Professional Documents

Culture Documents

04 - Internal Audit Report and Check List

Uploaded by

Sriramhospital HopeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04 - Internal Audit Report and Check List

Uploaded by

Sriramhospital HopeCopyright:

Available Formats

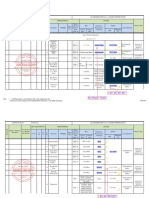

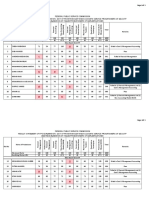

FORMAT NO OA/F/06

OM AUTOMATES REV NO 02

INTERNAL AUDIT REPORT & CHECK LIST REV NO DATE 01/04/2023

Processes of the Organization

ISO 9001:2015

Reference Number

Nut Farmar M/C Dept

Clause Number

House Keeping Dept

Quality Control Dept

Quality

Top Management

Traub M/C Dept

Tapping M/C Dept

Drilling M/C Dept

Internal Audit

Discrepancy

Purchase Dept

Management

Maintenance

MRM

Systems:

Store

Requirements

Clause

Description

Understanding the

4.1 organization and its X X X X X X X X X X X X

context

Needs and

4.2 Expectations of the X X X X X X X X X X X X

Interested Parties

Determining the

scope of the QMS X X X X X X X X X X X X

4.3

management

system

QMS

4.4 Management X X X X X X X X X X X X

System

Leadership and X X X X X X X X X X X X

5.1

commitment

5.2 QMS Policy X X X X X X X X X X X X

Organizational

roles, X X X X X X X X X X X X

5.3

responsibilities

and authorities

Actions to address

6.1 risks and X X X X X X X X X X X X

opportunities

Quality objectives

6.2 and planning to X X X X X X X X X X X X

achieve them

Planning of X X X X X X X X X X X X

6.3

Changes

7.1 Resources X X X D X D X X X X X X

7.2 Competence X X X X X X X X X X X X

7.3 Awareness X X X X X X X X X X X X

7.4 Communication X X X X X X X X X X X X

Documented X X X X X X X X X X X X

7.5

Information

Processes of the Organization

C

l

Prepared By Verified By Approved By

S SASIKUMAR MANJUNATH S Mr. LOKESH

Confidential: For Internal Use Only Page 1 of 4

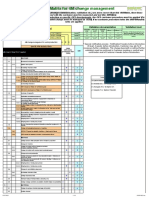

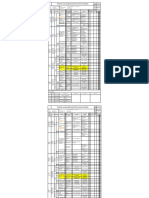

FORMAT NO OA/F/06

OM AUTOMATES REV NO 02

INTERNAL AUDIT REPORT & CHECK LIST REV NO DATE 01/04/2023

Quality Control Dept

ISO 9001:2015

Reference Number

Top Management

Nut Farmar M/C

Traub M/C Dept

Tapping M/C Dept

ause Number

Drilling M/C Dept

Internal Audit

QMS

House Keeping

Discrepancy

Purchase Dept

Maintenance

Management

Store

MRM

Dept

Dept

Systems:

Requirements

Clause

Description

7.5.1 General X X X X X X X X X X X X

Creating and X X X X X X X X X X X X

7.5.2

updating

Control of

7.5.3 documented X X X X X X X X X X X X

Information

8 Operation X X X X X X X X X X X X

8.1 Operational

Planning and X X X X X X X X X X X X

control

Determination of

requirements for X X X X X X X X X X X X

8.2

products and

services

Design and

development of X X X X X X X X X X X X

8.3

products and

services

Control of

externally X X X X X X X X X X X X

8.4

provided products

and services

Production and X X X X X X X X X X X X

8.5

service provision

Release of

8.6 products and X X X X X X X X X X X X

services

Control of

nonconforming

8.7 process outputs, X X X X X X X X X X X X

products and

services

Performance X X X X X X X X X X X X

9

evaluation

Prepared By Verified By Approved By

S SASIKUMAR MANJUNATH S Mr. LOKESH

Confidential: For Internal Use Only Page 2 of 4

FORMAT NO OA/F/06

OM AUTOMATES REV NO 02

INTERNAL AUDIT REPORT & CHECK LIST REV NO DATE 01/04/2023

ISO 9001:2015 Processes of the Organization

Clause Number

QMS

Top Management

Nut Farmar M/C

Traub M/C Dept

Quality Control

Drilling M/C Dept

Internal Audit

House Keeping

Discrepancy

Purchase Dept

Management

Reference

Tapping M/C

Number

Maintenance

Systems:

Store

MRM

Dept

Dept

Dept

Dept

Requirements

Clause

Description

Monitoring,

measurement, X X X X X X X X X X X X

9.1

analysis and

evaluation

9.2 Internal audit X X X X X X X X X X X X

Management X X X X X X X X X X X X

9.3

Review

10 Improvement X X X X X X X X X X X X

10.1 General X X X X X X X X X X X X

Nonconformity

10.2 and Corrective X X X X X X X X X X X X

action

Continual X X X X X X X X X X X X

10.3

Improvement

* Use an “X” to indicate that the clause was assessed in the area described. Use a “D” to indicate

that a discrepancy was found

AUDIT REFERENCE 2/IQA/2023

DATE OF AUDIT 10-04-2023

Prepared By Verified By Approved By

S SASIKUMAR MANJUNATH S Mr. LOKESH

Confidential: For Internal Use Only Page 3 of 4

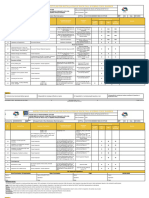

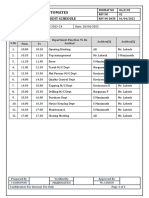

FORMAT NO OA/F/06

OM AUTOMATES REV NO 02

INTERNAL AUDIT REPORT & CHECK LIST REV NO DATE 01/04/2023

AUDIT TEAM OM AUTOMATES INTERNAL AUDIT TEAMS

Opportunity for improvement

1. Fire Exit Sign Board Display in production area

2. Fire Assembly point mark in company out side area

3. New Machines Identification board display

Status of Audit Finding

CLAUSE REQUIREMENT MAJOR MINOR

4 Context of the organization 0 0

4.1 Understanding the organization and its context 0 0

4.2 Understanding the needs and expectations of interested parties 0 0 0 0

4.3 Determining the scope of the quality management system 0 0

4.4 Quality Management System and its Process 0 0

5 Leadership 0 0

5.1 Leadership and Commitment 0 0 0

5.2 Quality Policy 0 0

5.3 Organizational roles, responsibilities and authorities 0 0

6 Planning for the quality management system 0 0

6.1 Actions to address risks and opportunities 0 0 0

0

6.2 Quality objectives and planning to achieve them 0 0

6.3 Planning of Changes 0 0

7 Support 0 0

7.1 Resources 1 0

7.2 Competence 0 1 0

0

7.3 Awareness 0 0

7.4 Communication 0 0

7.5 Documented Information 0 0

8 Operation 0 0

8.1 Operational Planning and control 0 0

8.2 Determination of requirements for products and services 0 0

8.3 Design and development of products and services 0 0 0

8.3 Control of externally provided products and services 0 0 0

8.3 Production and service provision 0 0

8.3 Release of products and services 0 0

Control of nonconforming process outputs, products and

8.7 0 0

services

9 Performance evaluation 0 0

9.1 Monitoring, measurement, analysis and evaluation 0 0

0 0

9.2 Internal audit 0 0

9.3 Management Review 0 0

10 Improvement 0 0

10.1 General 0 0

0

0 0

10.2 Nonconformity and Corrective action 0

10.3 Continual Improvement 0 0

0

TOTAL NONCONFORMANCES 1 1 0

Prepared By Verified By Approved By

S SASIKUMAR MANJUNATH S Mr. LOKESH

Confidential: For Internal Use Only Page 4 of 4

You might also like

- Kombolcha Institute of Technology: Department of Mechanical Engineering Intership Report & ProjectDocument25 pagesKombolcha Institute of Technology: Department of Mechanical Engineering Intership Report & ProjectDawit SolomonNo ratings yet

- RP2-ISO9001 2015 ADocument50 pagesRP2-ISO9001 2015 AMasrawana Mohd Masran100% (1)

- Lampiran - IKA CM Rotating EquipmentDocument1 pageLampiran - IKA CM Rotating Equipmentahmadalfan662No ratings yet

- Request For IMDS Data Registration of New PartDocument2 pagesRequest For IMDS Data Registration of New Partminhchi2608No ratings yet

- QM Process Map PDFDocument1 pageQM Process Map PDFghafoorian_khoshgovar148850% (2)

- Annexure 2A - ITP For CS LTCS Welded Fittings To A 234 WPBW A 420WPL6W For Normal NACE IBRDocument3 pagesAnnexure 2A - ITP For CS LTCS Welded Fittings To A 234 WPBW A 420WPL6W For Normal NACE IBRPranav JadhavNo ratings yet

- 18-Mce-18 Ali Raza: Hoq For A New Bank Service (Branch) Located Inside Nfc-IefrDocument1 page18-Mce-18 Ali Raza: Hoq For A New Bank Service (Branch) Located Inside Nfc-IefrAliNo ratings yet

- Purpose:: Monthly Theme Based ActivityDocument6 pagesPurpose:: Monthly Theme Based Activitybabuhsr5096100% (2)

- Form2!01!01Process FMEA Worksheet (RCL SMALL)Document1 pageForm2!01!01Process FMEA Worksheet (RCL SMALL)Muhammad Reza GadranNo ratings yet

