Professional Documents

Culture Documents

Untitled

Uploaded by

CosphiiiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Untitled

Uploaded by

CosphiiiCopyright:

Available Formats

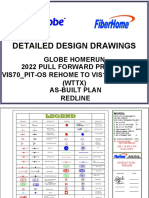

BAfl - Bulk Liquid Project CM

Services lE$rtlr *mE*,ffiil*

TELA$co

Date :

Submission 23 Februari 2023

Discipline; : Civil E Structure El Architecture E Mechanical El Electrical EI Piping EI

Area concerned: : Building 32

Consultant Requelt;

Reff Dwg : BAT-DWG-DD-ME-01-EP-50OURev. B

BAT-DWG-DD-M E-01-LP-1102.0LlRev. A

BAT-DWG-DD-M E-0 l-LP-1 102,02/Rev. A

1. IFC for typical detail installation of lighting (BAT-DWG-DD-ME-01-EP-5001/Rev. B)

2. IFC for lighting installation layout ( BAT-DWG-DD-ME-01-LP-1102.0URev. A and BAT-DWG-DD-ME-01-LP-1102.o2lRev.

A)

Attachment

1. Specification Comparison Sheet YesE No E 4. Brochure / Catalogue Yes E No EI

2. Samplesubmitted YesE No E 5. Supplier Distributor Certificate Yes E No E

3. Test Report Yes E No E 6. Other suonortive Documents Yes EI No fl

Signature: Signature:

Name: Name:

Title: Title:

Date: Date:

I

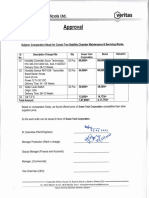

consurtant Reorv:

thwo k\^-l €-,wd6ail' d-t^, < t&J'

., BN WGteD",tQVdq.Sdl Bzry"o t-, tw

v* PwG "vP fv,

-./- gm ol *ltaz"ot Qr^€rNa yr

?,Nk w t:tg- CI\ t-( \loz" dz O "<' t-f -f-*

Replied bv: PT.Archetyoe lndonesia Received bv: PT. Livia Andalan lndoneila

Signature: Signature:

)

Name: 'f- Name:

"-Y1 A.^M-

Title: Titler

Date: I a7l'w*3 Date:

Filina: Oriainal with Doc Contlolle{ {for later tlient handaverl - Canies to oll concerned neonle

Note: This submiltol was reviewed and commented by the Engineer based from the avoiloble refercnces os per contractot's submittal ond contruct documents,

As per Generol Conditions al the contract, any opproval, check, certificate,consent, examinstion, inspection, instuction notice, proposol, request, test, or similor

act by the Engineer (including obsence of approval) shall not relieve the Contrdctor ftom any responsibility he has under the cantrdct, including responsibitity for

errors, omissions, descrepancies ond non compliances.

QA{DN-PCM-Request For Information Rev A Page Ul

NORTH

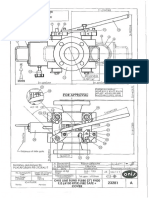

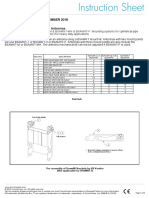

COVER

ROD Ø10

Z PURLIN

BEAM STRUCTURE

TRUNKING / C-CHANEL /

WIREMESH

100x75 CLAMP

ROD Ø10

SOCKET OUTLET

BEAM CLAMP TRUNKING SOCKET OUTLET

- ALL DIMENSIONS ARE IN MILLIMETERS UNLESS NOTED OTHERWISE

- ALL LEVELS ARE IN METERS UNLESS NOTED OTHERWISE

TRUNKING SOCKET OUTLET

CABLE

Cu/PVC/PVC LED HIGH BAY, HIGH PERFORMANCE,

IN FLEXIBLE STEEL CONDUIT DIE-CASTING ALUMINUM HOUSING, IP65

CABLE GLAND

LED HIGH BAY, HIGH PERFORMANCE,

DIE-CASTING ALUMINUM HOUSING, IP65

TYPICAL DETAIL INSTALLATION TRUNKING FOR LIGHTING TYPICAL DETAIL INSTALLATION FOR HIGHBAY WITH TRUNKING

Z PURLIN

CLAMP

Z PURLIN CLAMP

CLAMP

CONCRETE SLAB

ROD Ø10

LED

ROD Ø10 DOWNLIGHT

CONDUIT CLAMP c/w BOLT & NUT

TRUNKING 100x75

TRUNKING PVC CONDUIT Dia,20mm

SOCKET OUTLET JUNCTION BOX

FLEXIBLE CONDUIT

CEILING

METAL JUNCTION BOX

LIGHTING

CABLE

Cu/PVC/PVC

LIGHTING DOWNLIGHT LED (INDOOR TYPE)

