Professional Documents

Culture Documents

Sop Cip

Uploaded by

sams0 ratings0% found this document useful (0 votes)

16 views2 pagesOriginal Title

SOP CIP RO

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views2 pagesSop Cip

Uploaded by

samsCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

3.3.

Chemical Cleaning Step :

Step 1 – A surfactant clean to remove organics and biofilm (KURIDINE M-303).

Step 2 – A surfactant + “booster” wash to remove iron and inorganic scale deposits

(KURIFLOAT CA)

If a cleaning solution shows heavy discoloration, discard and make up new solution and

repeat cleaning stage.

Step 1:

• Flush systems with permeate water.

• Prepare a 5% v/v solution of KURIDINE M-303 at 30 – 35oC and maintain pH at 10.5

– 12 (adjust with caustic if necessary).

• Flush 20% of solution through the membranes to drain.

• Circulate & soak remaining solutions for 30 minutes intervals for 6-8 hours.

• Discard and flush thoroughly with good quality, chlorine free water.

Step 2:

• Prepare a 5 % v/v solution of KURIFLOAT CA at 25 – 30oC.

• Add 0.5% (by weight) KURIFLOAT CA (powder form).

• Flush 20% of solution through membranes to drain.

• Circulate & soak remaining solutions for 30 minutes intervals for 6-8 hours.

• Discard and flush thoroughly with good quality, chlorine free water.

NOTE:

• Membrane manufactures guidelines must always be followed with respect to pH,

temperature, flow rate and differential pressure. Membranes should always be

thoroughly flushed out with good quality, chlorine-free water between each cleaning

stage.

CIP Proposal for Reserve Osmosis Page 1

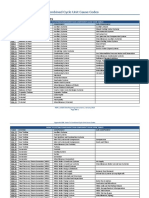

4. RECOMMENDED CHEMICAL APPLICATION

Below for overcome foulant trouble we recommend to apply below chemical as Chemical

Cleaning sloutoion preparation:

Chemical Name Active Content Packing Style

KURIDINE M-303 Surfactant 20 kg/plastic jerry can

KURIFLOAT CA Citric Acid + Booster 20 kg/Carton box

CIP Proposal for Reserve Osmosis Page 2

You might also like

- Cleaning Procedure-GeneralDocument2 pagesCleaning Procedure-Generalmunawar786100% (1)

- Cleaning CalculationDocument5 pagesCleaning CalculationIlham WahyuNo ratings yet

- TSG C 001 Membrane Cleaning Guide Water Application ElementsDocument5 pagesTSG C 001 Membrane Cleaning Guide Water Application ElementsSaeed DehestaniatharNo ratings yet

- Technical Service Bulletin: Procedure For Cleaning Hydracap Module (S)Document4 pagesTechnical Service Bulletin: Procedure For Cleaning Hydracap Module (S)patelpiyushbNo ratings yet

- TSB 112Document3 pagesTSB 112ragu19vNo ratings yet

- MCT 511 - CleanerDocument2 pagesMCT 511 - Cleanerpatelpiyushb100% (1)

- RCL-59 - Reduction Clearning Agent For TextilesDocument6 pagesRCL-59 - Reduction Clearning Agent For Textilessusheel deoraNo ratings yet

- Disposal Information For KB Internationals Polymer Systems 22032023GPDocument3 pagesDisposal Information For KB Internationals Polymer Systems 22032023GPeconpile ep525No ratings yet

- 05chemicalDocument2 pages05chemicaldalton2004No ratings yet

- Technical Data Sheet Chemitac 26: DescriptionDocument3 pagesTechnical Data Sheet Chemitac 26: Descriptionmaicon sulivanNo ratings yet

- KKL07 US 275chemicalDocument2 pagesKKL07 US 275chemicaldalton2004No ratings yet

- Symrpl 15 KLD STPDocument15 pagesSymrpl 15 KLD STPDnyaneshwar Dattatraya Phadatare100% (3)

