Professional Documents

Culture Documents

TRB-DS-01217-EN Blancett 1100 Turbine Flow Meter Product Data Sheet

Uploaded by

FershaalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TRB-DS-01217-EN Blancett 1100 Turbine Flow Meter Product Data Sheet

Uploaded by

FershaalCopyright:

Available Formats

Turbine Flow Meter

Model 1100

DESCRIPTION

The Model 1100 turbine flow meter is designed to withstand the

demands of the most rigorous flow measurement applications.

Originally developed for the secondary oil recovery market,

the Model 1100 flow meter is an ideal meter for liquid flow

measurement on or off the oil field.

The meter features a rugged 316 stainless steel housing and rotor

support assemblies, CD4MCU stainless steel rotor, and

abrasive-resistant tungsten carbide rotor shaft and journal bearings.

The Model 1100 maintains measurement accuracy and mechanical

integrity in the corrosive and abrasive fluids commonly found in oil

field water flood projects and many industrial applications.

When paired with a Blancett flow monitor, the Model 1100 turbine

meter meets a wide range of measurement requirements. This

makes it ideal for applications such as pipelines, production/

injection fields, in-situ mining operations, offshore facilities, and

other industrial applications. For a full list of Blancett flow monitors,

see www.badgermeter.com. INSTALLATION

The Model 1100 turbine meter is simple to install and service. It

FEATURES operates in any orientation (horizontal to vertical) as long as the

• Offers accurate and repeatable flow measurement in ranges “flow direction” arrow is aligned in the same direction as the actual

from 0.6…5000 gmp (20…171,000 bpd) line flow. For optimum performance, the flow meter should be

• Cost-effective solution for turbine flow meter applications installed with a minimum of 10 diameters upstream straight pipe

length and 5 diameters downstream straight pipe length.

• Rugged 316 stainless steel construction offers long service life

in severe operating environments

REPAIR KITS

• Available in NPT, BSP, Victaulic®, flange, or hose barbed

end connections The repair kits are designed for easy field service of a damaged flow

• NIST traceable calibration meter. Model 1100 repair kits replace only the internal parts, rather

than replacing the entire flow meter. Repair parts use stainless steel

• Installation in pipe sizes from 1/2…10 in. Can integrate

alloys and tungsten carbide construction materials.

electronically with a Blancett flow monitor

• K-factor Scaler, or the F to I/F to V Intelligent Converter Field Each repair kit is factory calibrated to provide accuracy throughout

replaceable repair kits allow for turbine replacement without the entire flow range. Each kit is complete and includes a new

loss of accuracy K-factor, which is the calibrated number of pulses generated

by each gallon of liquid. Recalibration of the monitor or other

electronics uses the K-factor to provide accurate output data.

TRB-DS-01217-EN-08 (November 2022) Product Data Sheet

Turbine Flow Meter, Model 1100

OPERATING PRINCIPLE

Fluid entering the meter passes through the inlet flow straightener which reduces its turbulent flow pattern and improves the fluid’s

velocity profile. Fluid then passes through the turbine, causing it to rotate at a speed proportional to fluid velocity. As each turbine blade

passes through the magnetic field at the base of the transducer, an AC voltage pulse is generated in the pickup coil. These pulses produce

an output frequency proportional to the volumetric flow through the meter.

Magnetic Pickup

or

Other Frequency

Output Device

Output

Turbine Rotor Signal

K-FACTOR

The K-factor represents the number of output pulses transmitted per gallon of fluid passing through the turbine meter. Each turbine has a

unique K-factor. However, turbine meters are not functionally consistent throughout the full flow range of the meter.

There are several forms of friction inherent in the turbine meters that retard the rotational movement of the turbine rotor. These frictional

forces include: magnetic drag, created by electromagnetic forces of pickup transducers; mechanical drag, due to bearing friction; and

viscous drag, produced by flowing fluid.

As flow increases, the frictional forces are minimized and the free-wheeling motion of the turbine rotor becomes more linear (proportional

to flow). The K-factor becomes relatively constant and the linear throughout the balance of the linear flow range. This is approximately a

10:1 turndown ratio from the maximum flow rate down to the minimum flow rate.

