Professional Documents

Culture Documents

7.1 Table I

Uploaded by

PabloOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7.1 Table I

Uploaded by

PabloCopyright:

Available Formats

INCH-POUND

A-A-59569C

22 January 2009

SUPERSEDING

A-A-59569B

12 February 2008

COMMERCIAL ITEM DESCRIPTION

BRAID, WIRE (COPPER, TIN-COATED, SILVER-COATED,

OR NICKEL COATED, TUBULAR OR FLAT)

The General Services Administration has authorized the use of this

commercial item description for all federal agencies.

1. SCOPE. This commercial item description (CID) covers the general requirements for braid, wire

(copper, tin-coated, silver-coated, or nickel coated, tubular or flat). Braid, wire (copper, tin-coated, silver-

coated, or nickel coated, tubular or flat) covered by this CID are intended for commercial/industrial

applications.

2. CLASSIFICATION/PART OR IDENTIFICATION NUMBER (PIN). This CID uses a classification

system which is included in the PIN as shown in the following example (see 7.1).

The PIN is made up of the basic CID number and a four-element alphanumeric number (see table I):

Example of PIN: AA59569R36T0375

AA59569 R 36 T 0375

Inside diameter (mils) (see table I)

T = Tin

Strand Coating S = Silver

N = Nickel

American Wire Gauge (AWG) of

individual strands (see table I)

Form R = Tubular

F = Flat

Federal specification

Beneficial comments, recommendations, additions, deletions, clarifications, etc., and any data that

may improve this document should be sent to: Defense Supply Center, Columbus, ATTN: DSCC-

VAI, P.O. Box 3990, Columbus OH 43218-3990, or email to WireCable@dscc.dla.mil. Since

contact information can change you may want to verify the currency of the address information

using the ASSIST Online database at http://assist.daps.dla.mil .

AMSC N/A FSC 6145

Source: https://assist.dla.mil -- Downloaded: 2016-06-14T20:12Z

Check the source to verify that this is the current version before use.

A-A-59569C

3. SALIENT CHARACTERISTICS.

3.1 Interface and physical dimensions. Braid wire supplied to this CID shall be as specified herein.

3.2 Materials. The wire used in the construction of braids shall conform to ASTM B33 for tinned copper,

ASTM B298 for silver-coated copper, except that the silver coating shall be a minimum of 40 micro-inches

thick, and ASTM B355 for nickel-coated copper, except the nickel coating shall be a minimum of 50

micro-inches thick.

3.2.1 Recycled, recovered, or environmentally preferable materials. Recycled, recovered, or

environmentally preferable materials should be used to the maximum extent possible provided that the

material meets or exceeds the operational and maintenance requirements, and promotes economically

advantageous life cycle costs.

3.3 Design and construction. The wire braid shall have the numbers of carriers and ends shown in

table I.

3.3.1 Wire lengths. Individual wires shall be to sizes shown in table I and shall be uniform in cross-

section. Each wire shall be one continuous length, free from splices except as specified herein.

3.3.2 Splices.

3.3.2.1 Carrier splices. There shall be no more than one splice or break in any carrier in each 25-foot

length of the braid.

3.3.2.2 Wire splices. Excluding the carrier splice, there shall be no more than one broken or spliced end

of wire in each 25-foot length of the braid.

Source: https://assist.dla.mil -- Downloaded: 2016-06-14T20:12Z

Check the source to verify that this is the current version before use.

A-A-59569C

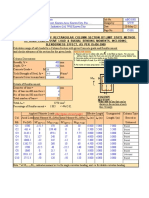

TABLE I. Braid dimensions and data.

