Professional Documents

Culture Documents

PWPS - 3G GMAW

PWPS - 3G GMAW

Uploaded by

asrafiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PWPS - 3G GMAW

PWPS - 3G GMAW

Uploaded by

asrafiCopyright:

Available Formats

Politeknik Negeri Batam

Jalan Ahmad Yani, Kel. Teluk Kering - Kec. Batam Kota

Batam 29461

Phone : (62) 778-469860 Fax : (62) 778-469860

Email : info@polibatam.ac.id

Page 1 of 2

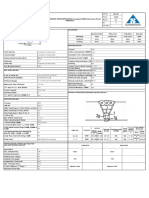

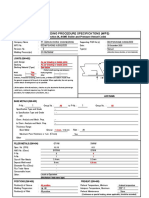

PRELIMINARY WELDING PROCEDURE SPECIFICATION (pWPS)

(Section IX, ASME Boiler and Pressure Vessel Code)

Company Name Politeknik Negeri Batam By : Nugroho

Welding Procedure Specification No. 02/pWPS/GMAW R0 Date February, 2022 Supporting PQR No. (s) : 02/PQR/GMAW R0 Date February, 2022

Revision No. 0

Welding Process (es) GMAW Type(s) Semi-Auto

(Automatic, Manual, Machine, or Semi-Auto)

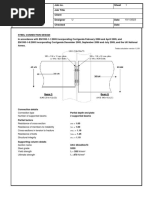

JOINTS (QW-402) Details Joint

Joint Design As Per Details Joint

Root Spacing As Per Details Joint

Backing (Yes) ( No) √

Backing Material (Type)

Metal Nonfusing Metal

Nonmetallic Other (Weld Metal)

Chemical Composition Backing N.A

Retainers Not Used

Sketches, Production Drawings, Weld Symbols or Written Description

shoul show the general arrangement of the parts to be welded. Where

applicable, the root spacing and details of weld groove may be specified.

(At the option of the Mfgr., sketches may be attached to illustrate joint design,

weld layers and bead sequence, e.g., for notch toughness procedures, for

multiple process procedures, etc.) or See Applicable Drawing & Weld Map

Joint Preparation

Shearing Machining Routing Other

Casting Stamping Thermal Cutting Process

Forging Filling Grinding

* BASE METALS (QW-403)

P-No. 1 Group No. 1 to P-No. 1 Group No. 1

OR

Specification and type / grade or UNS Number SA-36

to Specification and type / grade or UNS Number SA-36

OR

Chem. Analysis and Mech. Prop. -

to Chem. Analysis and Mech. Prop. -

Thickness Range :

Base Metal : CJP Groove 12 mm Fillet N.A

PJP Groove N.A Diameters N.A

Short Circuiting Transfer N.A

Maximum Pass Thickness ≤ 1/2 in. (13mm) (Yes) √ (No)

Other CJP = Complete Joint Penetration, PJP = Partial Joint Penetration

* FILLER METALS (QW-404)

Spec. No. (SFA) 5.18

AWS No. (Class) ER 70S-6

F-No. 6

A-No. 1

Size of Filler Metal(s)/Electrode(s) 1.2 mm

Filler Metal Product Form (Solid/Metal or Flux Cored) Solid

Flux/Wire Classification N.A

Alloy Flux N.A

± Filler N.A

± Flux N.A

Consumable Insert N.A

Alloy Element N.A

Supplemental Filler Metal N.A

Flux Trade Designation N.A

t Deposit/Weld Metal

Thickness Range :

Groove : 12 mm

Fillet : N.A

Flux Type N.A

Recrushed Slag N.A

Flux Type & Composition For ESW N.A

Wire to Plate N.A

Consumable Guide N.A

Other Manufacture brand ESAB Aristorod 12.50

Politeknik Negeri Batam

Jalan Ahmad Yani, Kel. Teluk Kering - Kec. Batam Kota

Batam 29461

Phone : (62) 778-469860 Fax : (62) 778-469860

Email : info@polibatam.ac.id

Page 2 of 2

WPS No.: 01/pWPS/GMAW R0 Rev.: 0

POSITION (QW-405) POSTWELD HEAT TREATMENT (QW-407)

Position(s) of Groove 3G Temperature Range None

Welding Progression : Uphill √ Downhill N.A Time Range None

Position(s) of Fillet N.A Other None

Other None

GAS (QW-408)