Typical K-factor Curve (Pulse per US Gallon)

+1%

OUTPUT FREQUENCY (CYCLES/SEC)

LINEARITY (DESIGN DEVIATION)

K-FACTOR (PULSES/GALLON)

K-FACTOR (CYCLES/GALLON)

+%

% OF VALUE AT FLOW RATE

100%

K-FA N)

AVG. K-FACTOR (K) CTO LO

50% R ( P U L S E/GAL

-%

0% 10% 50% 100% -1%

FULL FLOW RANGE

LINEAR FLOW RANGE STANDARD TURNDOWN APPROX. 10:1

-1%

SPECIFICATIONS

Body 316 stainless steel

Rotor CD4MCU stainless steel

Materials of Construction Bearings —

Rotor Shaft Tungsten carbide

Rotor Support 316 stainless steel

Operating Temperature –150…350° F (–101…177° C)

Pressure Rating 800 or 5000 psi

End Connections NPT, BSP, Victaulic®, flange, hose barbed

Turndown Ratio 10:1

±1% of reading for 7/8 in. and larger meters

Accuracy

±1% of reading over the upper 70% of the measuring range for 3/8, 1/2, and 3/4 in. meters

Repeatability ±0.1%

Calibration Water (NIST traceable calibration)

Pickup B111109

Met Labs File No. E112860 (for explosion proof models only)

Certifications - UL1203, Fourth Edition: Explosion-Proof and Dust-Ignition-Proof Electrical Equipment for Use in Hazardous (Classified) Locations

- CSA C22.2 No. 30-M1986, Third Edition: Explosion-Proof Enclosures for Use in Class I Hazardous Locations

* Contact factory for ordering options

Page 2 TRB-DS-01217-EN-08 November 2022

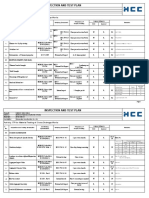

Meter Parts

METER PARTS

NOTE: If the meter repair kit part number ends in NCC (no calibration), it was not factory calibrated. For these repair kits, use

the nominal K factor supplied.

REPAIR KIT PART NUMBER INFORMATION

Replacement Kit Fits

Flow Meter Size Repair Kit Part Number

Meter Part Number

3/8 in. B110-375, B110-375-1/2 B251-102

1/2 in. B110-500, B110-500-1/2 B251-105

3/4 in. B110-750, B110-750-1/2 B251-108

7/8 in. B110-875 B251-109

1 in. B111-110 B251-112

1-1/2 in. B111-115 B251-116

2 in. Low B111-121 B251-116

2 in. B111-120 B251-120

3 in. B111-130 B251-131

4 in. B111-140 B251-141

6 in. B111-160 B251-161

8 in. B111-180 B251-181

10 in. B111-200 B251-200

Standard Magnetic Pickup All Meter Sizes B111109

November 2022 TRB-DS-01217-EN-08 Page 3

Turbine Flow Meter, Model 1100

PART NUMBER INFORMATION

Flow Ranges Approx. Meter

Part

1

End Max. Strainer End to End

Bore Size K-factor Weight

Number Connection PSI gpm (lpm) bpd m3/d Mesh Length

Pulse/Gal (lb)

3/8 in. 0.6…3 3.00 in.

B110-375-½ 1/2 in. male NPT 5000 20…100 3.3…16 60 18000 1

(9.5 mm) (2.3…11.4) (76.20 mm)

1/2 in. 0.75…7.5 3.00 in.

B110-500-½ 1/2 in. male NPT 5000 25…250 4.1…41 60 13000 1

(12.7 mm) (2.8…28.4) (76.20 mm)

3/4 in. 2…15 3.00 in.

B110-750-½ 1/2 in. male NPT 5000 68…515 10.9…81.75 60 3300 1

(19.1 mm) (7.6…56.7) (76.20 mm)

3/8 in. 0.6…3 4.00 in.

B110-375 1 in. male NPT 5000 20…100 3.3…16 60 18000 2

(9.5 mm) (2.3…11.4) (101.60 mm)

1/2 in. 0.75…7.5 4.00 in.

B110-500 1 in. male NPT 5000 25…250 4.1…41 60 13000 2

(12.7 mm) (2.8…28.4) (101.60 mm)

3/4 in. 2…15 4.00 in.