- 962 09Document4 pages962 09Arellanes JmzNo ratings yet

- 1065 - Bleaching Powder StableDocument10 pages1065 - Bleaching Powder StableKaushik SenguptaNo ratings yet

- HYDRANAUTICS - Technical Service BulletinDocument50 pagesHYDRANAUTICS - Technical Service Bulletindpahomi1No ratings yet

- Reverse Osmosis System FaridDocument30 pagesReverse Osmosis System FaridAchFaridWadjdiNo ratings yet

- Textile Wastewater TreatmentDocument14 pagesTextile Wastewater TreatmentBengisu ÖzNo ratings yet

- Pre TreatmentDocument5 pagesPre TreatmentYashwant MisaleNo ratings yet

- Contrad 70 Tech SheetDocument2 pagesContrad 70 Tech SheetPeter RichterNo ratings yet

- Tank Cleaning ProcessDocument7 pagesTank Cleaning ProcessgbogboiweNo ratings yet

- ETP UpgradationDocument7 pagesETP UpgradationYogesh DhekaleNo ratings yet

- Pollution Abatement in The Different Textile IndustriesDocument16 pagesPollution Abatement in The Different Textile Industriesnat_236No ratings yet

- KMS Membrane CleaningDocument2 pagesKMS Membrane CleaningmagzigioNo ratings yet

- BAM-S01-06 Volumetric (Flask) Preparations - Oct99Document8 pagesBAM-S01-06 Volumetric (Flask) Preparations - Oct99DhileepNo ratings yet

- Validation of Sterilizing Grade Filters: Laura Okhio-Seaman Sartorius CorporationDocument52 pagesValidation of Sterilizing Grade Filters: Laura Okhio-Seaman Sartorius CorporationAjay KumarNo ratings yet

- Physicochemical Treatment of Textile Industry Waste Water: Salman Mo Tabani, and Omprakash SahuDocument3 pagesPhysicochemical Treatment of Textile Industry Waste Water: Salman Mo Tabani, and Omprakash SahuCarlos Manuel RamosNo ratings yet

- Assignment 5Document20 pagesAssignment 5Kumar NihalNo ratings yet

- Calcium HypochloriteDocument7 pagesCalcium HypochloriteFrancois BresseNo ratings yet

- Assignment 3Document37 pagesAssignment 3NAJIHANo ratings yet

- Cleaning of Dairy EquipmentDocument20 pagesCleaning of Dairy Equipmentmilind_vetyNo ratings yet

- 45chemicalDocument2 pages45chemicaldalton2004No ratings yet

- Sitara Internship ReportDocument19 pagesSitara Internship ReportEngr Hafiz Husnain BasraNo ratings yet

- Bleachnig TextilesDocument7 pagesBleachnig TextilesrahilwalaniNo ratings yet

- Diamond Oxide 2Document33 pagesDiamond Oxide 2nagaria100% (2)

- TSG C 003 Membrane Cleaning Guide Food Dairy RO NF ElementsDocument3 pagesTSG C 003 Membrane Cleaning Guide Food Dairy RO NF ElementsOmid LarkiNo ratings yet

- Membrane CleanerDocument2 pagesMembrane CleanerJoselito Cortes100% (1)

- Misr Spinning & Weaving Co. (Mehalla Kubra) : Industrial Waste Water Treatment PlantDocument29 pagesMisr Spinning & Weaving Co. (Mehalla Kubra) : Industrial Waste Water Treatment PlantmohamedqadiNo ratings yet

- Smart Prep Cibacron On SlavosDocument4 pagesSmart Prep Cibacron On SlavosagnberbcNo ratings yet

- Wastewater Treatment: On Completion of This Segment You Should BeDocument57 pagesWastewater Treatment: On Completion of This Segment You Should BeGourav MehtaNo ratings yet

- Kleen: Koch Additive Z Membrane CleanerDocument2 pagesKleen: Koch Additive Z Membrane Cleanerdalton2004No ratings yet

- KK260 US 40chemicalDocument2 pagesKK260 US 40chemicaldalton2004No ratings yet

- Product Spesification NCLDocument6 pagesProduct Spesification NCLramadhani ilhamNo ratings yet