PIN 1/ Strand Current Approx. Flat form width

Tubular inside

wire Number of Number of rating AWG x thickness

diameter (inches)

size carriers ends (amps) equiv. (inches)

AA59569 2/

(AWG) 3/ 4/ 5/

*36*0031 36 .031 24 24 7.0 22 .046x.020

*36*0062 36 .062 24 48 11.0 19 .093x.031

*34*0062 34 .062 16 32 11.0 19 -

*32*00627/ 32 .062 16 16 9.0 20 -

*36*0078 36 .078 24 72 16.0 18 .125x .020

*36*0109 36 .109 24 96 19.0 16 .156x .031

*34*01097/ 34 .109 16 64 19.0 16 -

*32*01097/ 32 .109 16 32 18.0 17 -

*36*0125 36 .125 24 120 25.0 15 .187x .020

*34*0125 34 .125 24 72 19.0 16 -

*32*01257/ 32 .125 24 48 25.0 15 -

*36*0156 36 .156 24 240 40.0 12 .250x.046

*36*0171 36 .171 24 168 32.0 14 .250x.030

*34*0171 34 .171 24 120 36.0 13 -

*32*01717/ 32 .171 24 72 32.0 14 -

*36*0203 36 .203 24 312 46.0 11 .281x.046

*34*0203 34 .203 24 192 46.0 11 -

*32*02037/ 32 .203 24 120 46.0 11 -

*36*0250 36 .250 24 384 53.0 10 -

*30*0281 30 .281 24 120 60.0 9 -

*36*0375 36 .375 48 384 53.0 10 .625x.030

*34*0375 34 .375 48 240 53.0 10 -

*32*0375 32 .375 48 144 46.0 11 -

*30*03757/ 30 .375 24 1686/ 75.0 8 -

*30*0437 30 .437 24 240 90.0 6 .500x.093

*36*0500 36 .500 48 528 62.0 9 .625x.046

*34*0500 34 .500 48 336 62.0 9 -

*32*05007/ 32 .500 48 192 62.0 9 -

*30*0500 30 .500 24 360 120.0 6 .625x.093

*30*0562 30 .562 48 480 145.0 3 -

*30*0656 30 .656 48 768 190.0 1 -

*36*0781 36 .781 48 864 88.0 7 .750x.040

*34*0781 34 .781 48 528 88.0 7 -

*32*0781 32 .781 48 336 88.0 7 -

*30*0875 30 .875 48 336 100.0 5 1.375x.050

*30*1000 30 1.000 48 384 120.0 4 -

*30*1125 30 1.125 48 432 130.0 4 -

*30*1375 30 1.375 48 528 150.0 3 1.500x.060

*30*1500 30 1.500 48 576 165.0 2 -

*30*2000 30 2.000 48 672 180.0 2 -

See footnotes on next page.

Source: https://assist.dla.mil -- Downloaded: 2016-06-14T20:12Z

Check the source to verify that this is the current version before use.

A-A-59569C

TABLE I. Braid dimensions and data -Continued.

1/ The complete PIN shall include additional information to indicate the form (first asterisk) and strand

coating (second asterisk) (see 7.1).

2/ Dimensional tolerances shall be as shown in table II.

3/ Direct current ratings are given for information only and are not requirements. Values shown are for

uninsulated braid in free air at 30 C. Values should be derated if the braid is insulated or in close

contact with other components.

4/ Approximate AWG equivalents are given for information only and are not requirements.

5/ Flat form width and thickness are given for information only and are not requirements. Tolerances

shall be as shown in table II.

6/ This PIN supersedes the similar construction using 96 ends.

7/ It may not be possible to produce 90% coverage on these constructions.

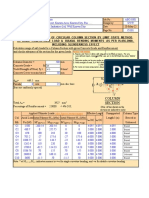

TABLE II. Dimensional tolerances (inches).

Dimensions Tolerance

.000 - .099 .010

.100 - .249 .016

.250 - .499 .031

.500 - .999 .063

Over .999 .094

3.3.3 Coverage (tubular braid only). Tubular braids shall have a braid angle or number of picks per inch

that produces a minimum of 90 percent coverage, except for .078-inch and smaller diameter braids,

which shall produce a minimum of 70 percent coverage. The percent of coverage shall be determined by

using the following formula.