CABLE GLAND

TYPICAL DETAIL INSTALLATION FOR BATTEN WITH TRUNKING TYPICAL DETAIL INSTALLATION FOR DOWNLIGHT = REVISION CLOUD

SOCKET

SANDWICH PIPE CLAMP FIXED Ø25 GI OUTLET

PANEL CEILING EVERY 1.2m CONDUIT

GALVANIZES

FLEXIBLE CONDUIT

CLAMP GALVANIZES

JUNCTION BOX 0 ISSUED FOR CONSTRUCTION BU IK IK 24.02.2023

CABLE INSTALLATION

BATTEN LED NO. DESCRIPTION BY CHKD APVD DATE

GALVANIZES CABLE GLAND CLAMP IN FLEXIBLE STEEL CONDUIT THIS DRAWING IS A PRIVATE AND CONFIDENTIAL

STEEL COMMUNICATION AND THE PROPERTY OF CLIENT.IT MUST

NOT BE COPIED OR LENT WITHOUT THE COMMENT OF

CONDUIT ∅ 32MM CLIENT AND MUST BE RETURNED WITH TENDER AND/OR

MUSHROOM HEAD SILICONE ON COMPLETION OF ORDER.

SUS316 SCREW M6x120mmL

SEALED TO SCREW & APPROVED BY CLIENT

& SUS316 WASHER,SEALED

PANEL

UNDER SCREW & WASHER

SANDWICH

PANEL CEILING

100

Sandwich Panel Sandwich Panel

Ceiling Ceiling

Recessed Cleanroom LED CEILING MOUNTING Menara 165, 12th Floor

BATTEN LED

(STANDARD Jl. TB Simatupang Kav. 1 Cilandak Timur

APPLICATIONS) GROUP Jakarta Selatan 12560 Indonesia

Shaping Tomorrow tel +62 21 2940 6840 - fax +62 2940 6841

BATI - DETAIL DESIGN

TYPICAL DETAIL INSTALLATION FOR RECESSED CLEAN ROOM TYPICAL DETAIL INSTALLATION FOR SUSPEND BATTEN LED

DRAWING TITLE :

35 ELECTRICAL & ELECTRONICAL

TYPICAL DETAIL INSTALLATION OF LIGHTING

SCALE : 1 : 100 FORMAT SIZE : A3

PROJECT DRAWING NO. REV

P-21-018 BAT-DWG-DD-ME-00-EP-5001 0

= DOUBLE SWITCH, 10 A

= HOTEL SWITCH, 10 A

XP

= EXPLOSSION PROOF INDICATOR

20 = TCW 097 DUST PROOF TYPE LED 20 W

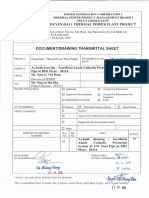

NORTH

9 10

L.26

42

MEETING n

42 10EL. +3.550 n

10 Area

ROOM Tangga

4260

L.26

10

MUSHOLA

16,44 m2

EL. +3.550 TOILET TOILET

EL. +3.550

42 42

9,2410m2 10 10 10

FEMALE L.26 MALE

8

6000 6000 1675

A B C A

-

FOAM

COLLECTING PIT

224

L.02

- ALL DIMENSIONS ARE IN MILLIMETERS UNLESS NOTED OTHERWISE

9 L.01

L.01 LIFT TRUCK L.02

- ALL LEVELS ARE IN METERS UNLESS NOTED OTHERWISE

QA LAB 52 42OFFICE42

LOBBY10 10

CHARGER

n

29 29

n

10

STAFF OFFICE

52

pxlxt 4 PCS 9 PCS p x l x t 3m42nx 2,9m42x 3m

4 PCS pxlxt pxlxt

4260

6m x 4.2m x 3.5m 3.8m x 4.2m10 x 3.5m FFL +0.000

3.5m x 4.2m x 3.5m 10 10 4.2m x 4.2m x 5m L.24

52 52

EL. ±0.000 EL. ±0.000n EL. ±0.000 EL. ±0.000

52 n

52 42 42 29 29

LIQUID FINISH GOOD TEMP : 21oC +- 3

EXIT

10 L.01 10 10 L.02 L.25 144

143

143

224

L.01 L.02

3630

364

8 MANUAL

115 115 115 n

115 p x l115

xt HUMID : 60%115+- 5

L.25

L.24

L.30

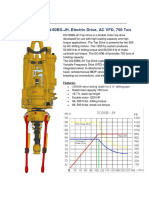

LEGEND : LUX CALCULATION BASED ON LAMP TYPE

STRAPPING

L.03

42m x 8.7m x 7m 448 PP

52 52 52 52 52 52 n

115 IFD IFD IFD EL. ±0.000 IFD n

115

316

L.04 42 = SMART PANEL 2.0 RC160V LED 34S 840 W60L60 42 W

4280

52 52

PARTISI

HOLDER

29 = WT198C LED40S/840 PSU L1200 LED 28,6 W

L.03 L.04

EXIT

L.03

52 52 n

52 52 52 n

52 = GREENUP ROUND HIGHBAY BY518P LED160/CW PSU WB GM LED 115 W

265

115

PAIL

PICK AND PLACE

PALETIZING AREA

7 pxlxt

52 = GP CLEAN ROOM CR468B LED 55 CW W60L60 52 W

13.6m x 9.9m x 5m

TEMP : 21 oC +- 3 L.06 L.05 274

4260

52 52 52 52 52 52 FFL.

