Professional Documents

Culture Documents

WPS-30

Uploaded by

srinivas raoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS-30

Uploaded by

srinivas raoCopyright:

Available Formats

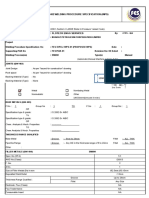

AL HAJIRY TRADING LLC

MECHANICAL ENGINEERING DIVISION

WELDING PROCEDURE SPECIFICATION (WPS)

(See Clause 4 of AWS D1.1/D1.1M ed 2015 Structural Welding Code -- Steel)

WPS No:- MED-WPS-5462-03 Date : 16.09.2023

COMPANY Occidental of Oman Inc.

CONTRACTOR Gulf Petrochemical Services & Trading LLC.

SUB CONTRACTOR Al Hajiry Trading LLC.

PROJECT All General Facility Services Contract Project

PQR No:- MED-PQR-30 Rev No. 00 Date : 16.01.2020

AWS Base Metal

BASE METALS Specification Type or Grade As-Welded With PWHT

Group No. Thickness

3mm to

Base Material BS EN10025 S275JR Unassigned CJP Groove welds N/A

Unlimited

Welded To BS EN10025 S275JR Unassigned Fillet Welds F&H N/A

Backing Material With or Without (Backing/Back Weld) Pipe Diameter Ø24''and Above N/A

Other :- N/A

01. JOINT DETAILS JOINT DETAIL (SKETCH)

Groove/Fillet Type As per Fabrication Drawing

Groove Angle 60°±5° C

Root Opening 2.5 to 3.5 mm

Root Face 1.0 to 2.0 mm

Backgouging/Backing With or Without (Backing/Back Weld)

ARC Gouging + Grinding (If

Method Required)

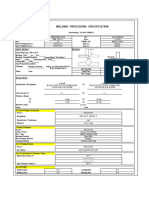

02. Process SMAW

Type (Semiautomatic, Mechanized,

Manual etc.)

MANUAL

03. PRE HEAT TREATMENT

(3mm to 20mm 50°C) (above20mm -

Temperature 38mm 65°C)

Burner (Propane gas

Preheat Method torch with nozzle )

MDMT 0°C

Interpaass Temperature Max 50°C - 210°C All Dimensions are in mm unless specified

04. PROCEDURE

Weld Layer(s) Multiple 08.Technique —

Weld Pass(es) Multiple Stringer or Weave Both

Max. weave width 2.5 X Electrode Dia. Multi or Single Pass (per side) Multiple

05. Filler Metal (AWS Spec.) A5.1 Number of Electrodes Single

AWS Classification E 7016-1H4 R & E 7018H4 R Longitudinal Spacing of Arcs N/A

Electrode Diameter/Filler wire

diameter Ø2.5, Ø3.2, Ø4 mm Lateral Spacing of Arcs N/A

Flux Classification (SAW) N/A Angle of Parallel Electrodes N/A

ESAB Welding Ltd/E 7016-1H4R (OK53.68) & E Angle of Electrode

Manufacturer/Trade Name 7018H4R(OK48.0) N/A

(Mech./Auto.)

Supplemental Filler Metal NA Normal To Direction of Travel N/A

Oscillation

GAS None

(Mechanized/Automatic)

