Professional Documents

Culture Documents

RB SD No. 01

RB SD No. 01

Uploaded by

safety SwrOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RB SD No. 01

RB SD No. 01

Uploaded by

safety SwrCopyright:

Available Formats

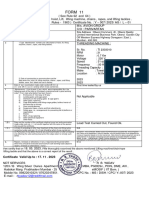

South Western Railway

Office of Sr. Divisional Safety Officer, Mysuru-570001

Ph: 66192 (Rly), 0821- 2427983 (BSNL), email: dsomysore@gmail.com

No. Y/T/389.RB SD-01/2023-24 Date:06.04.2023

Sr.DEN/Co-Ord, Sr.DEN/N, Sr.DEN/C, Sr.DEE,

Sr.DEE/EEM, Sr.DSTE, Sr.DME, DEN/W

(RB Safety Drive No. 01)

Sub: Week long Safety Drive for the month of April 2023.

Ref: PCSO lr. no. T.389/Safety Drive/01/RB/2023-24 dt.06.04.2023.

******

With respect to above subject and letter in reference, Safety Drive is launched for period of

one-week w.e.f. 10.04.2023 onwards duly emphasizing all the points pertaining to your department

by concerned Officers & Supervisors. Special emphasis to be given by all concerned Officers /

Supervisors to the following aspects and inspections of their department items of the above drive &

daily progress to be updated through Google Spread Sheet being shared shortly.

S.No. Department Items to be covered

1. ELECTRICAL i) TRD: Drive for OHE structure such as Check rail level, Tilting of masts,

Condition of embankments with respect to stability of masts and

Condition of location number plate etc.

ii) CREW: Crew Competency, Breath Analyzer Machine in working order

or not and CMS Integration with BA, Spare BA availability.

iii) LOCOMOTIVES: Under carriage drive such as adequate level of

suspension bearing oil and its filling cap, Cardium compound in gear

case and its cover, felt wick carrier screw and its sealing and mounting

brackets and strength of under frame equipments.

iv) Safety at RE work spots.

2. MECHANICAL i) To check and ensure fitment of side frame key, shackle lock, Pivot pin

washer in wagons.

ii) To ensure checking of CBC including APMs, Knuckle, lock lifter

assembly, Knuckle pin, Anti rotation lug, Coupler heads, etc. Also

checking of coaching couplers for the relevant items and in addition

shim heights etc. Condition of operating handle including bends, wear

of bolts, corrosion in brackets, groove in bore of bracket etc. Condition

of supporting device and its springs. Check all the gauges for wear

measurement in CBC along with calibration records of these gauges for

concurrency.

iii) Check Side buffers in locomotives and coaches for height, drooping and

cracks in the casting, completeness of bolts securing them with the

rolling stock.

iv) Maintenance of draft gear in workshops including loose bolts, external

damage, seating in pocket, condition of buff plate and application of

grease, pre-load value, condition of spring column.

v) Any other items as decided by DRM.

3. S&T i) To check & ensure working of Data logger & its networking with

Central System at Divisional HQ.

ii) Check to ensure proper working of DC Track Circuits in Rusty Rail Area.

iii) Any other items as decided by DRM.

4. ENGINEERING i) Preparation of Hot Weather Precautions- ensuring zero missing fitting,

completeness of ballast profile including distressing of LWRs.

ii) Safety at Engg./CN work spots.

The detailed report on the above Safety Drive should reach this office on 18.04.2023 for

consolidating and forwarding to Hqrs.

Digitally signed

NEERAJ byBAPNA

NEERAJ

BAPNA Date:

2023.04.06

13:37:05 +05'30'

(Neeraj Bapna)

Sr.Divisional Safety Officer

S.W.Rly, Mysuru

C/- PCSO/SWR/UBL: for kind inf. pls

DRM, ADRM/I & II: for kind inf. pls

You might also like

- 011 - JSA (Tower Crane)Document9 pages011 - JSA (Tower Crane)satti80% (5)

- Best Torrent Sites 2019Document9 pagesBest Torrent Sites 2019gda gdaNo ratings yet

- JI 2027 JSA 039 Lifting and Rigging Activities by Tandem Lifting PDFDocument3 pagesJI 2027 JSA 039 Lifting and Rigging Activities by Tandem Lifting PDFYawar Qureshi100% (3)

- Method Statement Bored PileDocument9 pagesMethod Statement Bored PileShuvro ChakravortyNo ratings yet

- CP Installation ManualDocument14 pagesCP Installation Manualjamal Alawsu100% (1)

- Method Statement Bored PileDocument22 pagesMethod Statement Bored PileDharma Pratap LamgadeNo ratings yet