B110-750 1 in. male NPT 5000 68…515 10.9…81.75 60 3300 2

(19.1 mm) (7.5…56.7) (101.60 mm)

7/8 in. 3…30 4.00 in.

B110-875 1 in. male NPT 5000 100…1000 16…160 60 3100 2

(22.2 mm) (11.4…113.6) (101.60 mm)

1 in. 5…50 4.00 in.

B111-110 1 in. male NPT 5000 170…1700 27.25…272.5 40 870 2

(25.4 mm) (18.9…189.3) (101.60 mm)

1-1/2 in. 1-1/2 in. male 15…180 6.00 in.

B111-115 5000 515…6000 82…981 20 330 5

(38.1 mm) NPT (56.8…681.4) (152.40 mm)

1-1/2 in. 15…180 6.00 in.

B111-121 2 in. male NPT 5000 515…6000 82…981 20 330 6

(38.1 mm) (56.8…681.4) (152.40 mm)

1-1/2 in. 2 in. grooved 15…180 6.00 in.

B311-066 5000 515…6000 82…981 20 330 6

(38.1 mm) end (56.8…681.4) (152.40 mm)

2 in. 40…400 10.00 in.

B111-120 2 in. female NPT 5000 1300…13000 218…2180 20 52 14

(50.8 mm) (151.4…1514.2) (245.00 mm)

3 in. 60…600 12.50 in.

B311-004 3 in. male NPT 800 2100…21000 327…3270 10 57 15

(76.2 mm) (227.1…2271.2) (317.50 mm)

3 in. 3 in. grooved 60…600 12.50 in.

B111-130 800 2100…21000 327…3270 10 57 15

(76.2 mm) end (227.1…2271.2) (317.50 mm)

4 in. 100…1200 12.00 in.

B311-084 4 in. male NPT 800 3400…41000 545…6540 10 29 20

(101.6 mm) (378.5…4542.5) (304.80 mm)

4 in. 4 in. grooved 100…1200 12.00 in.

B111-140 800 3400…41000 545…6540 10 29 20

(101.6 mm) end (378.5…4542.5) (304.80 mm)

6 in. 200…2500 12.00 in.

B311-085 6 in. male NPT 800 6800…86000 1090…13626 4 7 46

(152.4 mm) (757.1…9463.5) (304.80 mm)

6 in. 6 in. grooved 200…2500 12.00 in.

B111-160 800 6800…86000 1090…13626 4 7 46

(152.4 mm) end (757.1…9463.5) (304.80 mm)

8 in. 8 in. grooved 350…3500 12.00 in.

B111-180 800 12000…120,000 1363…19076 4 3 56

(203.2 mm) end (1324.9…13248.9) (304.80 mm)

10 in. 10 in. grooved 500…5000 12.00 in.

B111-200 800 17000…171,000 2725…27252 4 1.6 80

(254 mm) end (1892.7…18927.1) (304.80 mm)

1

Includes Standard Mag Pickup, p/n B111109, -150…330° F (-101…165° C), suitable for all mounting styles

Control. Manage. Optimize.

Blancett is a registered trademark of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities. Due to continuous research,

product improvements and enhancements, Badger Meter reserves the right to change product or system specifications without notice, except to the extent an outstanding

contractual obligation exists. © 2022 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

You might also like

- Product Data Sheet: Turbine Flow MeterDocument4 pagesProduct Data Sheet: Turbine Flow MeterJavier EncaladaNo ratings yet

- Turbine Meter Tech GuideDocument22 pagesTurbine Meter Tech GuideOscar MarinNo ratings yet

- FT 1000 - FP 1000 - TG L111eDocument12 pagesFT 1000 - FP 1000 - TG L111eaditya pamungkasNo ratings yet

- Cost Effective Float Tank GaugesDocument12 pagesCost Effective Float Tank Gaugesoni tofanNo ratings yet

- Turbine Meter Tech GuideDocument24 pagesTurbine Meter Tech GuideDenilson Souto Dos Santos100% (1)

- Control Valves and SensorsDocument86 pagesControl Valves and SensorsWilmar Antonio Zuluaga ArangoNo ratings yet

- Dual Laterolog ToolDocument44 pagesDual Laterolog ToolTo Pham Ha TrieuNo ratings yet

