Professional Documents

Culture Documents

Section 21 - Completion Installation Exercise

Section 21 - Completion Installation Exercise

Uploaded by

ayhamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 21 - Completion Installation Exercise

Section 21 - Completion Installation Exercise

Uploaded by

ayhamCopyright:

Available Formats

10/21/2013

Completion Installation Exercise #1

• Adco Asab Field

• Well SB‐477

• Running 3½”x4½” DTS

Completion

– No rotation possible

– Completion run to 19,354’

Learning Objectives

Input Output

• Actual survey • Calculate drag risk

• Enter hole and string tensions

details • Calculate buckling

• Enter friction factors risk@depth

• Discuss sensitivity

• Review actual DTS run

Completion Installation Exercise 1

10/21/2013

Inputs ‐ Survey and Hole Details:

Well Path

• Actual survey – SB‐477

• Select survey as txt file

Enter Hole Details:

• 9 5/8” 47# to 6,397’

(above top of 7” liner)

• 7” 26# to 9,338’

• 6 1/8” Hole to 99999’

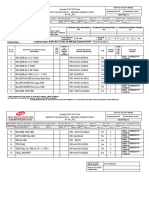

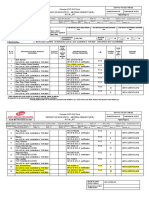

Inputs ‐ Completion String

Completion Installation Exercise 2

10/21/2013

Inputs ‐ Torque & Drag Scenario

Inputs ‐ Friction Factors

OPERATION P/U S/O OB T COMMENT

Planning 3½” x 4½” Tbg 0.1 – 0.3 N/A

Solids free WBM assumed

Actual 3½” x 4½” Tbg (SB-477) 0.05 – 0.1 N/A with Polymer protectors in

6⅛”hole

Notes: Use average FF (Cased and open hole)

0.2 SO FF used for standoff calculation

Notes:2 centralizer per joint = 15’ tubing lengths

as only cross coupling clamps approved for use

Completion Installation Exercise 3

10/21/2013

Running DTS Completion – Drag Chart

• Completion will run for

SOFF = 0.20

• Why will liner not run

for SOFF ≥ 0.25 ?

• Is that acceptable ?

• What are the results

sensitive to ?

Standoff calculation ‐ Inputs

Completion Installation Exercise 4

10/21/2013

Standoff calculation

• Acceptable standoff at TD

– No wall contact with DTS

cable

– Is that OK ?

• What are the results

sensitive to ?

Standoff calculation ‐ Slideshow

Completion Installation Exercise 5

10/21/2013

Actual DTS run on 12.7k’ 3½”9.2#x4½”12.75# Tubing

• Note: 12,687’ of 3½ tubing run from

TD to +/‐6,800’ (lateral and build up

sections) with 4½” tubing in the low

angle section

• Radiagreen lubricant at 1.5% helped

reduce axial drag

• At TD, drilling BHA was backreamed

out of hole and inside the 7” liner

• 5.75” OD polymer centralizers

lowered drag and provided

protection to the DTS cable

• K&M input into planning and K&M

engineer on rig for run

Completion Installation Exercise#2

• Running 4½” Slotted

Liner on 5½” x 4” DP

• Adco Bab Field

• 10k Lateral ERD well, 5k

Step out and 50° Az Turn

Completion Installation Exercise 6

10/21/2013

Learning Objectives

Input Output

• Apply tortuosity to • Calculate drag risk

planned well path tensions

• Enter hole and string • Calculate off bottom

details torque

• Enter friction factors • Calculate buckling

risk@depth

• Discuss potential

solutions

Inputs ‐ Survey Details:

• Survey for – “10K

Lateral ERD Well”

• 5k step out to heel

• 50 ◦ Azimuth turn

• Select survey file with

tortuosity to simulate

actual survey

Completion Installation Exercise 7

10/21/2013

Inputs ‐ Liner and Drill Pipe

Size Weight Adj Wt Grade Connection Tensile Tube TQ MUT

(in) (lb/ft) (lb/ft) Type (kips) (k ft-lbs) (k ft-lbs)

5½” 21.9 24.96 VM-105 6⅝” x 4” VX54 483 56 33.6

4” 15.7 17.64 VM-105 4⅞” x 29/16” VX39 355 28 15

4½” 12.6 12.6 L80 VAGT 288 27.6 5.2

Notes: Assumes no reduction in tensile or torsional strength due to slots

Inputs ‐ Friction Factors

Completion Installation Exercise 8

10/21/2013

Running Slotted Liner – Drag Chart Results

• 4½”Liner will just run

for SOFF ≤ 0.25

• Why will liner not run

for SOFF ≥ 0.30 ?