- Professional Marketing Competencies 2016 - InteractiveDocument19 pagesProfessional Marketing Competencies 2016 - InteractiveOriginalo VersionaNo ratings yet

- Technical Procedure For Jacket Installation PDFDocument19 pagesTechnical Procedure For Jacket Installation PDFflawlessy2k100% (3)

- Working at Heights ProcedureDocument11 pagesWorking at Heights ProcedureMo AboukhzamNo ratings yet

- Sraco-Const-Doc-Mos-08 - Concrete Masonry Units and PlasteringDocument13 pagesSraco-Const-Doc-Mos-08 - Concrete Masonry Units and PlasteringMohammed Perwez AlamNo ratings yet

- Robotics: 3rd EditionFrom EverandRobotics: 3rd EditionRating: 1 out of 5 stars1/5 (1)

- Fence InstallationDocument10 pagesFence InstallationanoopyohNo ratings yet

- The New Public Leadership Challenge 2010Document434 pagesThe New Public Leadership Challenge 2010waqas724No ratings yet

- Ipc9850 PDFDocument56 pagesIpc9850 PDFCarlos MascioniNo ratings yet

- Method Statement For Rebar InstallationDocument4 pagesMethod Statement For Rebar InstallationPaul Ladjar100% (2)

- Compressor and Preservation InstallationDocument7 pagesCompressor and Preservation InstallationMohamed Elarabi0% (1)

- Acil Mmrda BL5463 06.10.2023 369Document1 pageAcil Mmrda BL5463 06.10.2023 369lelu ojhaNo ratings yet

- 53 - SOP For Cable Laying Termination in SwitchyardDocument8 pages53 - SOP For Cable Laying Termination in SwitchyardVipin SinghNo ratings yet

- Adobe Scan May 07, 2023Document2 pagesAdobe Scan May 07, 2023Siddhartha Sankar GayenNo ratings yet

- MOS Lifting PlanDocument14 pagesMOS Lifting Planmuiqbal.workNo ratings yet

- Mega Safety Drive No-5 (RB)Document76 pagesMega Safety Drive No-5 (RB)PUBG Mobile TricksNo ratings yet

- Ssep - January - 2023Document2 pagesSsep - January - 2023Mano ShankarNo ratings yet

- Methodology For Erection of Precast I-Girders Aakar Abhinav Consultants Pvt. LTDDocument4 pagesMethodology For Erection of Precast I-Girders Aakar Abhinav Consultants Pvt. LTDAbhiNo ratings yet

- Indian Navy Civilian Entrance Test INCET-CM (MECH) & CM (AMMN & EXPL) - 03/2019Document16 pagesIndian Navy Civilian Entrance Test INCET-CM (MECH) & CM (AMMN & EXPL) - 03/2019tulasiraoNo ratings yet

- UntitledDocument26 pagesUntitledRakibul IslamNo ratings yet

- MOP - New Link 10 Ge C-SBRKO-01 - C-BJAHY-01Document17 pagesMOP - New Link 10 Ge C-SBRKO-01 - C-BJAHY-01Ary FajriNo ratings yet

- 005-MS-Steel Reinforcement - AlilaDocument5 pages005-MS-Steel Reinforcement - AlilaaruanNo ratings yet

- Fukushima Poster FinalDocument1 pageFukushima Poster FinalDaniel PopaNo ratings yet

- Advt. No. 01-2023Document5 pagesAdvt. No. 01-2023Simulacra TechnologiesNo ratings yet

- Letter On CBC Marking-19.09.23Document6 pagesLetter On CBC Marking-19.09.23shanmugarajanNo ratings yet

- MOS Kettle Lifting NewDocument9 pagesMOS Kettle Lifting Newmuiqbal.workNo ratings yet

- GDR Check TimeDocument12 pagesGDR Check TimeMurali KrishnanNo ratings yet

- Budgetary Offer For 3 Axes Rate Table Rev01Document7 pagesBudgetary Offer For 3 Axes Rate Table Rev01Sriram SistaNo ratings yet

- Joint Rig Committee Rig Location & Move Warranty Survey Scope of Work (SOW)Document8 pagesJoint Rig Committee Rig Location & Move Warranty Survey Scope of Work (SOW)chameleon131185 ओतजत परक्षीयुालीालुगNo ratings yet

- IDBC-EJ-CPPRO-WC0501-301 - B - Method Statement For Rig Pad Work WPC Civil Work Site PreparationDocument19 pagesIDBC-EJ-CPPRO-WC0501-301 - B - Method Statement For Rig Pad Work WPC Civil Work Site PreparationAMINNo ratings yet

- HSE-E&D.ge.007 Procedure For Managing Casing and Tubing Straps On The Rig - FinalDocument6 pagesHSE-E&D.ge.007 Procedure For Managing Casing and Tubing Straps On The Rig - FinalAbderrahmene SaciNo ratings yet