- Sales Area Transportation Planning Point Sales OrganizationDocument3 pagesSales Area Transportation Planning Point Sales OrganizationclaokerNo ratings yet

- Form2-01-01Process FMEA WorksheetDocument1 pageForm2-01-01Process FMEA WorksheetMuhammad Reza GadranNo ratings yet

- Full CMC Template CalibrationDocument31 pagesFull CMC Template CalibrationStudent ForeignNo ratings yet

- Protection Wire Mesh ITPDocument3 pagesProtection Wire Mesh ITPVishnudas MgNo ratings yet

- 3MIS and WLRC Training 9.2023Document49 pages3MIS and WLRC Training 9.2023mags2796No ratings yet

- 447 Final Inspn Edited PDFDocument3 pages447 Final Inspn Edited PDFATHIBAN VNo ratings yet

- 7 LN562 - Topic 2.3 ECADocument14 pages7 LN562 - Topic 2.3 ECAaremyulNo ratings yet

- Component Management StrategicDocument20 pagesComponent Management StrategicJean Claude EidNo ratings yet

- Annex2 Suppliers Summary DataDocument1 pageAnnex2 Suppliers Summary DataHan HanNo ratings yet

- MLK MNL HIC EL BM G01 00 0025 00 ReplyDocument2 pagesMLK MNL HIC EL BM G01 00 0025 00 Replyيوسف خضر النسورNo ratings yet

- Equipment Calibration LogDocument5 pagesEquipment Calibration LogNasional GotongroyongNo ratings yet

- CIPM MRA Appendix C Calibration and Measurement Capability (CMC) DeclarationsDocument31 pagesCIPM MRA Appendix C Calibration and Measurement Capability (CMC) DeclarationskarthickNo ratings yet

- U1l2 DBSDocument10 pagesU1l2 DBSpmcisissengueNo ratings yet

- Contoh Business Process MapDocument1 pageContoh Business Process MapIlham KasumaNo ratings yet

- 4.3.2 F CSR Matrix ADocument6 pages4.3.2 F CSR Matrix ArohitNo ratings yet

- Annexure 5A - ITP For Alloy Steel Seamless & Forged Fittings A234WP5 WP9 WP91 A182 F5 F9 & F91 For Normal NACE & IBRDocument3 pagesAnnexure 5A - ITP For Alloy Steel Seamless & Forged Fittings A234WP5 WP9 WP91 A182 F5 F9 & F91 For Normal NACE & IBRPranav JadhavNo ratings yet

- CD6 Prototype Control PlanDocument3 pagesCD6 Prototype Control Planmpedraza-1No ratings yet

- BMW of North America, LLC 2001 Models (Except X5) Service Maintenance ChecklistDocument2 pagesBMW of North America, LLC 2001 Models (Except X5) Service Maintenance ChecklistQuốc Phú ĐinhNo ratings yet

- Annexure 1A - ITP For CS LTCS Forged Seamless Fittings To A 105 A234 WPB A 350 LF2 A 420 WPL6 For Normal NACE IBRDocument3 pagesAnnexure 1A - ITP For CS LTCS Forged Seamless Fittings To A 105 A234 WPB A 350 LF2 A 420 WPL6 For Normal NACE IBRPranav JadhavNo ratings yet

- Indiana Machine Tools (Mohali) Non-Conformity Report: F/MR/830/01 Approved by Issue 01 8/9/2005 Rev 00 MRDocument7 pagesIndiana Machine Tools (Mohali) Non-Conformity Report: F/MR/830/01 Approved by Issue 01 8/9/2005 Rev 00 MRsavita17julyNo ratings yet

- Payroll (HR) RCM 2022-2023Document1 pagePayroll (HR) RCM 2022-2023Aman ParchaniNo ratings yet

- 4M Change ManagementDocument2 pages4M Change ManagementDamodaran RajanayagamNo ratings yet

- Special Process: Coating System Assessment Version 3 Issued 07/2020Document10 pagesSpecial Process: Coating System Assessment Version 3 Issued 07/2020r arumugamNo ratings yet

- Assessment and Collection Dept. Description & Details of Capital Value Calculation Annexure "A"Document2 pagesAssessment and Collection Dept. Description & Details of Capital Value Calculation Annexure "A"Suraj VarmaNo ratings yet

- SOURCE: FAA AMT Airframe Handbook, Aircraft Metal Structural Repair, Chapter 4Document2 pagesSOURCE: FAA AMT Airframe Handbook, Aircraft Metal Structural Repair, Chapter 4Mani Rathinam RajamaniNo ratings yet

- System For Determine The Key CharacteristicsDocument33 pagesSystem For Determine The Key Characteristicsjohnoo7No ratings yet