K 100 2F F 2

NPW

F

CSinA

2πD 2W P

tanA

C

Where:

K = percent coverage of braided shield

A = braid angle

C = number of carriers (see table I)

D = inside diameter in inches (see table I)

N = total number of ends (see table I)

P = picks per inch (the number of times the carriers in a braid cross over each other in the

same direction along the longitudinal axis for each inch of length)

W= diameter of individual braid wire in inches

3.4 Flattening of tubular braid. Unless otherwise specified in the contract or order (see 7.2), tubular

shielding braid shall not be flattened beyond the point that would occur by its own weight only, when

wound on spools for shipping.

3.5 Solderability. Tin-coated and silver-coated braids shall possess good electrical and mechanical

solder joints when tested in accordance with MIL-STD-202, method 208.

Source: https://assist.dla.mil -- Downloaded: 2016-06-14T20:12Z

Check the source to verify that this is the current version before use.

A-A-59569C

3.6 Workmanship. The braid wire shall be processed in such a manner as to be uniform in quality and

shall be free from other defects that will affect life, serviceability, or appearance.

3.7 Marking. The braid wire supplied to this CID shall be marked with the manufacturer’s (MFR’s)

standard commercial PIN. The part number marked on the unit pack shall be the CID PIN.

4. REGULATORY REQUIREMENTS. The offeror/contractor is encouraged to use recovered materials to

the maximum extent practicable, in accordance with 23.403 of the Federal Acquisition Regulation (FAR).

5. PRODUCT CONFORMANCE PROVISIONS.

5.1 Product conformance. The products provided shall meet the salient characteristics of this CID,

conform to the producer’s own drawings, specifications, standards and quality assurance practices, and

be the same product offered for sale in the commercial market. The Government reserves the right to

require proof of such conformance.

5.2 Market acceptance. The following market acceptance criteria are necessary to document the quality

of the product to be provided under this CID:

a. The company producing the item must have been producing a product meeting the

requirements of this CID for at least 2 years.

b. The company producing the item must have sold 1,000 units meeting this CID in the

commercial marketplace over the past 2 years.

6. PACKAGING. Preservation, packing, and marking shall be as specified in the contract or order.

7. NOTES.

7.1 PIN. The PIN should be used for Government purposes to buy commercial products to this CID.

See section 2 for PIN format example.

7.2 Environmentally preferable material. Environmentally preferable materials should be used to the

maximum extent possible to meet the requirements of this specification. As of the dating of this

document, the U.S. Environmental Protection Agency (EPA) is focusing efforts on reducing 31 priority

chemicals. The list of chemicals and additional information is available on their website

http://www.epa.gov/osw/hazard/wastemin/priority.htm. Use of these materials should be minimized or

eliminated unless needed to meet the requirements specified herein (see section 3.)

7.3 Commercial and Government Entity (CAGE) code. For ordering purposes, inventory control, and

submission of these braids to DSCC under the Military Parts Control Advisory Group (MPCAG) evaluation

program, CAGE code 26916 should be used.

Source: https://assist.dla.mil -- Downloaded: 2016-06-14T20:12Z

Check the source to verify that this is the current version before use.

A-A-59569C

7.4 Source of documents.

FEDERAL STANDARD

FED-STD-123 - Marking for Shipment (Civil Agencies)

DEPARTMENT OF DEFENSE SPECIFICATION

MIL-DTL-12000 - Cable, Cord, and Wire, Electric, Packaging of

DEPARTMENT OF DEFENSE STANDARD

MIL-STD-202 - Electronic and Electrical Component Parts

(Copies of these documents are available online at http://assist.daps.dla.mil/quicksearch/ or from the

Standardization Document Order Desk, 700 Robbins Avenue, Building 4D, Philadelphia, PA 19111-

5094.)

FEDERAL REGULATIONS

FAR - Federal Acquisition Regulations (FAR).

(Copies of these documents are available online at www.acquisition.gov/comp/far/index.html or from

the U.S. Government Printing Office, 732 North Capital Street, NW, Washington D.C. 20401.)