Purpose GAS % of Com Flow rate Traverse Length N/A

sheilding NA NA NA Traverse Speed N/A

Backing NA NA NA Dwell Time NA

Trailing NA NA NA Peening None

06. POSITION and GROOVE Falt, Horizontal Interpass Cleaning Yes - Grinding

Weld Progression NA 09.POSTWELD HEAT TREATMENT

With or Without

Backing (Backing/Back Weld) Temperature N/A

07. Electrical Characteristics Time at Temperature N/A

Current Type & Polarity DCEP Other N/A

Amps Range 61 A - 172 A Test Conducted by Mr. Paul K John, QCI

Volts Range 20 V - 30 V

Wire Feed Speed, Range N/A

Travel Speed, Range 46 - 248 mm/min

Maximum Heat Input 2.48 KJ/mm

Welder Name : Mr. PAPPU CHAUHAN Welder ID: AOG - W - 48

Current Travel speed Heat Input

Weld Pass Process Electrode Class Dia mm AWS Spec Amps Range Volts Range

Polarity mm/min KJ/mm

Root SMAW E 7016-1 H4R 2.5 A5.1 DCEP 61 - 75 22 - 25 46 - 60 1.77 - 2.47

Hot Pass SMAW E 7018 H4R 3.2 A5.1 DCEP 100 - 120 21 - 26 90 - 105 1.40 - 2.08

Fillup SMAW E 7018 H4R 3.2 A5.1 DCEP 111 - 150 20 - 28 126 - 240 0.63 - 1.69

Fillup SMAW E 7018 H4R 4 A5.1 DCEP 138 - 172 22 - 30 116 - 125 1.65 - 2.48

Capping SMAW E 7018 H4R 2.5 A5.1 DCEP 118 - 130 22 - 27 231 - 248 0.63 - 0.93

Refer Report no:-PQR & WPS Inspection Reports: QC/PQR-30/01, 02, & 03

We, the undersigned, certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in accordance with the

requirements of Clause 4 of AWS D1.1/D1.1M, 2015 Structural Welding Code Steel.

Name : Name :

Signature : Signature :

Date : 16.01.2020 Date :

MED-08-078, Rev 0 Page 01 of 01

You might also like

- GMAW welding parameters for SS400 pipeDocument2 pagesGMAW welding parameters for SS400 pipeAnonymous zfC1zo9C100% (1)

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- Prequalified Qualified by TestingDocument5 pagesPrequalified Qualified by Testingcarlosoliveros1967No ratings yet

- Prequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Document2 pagesPrequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Nuril VS theWorldNo ratings yet

- DEE-920-12 - Rev 0Document3 pagesDEE-920-12 - Rev 0Karim ZahranNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- OSD Welding ProcedureDocument6 pagesOSD Welding ProcedureVijayakumar Chandran100% (1)

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- BGR Energy Systems Limited: Oil & Gas Equipment Division Welding Procedure Specification (WPS) - Aws D1.1Document1 pageBGR Energy Systems Limited: Oil & Gas Equipment Division Welding Procedure Specification (WPS) - Aws D1.1Eswar Enterprises QcNo ratings yet

- Procedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherDocument2 pagesProcedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherPanneer SelvamNo ratings yet

- Welding Procedure Specification (WPS) Pipeline: Lower Than PQR Preheat TempDocument1 pageWelding Procedure Specification (WPS) Pipeline: Lower Than PQR Preheat TempPanneer SelvamNo ratings yet

- Quy trình hàn vết nứt vành lò dùng que KNCF3 PDFDocument3 pagesQuy trình hàn vết nứt vành lò dùng que KNCF3 PDFDương Quang KhánhNo ratings yet

- Ongc WPS 1 of 2Document4 pagesOngc WPS 1 of 2Kiran NikateNo ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- WPS SMAW Fillet Welding ProcedureDocument2 pagesWPS SMAW Fillet Welding ProcedurecrysNo ratings yet

- Preliminary Welding Procedure Specification (PWPS)Document2 pagesPreliminary Welding Procedure Specification (PWPS)Maneesh0% (1)

- WPS Vessel 1Document4 pagesWPS Vessel 1Naqqash SajidNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Qw-482 Suggested Format For Welding Procedure Specification (WPS)Document2 pagesQw-482 Suggested Format For Welding Procedure Specification (WPS)ING HARRINSON FERREBUSNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- SPL - PQR-WPS-SWPS SmawDocument7 pagesSPL - PQR-WPS-SWPS Smawgopuvinu4uNo ratings yet

- (Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Document6 pages(Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Saifulla CmpNo ratings yet

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Prequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Document2 pagesPrequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Nuril VS theWorld100% (1)

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- PQR Procedure Qualification Record Krishna SteelDocument2 pagesPQR Procedure Qualification Record Krishna SteelHarshit Adwani100% (2)

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (2)

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Filled WPS Single FCAWDocument3 pagesFilled WPS Single FCAWAhmad ShaheenNo ratings yet

- WPS For Structure Mild Steel Fillet Weld PDFDocument2 pagesWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniNo ratings yet