- 20sda023 KrianDocument332 pages20sda023 KrianHaryo WNo ratings yet

- WMS - C&S - 039 - WMS For UPV and Coring TestDocument4 pagesWMS - C&S - 039 - WMS For UPV and Coring TestEchoNo ratings yet

- CRISP-SUT2-SY2-MSRA-4-015 - RC - MSRA Instruments & Cables Dismantling InstallnDocument22 pagesCRISP-SUT2-SY2-MSRA-4-015 - RC - MSRA Instruments & Cables Dismantling InstallnKamruzzaman KhokonNo ratings yet

- Man Basket - 02 - 10 - 03-2022Document1 pageMan Basket - 02 - 10 - 03-2022Gokul Raj DarojiNo ratings yet

- RDSO 2013 CG-06 - Final DraftDocument11 pagesRDSO 2013 CG-06 - Final DraftDhanushNo ratings yet

- MOS Piping WorksDocument14 pagesMOS Piping Worksmuiqbal.workNo ratings yet

- SOPDocument2 pagesSOPwingwiryawanNo ratings yet

- Equipment RotaticDocument9 pagesEquipment Rotaticverall_averusNo ratings yet

- Indian Navy Chargement Recruitment Engineering Diploma 07 04Document14 pagesIndian Navy Chargement Recruitment Engineering Diploma 07 04HareshNo ratings yet

- Indian Navy Recruitment 2019 For 172 Chargeman PostsDocument14 pagesIndian Navy Recruitment 2019 For 172 Chargeman PostsAshu SinghNo ratings yet

- Vendor Approval Requirements For Transformers RDSODocument6 pagesVendor Approval Requirements For Transformers RDSORishik SainiNo ratings yet

- Accident Proforma 2019Document34 pagesAccident Proforma 2019ArijitNandiNo ratings yet

- Safety DriveDocument5 pagesSafety DriveMANIT KUMAR BHOINo ratings yet

- Frey-Fil Corporation: Pile Dynamic TestDocument7 pagesFrey-Fil Corporation: Pile Dynamic TestRolly Marc G. SoteloNo ratings yet

- PTW Tower Cranes Paaun2Document2 pagesPTW Tower Cranes Paaun2Mohamed MostafaNo ratings yet

- SMS 082 Navigation and Competency BRIEFINGDocument2 pagesSMS 082 Navigation and Competency BRIEFINGLincoln AkintolaNo ratings yet

- Certificate of Avion GroupDocument2 pagesCertificate of Avion GroupAmit BhattNo ratings yet

- MSRA - DemolitionDocument30 pagesMSRA - DemolitionCharmie Del CampoNo ratings yet

- Wireline Logging OperationsDocument15 pagesWireline Logging Operationsgladwin CorreiaNo ratings yet

- Method Statement For Site Survey, Utility Scanning & Trail Pit ExcavationDocument18 pagesMethod Statement For Site Survey, Utility Scanning & Trail Pit Excavationshyam NandanNo ratings yet

- Site Inspection Checklist For Tibig 1 Waterway Bridge WB18.odsDocument3 pagesSite Inspection Checklist For Tibig 1 Waterway Bridge WB18.odsGlenda SibongaNo ratings yet

- Job Safety Analysis: SKSA-JSA-23 - 171-001 00 05/10/2023 10-13173Document7 pagesJob Safety Analysis: SKSA-JSA-23 - 171-001 00 05/10/2023 10-13173skmohdmusthafaNo ratings yet

- SMI - BBSR - OPN - WI 01.01, Receiving and Initial CheckingDocument2 pagesSMI - BBSR - OPN - WI 01.01, Receiving and Initial CheckingImmalatulhusnaNo ratings yet

- One Month Drive For Point Machine Letter 1Document5 pagesOne Month Drive For Point Machine Letter 1santosh kumarNo ratings yet

- Cable Tray Erection ProcedureDocument3 pagesCable Tray Erection ProcedureAnmohieyNo ratings yet

- Procedure For Structural Bolt TighteningDocument17 pagesProcedure For Structural Bolt TighteningSyedAsrarNo ratings yet

- Southern Railway Divisional Office General Branch Chennai - 600003. No.M.G/157/G/DRM/Note/2023 Dated 27.03.2023 NoteDocument2 pagesSouthern Railway Divisional Office General Branch Chennai - 600003. No.M.G/157/G/DRM/Note/2023 Dated 27.03.2023 Notesanthoesh g.sNo ratings yet