Other Publications

ASTM INTERNATIONAL

ASTM B33 - Wire, Tinned Soft or Annealed Copper for Electrical Purposes

ASTM B298 - Wire, Copper, Silver-Coated Soft or Annealed

ASTM B355 - Nickel-Coated Soft or Annealed Copper Wire

(Copies of these documents are available online at http://www.astm.org or from the ASTM International,

P.O. Box C700, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959.)

7.5 Ordering data. The contract or order should specify the following:

a. CID document number, revision, and CID PIN.

b. PIN (see table I and 7.1)

c. Resistance to flattening, if other than specified (see 3.4)

d. Packaging requirements (see 6. and 7.8)

e. Unspliced braid length requirements and proportions (see 7.7)

7.6 Nickel coating. The use of nickel-coated copper braids shall be used only when tin-coated or silver-

coated braids cannot meet the intended performance requirements.

7.7 Braid lengths. Unless otherwise specified in the contract or order (see 7.5), 90 percent of the total

order for braid shall be supplied in continuous, unspliced lengths as shown in table III. The remaining 10

percent of the total order for braid shall be acceptable in random unspliced lengths as shown in table III.

Source: https://assist.dla.mil -- Downloaded: 2016-06-14T20:12Z

Check the source to verify that this is the current version before use.

A-A-59569C

TABLE III. Unspliced braid length.

Braid Unspliced lengths

Diameter 90% 10%

(inches) (nominal lengths) (minimum lengths)

.171 250 feet 50 feet

.203 100 feet 25 feet

7.8 Packaging requirements. The packaging and marking requirements for wire braid should be in

accordance with MIL-DTL-12000, except for the marking of shipments to civil agencies and the additional

marking of spools and reels, both listed below.

7.8.1 Marking for civil agency procurement. The container marking of shipments to civil agencies should

be in accordance with FED-STD-123.

7.8.2 Marking of spools and reels. In addition to the marking requirements of MIL-DTL-12000, each

spool and reel should be marked with the following information:

a. PIN

b. Net weight (in pounds)

c. Date (month, day, and year) of manufacture

d. Manufacturer’s CAGE Code or trademark

7.9 Commercial products. As part of the market analysis and research effort, this CID was coordinated

with the following manufacturers of commercial products. At the time of CID preparation and

coordination, these manufacturers were known to have commercial products that would meet the

requirements of this CID. (NOTE: This information should not be considered as a list of approved

manufacturers or be used to restrict procurement to only the manufacturers shown.)

MFR's CAGE MFR's name and address

26916 Northrup Grumman Systems Corporation

600 Hicks Road

Rolling Meadows, IL 60008-1098

Telephone: 410-765-8926

Fax: 410-765-6809

http://www.northgrum.com

7.10 P/N supersession data. These CID PINs supersede the following MFR’s P/N's as shown

(see table IV). This information is being provided to assist in reducing proliferation in the Government

inventory system.

TABLE IV. P/N supersession data.

Dash number MFR's CAGE MFR's P/N 1/

(see table I)

*36*0375

001 26916 087-011309-011

1/ The manufacturer's P/N shall not be used for procurement to the requirements of this

CID. At the time of preparation of this CID, the aforementioned commercial products

were reviewed and could be replaced by the CID PIN shown.

Source: https://assist.dla.mil -- Downloaded: 2016-06-14T20:12Z

Check the source to verify that this is the current version before use.

A-A-59569C

7.11 Government users. To acquire information on obtaining these wire braids from the Government

inventory system, contact Defense Supply Center, Columbus, ATTN: DSCC-CDCA, P.O. Box 3990,

Columbus, OH 43218-3990, or telephone (614) 692-7940.

7.11.1 National stock number (NSN). The following is a list of NSN's assigned which correspond to this

CID (see table V). The list is for information only and may not be indicative of all possible NSN's

associated with the CID. For up to date information on assigned NSN's, please contact the

aforementioned DSCC office (see 7.11).

TABLE V. NSN's.