52 -0.100 52 10 = GREEN SPACE G5 DN 391B LED 11-840 PSU D150 WH 9,7 W

PALLET

DISPENSER

HUMID : 60% +- 5

IFD EL. ±0.000

24 PCS

IFD IFD IFD IFD 14500

IFD

MATERIAL STORAGE TEMP : 21oC +- 3 L.23

4000 865 2500 EXIT = EXIT LIGHTING WITH BATTERY PACK FOR 2 HOURS BACKUP TIME

XP

EMPTY

PALLET

XP

L.05 L.06

6 pxlxt HUMID : 60% +- 5 L.22

4444

52 52 52 52 52 52 n

115 115 115 n

115 115 115 n

115 115 n = NICAD BATTERY RATED DURATION 1 HOUR

34.7m x 14.2m x 7m 608 PP 52 52

L.06

L.05

EL. ±0.000

344

D = SINGLE SWITCH, 10 A

203

144

NITROGEN GENERATOR

L.10 15 PCS 02-00-03

4400

EL. -0.100

L.09

5000

29AIR LOCK29 FFL. +1.570 F4

29 L.08

SEALER

SEALER

SEALER

L.05

Oxigen Spray

Oxigen Spray

Oxigen Spray

L.06 L.07

L.10 L.09 = DOUBLE SWITCH, 10 A

L.10

144

144

52 52 52 52 7000

DOSE DOSE L.09 DOSE

L.07

34143

NITROGEN NITROGEN NITROGEN

= HOTEL SWITCH, 10 A

L.08 52 52 n

52 52

5 L.07 L.08 52 52

EXPANSION

Dust Collector

Dust Collector

Dust Collector

FUTURE

FILLING

FILLING

FILLING

PSA

XP = EXPLOSSION PROOF INDICATOR

PIT

3500

FUTURE 52 20 = TCW 097 DUST PROOF TYPE LED 20 W

4260

n

115 115 115 n

115 115 115 n

115

52 52 52 52

40 PCS 52 52 52

EXPANSION

DISPENSER

DISPENSER

DISPENSER

BLUDDER TANK COLLECTION PIT

IFD IFD

FFL 52-0.050 52

PAIL

PAIL

PAIL

Oxigen Spray &

Oxigen Spray &

Oxigen Spray &

IFD

Dust Collector

Dust Collector

Dust Collector

L.21 L.29

IFD IFD XP

L.28

XP

4 L.20

SMALL BATCH

144

LIQUID DISPENSING

n AREA n

EXIT

52 52 52 52 52 52 52 52

MIXER

XP

L.21

pxlxt

4280

25m x 15.7m x 5m 29

TEMP : 21 oC +- 3 144

n

52 52 NICOTINE

52 ROOM n

52

341

52

CHANGING L.17 pxlxt

HUMID : 35% +- 5 NICOTINE STORAGE EL. ±0.000

52 52 52 52 52 52 52 n

52 ROOM

n

29 15m x 6.7m x 5m

EL. ±0.000

EXIT

203 n

52 52 52 p x l x t52 52 52 52

3 L.08

TEMP : 21oC +- 3 L.17 20m x 6.7m x 5m L.19

4370

IFD IFD 14 PCS

IFD 52 IFD

52 52 IFD

DAILY TANK 52 HUMID : 60% +- 52

5 TEMP : 21oC +- 3

IFD 14 PCS L.18

MIXER MIXER = REVISION CLOUD

EL. ±0.000

LARGE BATCH MEDIUM BATCH 52 HUMID : 60% n +- 5

4260

POWDER 52 52 52 52 52 n

52

52 52 52 52 52 n

52 52 52

L.17

EL. ±0.000 FFL -0.050

PREMIX L.16 52

52 52 52 52 52

CA TANK L.16 BATTERY

L.13 L.18

EXIT

CHARGING

2

361

AIR LOCK

203

361

L.11

L.12

29 29 29 ZERO NICOTINE

144

TOTE WASHING ROOM

29

L.13 243

29 29 29 29 29

n

52 ROOM 52 29EL. ±0.00029 52 8.4m x 5.7m

52 x 4.5

52 L.15

52 HOT WATER29 29

4143

WTP / RO L.12

29 n

29 29 TEMP : 21 oC +- 3 TEMP : 21oC +- 3 TANK

144

ROOM L.11 L.13

HUMID : 35% +- 5 L.13 HUMID : 60% +- 5 AHU ROOM

L.11

TOTE AFTER

: 21oC52+- 3

6 PCS L.14

52 EL. ±0.000

HOT PRODUCT 29 29 29

WATER

CIP WATER

NORMAL WATER 52 WASHING 52

52 ROOM

n TEMP

52 EL. ±0.000 29 198 M2 n

29 29 29 n

29

EXIT

1 5mX4.5mX4.5m

EL. ±0.000 HUMID : 60% +- 5

L.13

TOTE52

WASTE RINSE AREA

52 WASH

HAZARDOUS TOTE n

52

n

29 29

EL. ±0.000 L.14

L.15

0 ISSUED FOR CONSTRUCTION BU IK IK 24.02.2023

STATION L.12

144 L.14 NO. DESCRIPTION BY CHKD APVD DATE

THIS DRAWING IS A PRIVATE AND CONFIDENTIAL

29 29 29 29 29 CHILLER AREA COMMUNICATION AND THE PROPERTY OF CLIENT.IT MUST

5000 FFL -0.050 NOT BE COPIED OR LENT WITHOUT THE COMMENT OF

CLIENT AND MUST BE RETURNED WITH TENDER AND/OR

9000 3000 2000 8650 1350 7150 ON COMPLETION OF ORDER.