- CRI Openwell PumpsDocument24 pagesCRI Openwell PumpskanaliNo ratings yet

- Brochure Liquid Flow MeterDocument12 pagesBrochure Liquid Flow MeterErick Perez MoralesNo ratings yet

- Ad9901 PDFDocument8 pagesAd9901 PDFDeep SahaniNo ratings yet

- Woltmann Helix Helical Vane Water Meters: Permanent Flow Rate (Q) KL/H Size - Nominal Diameter (DN) MMDocument2 pagesWoltmann Helix Helical Vane Water Meters: Permanent Flow Rate (Q) KL/H Size - Nominal Diameter (DN) MMMijomirNo ratings yet

- 24.3 Cách Đo Ripple & Transient - Analog DeviceDocument8 pages24.3 Cách Đo Ripple & Transient - Analog Devicetai08cdt2No ratings yet

- Turbine FL Ow Meter SCFT AnalogueDocument5 pagesTurbine FL Ow Meter SCFT AnalogueCésar PérezNo ratings yet

- F 1000 Turbine Catalog SheetDocument4 pagesF 1000 Turbine Catalog SheetTrongtuyen HoangNo ratings yet

- ON Icon: Inline Ultrasonic Flow MeterDocument4 pagesON Icon: Inline Ultrasonic Flow MeterJayaminNo ratings yet

- Onicon F-1100Document7 pagesOnicon F-1100Darnell GracenNo ratings yet

- Turn Ratio TestDocument8 pagesTurn Ratio TestImran Nawaz MehthalNo ratings yet

- High Performance Turbine Meter: A Product Sheet of Neptune Technology GroupDocument4 pagesHigh Performance Turbine Meter: A Product Sheet of Neptune Technology GroupRajibNo ratings yet

- Ingedrive Mv500 EngDocument2 pagesIngedrive Mv500 EnginakigarateNo ratings yet

- Turbine Meters Design & ApplicationDocument33 pagesTurbine Meters Design & ApplicationAnnisa RahmadayantiNo ratings yet

- Electrical Formulae Used in CalculationsDocument17 pagesElectrical Formulae Used in Calculationsmohit18dNo ratings yet

- Actaris Transmitters SpecDocument4 pagesActaris Transmitters SpecDaniel GarciaNo ratings yet

- LCI Brushless Exciter VFD System OverviewDocument58 pagesLCI Brushless Exciter VFD System Overviewakm-ntpc100% (4)

- Dan Liq TM TG 0122Document22 pagesDan Liq TM TG 0122Abdeldjalil AchourNo ratings yet

- Deadbeat Flux Level Control of Direct Field-Oriented High Horse Power Induction Servo Motor Using Adaptive Rotor Flux ObserverDocument9 pagesDeadbeat Flux Level Control of Direct Field-Oriented High Horse Power Induction Servo Motor Using Adaptive Rotor Flux Observerapi-3826450No ratings yet

- Control Chapter 5 - RemoteDocument87 pagesControl Chapter 5 - RemoteJhonny PerezNo ratings yet

- Electrohydraulic Proportional ValvesDocument2 pagesElectrohydraulic Proportional Valveschandushar1604No ratings yet

- VT 11075Document4 pagesVT 11075horcsabNo ratings yet

- Rycom Model 2172 Frequency Selective Voltmeter Maintenance-Manual W0585-6FD, 1967.Document27 pagesRycom Model 2172 Frequency Selective Voltmeter Maintenance-Manual W0585-6FD, 1967.Bob Laughlin, KWØRLNo ratings yet

- Example Electronics Project Proposal (Based On and Liberally Quoting Chris Adam's Thesis)Document3 pagesExample Electronics Project Proposal (Based On and Liberally Quoting Chris Adam's Thesis)LJ MutucNo ratings yet

- Meteorological Instruments: MODEL 05103-45Document11 pagesMeteorological Instruments: MODEL 05103-45Jay SanchaniyaNo ratings yet

- CIGRE Curso HVDC - Perdas - Canelhas PDFDocument10 pagesCIGRE Curso HVDC - Perdas - Canelhas PDFcarlosrenatorcNo ratings yet

- LMCB24-SR (-T) : Proportional Control, Non-Spring Return, Direct Coupled, 24V, For 2 To 10 VDC and 4 To 20 MaDocument5 pagesLMCB24-SR (-T) : Proportional Control, Non-Spring Return, Direct Coupled, 24V, For 2 To 10 VDC and 4 To 20 MaHector Hugo GutierrezNo ratings yet