Dash number NSN

(see table I)

*36*0375

001 6145-00-194-9829

7.12 Key words.

Shield

7.13 Changes from previous issue. Marginal notations are not used in this revision to identify changes

with respect to the previous issue due to the extensiveness of the changes.

MILITARY INTERESTS: CIVIL AGENCY

COORDINATING ACTIVITIES:

Custodians:

Army - CR GSA - FSS

Navy - AS

Air Force - 85 Preparing Activity:

DLA - CC DLA - CC

Review activities: (Project 6145-2008-114)

Army - AR, AT, AV, CR4, MI

Navy - MC, OS, SH

DTRA - DS

NSA - NS

NOTE: The activities listed above were interested in this document as of the date of this document. Since

organizations and responsibilities can change, you should verify the currency of this information above

using the ASSIST Online database at http://assist.daps.dla.mil.

Source: https://assist.dla.mil -- Downloaded: 2016-06-14T20:12Z

Check the source to verify that this is the current version before use.

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Glenair:

AA59569R36T0125 AA59569R36T0250 AA59569R30T1375 AA59569R36T0781 AA59569R36T0375

AA59569R36T0171 AA59569R36S0109 AA59569R34T0781 AA59569R36S0250 AA59569R30N0437

AA59569R32T0500 AA59569R34N0203 AA59569R34T0125 AA59569R34T0500 AA59569R36N0250

AA59569R36N0375 AA59569R36N0500 AA59569R36N0781 AA59569R36S0078

You might also like

- HV Connectors Test Report PDFDocument21 pagesHV Connectors Test Report PDFMohammed ShoaibNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Structural Details of Column: Table of Reinforcement DetailsDocument1 pageStructural Details of Column: Table of Reinforcement DetailsAswin KumarNo ratings yet

- Raychem Wire To Wire SpliceDocument4 pagesRaychem Wire To Wire SpliceRiki NurzamanNo ratings yet

- Fineadjust Applicator Specification Sheet Order No. 63900-0100Document5 pagesFineadjust Applicator Specification Sheet Order No. 63900-0100Amine MaaouiNo ratings yet

- Actuators Complet RDocument44 pagesActuators Complet RAhmed ElkashifNo ratings yet

- Slab Design PDFDocument2 pagesSlab Design PDFlohithaNo ratings yet

- MMBD3004A/C/S: High Voltage Surface Mount Dual Switching DiodeDocument5 pagesMMBD3004A/C/S: High Voltage Surface Mount Dual Switching DiodemrscribdNo ratings yet

- For Axial Compressive Load & Biaxial Bending Moments, Including Slenderness Effect, As Per Is:456-2000Document43 pagesFor Axial Compressive Load & Biaxial Bending Moments, Including Slenderness Effect, As Per Is:456-2000Satish Khadse100% (1)

- DryLin T TS-01Document1 pageDryLin T TS-01Fábio LeiteNo ratings yet

- Tinned Copper Flexible Braid SpecificationDocument1 pageTinned Copper Flexible Braid SpecificationvkmsNo ratings yet

- Locater 1Document76 pagesLocater 1Riky NailizaNo ratings yet

- Circular Column DesignDocument24 pagesCircular Column DesignnpwalNo ratings yet

- Series CatalogueDocument13 pagesSeries Catalogueatul vermaNo ratings yet

- PB-B1 Surface 400 Basement 80 100Document1 pagePB-B1 Surface 400 Basement 80 100rawda moawadNo ratings yet

- Power and Wiring CablesDocument82 pagesPower and Wiring CablesZzzdddNo ratings yet

- TD012036EN Series C - MDL-FRAME PDFDocument16 pagesTD012036EN Series C - MDL-FRAME PDFBolivar MartinezNo ratings yet

- Molex Maquina Terminales 2002181900-000Document8 pagesMolex Maquina Terminales 2002181900-000FransoloNo ratings yet

- DW144 Smacna 2005Document32 pagesDW144 Smacna 2005Angel Daniel GarciajoyaNo ratings yet