APPROVED BY CLIENT

2 3 4 C 1

- - - - -

28850

6000 6000 6000 6000 6000 6000 6000 6000 6000 6000 6000 6000

60000 11204 Menara 165, 12th Floor

Jl. TB Simatupang Kav. 1 Cilandak Timur

GROUP Jakarta Selatan 12560 Indonesia

A B C D E F G H I J K L M Shaping Tomorrow tel +62 21 2940 6840 - fax +62 2940 6841

BATI - DETAIL DESIGN

DRAWING TITLE :

35 ELECTRICAL & ELECTRONICAL

LIGHTING INSTALLATION LAYOUT

SCALE : As indicated FORMAT SIZE : A3

PROJECT DRAWING NO. REV

P-21-018 BAT-DWG-DD-ME-01-LP-1102.01 0

NORTH

1000 15800 1000

R1 R1

EL. +8.590

1000

6

2890

HANDRAIL HOT DIP GALV Ø 2"

+ PAINT FINISH WITH KICK

PLATE

R1

2500

PIPERACK

XP

EL. +5.725 F6

7000

5000

8890

2500

R1 STEEL COLUMN

SEE STR. DWG.

5200

- ALL DIMENSIONS ARE IN MILLIMETERS UNLESS NOTED OTHERWISE

5 - ALL LEVELS ARE IN METERS UNLESS NOTED OTHERWISE

1000

: LUX CALCULATION BASED ON LAMP TYPE

4400

LEGEND

XP

PIT 42 = SMART PANEL 2.0 RC160V LED 34S 840 W60L60 42 W

XP

EL. +0.500 29 = WT198C LED40S/840 PSU L1200 LED 28,6 W

BLUDDER TANK COLLECTION PIT

02-00-03

= GREENUP ROUND HIGHBAY BY518P LED160/CW PSU WB GM LED 115 W

800

EL. -0.100

115

EL. -0.300

52 = GP CLEAN ROOM CR468B LED 55 CW W60L60 52 W

10 = GREEN SPACE G5 DN 391B LED 11-840 PSU D150 WH 9,7 W

6000 6000 6000 6000 600 4400

EXIT = EXIT LIGHTING WITH BATTERY PACK FOR 2 HOURS BACKUP TIME

L M N O P 6 5 n = NICAD BATTERY RATED DURATION 1 HOUR

= SINGLE SWITCH, 10 A

= DOUBLE SWITCH, 10 A

= HOTEL SWITCH, 10 A

XP

= EXPLOSSION PROOF INDICATOR

20 = TCW 097 DUST PROOF TYPE LED 20 W

= INDUSTRIAL SOCKET OUTLET - WALL

MOUNTED 16A; 250V; 1P+N+PE - DOUBLE GANG

FFL. -0.100 14500 4300 3600 3600 4300 7900 = AIR TERMINAL COPPER ROD Ø16mm,

1500mm HEIGHT

7365 = EARTH PIT

900

HOT DIP. GALV. CHEQUERED PLATE T=4.5mm

= EARTHING BONDING BAR (COPPER BAR)

40X3MM THK, LENGTH AS REQUIRED C/W

600

HANDRAIL HOT DIP GALV Ø 2" ISOLATOR

6 20 20

PLATFORM

20

+ PAINT FINISH

20

= BARE COPPER LIGHTNING DOWN

HANDRAIL HOT DIP GALV Ø 2" 02-01-01 CONDUCTOR 50m

+ PAINT FINISH EL. +5.725

F6 = MAIN GROUNDING RING BC 70mm2/ SHALL BE

BURIED 600mm BELOW GRADE AND

XP APROXIMATELY 1,000mm FROM BUILDING

PERIMETER.

5000

5000

00 0 0

ø28

00

ø28 80 80

ø2 ø2

4400

4400

5000

FFL. +1.570

= REVISION CLOUD

7000 XP

L.5

20 20 20

HANDRAIL HOT DIP GALV. Ø 2"

+ PAINT FINISH

20

EL. +5.700

5

XP

2200

L.5

PIT

BLUDDER TANK COLLECTION PIT

0 ISSUED FOR CONSTRUCTION BU IK IK 24.02.2023

STAFF OFFICE FFL -0.050 NO. DESCRIPTION

THIS DRAWING IS A PRIVATE AND CONFIDENTIAL

BY CHKD APVD DATE

COMMUNICATION AND THE PROPERTY OF CLIENT.IT MUST

3m x 2,9m x 3m NOT BE COPIED OR LENT WITHOUT THE COMMENT OF

CLIENT AND MUST BE RETURNED WITH TENDER AND/OR

ON COMPLETION OF ORDER.

