Professional Documents

Culture Documents

Wish List For CTR 88 Kaji Compressor Station Flare System Improvement

Uploaded by

Kuncoro Hadi WibowoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wish List For CTR 88 Kaji Compressor Station Flare System Improvement

Uploaded by

Kuncoro Hadi WibowoCopyright:

Available Formats

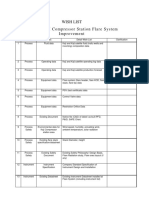

WISH LIST

CTR 88 KAJI Compressor Station Flar e System

Improvement

No Discipline Topic Detail Wish List Clarification

1 Process Fluid data Kaji and Kaji satelite fluid (insitu wells and

incoming) composition data

2 Process Operating data Kaji and Kaji satellite operating log data

3 Process Operating data Kaji and Kaji satellite production forecast

4 Process Equipment data Flare system (flare header, flare KOD, flare

stack, flare tip) data

5 Process Equipment data PSV (test certificate) data

6 Process Equipment data Control Valve data

7 Process Equipment data Restriction Orifice Data

8 Process Existing Document Native file (CAD) of latest/ as-built PFD,

P&ID, SAFE Chart.

9 Process Environmental data for Wind speed, humidity, prevailing wind,

Safety Kaji Compressor ambient temperature, solar radiation

station area

10 Process Existing flare stack Stack Diameter, height

Safety specification/datasheet

11 Process Existing Safety Existing Safety Philosophy/ Design Basis,

Safety Document Flare Radiation study, Flare area layout (if

any)

12 Instrument Instrument Company Standard Specification of

Specification Instrument Design and Installation

13 Instrument Existing Datasheet Existing Instrument Datasheet installed at

Flare System (including instrument list)

14 Instrument Operating Narrative Existing control & safety narrative for Kaji

Compressor Station

15 Instrument ICS Existing Drawing 1. Existing drawing for Control and Safety

System Architecture Diagram (note: we

need the baseline of architecture diagram

and update it to the CTR 88 Kaji

Compressor Station Flare System

Improvement).

2. Exisiting instrument location plan layout

drawing (note: we need to update it to CTR

88 if there is any additional item of

instrument devices).

3. Existing tubing or cable tray routing layout

(note: this existing drawing will become

baseline to update tubing/tray route at CTR

88 Kaji Compressor Station Flare System

Improvement).

4. Existing wiring and termination diagram.

16 Instrument Control Architecture Drawing schematic indicating overall control

& safety system of Kaji Station.

17 Piping Drawing Data - Native (Autocad) Plot Plan Existing Butuh Native File (Autocad)

- Native (Autocad) Piping Plan Existing untuk mempercepat

- MES Update/ Terbaru pekerjaan, jika dari PDF

- K.O. Drum GA Drawing maka harus redraw dengan

( Jika menggunakan K.O. Drum Existing ) durasi waktu yang agak

lama.

18 Civil Calculation Data - Topography & Soil Data

19 Electrical Drawing Data - Existing single line diagram

- Existing lighting layout

- Existing grounding layout

- Existing cable tray and cable layout

20 Mechanical Project atau - Specification Pressure Vessel Spec

coorporate standrd - Specification Painting

specification - Specification Flare Package

- Specification API Pump, baik type API

610 dan atau maupun API 674/5

- Specification non-API Pump (ASME)

untuk pit sum pump

21 Mechanical Datasheet peralatan • Data Sheet Flare Package Existing, PDF

existing & Native File (ms office; excel /word)

• Data Sheet KO Drum Pump – Existing,

PDF & Native File (ms office; excel /word)

• Data Sheet KO Drum – Existing, PDF &

Native File (ms office; excel /word)

22 Mechanical Drawing data • GA Drawing Vendor Data KO Drum –

Existing (PDF)

• GA Darwing Sump Pit Existing

• GA Darwing Vendor Data KO Drum

Pump

• GA Drawing Vendor Data Pit Sump

Pump

23 Mechanical Project standard • Pressure Vessel Standard Drawings

Drawings

24 Mechanical Others • Approved Manufacturere List (AML)

Contact Person Medco Team (PIC)

PIC Nama Alamat Email No. HP (WA)

Process Engineer

Process Safety Engineer

Piping

Mechanical Arief Budiman

Instrument

Electrical

Civil

Dokon

Project Control

You might also like

- EL 501 OSP 5020 Electrical Maintenance RevDDocument478 pagesEL 501 OSP 5020 Electrical Maintenance RevDAntonio Lucas100% (4)

- Engineering BasicsDocument31 pagesEngineering BasicsSandeep KolappuramNo ratings yet

- Chapter 4d) HAZOP PDFDocument61 pagesChapter 4d) HAZOP PDFAmritRoshniKaurNo ratings yet