- Curso de Transmissão em Corrente Contínua: Station LossesDocument10 pagesCurso de Transmissão em Corrente Contínua: Station LossesCarlos FigueiredoNo ratings yet

- Reactive Power and Harmonic Filter - ABBDocument49 pagesReactive Power and Harmonic Filter - ABBpongpumNo ratings yet

- MCV116 Pressure Control Pilot Valve (PCP)Document17 pagesMCV116 Pressure Control Pilot Valve (PCP)Justin100% (1)

- Coriolis Mass Flow Meters: R. Mascomani Chief Research Engineer Fcri, PalakkadDocument79 pagesCoriolis Mass Flow Meters: R. Mascomani Chief Research Engineer Fcri, PalakkadabhaysinghpatelNo ratings yet

- SCFT Measurement Turbine: Device FeaturesDocument4 pagesSCFT Measurement Turbine: Device FeaturesBHAART PANCHALNo ratings yet

- Arteche Ds Trfmvguide enDocument248 pagesArteche Ds Trfmvguide enKim ChanNo ratings yet

- Vortex Flow MeterDocument2 pagesVortex Flow MeterhotnatkapoorNo ratings yet

- Atrato Instruction Ficha - Just SolcoincoDocument7 pagesAtrato Instruction Ficha - Just SolcoincoJohn Jairo CelisNo ratings yet

- Orifice Flow Meter (Series KOP/KOE) : AXI LODocument16 pagesOrifice Flow Meter (Series KOP/KOE) : AXI LOmounrNo ratings yet

- Variable Transformers-Prod - Design & Engineer - Data-StacoDocument7 pagesVariable Transformers-Prod - Design & Engineer - Data-StacoAirton José FloresNo ratings yet

- Renesas - Design of PSFBDocument18 pagesRenesas - Design of PSFBAnurag1996No ratings yet

- CE 111 - 02a Hydraulic Machinery-Turbines PDFDocument18 pagesCE 111 - 02a Hydraulic Machinery-Turbines PDFAyeeSerranoNo ratings yet

- Relay Coordination Preliminary Report Draft-BDocument4 pagesRelay Coordination Preliminary Report Draft-Bramesh1950No ratings yet

- BHMN 80128013 FS 19702B X 0820 EnglishDocument8 pagesBHMN 80128013 FS 19702B X 0820 EnglishYelena ObyazovaNo ratings yet

- Function GeneratorDocument78 pagesFunction GeneratorVishali Chowdary100% (1)

- MiniDocument4 pagesMinicitramuaraNo ratings yet

- Tan-005Document9 pagesTan-005mark363No ratings yet

- Variable Hydraulic Pump Series VP1-120Document2 pagesVariable Hydraulic Pump Series VP1-120Francisco Javier Sierra TrujilloNo ratings yet

- Gas Turbin Meter CatalogDocument16 pagesGas Turbin Meter CatalogAlvaro Joel Quinteros RochaNo ratings yet

- ChE 404-Chapter 08Document38 pagesChE 404-Chapter 08aliNo ratings yet

- ZVSDocument28 pagesZVS12BACAUNo ratings yet

- Generator Excitation SystemDocument34 pagesGenerator Excitation Systemveerclaire83% (6)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Turbine Flow Meter: Technical Data SheetDocument7 pagesTurbine Flow Meter: Technical Data SheetFershaalNo ratings yet

- TW DasDocument4 pagesTW DasFershaalNo ratings yet

- Zone ClassificationDocument1 pageZone ClassificationFershaalNo ratings yet

- Introduction & Refreshment of Power Plants - FSADocument1 pageIntroduction & Refreshment of Power Plants - FSAFershaalNo ratings yet

- Orifice plate dimensioning for air flowDocument21 pagesOrifice plate dimensioning for air flowDang Hieu NguyenNo ratings yet

- Turbine Flow Meter: Technical Data SheetDocument7 pagesTurbine Flow Meter: Technical Data SheetFershaalNo ratings yet