Running Slotted Liner – Buckling Risk Plot

• Buckling of the 4½”

liner / 4” DP is the issue

• What are potential

solutions ?

Completion Installation Exercise 9

10/21/2013

Running Slotted Liner – Off Bottom Torque

• Reaming is not likely to

be possible

– OBT > 4½” MUT (0.25 FF)

– VAGT MUT is ± 5 k ft‐lbs

– Upgrade connection e.g.

Hydril 563 ± 10 k ft‐lbs

– or Buttress with Tesco

torque ring ± 8 k ft‐lbs

Running Slotted Liner ‐ Solutions

• Use 5½” x 4” HWDP

– With HWDP, can now

run for 0.3 SO FF

Completion Installation Exercise 10

10/21/2013

Running Slotted Liner ‐ Solutions

• Run 2000’ HWDP +

swivel above liner

– With DP rotation only, can

now run for 0.3 SO FF

Back Up Slides – Pipe Specifications

Completion Installation Exercise 11

10/21/2013

Completion Installation Exercise 12

10/21/2013

Completion Installation Exercise 13

You might also like

- Cyber BaseDocument39 pagesCyber BaseayhamNo ratings yet

- Abf 000042 01 en PDFDocument92 pagesAbf 000042 01 en PDFalexsandr100% (2)

- Angus Jamieson Wellbore TortuosityDocument32 pagesAngus Jamieson Wellbore TortuosityCesar CasielloNo ratings yet

- ClockingDocument22 pagesClockingKu Mar Sa Ndesh100% (1)

- Cm-Hot:hem F 471 Trr-4-w Irdi4-Br: Standard Specification FOR Air Conditioning SystemDocument42 pagesCm-Hot:hem F 471 Trr-4-w Irdi4-Br: Standard Specification FOR Air Conditioning SystemHriday AgarwalNo ratings yet

- Creating Documentation For Successful PCB ManufacturingDocument38 pagesCreating Documentation For Successful PCB Manufacturingsandee kumarNo ratings yet

- ZMP-EDICON-2023 Chip Level DesignDocument18 pagesZMP-EDICON-2023 Chip Level DesignVinay TescoNo ratings yet

- 01 Simple Casing Design - Excel BasedDocument22 pages01 Simple Casing Design - Excel Basedfashola adeyemiNo ratings yet

- 2018-01-16 Pile Integrity TestDocument19 pages2018-01-16 Pile Integrity Testassistant directorNo ratings yet

- Vlsi Physical DesignDocument26 pagesVlsi Physical Designilias ahmed100% (1)

- MIT Scan2 Experience: Ohio DOTDocument13 pagesMIT Scan2 Experience: Ohio DOTJenny SánchezNo ratings yet

- Modular Welding Fixtures Poster PresentationDocument1 pageModular Welding Fixtures Poster Presentationachyutreddy2001No ratings yet

- CENG 5503 Chapter 2Document13 pagesCENG 5503 Chapter 2Getachew MekuriawNo ratings yet

- Nsba Basics of Steel Bridge Design Workshop - Part 3aDocument28 pagesNsba Basics of Steel Bridge Design Workshop - Part 3aLuis CortesNo ratings yet

- Cable PullingDocument2 pagesCable PullingZaini DalimusNo ratings yet

- Steel Design Flowcharts: Read Chapter 2 of Aisc For General InformationDocument70 pagesSteel Design Flowcharts: Read Chapter 2 of Aisc For General InformationNathaniela LoretoNo ratings yet

- Clock Network Synthesis: Prof. Shiyan Hu Shiyan@mtu - Edu Office: EREC 731Document22 pagesClock Network Synthesis: Prof. Shiyan Hu Shiyan@mtu - Edu Office: EREC 731Sanjay KumarNo ratings yet