- Pre-Loop Check ProcedureDocument1 pagePre-Loop Check ProceduresithulibraNo ratings yet

- Biogas Boiler DesignDocument6 pagesBiogas Boiler DesignEyosyas NathanNo ratings yet

- Design Procedure - ProcessDocument4 pagesDesign Procedure - ProcessNutthakarn WisatsiriNo ratings yet

- Sl. No Item Description Mechanical: PSSR Package Documents and RequirementsDocument6 pagesSl. No Item Description Mechanical: PSSR Package Documents and Requirementsli xianNo ratings yet

- Phase Control For P&IDDocument1 pagePhase Control For P&IDPichai ChaibamrungNo ratings yet

- Plant Performance CalculationsDocument2 pagesPlant Performance CalculationsKalki Communication Technologies Ltd100% (1)

- My Siwes ReportDocument71 pagesMy Siwes ReportOrji Christian100% (2)

- Design Procedure - ProcessDocument4 pagesDesign Procedure - ProcessNutthakarn WisatsiriNo ratings yet

- Recent Changes To API 521 PDFDocument23 pagesRecent Changes To API 521 PDFPablo R. Jimenez SalcesNo ratings yet

- Piping Overview 01Document18 pagesPiping Overview 01Rajkumar ANo ratings yet

- I&cDocument14 pagesI&cVioleta TaniNo ratings yet

- FEED Deliverable List (Sample) - The Project Definition PDFDocument5 pagesFEED Deliverable List (Sample) - The Project Definition PDFbecpavanNo ratings yet

- Gas Monetization in NigeriaDocument8 pagesGas Monetization in NigeriasegunoyesNo ratings yet

- AIX SYSTEM & Device ConfigurationDocument21 pagesAIX SYSTEM & Device ConfigurationArun PrabhuNo ratings yet

- GeoFans Mud Logging Software IntroductionDocument20 pagesGeoFans Mud Logging Software IntroductiongqzxmNo ratings yet

- Flare Technology PDFDocument109 pagesFlare Technology PDFhahrila100% (1)

- Detailed Engineering Design of Self-Supported Flare Stack UnitDocument6 pagesDetailed Engineering Design of Self-Supported Flare Stack UnitMathias OnosemuodeNo ratings yet

- FEED Deliverable List (Sample) - The Project DefinitionDocument8 pagesFEED Deliverable List (Sample) - The Project DefinitionKerleauNo ratings yet

- Pending MDL SiemensDocument14 pagesPending MDL SiemensSantoshkumar GuptaNo ratings yet

- Introductiontogastransportation 161222145926 PDFDocument26 pagesIntroductiontogastransportation 161222145926 PDFAl Jawad100% (1)

- Tie-In List (Epcc-09) : DOC. NO.: IBCE-6373-471-PRS-IFD-000-0001Document3 pagesTie-In List (Epcc-09) : DOC. NO.: IBCE-6373-471-PRS-IFD-000-0001srini100% (1)

- Project Documents and Work ScopeDocument2 pagesProject Documents and Work Scopereza buildtradefoilsNo ratings yet

- Saep 405 PDFDocument17 pagesSaep 405 PDFRami Elloumi100% (1)

- Structural (STAAD) & Pipe Stress Analysis (AutoPIPE) IntegrationDocument21 pagesStructural (STAAD) & Pipe Stress Analysis (AutoPIPE) Integrationmapasabc100% (1)

- Master Document Register-Attachment 10Document6 pagesMaster Document Register-Attachment 10DAYONo ratings yet

- Reliance - Flare Gas Recovery IMPDocument6 pagesReliance - Flare Gas Recovery IMPsvnaik14No ratings yet

- Material Flare StackDocument10 pagesMaterial Flare StackcandratrikusumaNo ratings yet

- Zero Flare ConceptDocument6 pagesZero Flare ConceptIshag HaroonNo ratings yet

- 1902 01GN 00 13K G0009 - D1 - Construction Strategy For Main Accommodation CampDocument50 pages1902 01GN 00 13K G0009 - D1 - Construction Strategy For Main Accommodation CampKuncoro Hadi WibowoNo ratings yet

- PCS7 Basico-AvanzadoDocument469 pagesPCS7 Basico-AvanzadoVictor NavarreteNo ratings yet

- Hardware Staging ChecklistDocument3 pagesHardware Staging ChecklistAlan Mudary100% (1)

- Scope of Work For BAsic Engineering PackageDocument1 pageScope of Work For BAsic Engineering Packagebhawani27No ratings yet

- Engineering Software ListDocument1 pageEngineering Software ListRubhendran KrishnanNo ratings yet

- SOW KJI KJC Flare System Improvement - Rev0a-Approved - CommDocument13 pagesSOW KJI KJC Flare System Improvement - Rev0a-Approved - CommKuncoro Hadi WibowoNo ratings yet