PREHEAT (QW-406) Percent Composition

Preheat Temperature, Minimum Min. 95 ⁰C Gas (es) (Mixture) Flow Rate

Interpass Temperature, Maximum Max. 250 ⁰C Shielding Ar/CO2 80%/balance 15 - 20 L/min

Preheat Maintenance None Trailing N.A N.A N.A

Other Heating by burner Backing N.A N.A N.A

(Continuous or special heating where applicable should be recorded) Other N.A N.A N.A

ELECTRICAL CHARACTERISTICS (QW-409)

Other

Filler Metal

Wire Feed

Weld Layer Current Type Amps Speed Energy or Power Travel Speed (e.g., Remarks,

Process Volts (Range), V Comments, Hot Wire

(s) and Polarity (Range), A (Range), (Range) (Range), mm/min

Classification Diameter mm/min Addition, Technique,

Torch Angle, Etc.)

(mm)

As Required GMAW ER 70S-6 1.2 DC EP 100 - 350 - - 20 - 26 60 - 100 -

(Amps and volts, or power or energy range, should be recorded for each electrode size, position, and thickness, etc)

Current AC or DC : DC Polarity : EP

Amperage : As Table Above Voltage : As Table Above

± Pulsing : N.A

Tungsten Electrode : N.A

Pure Tungsten, 2 % Thoriated, etc

Mode of Transfer : Globular

Globular, Spray, Pulsed Spray Transfer to Short Circuiting Transfer or Vice Versa

Heat Input :

Other : None

TECHNIQUE (QW-410)

String or Weave : Weave (one capping)

Forehand or Backhand : N.A

Flame Characteristic : N.A

Orifice, Nozzle, or Gas Cup Size : nozzle ukuran berapa?

Method of Cleaning : Brushing, Grinding, Pickling or Other Mechanical Cleaning

Method of Back Gouging : N.A

Oscillation : N.A

Tube to Work Distance : N.A

Multiple or Single Pass (Per Side) : Multiple Pass Per Side

Multiple or Single Electrode(s) : Single Electrode

Closed to Out of Chamber Welding : N.A

Melt-in to Key Hole : N.A

Electrode Spacing : N.A

Peening : None

Thermal Process for P 11A & 11B: Not Used

Other : None

Prepared by, Approved by, Review/Approved by,

Welding Engineer QA/QC Manager

You might also like

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- WPS-46 - Gtaw & Smaw Tig + SmawDocument8 pagesWPS-46 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaNo ratings yet

- Beam To Column Connection ExampleDocument9 pagesBeam To Column Connection ExampleLuqman ZolkibliNo ratings yet

- Electrically Assisted Forming: Wesley A. Salandro Joshua J. Jones Cristina Bunget Laine Mears John T. RothDocument366 pagesElectrically Assisted Forming: Wesley A. Salandro Joshua J. Jones Cristina Bunget Laine Mears John T. RothKatia libertad López JuarezNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (3)

- 06 GTAW Stainless SteelDocument4 pages06 GTAW Stainless SteelMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Revised PWPS 001Document2 pagesRevised PWPS 001stdshopNo ratings yet

- Wps Aws d1.1 Ss400 To Ss400 Gmaw-RevDocument2 pagesWps Aws d1.1 Ss400 To Ss400 Gmaw-RevAnonymous zfC1zo9C100% (2)

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)mohammadNo ratings yet

- 04 WPS Atp Asme 2012 (A312 304) (A312 310)Document6 pages04 WPS Atp Asme 2012 (A312 304) (A312 310)lailatul kodriNo ratings yet

- Wps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Document4 pagesWps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Nilotpal Kumar RaiNo ratings yet

- Welding Procedure Specification FormatDocument3 pagesWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- PWPS WPS CAP 039 PQR 035Document15 pagesPWPS WPS CAP 039 PQR 035GOPINATH KRISHNAN NAIRNo ratings yet

- Hust WPS Gtaw - Smaw 6GDocument4 pagesHust WPS Gtaw - Smaw 6GtruongtrungplhdNo ratings yet

- Draft Wps Astm A 743 GR - Ca6nmDocument2 pagesDraft Wps Astm A 743 GR - Ca6nmIlham PaneNo ratings yet

- Smaw Wps FinalDocument3 pagesSmaw Wps FinalsheikmoinNo ratings yet

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Abdulmecit YetisNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps PQR PDFDocument35 pagesWps PQR PDFquality unifab83% (6)