FFL +0.000 865 2500 3500 800 3600 3600 4300 7224 APPROVED BY CLIENT

6000 6000 6000 6000 6000 6000

Menara 165, 12th Floor

K L M N O P Q Jl. TB Simatupang Kav. 1 Cilandak Timur

EL. ±0.000 Shaping Tomorrow

GROUP Jakarta Selatan 12560 Indonesia

tel +62 21 2940 6840 - fax +62 2940 6841

BATI - DETAIL DESIGN

DRAWING TITLE :

35 ELECTRICAL & ELECTRONICAL

LIGHTING & LIGHTNING INSTALLATION LAYOUT

SCALE : 1 : 100 FORMAT SIZE : A3

PROJECT DRAWING NO. REV

P-21-018 BAT-DWG-DD-ME-01-LP-1102.02 0

You might also like

- CLIO 3 Fuses and RelaysDocument30 pagesCLIO 3 Fuses and RelaysCorteZPKPNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Itp BMSDocument8 pagesItp BMSCosphiii100% (1)

- Unit 27 Photography ResearchDocument8 pagesUnit 27 Photography Researchapi-530043460100% (1)

- Verti-G and CVG Quick Reference Guide - Rev ADocument40 pagesVerti-G and CVG Quick Reference Guide - Rev ARicardo Villar100% (2)

- SIEMENS Rly PNL Drgs-1Document12 pagesSIEMENS Rly PNL Drgs-1Amit Kundu DVCNo ratings yet

- Panoroma Final BillDocument8 pagesPanoroma Final BillMd.Mamunur RashidNo ratings yet

- Condensate Tank Foundation 26-10 WormingDocument30 pagesCondensate Tank Foundation 26-10 WormingHabibur RahmanNo ratings yet

- Drainage NEW Approval CopiesDocument45 pagesDrainage NEW Approval CopiesIram StoresNo ratings yet

- Flush Bottom ValvesDocument3 pagesFlush Bottom ValvesErkan TakNo ratings yet

- For Construction: Bio-Fuel Ethanol Plant in Northern Region ProjectDocument13 pagesFor Construction: Bio-Fuel Ethanol Plant in Northern Region ProjectajmainNo ratings yet

- FakinasolDocument17 pagesFakinasolmasgontarNo ratings yet

- Spillways 2Document29 pagesSpillways 2Kwabena OtchereNo ratings yet

- VP N2 El DSD 001 206Document3 pagesVP N2 El DSD 001 206phuoc leNo ratings yet

- Vis1183 - Ceb733 (Rehome From Vis70 - Pitos) - As - Built - Redline (2022 Pull Forward)Document21 pagesVis1183 - Ceb733 (Rehome From Vis70 - Pitos) - As - Built - Redline (2022 Pull Forward)InsikNo ratings yet

- DH3E-L-SC-A3-K-170511-0021 Commissioning Inspection & Test Plan For BC1, TT1, TT1 A and BC7 (Coal Handling Acceleration)Document2 pagesDH3E-L-SC-A3-K-170511-0021 Commissioning Inspection & Test Plan For BC1, TT1, TT1 A and BC7 (Coal Handling Acceleration)Bình Quách HảiNo ratings yet

- 65 Titik 1.5-2 LC Gempa BumiDocument28 pages65 Titik 1.5-2 LC Gempa BumidenyNo ratings yet

- NSRPDocument19 pagesNSRPPhương PhạmNo ratings yet

- Proforma 1invoice Pump Dump FloodingDocument5 pagesProforma 1invoice Pump Dump FloodingNg RessNo ratings yet

- Pile Cap ChecksDocument6 pagesPile Cap ChecksNikhilNo ratings yet

- 3 150 PLB (Ica Fluor)Document1 page3 150 PLB (Ica Fluor)Mauricio Sanchez VivancoNo ratings yet

- MSCL-SEC-ME-ISO-002 Rev.BDocument2 pagesMSCL-SEC-ME-ISO-002 Rev.BMohd Sami UddinNo ratings yet

- Cable Schedule - ST OXD - RP Rev 1Document2 pagesCable Schedule - ST OXD - RP Rev 1mukesh_kht1No ratings yet

- Comant II A12055 C120-200G-S InstallationDocument2 pagesComant II A12055 C120-200G-S InstallationFrank JansenNo ratings yet

- BMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. ADocument19 pagesBMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. AAgus SupriadiNo ratings yet

- Stability Chamber - QuotationDocument4 pagesStability Chamber - QuotationdidarNo ratings yet

- BMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. A CoverDocument5 pagesBMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. A CoverAgus SupriadiNo ratings yet

- ZE07 A 430 511 Equipment Number Calculation Rev0 1 BVDocument13 pagesZE07 A 430 511 Equipment Number Calculation Rev0 1 BVLuka DjigasNo ratings yet

- 12V DC Pin Hole TesterDocument1 page12V DC Pin Hole TesterjamilNo ratings yet

- Rough Takeoff Sheet: Est. No: Fire Alarm Sheetno: OF: 1Document35 pagesRough Takeoff Sheet: Est. No: Fire Alarm Sheetno: OF: 1kmleongmyNo ratings yet