- Bs 170Document4 pagesBs 170zektorNo ratings yet

- HoshizakiDocument40 pagesHoshizakiDaniel jimenezNo ratings yet

- Sony klv-22bx300 klv-26bx300 klv-32bx300 klv-40bx400 SMDocument24 pagesSony klv-22bx300 klv-26bx300 klv-32bx300 klv-40bx400 SMGerardo ReyesNo ratings yet

- Bi Ax Column DesignDocument44 pagesBi Ax Column DesignRAJESHRANE0% (1)

- 9619 Sony KLV-22BX300 26BX300 32BX300 40BX400 Chassis AZ1-A Televisor LCD Manual de ServicioDocument24 pages9619 Sony KLV-22BX300 26BX300 32BX300 40BX400 Chassis AZ1-A Televisor LCD Manual de ServicioAnibal Pereira0% (1)

- Flexible Cables and Cords: PVC Types Rubber TypesDocument68 pagesFlexible Cables and Cords: PVC Types Rubber TypeswhendelNo ratings yet

- CableDocument68 pagesCableS.L.jayaratneNo ratings yet

- D1836 Series (Nas1836)Document1 pageD1836 Series (Nas1836)blackhawkNo ratings yet

- Cir ColumnDocument24 pagesCir ColumnSatish KhadseNo ratings yet

- SC103Document11 pagesSC103Amr HassanNo ratings yet

- Column Splice Connection (In-Situ)Document2 pagesColumn Splice Connection (In-Situ)Nitesh Singh100% (1)

- AXIS Cable Glands - AKBAR TRADING EST - SAUDI ARABIA - Mail@Document20 pagesAXIS Cable Glands - AKBAR TRADING EST - SAUDI ARABIA - Mail@GIBU100% (1)

- 285FPJ 270Document2 pages285FPJ 270dip461No ratings yet

- Description: Mechanical DataDocument2 pagesDescription: Mechanical Datadip461No ratings yet

- I - Rectangular Ducts: II - Rectangular Ducts WeldedDocument32 pagesI - Rectangular Ducts: II - Rectangular Ducts WeldedRoy Anthone Layson100% (11)

- BS 6622 XLPE PVC 6.35/11 (12) KV CableDocument4 pagesBS 6622 XLPE PVC 6.35/11 (12) KV Cablemo shNo ratings yet

- MS27039FDocument6 pagesMS27039FbobbyfortunaNo ratings yet

- H05BZ5-F / H07BZ5-F EV Connection Cable: Standards ApplicationDocument2 pagesH05BZ5-F / H07BZ5-F EV Connection Cable: Standards ApplicationIonut CamelinNo ratings yet

- Control and Signal CableDocument3 pagesControl and Signal CableLuis Carlos ValdezNo ratings yet

- Power CableDocument5 pagesPower Cablemohan babuNo ratings yet

- SC103Document11 pagesSC103Amr HassanNo ratings yet

- Sap Inspection Lot Status - 4 Jan 2017Document3 pagesSap Inspection Lot Status - 4 Jan 2017bahrian907No ratings yet

- Panel Strength Calclation (4t APfr)Document2 pagesPanel Strength Calclation (4t APfr)Azahar Bin HashimNo ratings yet

- Clampstar Data Chart U.S.Document1 pageClampstar Data Chart U.S.Chris CostanzoNo ratings yet

- Section 1 Power & Wiring Cables PDFDocument83 pagesSection 1 Power & Wiring Cables PDFMohamed AhmedNo ratings yet

- T SR ARMET SIMRIT I II Tape Silicone Rubber Freudenberg NOK Equivalent Electrical InsulationDocument1 pageT SR ARMET SIMRIT I II Tape Silicone Rubber Freudenberg NOK Equivalent Electrical InsulationFábioNo ratings yet

- 2.bien Phap Thi Cong Ong GioDocument19 pages2.bien Phap Thi Cong Ong GioQuang Do HoangNo ratings yet