- TRB-DS-01217-EN Blancett 1100 Turbine Flow Meter Product Data SheetDocument4 pagesTRB-DS-01217-EN Blancett 1100 Turbine Flow Meter Product Data SheetFershaalNo ratings yet

- Data Sheet Turbina Medidora de GasDocument2 pagesData Sheet Turbina Medidora de GasDiego RuanoNo ratings yet

- LWGY Liquid Turbine Flow MeterDocument14 pagesLWGY Liquid Turbine Flow MeterFershaalNo ratings yet

- Basic Instrumentation Measuring Devices and Basic Pid ControlDocument125 pagesBasic Instrumentation Measuring Devices and Basic Pid ControlCuong Nguyen ChiNo ratings yet

- Data Sheet For Actuators For On-Off Valves: OctoberDocument13 pagesData Sheet For Actuators For On-Off Valves: OctoberFershaalNo ratings yet

- 001 Verilog-IntroDocument193 pages001 Verilog-IntroSaurabh KoranglekarNo ratings yet

- Orifice Plate Specification SheetDocument3 pagesOrifice Plate Specification SheetFershaalNo ratings yet

- Inspection and Test Plan: Activity: ITP For Material Testing of Cross Drainage WorksDocument8 pagesInspection and Test Plan: Activity: ITP For Material Testing of Cross Drainage WorksjitendraNo ratings yet

- An Object Oriented Graphical User Interface (GUI) For Optimal Placement of Phasor Measurement UnitsDocument6 pagesAn Object Oriented Graphical User Interface (GUI) For Optimal Placement of Phasor Measurement UnitsFershaalNo ratings yet

- HJK Ce Atex-Nec-Cen-Iec - 2021Document25 pagesHJK Ce Atex-Nec-Cen-Iec - 2021FershaalNo ratings yet

- Reliability and availability modeling of Subsea Autonomous High Integrity Pressure Protection System with partial stroke test by Dynamic BayesianDocument14 pagesReliability and availability modeling of Subsea Autonomous High Integrity Pressure Protection System with partial stroke test by Dynamic BayesianFershaalNo ratings yet

- Design and Implementation Wind Turbine Power Control System Base Particle Swam Optimization at Low Rate Wind FarmDocument9 pagesDesign and Implementation Wind Turbine Power Control System Base Particle Swam Optimization at Low Rate Wind FarmFershaalNo ratings yet

- PROCEDURE COMMISSIONING STEAM TURBINE – BFWPDocument20 pagesPROCEDURE COMMISSIONING STEAM TURBINE – BFWPFershaalNo ratings yet

- Reliability and Availability Modeling of Subsea Autonomous High Integrity Pressure Protection System With Partial Stroke Test by Dynamic BayesianDocument15 pagesReliability and Availability Modeling of Subsea Autonomous High Integrity Pressure Protection System With Partial Stroke Test by Dynamic BayesianFershaalNo ratings yet

- Product Catalog: Measurement & InstrumentationDocument304 pagesProduct Catalog: Measurement & InstrumentationFershaalNo ratings yet

- P&ID SementaraDocument1 pageP&ID SementaraFershaalNo ratings yet

- Steam System Design and Commissioning Guidance: Precommissioning ChecklistDocument8 pagesSteam System Design and Commissioning Guidance: Precommissioning ChecklistMirsoNo ratings yet

- 2669 Article - Text 13607 1 10 20150623Document11 pages2669 Article - Text 13607 1 10 20150623FershaalNo ratings yet

- Cause and Effect MatrixDocument5 pagesCause and Effect MatrixKotteswaran PnNo ratings yet

- Fe412farm Module N Cost BenefitDocument34 pagesFe412farm Module N Cost BenefitYaswanth NaikNo ratings yet

- Filtrair Filter Media VNF M1 Series ENDocument2 pagesFiltrair Filter Media VNF M1 Series ENThái Hòa GiangNo ratings yet

- Build a Homebrew Pre-Amplified MicrophoneDocument3 pagesBuild a Homebrew Pre-Amplified MicrophoneMacario Imbudo BukatotNo ratings yet

- Mp1 Type 1 ManualDocument69 pagesMp1 Type 1 ManualJerryNo ratings yet

- Slide No. 04 - Pert - Cpm1Document27 pagesSlide No. 04 - Pert - Cpm1NUSRAT RITUNo ratings yet