- Wps-01 C.S. GtawDocument2 pagesWps-01 C.S. GtawMohamed Tarek HamamNo ratings yet

- Pwps Asme Gtaw & SmawDocument2 pagesPwps Asme Gtaw & SmawMuhammad Fitransyah Syamsuar Putra100% (1)

- Procedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherDocument2 pagesProcedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherPanneer SelvamNo ratings yet

- PT. FAB: Proposed Welding Procedure Specification (PWPS)Document12 pagesPT. FAB: Proposed Welding Procedure Specification (PWPS)dharwinNo ratings yet

- Wps Hzi SMAWDocument18 pagesWps Hzi SMAWMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- Kitap Bolumu 2Document121 pagesKitap Bolumu 2Oscar LyonNo ratings yet

- PWPS - 3G FCAWDocument2 pagesPWPS - 3G FCAWasrafiNo ratings yet

- Wps Train 01 (AIDIL)Document2 pagesWps Train 01 (AIDIL)aidil30No ratings yet

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Balkishan DyavanapellyNo ratings yet

- 001 WPS Cntim 2023Document10 pages001 WPS Cntim 2023shangyuan1079163.comNo ratings yet

- Wps For Butt Weld Qualification 4 Inch Cs Pipe To Cs Pipe - p0Document3 pagesWps For Butt Weld Qualification 4 Inch Cs Pipe To Cs Pipe - p0YokeshAnandNo ratings yet

- Pt. Stainless Steel Primavalve Majubersama: ASME Section IX - 2021 Preliminary Welding Procedure Specification (PWPS)Document1 pagePt. Stainless Steel Primavalve Majubersama: ASME Section IX - 2021 Preliminary Welding Procedure Specification (PWPS)Ilham PaneNo ratings yet

- Wps 18Document2 pagesWps 18Avishek GuptaNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad MunadiNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)pradeep4545No ratings yet

- Wps Ausa Gtaw Smaw 002 2018 Ok RDocument2 pagesWps Ausa Gtaw Smaw 002 2018 Ok RIvan Dario Carrillo Rubio0% (1)

- Ejemplo Prueba 991003Document2 pagesEjemplo Prueba 991003MARIO ALBANo ratings yet

- WPS14-1 A106 B SmawDocument4 pagesWPS14-1 A106 B SmawRahul MoottolikandyNo ratings yet

- WPS 1-1-GT-SM-6 Rev. 0Document8 pagesWPS 1-1-GT-SM-6 Rev. 0Melby de la rosaNo ratings yet

- 3 BodyPart Edcb3a5f Eede 445f A423 Ea2f5809c15eDocument6 pages3 BodyPart Edcb3a5f Eede 445f A423 Ea2f5809c15emayank0738No ratings yet

- WPS Astm - A 53Document2 pagesWPS Astm - A 53S. K. M. ShujonNo ratings yet

- SILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Document2 pagesSILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Abdulmecit YetisNo ratings yet

- WPS Vessel 1Document4 pagesWPS Vessel 1Naqqash SajidNo ratings yet

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument5 pagesJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCmkhalil1148No ratings yet

- WPS 19Document15 pagesWPS 19Avishek Gupta100% (1)

- Pwps-Gtaw FcawDocument2 pagesPwps-Gtaw FcawAhmed ElsharkawNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- P. WpsDocument14 pagesP. WpsIsmiArdyNo ratings yet

- First: Qw-482 Welding Procedure Specification (WPS) For General Contracs and SuppliesDocument3 pagesFirst: Qw-482 Welding Procedure Specification (WPS) For General Contracs and SuppliesAhmed AbdoNo ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- WPS SS316Document4 pagesWPS SS316Budi Setia RahmanNo ratings yet

- WPS-30Document2 pagesWPS-30srinivas raoNo ratings yet

- GCB WPS Tsila 012Document19 pagesGCB WPS Tsila 012AslaouiNo ratings yet

- Val Caraig WPQTDocument1 pageVal Caraig WPQTMark Jason M. BrualNo ratings yet

- PWPS 001Document2 pagesPWPS 001Mehrdad RezaeiNo ratings yet

- PRDocument3 pagesPRasrafiNo ratings yet

- INDocument1 pageINasrafiNo ratings yet

- LFDocument2 pagesLFasrafiNo ratings yet

- Soal SMK 6Document4 pagesSoal SMK 6asrafiNo ratings yet

- FCAW-GS Flux Cored Arc Welding-Gas ShieldedDocument20 pagesFCAW-GS Flux Cored Arc Welding-Gas ShieldedasrafiNo ratings yet

