yet

- PW-3 Part Design For Ultrasonic Welding (Single PGS) HRDocument8 pagesPW-3 Part Design For Ultrasonic Welding (Single PGS) HRHugoAlvarez100% (1)

- Prestressed Concrete Poles - State-of-the-Art PDFDocument52 pagesPrestressed Concrete Poles - State-of-the-Art PDFEduardo QuintanaNo ratings yet