- 15.1.4 Fi800237 Int VND BD 10Document14 pages15.1.4 Fi800237 Int VND BD 10sathyanand tkNo ratings yet

- 042000-104-0013 - Unit Masonry - Material CertificatesDocument4 pages042000-104-0013 - Unit Masonry - Material CertificatesbubbacupcakeNo ratings yet

- BMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. ADocument6 pagesBMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. AAgus SupriadiNo ratings yet

- Myp TQ Sac Sa 0501Document6 pagesMyp TQ Sac Sa 0501home7403No ratings yet

- Rfi Novec R9&R10Document2 pagesRfi Novec R9&R10MOSTAFA SHARAFNo ratings yet

- ED1801 Ventilation Fan WOKDocument46 pagesED1801 Ventilation Fan WOKJOHAN VILCHEZNo ratings yet

- Painampuram, Muthukurmandal, S.P.S.R. Nellore District, A.PDocument53 pagesPainampuram, Muthukurmandal, S.P.S.R. Nellore District, A.Pkkumar_717405No ratings yet

- QAP For PTFE-POT Bearing 11756 R1 18m Span For ROB 56+306Document9 pagesQAP For PTFE-POT Bearing 11756 R1 18m Span For ROB 56+306Niranjan KumarNo ratings yet

- Drawing (p15 Ace 857)Document14 pagesDrawing (p15 Ace 857)ritoh8657No ratings yet

- Datahseet For Strainer With Air EliminatorDocument4 pagesDatahseet For Strainer With Air Eliminatorvinoj chandranNo ratings yet

- Clleck O: RT1o4ah0oDocument3 pagesClleck O: RT1o4ah0oAhsan HabibNo ratings yet

- O - CIL-SBUT-SECTOR 4-319 - ForMWORK - Design & Scheme of Formwork For Column 4.Lm HT Up To 1.2mxl.2m Size (MFE Aluminum Panel) - 02.06.2023Document10 pagesO - CIL-SBUT-SECTOR 4-319 - ForMWORK - Design & Scheme of Formwork For Column 4.Lm HT Up To 1.2mxl.2m Size (MFE Aluminum Panel) - 02.06.2023yusufdoctor0No ratings yet

- 32 0473 PP0000 CV Gar 0005Document1 page32 0473 PP0000 CV Gar 0005Saeed MohebbiNo ratings yet

- Berita Acara Disposal AprilDocument1 pageBerita Acara Disposal Aprilangelina christineNo ratings yet

- E36 Test PanelDocument12 pagesE36 Test PanelGanesa MurthyNo ratings yet

- 4-9 All ConplitionDocument9 pages4-9 All Conplitionkaliangi bharviNo ratings yet

- Piping ConstructionDocument31 pagesPiping ConstructionAnonymous dSFbLxc9No ratings yet

- DH1-A3-De-M-15-0187 As-Built Drawing - Sacrificial Anode Cathodic Protection System of CW Steel Pipe in DH1 Plant - S0114Document6 pagesDH1-A3-De-M-15-0187 As-Built Drawing - Sacrificial Anode Cathodic Protection System of CW Steel Pipe in DH1 Plant - S0114Võ Minh TuấnNo ratings yet

- 382.003 Final Drawing For Tank Cleaning HeaterDocument37 pages382.003 Final Drawing For Tank Cleaning HeaterAndrewNo ratings yet

- Piping Stress Analysis Design Basis PDFDocument38 pagesPiping Stress Analysis Design Basis PDFSaima SaimaNo ratings yet

- Asme PTC 10Document191 pagesAsme PTC 10ipapucNo ratings yet

- Dokumen - Tips - Piping Stress Analysis Design BasisDocument38 pagesDokumen - Tips - Piping Stress Analysis Design BasisDan PastorNo ratings yet

- Taj Uruk M 67 6502Document4 pagesTaj Uruk M 67 6502Alaa ZoraNo ratings yet

- QGX T CS CCS 00353Document22 pagesQGX T CS CCS 00353Omar TocmoNo ratings yet

- Transv and BulkheadDocument7 pagesTransv and BulkheadmarjukiNo ratings yet

- Upvc Catch Basin Submittal - CosmoplastDocument30 pagesUpvc Catch Basin Submittal - CosmoplastAburvaraj0% (1)

- Electrical Power and Control Cable Schedule at Camp Area (ES-9050)Document4 pagesElectrical Power and Control Cable Schedule at Camp Area (ES-9050)Refki BudimanNo ratings yet

- I de 3010.64.1200 223 PWR 034 - Sup. - 3 - Rev. - 0 PDFDocument8 pagesI de 3010.64.1200 223 PWR 034 - Sup. - 3 - Rev. - 0 PDFOrlando PWRNo ratings yet

- BOSCH - Master Brake Cylinder & EPDM SealsDocument3 pagesBOSCH - Master Brake Cylinder & EPDM Sealsgautamnaveen1986No ratings yet

- Slope HammockDocument28 pagesSlope HammockAbdul Rahman HilmiNo ratings yet

- Daily Report Hydro 4 AprilDocument1 pageDaily Report Hydro 4 Aprildeny fajarNo ratings yet