- PRELIMINARY WELDING PROCEDURE AND QUALIFICATION FOR GTAWDocument8 pagesPRELIMINARY WELDING PROCEDURE AND QUALIFICATION FOR GTAWmegantara maromNo ratings yet

- GCB WPS Tsila 012Document19 pagesGCB WPS Tsila 012AslaouiNo ratings yet

- PREQUALIFIED WELDING PROCEDURE SPECIFICATION (WPSDocument2 pagesPREQUALIFIED WELDING PROCEDURE SPECIFICATION (WPSNuril VS theWorldNo ratings yet

- Welding Procedure Specification (WPS) : (Applicable Code/Standard: ISO 15614-2 Edition 2005)Document2 pagesWelding Procedure Specification (WPS) : (Applicable Code/Standard: ISO 15614-2 Edition 2005)saioman100% (7)

- Smaw Wps FinalDocument3 pagesSmaw Wps FinalsheikmoinNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument5 pagesJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCmkhalil1148No ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- QW - 482 Welding Procedure Specification (WPS)Document5 pagesQW - 482 Welding Procedure Specification (WPS)Arijit GhoshNo ratings yet

- Welding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeDocument2 pagesWelding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeNuwan RanaweeraNo ratings yet

- PREQUALIFIED WELDING PROCEDURE SPECIFICATIONDocument1 pagePREQUALIFIED WELDING PROCEDURE SPECIFICATIONErick VazquezNo ratings yet

- PQR 03 2014Document2 pagesPQR 03 2014vinuNo ratings yet

- DEE-920-11 - Rev 0Document3 pagesDEE-920-11 - Rev 0Karim ZahranNo ratings yet

- Welding Procedure Specification GuideDocument2 pagesWelding Procedure Specification GuidepoulmackNo ratings yet

- Afcons Infrastructure Limited: Procedure Qualification Record (PQR)Document21 pagesAfcons Infrastructure Limited: Procedure Qualification Record (PQR)GaapchuNo ratings yet

- Welding Procedure Specification for Vertical Storage TanksDocument6 pagesWelding Procedure Specification for Vertical Storage TanksYASH BARDHAN SinghNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- WELDING PROCEDURE SPECIFICATION FOR FILLET WELDSDocument2 pagesWELDING PROCEDURE SPECIFICATION FOR FILLET WELDSAhmed saberNo ratings yet

- Aws D1.6 - SS316 WPSDocument1 pageAws D1.6 - SS316 WPSBoby Thomas0% (1)

- APL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - IxDocument2 pagesAPL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - Ixmc160403810 Usman AliNo ratings yet

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- WPS for Urea Reclaimer Butt Joint WeldingDocument1 pageWPS for Urea Reclaimer Butt Joint Weldingasirul_meNo ratings yet

- Technical Data PWPS Structure Plate PT. Arung Rev.0Document4 pagesTechnical Data PWPS Structure Plate PT. Arung Rev.0YUDI IRMAWANTONo ratings yet

- GTAW Welding Procedure for ASTM A53 PipeDocument2 pagesGTAW Welding Procedure for ASTM A53 PipeS. K. M. ShujonNo ratings yet

- Preliminary - Welding Procedure Specification (WPS)Document1 pagePreliminary - Welding Procedure Specification (WPS)Rudi DaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Adaboost With Totally Corrective Updates For Fast Face DetectionDocument6 pagesAdaboost With Totally Corrective Updates For Fast Face DetectionNguyen Quoc TrieuNo ratings yet

- 6.1 Futures and Options AnalysisDocument2 pages6.1 Futures and Options AnalysisSuraj DecorousNo ratings yet

- Develop, Implement and Maintain WHS Management System Task 2Document4 pagesDevelop, Implement and Maintain WHS Management System Task 2Harry Poon100% (1)

- Surface Wettability of Paper (Angle-of-Contact Method) : Standard Test Method ForDocument4 pagesSurface Wettability of Paper (Angle-of-Contact Method) : Standard Test Method ForfadjarNo ratings yet

- Professional Industrial Engineering Program: Technical EnglishDocument15 pagesProfessional Industrial Engineering Program: Technical EnglishFabio fernandezNo ratings yet