- ChemicalDocument2 pagesChemicalFiaz jutt100% (1)

- Caustic Management and Reuse in The Beverage Bottling IndustryDocument52 pagesCaustic Management and Reuse in The Beverage Bottling IndustrydingobkNo ratings yet

- Cleaning Sanitizing Chain Lubricating in Breweries 2010 01Document20 pagesCleaning Sanitizing Chain Lubricating in Breweries 2010 01Kaushik100% (2)

- Choose A Proper Cleaning Agent For UF Membrane Chemical CleaningDocument2 pagesChoose A Proper Cleaning Agent For UF Membrane Chemical CleaningMax JunghannsNo ratings yet

- Requirements For Transport Sequence 28 4 2022Document5 pagesRequirements For Transport Sequence 28 4 2022dpanggabean285No ratings yet

- Treatment of Cosmetic Waste WaterDocument5 pagesTreatment of Cosmetic Waste WaterfamNo ratings yet

- Dialyser Reuse/Reprocessing HistoryDocument73 pagesDialyser Reuse/Reprocessing HistoryKushalDpNo ratings yet

- Effluent TreatmentDocument21 pagesEffluent TreatmentRadhika AnandkumarNo ratings yet

- Recovery Processes of Organic Acids From Fermentation Broths inDocument8 pagesRecovery Processes of Organic Acids From Fermentation Broths inRocio ChongNo ratings yet

- FOT207 Assignment1Document7 pagesFOT207 Assignment1BRO CODENo ratings yet

- Modified Zeolite For Wastewater TreatmentDocument2 pagesModified Zeolite For Wastewater TreatmentdainguyenlamNo ratings yet

- Pickling & Passivation ProcedureDocument2 pagesPickling & Passivation ProcedureSunil Kumar GoudaNo ratings yet

- Parenterals PartDocument38 pagesParenterals Partrajgorm34No ratings yet

- International Quality Module 15: MicrobiologyDocument53 pagesInternational Quality Module 15: MicrobiologyAisarya DasNo ratings yet

- Water Treatment Plant Performance Evaluations and OperationsFrom EverandWater Treatment Plant Performance Evaluations and OperationsNo ratings yet

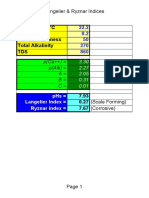

- Calculator LangelierRyznarDocument1 pageCalculator LangelierRyznarsamsNo ratings yet

- Appendix B04 CoGenerator Steam Turbine Unit Cause Codes 2023 DRIDocument59 pagesAppendix B04 CoGenerator Steam Turbine Unit Cause Codes 2023 DRIsamsNo ratings yet

- 2022 Conventional GADS Training Module 02 History of NERC and GADSDocument15 pages2022 Conventional GADS Training Module 02 History of NERC and GADSsamsNo ratings yet

- Appendix B02 Combined Cycle Steam Turbine Unit Cause Codes 2023 DRIDocument60 pagesAppendix B02 Combined Cycle Steam Turbine Unit Cause Codes 2023 DRIsamsNo ratings yet

- Appendix B03 CoGenerator Gas Turbine Unit Cause Codes 2023 DRIDocument59 pagesAppendix B03 CoGenerator Gas Turbine Unit Cause Codes 2023 DRIsamsNo ratings yet

- Divergence Between PJM - NE-ISO - MISO and NERC GADS 2016Document10 pagesDivergence Between PJM - NE-ISO - MISO and NERC GADS 2016samsNo ratings yet

- Conventional GADS FAQ 013-ERDocument1 pageConventional GADS FAQ 013-ERsamsNo ratings yet

- Appendix E6: Unit Design Data - Gas Turbine or Jet Engine (Voluntary Reporting)Document5 pagesAppendix E6: Unit Design Data - Gas Turbine or Jet Engine (Voluntary Reporting)samsNo ratings yet