- Project No. P12513 Feed For New Flow Suction Tank On Bu Hasa CdsDocument6 pagesProject No. P12513 Feed For New Flow Suction Tank On Bu Hasa CdssarathNo ratings yet

- Screw Propeller - Finished DrawingDocument71 pagesScrew Propeller - Finished DrawingZakariya KareemNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Bat-Dwg-Dd-Me-01-Lp-1102.02 - R0 - Lighting & Lightning Installation LayoutDocument1 pageBat-Dwg-Dd-Me-01-Lp-1102.02 - R0 - Lighting & Lightning Installation LayoutCosphiiiNo ratings yet

- TAG BOARD PENETRANT - Rev 1Document1 pageTAG BOARD PENETRANT - Rev 1CosphiiiNo ratings yet

- Tag Board Tes Rendam (Finish)Document1 pageTag Board Tes Rendam (Finish)CosphiiiNo ratings yet

- Bat-Dwg-Dd-Me-00-Eg-6101 - R0 - Grounding, Earthing and Lightning Protection System Shematic DiagramDocument1 pageBat-Dwg-Dd-Me-00-Eg-6101 - R0 - Grounding, Earthing and Lightning Protection System Shematic DiagramCosphiiiNo ratings yet

- Bat-Dwg-Dd-Me-00-Ca-6301 - R0 - P & Id Compressed Air Distribution SystemDocument1 pageBat-Dwg-Dd-Me-00-Ca-6301 - R0 - P & Id Compressed Air Distribution SystemCosphiiiNo ratings yet

- Tag Board Tes Rendam (Start)Document1 pageTag Board Tes Rendam (Start)CosphiiiNo ratings yet

- TAG BOARD HYDRO Test - Rev 1 (START)Document1 pageTAG BOARD HYDRO Test - Rev 1 (START)CosphiiiNo ratings yet

- ITP Socket Data and TelephoneDocument6 pagesITP Socket Data and TelephoneCosphiiiNo ratings yet

- Hvac-05 Air CoilsDocument3 pagesHvac-05 Air CoilsCosphiiiNo ratings yet

- Bat-Dwg-Dd-Me-00-Ep-6002 - R0 - Load Schedule Diagram of PP - LP - Building 32Document1 pageBat-Dwg-Dd-Me-00-Ep-6002 - R0 - Load Schedule Diagram of PP - LP - Building 32CosphiiiNo ratings yet

- TAG BOARD HYDRO Test - Rev 1 (FINISH)Document1 pageTAG BOARD HYDRO Test - Rev 1 (FINISH)CosphiiiNo ratings yet

- Hvac-01 Duct InsulationDocument5 pagesHvac-01 Duct InsulationCosphiiiNo ratings yet

- Bat-Dwg-Dd-Me-01-Ed-1102.01 - R0 - Cable Tray Installation LayoutDocument1 pageBat-Dwg-Dd-Me-01-Ed-1102.01 - R0 - Cable Tray Installation LayoutCosphiiiNo ratings yet

- Bat-Dwg-Dd-Me-01-Ed-1102.02 - R0 - Cable Tray Installayion LayoutDocument1 pageBat-Dwg-Dd-Me-01-Ed-1102.02 - R0 - Cable Tray Installayion LayoutCosphiiiNo ratings yet

- Bat-Dwg-Dd-Me-00-Ep-6003 - R0 - Load Schedule Diagram of PP Chiller - PP - AhuDocument1 pageBat-Dwg-Dd-Me-00-Ep-6003 - R0 - Load Schedule Diagram of PP Chiller - PP - AhuCosphiiiNo ratings yet

- Bat-Dwg-Dd-Me-00-Md-6101 - R0 - Electrical Distribution System Block DiagramDocument1 pageBat-Dwg-Dd-Me-00-Md-6101 - R0 - Electrical Distribution System Block DiagramCosphiiiNo ratings yet

- Bat-Dwg-Dd-Me-01-Eg-1101.01 - R0 - Earthing and Grounding Installation LayoutDocument1 pageBat-Dwg-Dd-Me-01-Eg-1101.01 - R0 - Earthing and Grounding Installation LayoutCosphiiiNo ratings yet

- Area Tangga: LegendDocument1 pageArea Tangga: LegendCosphiiiNo ratings yet

- Bat-Dwg-Dd-Me-01-Al-1601.01 - R0 - Lightning Protection Installation LayoutDocument1 pageBat-Dwg-Dd-Me-01-Al-1601.01 - R0 - Lightning Protection Installation LayoutCosphiiiNo ratings yet

- Bat-Dwg-Dd-Me-00-Ep-6004 - R0 - Load Schedule Diagram of PP Hvac Office - PP Battery ChargerDocument1 pageBat-Dwg-Dd-Me-00-Ep-6004 - R0 - Load Schedule Diagram of PP Hvac Office - PP Battery ChargerCosphiiiNo ratings yet

- Bat-Dwg-Dd-Me-01-Eg-1101.02 - R0 - Earthing and Grounding Installation LayoutDocument1 pageBat-Dwg-Dd-Me-01-Eg-1101.02 - R0 - Earthing and Grounding Installation LayoutCosphiiiNo ratings yet