- QT Iii 7622 S2Document28 pagesQT Iii 7622 S2ING CASTILLONo ratings yet

- K034 - Daikoflux 940Document1 pageK034 - Daikoflux 940cwiksjNo ratings yet

- Catalog Thang Mang Cap enDocument20 pagesCatalog Thang Mang Cap endangtuan27No ratings yet

- Skirt Support Analysis TransportDocument5 pagesSkirt Support Analysis TransportHunnymijie NorNo ratings yet

- 0361TQ BS EN 60332-1-2 BS 638: Orange Welding CableDocument3 pages0361TQ BS EN 60332-1-2 BS 638: Orange Welding CableFacundo ArlistanNo ratings yet

- SHIMANO 105 Front Derailleur: (2x11-Speed) Black / SilverDocument1 pageSHIMANO 105 Front Derailleur: (2x11-Speed) Black / SilverBrandon GomezNo ratings yet

- 2491x h05v K h07v K Bs en 50525 2 31 Flexible CableDocument3 pages2491x h05v K h07v K Bs en 50525 2 31 Flexible CableRicardo Mendes100% (1)

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- Switchcraft 712aDocument2 pagesSwitchcraft 712aAlexandruStratilaNo ratings yet

- 3PS 250 2WT 2Document6 pages3PS 250 2WT 2PabloNo ratings yet

- HTCM SCE TP 1 - 2 4H 9kDocument4 pagesHTCM SCE TP 1 - 2 4H 9kPabloNo ratings yet

- Axon pCLAMP 11Document4 pagesAxon pCLAMP 11PabloNo ratings yet

- MBS0 50SVDocument2 pagesMBS0 50SVPabloNo ratings yet

- PKN0 13BKDocument1 pagePKN0 13BKPabloNo ratings yet

- Part Number: Status: Overview: Description:: DocumentsDocument1 pagePart Number: Status: Overview: Description:: DocumentsPabloNo ratings yet

- 7.1 Table IDocument9 pages7.1 Table IPabloNo ratings yet

- Part Number: Status: Overview: Description:: DocumentsDocument1 pagePart Number: Status: Overview: Description:: DocumentsPabloNo ratings yet

- M27500 22sr2u00Document5 pagesM27500 22sr2u00PabloNo ratings yet

- Part Number: Status: Overview: Description:: DocumentsDocument1 pagePart Number: Status: Overview: Description:: DocumentsPabloNo ratings yet

- TYZ523MDocument3 pagesTYZ523MPabloNo ratings yet

- Thin-Wall, Semirigid, Fluoropolymer Heat-Shrinkable Tubing: Temperature RatingDocument3 pagesThin-Wall, Semirigid, Fluoropolymer Heat-Shrinkable Tubing: Temperature RatingPabloNo ratings yet

- M22759 - 33 26 9Document3 pagesM22759 - 33 26 9PabloNo ratings yet

- ST18 3 55 22 5Document1 pageST18 3 55 22 5PabloNo ratings yet

- SN63 PB37Document1 pageSN63 PB37PabloNo ratings yet

- Band-It: Tools and Tool Kits For Reliable Shield TerminationDocument5 pagesBand-It: Tools and Tool Kits For Reliable Shield TerminationPabloNo ratings yet

- NAS1744Document2 pagesNAS1744PabloNo ratings yet

- CPS Fitting Stations by County - 22 - 0817Document33 pagesCPS Fitting Stations by County - 22 - 0817Melissa R.No ratings yet

- Industrial Disputes Act1947 Cases: By: Anil Ashish Topno ROLL NO: 12003 Retail Management 2 YearDocument15 pagesIndustrial Disputes Act1947 Cases: By: Anil Ashish Topno ROLL NO: 12003 Retail Management 2 YearAnil Ashish Topno100% (1)

- Error Codes & Diagram DCF80-100Document247 pagesError Codes & Diagram DCF80-100Dat100% (1)

- Oil and Gas CompaniesDocument4 pagesOil and Gas CompaniesB.r. SridharReddy0% (1)