- Rdso TESTDocument17 pagesRdso TESTmachinery and plantsNo ratings yet

- 7 JPO On EURDocument9 pages7 JPO On EURsafety SwrNo ratings yet

- Objectives:: Methodology: Unit: Unit Name: Date: From: ToDocument2 pagesObjectives:: Methodology: Unit: Unit Name: Date: From: Tosafety SwrNo ratings yet

- Cover SheetDocument1 pageCover Sheetsafety SwrNo ratings yet

- You Are Not Allowed To Print Preview This Page, Thank YouDocument1 pageYou Are Not Allowed To Print Preview This Page, Thank Yousafety SwrNo ratings yet

- Visualising The Solid Shapes Class 8 THDocument9 pagesVisualising The Solid Shapes Class 8 THsafety SwrNo ratings yet

- Maths Unit TestDocument5 pagesMaths Unit Testsafety SwrNo ratings yet

- Unit Test 2 Computer ScienceDocument2 pagesUnit Test 2 Computer Sciencesafety SwrNo ratings yet

- D Block Elements NotesDocument12 pagesD Block Elements NotesSMELLY CATNo ratings yet

- A Study of Mutual Fund Management at LIC, JabalpurDocument38 pagesA Study of Mutual Fund Management at LIC, JabalpurArsh TiwariNo ratings yet

- The Therapeutic PrisonDocument16 pagesThe Therapeutic PrisonjavvnNo ratings yet

- Reasoning NV Embeddedfigures 01Document5 pagesReasoning NV Embeddedfigures 01Sheetal VatsaNo ratings yet

- FDocument36 pagesFBrezeanu CatalinaNo ratings yet

- 1 GENERAL NOTES MergedDocument23 pages1 GENERAL NOTES MergedLaedyn Faye IsipNo ratings yet

- Family MeetingDocument4 pagesFamily MeetingPatama GomutbutraNo ratings yet

- Construction and Behavior of Drilled ShaftsDocument12 pagesConstruction and Behavior of Drilled ShaftsapapadiaNo ratings yet

- Overview of Economic EnvironmentDocument33 pagesOverview of Economic EnvironmentRanju katochNo ratings yet

- Pengetahuan Wirausaha Dan Minat Berwirausaha Pada Siswa SMK: Sahade Dan M. Yusuf A. NgampoDocument6 pagesPengetahuan Wirausaha Dan Minat Berwirausaha Pada Siswa SMK: Sahade Dan M. Yusuf A. NgampoFani Rachmawaty Putri, S.Pd (Guru)No ratings yet

- S36-23302 SIE Service Offshore 12pp.Document7 pagesS36-23302 SIE Service Offshore 12pp.Uhrin ImreNo ratings yet

- Frog Muscular SystemDocument10 pagesFrog Muscular SystemJulius Patrick BobierNo ratings yet

- 1.CHCCOM ISBAR Activity For Session 1Document1 page1.CHCCOM ISBAR Activity For Session 1ko chunNo ratings yet

- Medical Parasitology LabDocument28 pagesMedical Parasitology LabJanielle Medina FajardoNo ratings yet

- Microbiology With Diseases by Taxonomy 4th Edition Bauman Test Bank 1Document538 pagesMicrobiology With Diseases by Taxonomy 4th Edition Bauman Test Bank 1ricardo100% (46)

- The Nature and Types of MoneyDocument12 pagesThe Nature and Types of MoneyShiraz KhanNo ratings yet

- CV of Zihan Soleh ZimahDocument1 pageCV of Zihan Soleh ZimahZee ZimahNo ratings yet

- I Will Turn All My Mountains Into RoadsDocument2 pagesI Will Turn All My Mountains Into RoadsAmanorNo ratings yet

- CH 9 Ethics and Information TechnologyDocument16 pagesCH 9 Ethics and Information Technologyfatima zaheerNo ratings yet

- $ AmyloidDocument293 pages$ Amyloidchakri reddyNo ratings yet

- Comments Received and Responses To Comments Water HeatersDocument16 pagesComments Received and Responses To Comments Water HeatersThanhNo ratings yet

- Manila Activity 1 Group 6Document5 pagesManila Activity 1 Group 6BOTIN, Kiarrah KatrinaNo ratings yet

- Ingles Tecnico Trabajo FinalDocument7 pagesIngles Tecnico Trabajo FinalArturo Tapia SolisNo ratings yet

- Shell Mysella S2 Z 40 Old Name R 40 PDFDocument2 pagesShell Mysella S2 Z 40 Old Name R 40 PDFhananNo ratings yet

- Jenny Saville PresentationDocument13 pagesJenny Saville Presentationapi-644927057No ratings yet

- Group 7 - Hypothesis Testing - 1Document25 pagesGroup 7 - Hypothesis Testing - 1John Christopher GozunNo ratings yet