- Electric Machine Design 01 Electric Machine DesignDocument10 pagesElectric Machine Design 01 Electric Machine Designkhodabandelou100% (1)

- MA 7 TranscriptDocument82 pagesMA 7 TranscriptBob AndrepontNo ratings yet

- Circuit Breaker GTSDocument31 pagesCircuit Breaker GTScpandey01_688066930No ratings yet

- 3.4 Linearization of Nonlinear State Space Models: 1 F X Op 1 F X Op 2 F U Op 1 F U Op 2Document3 pages3.4 Linearization of Nonlinear State Space Models: 1 F X Op 1 F X Op 2 F U Op 1 F U Op 2Ilija TomicNo ratings yet

- Lanco Solar EPC leaderDocument19 pagesLanco Solar EPC leaderShabir TrambooNo ratings yet

- Telstra Strategic Issues and CEO Leadership Briefing PaperDocument16 pagesTelstra Strategic Issues and CEO Leadership Briefing PaperIsabel Woods100% (1)

- Captiva 2013 Systema Electric 3.0Document13 pagesCaptiva 2013 Systema Electric 3.0carlos martinez50% (2)

- How to Critique a Work in 40 StepsDocument16 pagesHow to Critique a Work in 40 StepsGavrie TalabocNo ratings yet

- I - Refracted EnergyDocument6 pagesI - Refracted EnergyAmmad Ali QureshiNo ratings yet

- COT English 3rd PrepositionDocument14 pagesCOT English 3rd PrepositionGanie Mae Talde Casuncad100% (1)

- Node - Js 8 The Right Way: Extracted FromDocument11 pagesNode - Js 8 The Right Way: Extracted FromRodrigo Románovich FiodorovichNo ratings yet

- Variety of Living Organisms WorksheetDocument7 pagesVariety of Living Organisms WorksheetSenuNo ratings yet

- Sleep Hygiene Sleep QualityandDocument8 pagesSleep Hygiene Sleep QualityandVriddhi AgrawalNo ratings yet

- Function Apollo Amadeus: Sign In/OutDocument16 pagesFunction Apollo Amadeus: Sign In/OutMabs GaddNo ratings yet

- Prelims Module On Forensic 1Document17 pagesPrelims Module On Forensic 1Vanessa CorpuzNo ratings yet

- Analyzing an Anti-Smoking Poster Using a Formalist ApproachDocument20 pagesAnalyzing an Anti-Smoking Poster Using a Formalist ApproachAlphred Jann NaparanNo ratings yet

- Find Out Real Root of Equation 3x-Cosx-1 0 by Newton's Raphson Method. 2. Solve Upto Four Decimal Places by Newton Raphson. 3Document3 pagesFind Out Real Root of Equation 3x-Cosx-1 0 by Newton's Raphson Method. 2. Solve Upto Four Decimal Places by Newton Raphson. 3Gopal AggarwalNo ratings yet

- Mercury MasterDocument18 pagesMercury MastersatishmuggulaNo ratings yet

- Mobilization and Participation: Social-Psychological Expansisons of Resource Mobilization TheoryDocument19 pagesMobilization and Participation: Social-Psychological Expansisons of Resource Mobilization TheoryJoaquim OliveiraNo ratings yet

- Install and Configure Computer Networks Training Session PlanDocument9 pagesInstall and Configure Computer Networks Training Session PlanMarvin AlcantaraNo ratings yet

- Guia Instalacion ENTECDocument15 pagesGuia Instalacion ENTECHislim SaidNo ratings yet

- June 28th Altran Capital Market Day Presentation DeckDocument52 pagesJune 28th Altran Capital Market Day Presentation Deckvenkata.krishnan100% (1)

- The World in Which We Believe in Is The Only World We Live inDocument26 pagesThe World in Which We Believe in Is The Only World We Live inYusufMiddeyNo ratings yet

- Intro To Factor AnalysisDocument52 pagesIntro To Factor AnalysisRawnak JahanNo ratings yet

- Proportional Valves: Adjustment ProcedureDocument11 pagesProportional Valves: Adjustment Procedureyaniprasetyo12No ratings yet