- Monitoring Cable AprilDocument12 pagesMonitoring Cable AprilCosphiiiNo ratings yet

- 05.catalog Ladder LightDocument17 pages05.catalog Ladder LightCosphiiiNo ratings yet

- Bat-Dwg-Dd-Me-00-Ep-6005 - R0 - Load Schedule Diagram of PP WWTP System - PP WTP SystemDocument1 pageBat-Dwg-Dd-Me-00-Ep-6005 - R0 - Load Schedule Diagram of PP WWTP System - PP WTP SystemCosphiiiNo ratings yet

- 03.catalog Tray V.3 BoltDocument27 pages03.catalog Tray V.3 BoltCosphiiiNo ratings yet

- DS-2DE3A404IW-DE-2.8-12-mm - 5.6.0 - 20210111 - PTZ CameraDocument6 pagesDS-2DE3A404IW-DE-2.8-12-mm - 5.6.0 - 20210111 - PTZ CameraCosphiiiNo ratings yet

- Monitoring Material AprilDocument60 pagesMonitoring Material AprilCosphiiiNo ratings yet

- M Ishaq Electrical SupervisorDocument7 pagesM Ishaq Electrical SupervisorMuhammad IshaqNo ratings yet

- Channel Amplifiers: User Guide Issue 5.2Document13 pagesChannel Amplifiers: User Guide Issue 5.2jacomartNo ratings yet

- DM Radbr10 03 EngDocument92 pagesDM Radbr10 03 EngsamNo ratings yet

- TEI-I-111.15: Transmission Engineering StandardDocument12 pagesTEI-I-111.15: Transmission Engineering StandardArnieNo ratings yet

- SD313 3 MFI Control System (G4HE/G4HG: EPSILON 1.0L/1.1L M/T)Document1 pageSD313 3 MFI Control System (G4HE/G4HG: EPSILON 1.0L/1.1L M/T)Huy Trần QuốcNo ratings yet

- Si 27 Manual UserDocument2 pagesSi 27 Manual Usertn7cnbt4zrNo ratings yet

- DAILY SSS SURVEILLANCE April 17-18.totalDocument120 pagesDAILY SSS SURVEILLANCE April 17-18.totalAldrich Ajang HenryNo ratings yet

- Commscope ToutDocument4 pagesCommscope ToutOlivier KnechtNo ratings yet

- GTP - 33KV (E) 3C AL XLPE Armd CableDocument1 pageGTP - 33KV (E) 3C AL XLPE Armd Cableshivam dwivediNo ratings yet

- Nightstick XPP 5465r ForgeDocument2 pagesNightstick XPP 5465r ForgeProject Sales CorpNo ratings yet

- TPI Certificate - RGB ExteriorsDocument1 pageTPI Certificate - RGB ExteriorsMohammad ArifNo ratings yet

- 1 - Final QuotationDocument7 pages1 - Final QuotationNM.ZIHANNo ratings yet

- DQ-90B-JH, 750ton, AC 1200HPDocument3 pagesDQ-90B-JH, 750ton, AC 1200HPSKLANTNo ratings yet

- List of Electrical Equipment & VehicleDocument2 pagesList of Electrical Equipment & VehicleDaneil HecterNo ratings yet

- Machine Shop ActivitiesDocument6 pagesMachine Shop ActivitiesCllyan ReyesNo ratings yet

- Lithonia Outdoor KVS Series Area Brochure 1-89Document6 pagesLithonia Outdoor KVS Series Area Brochure 1-89Alan MastersNo ratings yet

- Gabinete - Nu-430-3000e - Nuaire - Manual de Operaciones y MantenimientoDocument99 pagesGabinete - Nu-430-3000e - Nuaire - Manual de Operaciones y MantenimientojuanNo ratings yet

- DAS Complete System - With S6 ThicknessDocument47 pagesDAS Complete System - With S6 ThicknessJun Rong FooNo ratings yet

- Fault Tracing: Checking The Starter Switch DiodeDocument1 pageFault Tracing: Checking The Starter Switch Diodeuser1No ratings yet

- 02 Fire Alarm Systems (Where Required) - HotelDocument42 pages02 Fire Alarm Systems (Where Required) - HotelMAKANNo ratings yet

- IR-2100 - 2101 - Infrared Systems DevelopmentDocument1 pageIR-2100 - 2101 - Infrared Systems DevelopmentFraser CastleNo ratings yet

- Residential Code Update Part 1 of 2 HrsDocument103 pagesResidential Code Update Part 1 of 2 HrsTakumi FujiwaraNo ratings yet

- Optical Communications: Chapter 1: IntroductionDocument17 pagesOptical Communications: Chapter 1: IntroductionDang KhueNo ratings yet

- Hose ListDocument6 pagesHose ListDrow RangerNo ratings yet

- ARCA Fly ReglerInstr GBDocument6 pagesARCA Fly ReglerInstr GBChanNo ratings yet

- Instrumentation Pipe Weld FittingsDocument20 pagesInstrumentation Pipe Weld FittingsAbel LopezNo ratings yet

- Delvo Main CatDocument68 pagesDelvo Main CatVinhNo ratings yet