- Conventional GADS FAQ 002-PDDocument1 pageConventional GADS FAQ 002-PDsamsNo ratings yet

- UntitledDocument657 pagesUntitledsamsNo ratings yet

- Conventional GADS FAQ 014-DSDocument1 pageConventional GADS FAQ 014-DSsamsNo ratings yet

- Appendix B06: Index To Combined Cycle Unit Cause CodesDocument72 pagesAppendix B06: Index To Combined Cycle Unit Cause CodessamsNo ratings yet

- Feedwater Pump Turbine Controls and Oil System Maintenance Guide PDFDocument196 pagesFeedwater Pump Turbine Controls and Oil System Maintenance Guide PDFsamsNo ratings yet

- Appendix B10: Index To Geothermal Unit Cause CodesDocument28 pagesAppendix B10: Index To Geothermal Unit Cause CodessamsNo ratings yet

- Appendix E4: Unit Design Data - Internal Combustion / Reciprocating Engine (Voluntary Reporting)Document3 pagesAppendix E4: Unit Design Data - Internal Combustion / Reciprocating Engine (Voluntary Reporting)samsNo ratings yet

- Appendix E5: Unit Design Data - Hydro or Pumped Storage (Voluntary Reporting)Document3 pagesAppendix E5: Unit Design Data - Hydro or Pumped Storage (Voluntary Reporting)samsNo ratings yet

- Appendix E7: Unit Design Data - Miscellaneous (Voluntary Reporting)Document4 pagesAppendix E7: Unit Design Data - Miscellaneous (Voluntary Reporting)samsNo ratings yet

- Appendix E3: Unit Design Data - Nuclear (Voluntary Reporting)Document5 pagesAppendix E3: Unit Design Data - Nuclear (Voluntary Reporting)samsNo ratings yet

- Appendix E8: Unit Design Data - Combined Cycle Units and Block Design Data (Voluntary Reporting)Document22 pagesAppendix E8: Unit Design Data - Combined Cycle Units and Block Design Data (Voluntary Reporting)samsNo ratings yet

- Appendix B09: Index To Gas Turbine/Jet Engine Unit Cause CodesDocument40 pagesAppendix B09: Index To Gas Turbine/Jet Engine Unit Cause CodessamsNo ratings yet

- Appendix B11: Index To Internal Combustion/Reciprocating Engine Unit Cause CodesDocument27 pagesAppendix B11: Index To Internal Combustion/Reciprocating Engine Unit Cause CodessamsNo ratings yet

- Deepfacelab: Integrated, Flexible and Extensible Face-Swapping FrameworkDocument10 pagesDeepfacelab: Integrated, Flexible and Extensible Face-Swapping FrameworksamsNo ratings yet

- ITTC - Recommended Procedures and Guidelines: Guide To The Expression of Uncertainty in Experimental HydrodynamicsDocument18 pagesITTC - Recommended Procedures and Guidelines: Guide To The Expression of Uncertainty in Experimental HydrodynamicssamsNo ratings yet

- I 9 XZ 8 Jgbnbxo 1 Anplj 2 yDocument75 pagesI 9 XZ 8 Jgbnbxo 1 Anplj 2 ysamsNo ratings yet

- Combustion Optimization For Coal Fired Power Plant Boilers Based On Imporoved Distributed ELM and Distibuted PSODocument24 pagesCombustion Optimization For Coal Fired Power Plant Boilers Based On Imporoved Distributed ELM and Distibuted PSOsamsNo ratings yet

- Item D-12 Attachment 1 Pt.3 LinkDocument27 pagesItem D-12 Attachment 1 Pt.3 LinksamsNo ratings yet

- 5-4 Data NormalizationDocument4 pages5-4 Data NormalizationsamsNo ratings yet

- Energies 13 04253 v2Document21 pagesEnergies 13 04253 v2samsNo ratings yet

- Instruction Manual HFU-typeHN 201610Document35 pagesInstruction Manual HFU-typeHN 201610samsNo ratings yet

- EJC167219Document10 pagesEJC167219samsNo ratings yet