- DTP - Digital Transformer ProtectionDocument13 pagesDTP - Digital Transformer ProtectionHBNBILNo ratings yet

- Zaldivar Et Al. 2017 (Dopamine Is Signaled by Mid-Frequency Oscillations and Boosts Output Layers Visual Information in Visual Cortex)Document30 pagesZaldivar Et Al. 2017 (Dopamine Is Signaled by Mid-Frequency Oscillations and Boosts Output Layers Visual Information in Visual Cortex)FRANCISCO ELI LEZAMA GUTIERREZNo ratings yet

- Wiring Diagrams Model Yk (Style G) Liquid Chillers Optiview Control Center With SSS, LV VSD W/ Modbus, & MV VSDDocument30 pagesWiring Diagrams Model Yk (Style G) Liquid Chillers Optiview Control Center With SSS, LV VSD W/ Modbus, & MV VSDAbdulSattarNo ratings yet

- Process Modeling in The Pharmaceutical Industry Using The Discrete Element MethodDocument29 pagesProcess Modeling in The Pharmaceutical Industry Using The Discrete Element MethodRonaldo MenezesNo ratings yet

- Algebra II PreAP SimplificationDocument4 pagesAlgebra II PreAP SimplificationSummer SharmaNo ratings yet

- Analyzing the Effects of Changing the Values of a, b, and c in the Equation of a Quadratic Function on Its GraphDocument13 pagesAnalyzing the Effects of Changing the Values of a, b, and c in the Equation of a Quadratic Function on Its GraphRamil NacarioNo ratings yet

- Hydrocarbon ReactionsDocument2 pagesHydrocarbon ReactionsJessa Libo-onNo ratings yet

- IR Spectroscopy Identification GuideDocument28 pagesIR Spectroscopy Identification GuideAby JatNo ratings yet

- 1N4001S THRU 1N4007S: General Purpose Silicon RectifierDocument2 pages1N4001S THRU 1N4007S: General Purpose Silicon RectifierBhadreshkumar SharmaNo ratings yet

- Syngo - Via: HW Data SheetDocument4 pagesSyngo - Via: HW Data SheetCeoĐứcTrườngNo ratings yet

- DD 24 DD 22Document2 pagesDD 24 DD 22evega97No ratings yet

- Replacing The Volvo Oil Trap and Oil Pan SumpDocument6 pagesReplacing The Volvo Oil Trap and Oil Pan SumpsaifrulNo ratings yet

- Wiring Harness Installation Instructions: For InstallersDocument12 pagesWiring Harness Installation Instructions: For Installersnirut_niceguyNo ratings yet

- Power Systems Analysis Short Ciruit Load Flow and HarmonicsDocument1 pagePower Systems Analysis Short Ciruit Load Flow and HarmonicsJurij BlaslovNo ratings yet

- 016 Muscoril COPPDocument3 pages016 Muscoril COPPTheRoom23No ratings yet

- Underwater Cutting and Welding Equipment - 89250054 - AbDocument38 pagesUnderwater Cutting and Welding Equipment - 89250054 - AbAhmed Adel100% (1)

- CompressorsDocument20 pagesCompressorsCarlos Alberto Huamaní GonzalesNo ratings yet

- 2K6 Ec 307 (P) : Basic Electronics Lab: Sessional Work AssessmentDocument1 page2K6 Ec 307 (P) : Basic Electronics Lab: Sessional Work AssessmentJoseph JohnNo ratings yet

- Agribusiness ManagementDocument20 pagesAgribusiness Managementronald_leabresNo ratings yet

- Kti Semuanya-DikonversiDocument59 pagesKti Semuanya-DikonversigacikNo ratings yet

- Phases of Clinical Trials: OverlapDocument3 pagesPhases of Clinical Trials: OverlapMohammed El-GezeiryNo ratings yet

- Heidegger and RhetoricDocument202 pagesHeidegger and RhetoricMagda AliNo ratings yet

- Modul 1 - Pengantar Remote SensingDocument60 pagesModul 1 - Pengantar Remote SensingNgurah Ade KalyanaNo ratings yet

- 2004 Big Bay Dam Failure in MississippiDocument62 pages2004 Big Bay Dam Failure in MississippianaNo ratings yet

- LastDocument6 pagesLastandypressNo ratings yet