- May 2021 Body Shop Operation Report: Edit - Joko - AB Review Rustam EffendiDocument5 pagesMay 2021 Body Shop Operation Report: Edit - Joko - AB Review Rustam EffendiMario MarfellyNo ratings yet

- 18 Management ReviewDocument1 page18 Management Reviewkumarnitesh173No ratings yet

- Ceklis Alat Berat - ResultDocument2 pagesCeklis Alat Berat - Resultary fauzi rahmanNo ratings yet

- Rock Fall Barrier ITPDocument2 pagesRock Fall Barrier ITPVishnudas MgNo ratings yet

- Fpo 2017 43rd CTP - PaasDocument3 pagesFpo 2017 43rd CTP - Paaswaleedrana786No ratings yet

- PMV Org Chart Mobile Workshop EtcDocument5 pagesPMV Org Chart Mobile Workshop EtcPoojaNo ratings yet

- MS ISO/IEC 17025 (Issue 3, 5 March 2019 Replacement of SAMM 218 Dated 30 November 2018)Document21 pagesMS ISO/IEC 17025 (Issue 3, 5 March 2019 Replacement of SAMM 218 Dated 30 November 2018)Ng Wei LihNo ratings yet

- Top 14 Contractor Performance Metrics in Heavy IndustryDocument27 pagesTop 14 Contractor Performance Metrics in Heavy IndustrysirizalNo ratings yet

- This Is To Request The Publication of The Following Vacant Positions of MARITIME INDUSTRY AUTHORITY in The CSC WebsiteDocument3 pagesThis Is To Request The Publication of The Following Vacant Positions of MARITIME INDUSTRY AUTHORITY in The CSC WebsitekaneNo ratings yet

- Quality Manual - StampedDocument46 pagesQuality Manual - Stampedyogesh pachankarNo ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document3 pagesPotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- 02 (SQ) Supplier System Audit SheetDocument5 pages02 (SQ) Supplier System Audit SheetDEVENDERNo ratings yet

- QA MATRIX SHEET - RadiatorDocument4 pagesQA MATRIX SHEET - RadiatorBaljeet SinghNo ratings yet

- ITP-Refrac 03B001&02B001-1Document2 pagesITP-Refrac 03B001&02B001-1มิตร อันมา100% (2)

- 9.55655-01-2007 - Septum Carton Tarred FeltDocument12 pages9.55655-01-2007 - Septum Carton Tarred Feltclaudio5475100% (1)

- Gantt Chart Part 1Document3 pagesGantt Chart Part 1MathanKumarNo ratings yet

- Italian-Thai Development Public Company Limited: The Quality Control PlanDocument1 pageItalian-Thai Development Public Company Limited: The Quality Control Planmahedi hasanNo ratings yet

- Epic FSBDocument12 pagesEpic FSBjoseNo ratings yet

- 4M Change Management FormatDocument1 page4M Change Management FormatSUBODHH100% (2)

- Rockwell Manual TP-0460 Lubrication IntervalsDocument2 pagesRockwell Manual TP-0460 Lubrication IntervalsScottNo ratings yet

- Arita Valve Factory Layout New Air CompressorDocument1 pageArita Valve Factory Layout New Air CompressorYusri WyeuserieyNo ratings yet

- Vendor Sales Operation Maintenance Purchase Hr/Finance: Coastal Energen Cross Functional Flow ChartDocument5 pagesVendor Sales Operation Maintenance Purchase Hr/Finance: Coastal Energen Cross Functional Flow ChartnarayananaliveNo ratings yet

- Philippine Deposit Insurance Corporation: Corp. Comm. DeptDocument1 pagePhilippine Deposit Insurance Corporation: Corp. Comm. DeptocssantiagoNo ratings yet

- Internal and External IssuesDocument3 pagesInternal and External IssuesSriramhospital HopeNo ratings yet

- UntitledDocument3 pagesUntitledSriramhospital HopeNo ratings yet

- 07 - First Aid BoxDocument1 page07 - First Aid BoxSriramhospital HopeNo ratings yet

- UntitledDocument7 pagesUntitledSriramhospital HopeNo ratings yet

- EOHS Management OBJECTIVES 2022: Authorized SignatoryDocument1 pageEOHS Management OBJECTIVES 2022: Authorized SignatorySriramhospital HopeNo ratings yet

- 05 - Corrective Action ReportDocument2 pages05 - Corrective Action ReportSriramhospital HopeNo ratings yet

- Om Automates: Approved Internal AuditorsDocument1 pageOm Automates: Approved Internal AuditorsSriramhospital HopeNo ratings yet

- 03 - Internal Audit ScheduleDocument1 page03 - Internal Audit ScheduleSriramhospital HopeNo ratings yet

- 02 - Internal Audit PlanDocument1 page02 - Internal Audit PlanSriramhospital HopeNo ratings yet