- Presentation Title: Asrafi Manager of Hangar Polibatam, Asrafi@polibatam - Ac.id Maintenance PracticeDocument11 pagesPresentation Title: Asrafi Manager of Hangar Polibatam, Asrafi@polibatam - Ac.id Maintenance PracticeasrafiNo ratings yet

- SanMar QA Manual 2022Document226 pagesSanMar QA Manual 2022Ahmed FirozNo ratings yet

- HyundaiWia - SKT21LMS INSTALL MAINT MANUALDocument335 pagesHyundaiWia - SKT21LMS INSTALL MAINT MANUALAminNo ratings yet

- Celanex+Impet+Vandar 手册Document48 pagesCelanex+Impet+Vandar 手册张彦海No ratings yet

- Mini Pleat Medium Filter f6 f9Document3 pagesMini Pleat Medium Filter f6 f9sandroNo ratings yet

- Muenstermann Conveying CompleteDocument12 pagesMuenstermann Conveying CompleteRafaelNo ratings yet

- LMT Belin 2015+ CATDocument68 pagesLMT Belin 2015+ CATShi SamNo ratings yet

- TVL Smaw11 Q1 M 9Document7 pagesTVL Smaw11 Q1 M 9Earl Christian BonaobraNo ratings yet

- Gen4000 Operating T4290 T4530 T4650Document25 pagesGen4000 Operating T4290 T4530 T4650EDWIN ODHIAMBONo ratings yet

- Astm A490m 1993Document5 pagesAstm A490m 1993Jesse ChenNo ratings yet

- Donghua Double Pitch ChainDocument611 pagesDonghua Double Pitch ChainErliana IndahNo ratings yet

- Standard Test Methods For Bend Testing of Material For Ductility PDFDocument12 pagesStandard Test Methods For Bend Testing of Material For Ductility PDFJuan VanegasNo ratings yet

- Retrofitting of Reinforced ConDocument11 pagesRetrofitting of Reinforced ConForsythe LearningNo ratings yet

- Lldpe FN810 (Octeno Sin Slip)Document2 pagesLldpe FN810 (Octeno Sin Slip)Hữu LộcNo ratings yet

- Art.15-Hardox PublicadoDocument9 pagesArt.15-Hardox PublicadoDevanandam SiddanthapuNo ratings yet

- Channel FUSDocument1 pageChannel FUSArunKumar RajendranNo ratings yet

- Assignment - 1 RC - IIDocument3 pagesAssignment - 1 RC - IIdawitdeginet096No ratings yet

- Orrcon National Product CatalogueDocument84 pagesOrrcon National Product CatalogueEswaran RajamaniNo ratings yet

- StiffweldDocument4 pagesStiffweldalfonso vergaraNo ratings yet

- ACUWELD MIG &TIG Welding WiresDocument38 pagesACUWELD MIG &TIG Welding WiresALOKE GANGULYNo ratings yet

- SCP (Solid Casting Processes)Document12 pagesSCP (Solid Casting Processes)jesssepinkman03No ratings yet

- JK Transmission EngDocument20 pagesJK Transmission EngJuan Pablo MayorgaNo ratings yet

- Table QW-442 Table QW-442 Table QW-432 QW-404.5: ASME BPVC - IX-2023Document1 pageTable QW-442 Table QW-442 Table QW-432 QW-404.5: ASME BPVC - IX-2023ahmadrizkiqcNo ratings yet

- Quantitative Assessment of Municipal Solid Waste Management PracticesDocument7 pagesQuantitative Assessment of Municipal Solid Waste Management Practicesvhea346No ratings yet

- JIT Inventory ManagementDocument25 pagesJIT Inventory ManagementPendyalaHariKrishnaNo ratings yet

- Asme3d1 nb-2000Document40 pagesAsme3d1 nb-2000KHALED OSMANNo ratings yet

- R&F TravellerDocument51 pagesR&F TravellerRanjan ChaudharyNo ratings yet

- 1 - Assignment SampleDocument15 pages1 - Assignment SamplesankalpaNo ratings yet