- Child Has Does: The Adultery, Child Be and Entitled His Own, The Child's That His DueDocument1 pageChild Has Does: The Adultery, Child Be and Entitled His Own, The Child's That His DuerickmortyNo ratings yet

- Tax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Document1 pageTax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Prànita Vailaya100% (1)

- Design of Earth Air Tunnel To Conserve Energy - FinalDocument19 pagesDesign of Earth Air Tunnel To Conserve Energy - FinalApurva AnandNo ratings yet

- NURS FPX 6218 Assessment 4 Advocating For Lasting ChangeDocument8 pagesNURS FPX 6218 Assessment 4 Advocating For Lasting Changefarwaamjad771No ratings yet

- 08147-416H - LEGEND - Wahl - Fact Sheets - 5StarSeries - GBDocument1 page08147-416H - LEGEND - Wahl - Fact Sheets - 5StarSeries - GBChristian ParedesNo ratings yet

- Crop Insurance Proposal 31.07.2023 (CLN) PCPMD Inputs Rev SCIDocument14 pagesCrop Insurance Proposal 31.07.2023 (CLN) PCPMD Inputs Rev SCIĐỗ ThăngNo ratings yet

- 7diesel 2016Document118 pages7diesel 2016JoãoCarlosDaSilvaBrancoNo ratings yet

- Student Counseling Management System Project DocumentationDocument4 pagesStudent Counseling Management System Project DocumentationShylandra BhanuNo ratings yet

- Satyam GargDocument2 pagesSatyam GargSatyam GargNo ratings yet

- 3Q21 TME Investor PresentationDocument27 pages3Q21 TME Investor PresentationVincent ChanNo ratings yet

- CASE Assignment #4Document3 pagesCASE Assignment #4Matti Hannah V.No ratings yet

- Debtors Application To Retain Gibson DunnDocument64 pagesDebtors Application To Retain Gibson DunnJSmithWSJNo ratings yet

- ReactJS Tutorial Full Course From ScratchDocument4 pagesReactJS Tutorial Full Course From ScratchMuhammadimran AliNo ratings yet

- Business Models, Institutional Change, and Identity Shifts in Indian Automobile IndustryDocument26 pagesBusiness Models, Institutional Change, and Identity Shifts in Indian Automobile IndustryGowri J BabuNo ratings yet

- Consumer Behaviour-Kiran GDocument9 pagesConsumer Behaviour-Kiran GVaibhav KhandelwalNo ratings yet

- Sop Welder TigDocument2 pagesSop Welder TigShahid RazaNo ratings yet

- 6LoWPAN TutorialDocument45 pages6LoWPAN TutorialEdita LatifiNo ratings yet

- Plaxis Products 2010 EngDocument20 pagesPlaxis Products 2010 EngAri SentaniNo ratings yet

- Vehicle T-Atv1200 Mil Specs 2015 Tech DescrDocument22 pagesVehicle T-Atv1200 Mil Specs 2015 Tech DescrpeiyingongNo ratings yet

- RRB Alp Tech. CBT 2 Master Question Paper Electrician Trade Date 22 1 2019 Shift 1Document58 pagesRRB Alp Tech. CBT 2 Master Question Paper Electrician Trade Date 22 1 2019 Shift 1arpitrockNo ratings yet

- Information For Producers of Emergency Fittings Acc. To Iec 60598 2 22Document10 pagesInformation For Producers of Emergency Fittings Acc. To Iec 60598 2 22mohammed imran pashaNo ratings yet

- LT32567 PDFDocument4 pagesLT32567 PDFNikolayNo ratings yet

- Case Study-Hain Celestial: Student Name Institution Affiliation DateDocument5 pagesCase Study-Hain Celestial: Student Name Institution Affiliation DategeofreyNo ratings yet

- 2019 Book TheEBMTHandbookDocument688 pages2019 Book TheEBMTHandbook88tk6rccsmNo ratings yet

- Reviewer MathDocument261 pagesReviewer MathMac Jayson DiazNo ratings yet