- Ctrend Presentation (Https://ctrend-Tech - Com)Document10 pagesCtrend Presentation (Https://ctrend-Tech - Com)Djigouadi RafikNo ratings yet

- List BantexDocument1 pageList BantexVigour Rizko MurdyneNo ratings yet

- HOD C& I Workshop Nov 2010finalDocument20 pagesHOD C& I Workshop Nov 2010finalsiddharth507No ratings yet

- CAEPIPE Presentation - v11.00Document17 pagesCAEPIPE Presentation - v11.00Johan ConradieNo ratings yet

- Experience Gained at Oao Emal'Yans With Constructing Automated Control Systems For Steam BoilersDocument3 pagesExperience Gained at Oao Emal'Yans With Constructing Automated Control Systems For Steam BoilersSairo MoisesNo ratings yet

- Flyercavotec Pca05102017ldDocument20 pagesFlyercavotec Pca05102017ldabdullah sahibNo ratings yet

- 08 Hyundai KPIT Performance BSW Modules Chassis ImplementationDocument23 pages08 Hyundai KPIT Performance BSW Modules Chassis ImplementationSonali ShreeNo ratings yet

- 03-Volume-III - Schedule-I-Unpriced BOQ 1st - StageDocument425 pages03-Volume-III - Schedule-I-Unpriced BOQ 1st - Stagesachin guptaNo ratings yet

- A-Pillar Activities 02-05-2020Document12 pagesA-Pillar Activities 02-05-2020MILINDNo ratings yet

- CDCDB 803Document34 pagesCDCDB 803tanoNo ratings yet

- 2019 ATUG File ManagementDocument17 pages2019 ATUG File ManagementsajuaanalsaNo ratings yet

- Release Notes: Altair Esacomp™ V2020Document2 pagesRelease Notes: Altair Esacomp™ V2020Oliver RailaNo ratings yet

- PGM Based Profibus - UpdatedDocument58 pagesPGM Based Profibus - UpdatedpianuelsNo ratings yet

- Input Required-1Document1 pageInput Required-1rupesh417No ratings yet

- 04 - VASS6 Nombres ProfinetDocument16 pages04 - VASS6 Nombres Profinetenrique sueldoNo ratings yet

- ds030 Fadec 011323Document2 pagesds030 Fadec 011323hamid mirNo ratings yet

- CS244-Introduction To Embedded Systems and Ubiquitous ComputingDocument38 pagesCS244-Introduction To Embedded Systems and Ubiquitous ComputingharithNo ratings yet

- VPNC 2002Document5 pagesVPNC 2002peymanNo ratings yet

- Cadprofi 2021 enDocument67 pagesCadprofi 2021 enPetru CorduneanuNo ratings yet

- Full Spectrum Simulation Platform (Miniature Academic Version) For Power Electronics and Power SystemsDocument35 pagesFull Spectrum Simulation Platform (Miniature Academic Version) For Power Electronics and Power SystemsMouliNo ratings yet

- Case StudyDocument18 pagesCase StudyGhi TtaNo ratings yet

- CME OverviewDocument44 pagesCME Overviewsav33No ratings yet

- Deployment & Available-To-Promise (ATP) in SCMDocument42 pagesDeployment & Available-To-Promise (ATP) in SCMTosca TestNo ratings yet

- 2X235 MW Attarat Oil Shale Power Plant Jordan Acronyms and AbbreviationsDocument3 pages2X235 MW Attarat Oil Shale Power Plant Jordan Acronyms and Abbreviationsscribd birdNo ratings yet

- Vc34 Kompend Kap084 eDocument60 pagesVc34 Kompend Kap084 eSafetyjoe2No ratings yet

- 43-RMR Project Line ItemsDocument6 pages43-RMR Project Line ItemsMuhammad azeemNo ratings yet

- Advanced In-Flight Data RecorderDocument6 pagesAdvanced In-Flight Data RecorderueidaqNo ratings yet

- SD 1Document3 pagesSD 1Jitendra Singh ChouhanNo ratings yet

- CDCDB 400Document33 pagesCDCDB 400tanoNo ratings yet

- Fauji Fertilizer Bin Qasim Limited: Human Resource Management "HR Practices in DCS Project" With Reference ToDocument26 pagesFauji Fertilizer Bin Qasim Limited: Human Resource Management "HR Practices in DCS Project" With Reference ToYASMIN AKRAMNo ratings yet

- Typical EPIC Contract: Basic Eng Detailed EngDocument12 pagesTypical EPIC Contract: Basic Eng Detailed EngshaifullahNo ratings yet

- Avionics IMA Design Lec 1 2020Document32 pagesAvionics IMA Design Lec 1 2020minydiNo ratings yet

- Software - Platform (Automation Builder) - ABBDocument12 pagesSoftware - Platform (Automation Builder) - ABBIrlan LeiteNo ratings yet

- PLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.From EverandPLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.No ratings yet

- SOW KJI KJC Flare System Improvement - Rev0a-Approved - CommDocument13 pagesSOW KJI KJC Flare System Improvement - Rev0a-Approved - CommKuncoro Hadi WibowoNo ratings yet

- Comment Response Sheet - Datasheet For Piping Specialty Item Rev BDocument1 pageComment Response Sheet - Datasheet For Piping Specialty Item Rev BKuncoro Hadi WibowoNo ratings yet

- CTR088 - Kaji Kaji Compressor Station Flare System Improvement FEED - Rev FDocument4 pagesCTR088 - Kaji Kaji Compressor Station Flare System Improvement FEED - Rev FKuncoro Hadi WibowoNo ratings yet

- Comment Response Sheet - Datasheet For Piping Specialty Item Rev BDocument1 pageComment Response Sheet - Datasheet For Piping Specialty Item Rev BKuncoro Hadi WibowoNo ratings yet

- IDC Routing FormDocument1 pageIDC Routing FormKuncoro Hadi WibowoNo ratings yet

- Wish List For CTR 88 Kaji Compressor Station Flare System ImprovementDocument3 pagesWish List For CTR 88 Kaji Compressor Station Flare System ImprovementKuncoro Hadi WibowoNo ratings yet

- Flare Pit Cleaning TechnologyDocument27 pagesFlare Pit Cleaning TechnologyAhmed GamaladdinNo ratings yet

- STD 106Document26 pagesSTD 106Jonas PadillaNo ratings yet

- B 350 Forced Air Vortex Flare System 1976Document6 pagesB 350 Forced Air Vortex Flare System 1976Hassan GDOURANo ratings yet

- 13-02-2019 - WinGD - Article - Volatile Organic Comp As FuelDocument4 pages13-02-2019 - WinGD - Article - Volatile Organic Comp As FuelAVINASH ANAND RAONo ratings yet

- Service Request For Quotation: M/S: - PO. Box: - Postal CodeDocument6 pagesService Request For Quotation: M/S: - PO. Box: - Postal CodeMirsoNo ratings yet

- Environmental, Health, and Safety Guidelines For Liquefied Natural Gas (LNG) FacilitiesDocument25 pagesEnvironmental, Health, and Safety Guidelines For Liquefied Natural Gas (LNG) FacilitiesshahjadaNo ratings yet

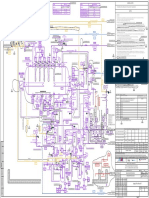

- 060-H-003A/B Item 060-V-011 Item 060-P-001A/B Item: General NotesDocument1 page060-H-003A/B Item 060-V-011 Item 060-P-001A/B Item: General NotesNathan NiuNo ratings yet

- Application Story: Thermal Imaging Cameras For Flare MonitoringDocument2 pagesApplication Story: Thermal Imaging Cameras For Flare MonitoringAnonymous Wu6FDjbNo ratings yet

- Flare (Extracto GPSA)Document5 pagesFlare (Extracto GPSA)veronicaNo ratings yet

- Seminar Pemerkasaan Perundangan, Pelesenan Dan Keselamatan Gas 26 Sept 2018Document54 pagesSeminar Pemerkasaan Perundangan, Pelesenan Dan Keselamatan Gas 26 Sept 2018INSTECH Consulting100% (1)

- Relief and Blowdown Systems: Are You Sure You Can Rely On Them?Document21 pagesRelief and Blowdown Systems: Are You Sure You Can Rely On Them?jayrolling dollazNo ratings yet

- XxxMechanical Equipment List - RevDocument9 pagesXxxMechanical Equipment List - RevACRILYC ACID i-III NSI PROJECTNo ratings yet

- ERCB - Inspection Manual001Document60 pagesERCB - Inspection Manual001bluesNo ratings yet

- SP 1060 Rev.1 Draft March, 2016Document39 pagesSP 1060 Rev.1 Draft March, 2016Kiran Babu KandulaNo ratings yet

- GI Dynamics - Enclosed Flare SystemDocument28 pagesGI Dynamics - Enclosed Flare SystemChris van der ZandeNo ratings yet

- GEO Plus 2022, AR5500 - SPECDocument4 pagesGEO Plus 2022, AR5500 - SPECHelen EnkhboldNo ratings yet

- Sigma Heater WorksheetDocument14 pagesSigma Heater WorksheetKareem RasmyNo ratings yet

- Retrofitting The Existing Flare / Burnery For Smoke Less OperationsDocument31 pagesRetrofitting The Existing Flare / Burnery For Smoke Less Operationsmehul10941No ratings yet