- Steel Structures-Lecture 4 PDFDocument15 pagesSteel Structures-Lecture 4 PDFAli FarooqNo ratings yet

- Lecture15-PCB DesignDocument47 pagesLecture15-PCB Designdlc352-sc1No ratings yet

- 8D Report - 지타워 이동케이블 - V0 - 291221 - TKEK QA - v2 (004) - ENGDocument2 pages8D Report - 지타워 이동케이블 - V0 - 291221 - TKEK QA - v2 (004) - ENGsanjurk1506No ratings yet

- Geomechanics in A Depleted Carbonate Environment 1695742520Document10 pagesGeomechanics in A Depleted Carbonate Environment 1695742520Clau BustamanteNo ratings yet

- Swell Packer Case HistoriesDocument32 pagesSwell Packer Case Historiesapi-16218084No ratings yet

- Computer Organization and Assembly Language: Pipeline: IntroductionDocument25 pagesComputer Organization and Assembly Language: Pipeline: IntroductionAroosa SheikhNo ratings yet

- Wave Soldering Back To Basics (2007)Document15 pagesWave Soldering Back To Basics (2007)Nigel John BurttNo ratings yet

- Through-Tubing Rotary Drilling (TTRD) PDFDocument27 pagesThrough-Tubing Rotary Drilling (TTRD) PDFAnwarNo ratings yet

- Brief Description: Application Note - Industries & MarketDocument2 pagesBrief Description: Application Note - Industries & MarketJose Oliveros ArdilaNo ratings yet

- SBT BakerDocument2 pagesSBT BakerTC ShekarNo ratings yet

- Lab 1 PCBDesignDocument38 pagesLab 1 PCBDesignrainceder100No ratings yet

- Intel Aug 01 Logical Hi Ear AchyDocument21 pagesIntel Aug 01 Logical Hi Ear AchyphoenixpavanNo ratings yet

- Section 09 - Surge & SwabDocument33 pagesSection 09 - Surge & SwabRicardo VillarNo ratings yet

- Eng BinDocument101 pagesEng BinAliNo ratings yet

- Design of Slabs 1-1Document25 pagesDesign of Slabs 1-1Wilbert Reuyan100% (2)

- 6 VSAT Installation and MaintenanceDocument28 pages6 VSAT Installation and MaintenanceAhmed EJNo ratings yet

- SC Duplex Connectors & Adapters: Applications Features & BenefitsDocument6 pagesSC Duplex Connectors & Adapters: Applications Features & BenefitsKhairul IdhamNo ratings yet

- PD InterviewDocument8 pagesPD InterviewPraveen Ramesh KarnamNo ratings yet

- c342 SlideDocument23 pagesc342 SlideVimalNo ratings yet

- Screw Piling Info SheetsDocument9 pagesScrew Piling Info SheetsGlen WardNo ratings yet

- EECS 247 Analog-Digital Interface Integrated Circuits © 2008Document24 pagesEECS 247 Analog-Digital Interface Integrated Circuits © 2008Hassan FarssiNo ratings yet

- Major Achievements and Highlights: Key Metric Goal Baseline WW35 15Document6 pagesMajor Achievements and Highlights: Key Metric Goal Baseline WW35 15bo viloriaNo ratings yet

- ICEM GeometryDocument11 pagesICEM GeometryMohsen SalehiNo ratings yet

- Ground-Mount Solar Array FoundationsDocument12 pagesGround-Mount Solar Array FoundationsimamtaNo ratings yet

- Traditional Asic DesignflowDocument103 pagesTraditional Asic DesignflowYamini SaraswathiNo ratings yet

- Workshop 3.1 Shell Meshing - Stamped Part: Introduction To ANSYS Icem CFDDocument12 pagesWorkshop 3.1 Shell Meshing - Stamped Part: Introduction To ANSYS Icem CFDPetco AndreiNo ratings yet

- DesignCon Case of The Closing Eyes PanelDocument33 pagesDesignCon Case of The Closing Eyes PanelJeff ChenNo ratings yet

- DPT1 - 01 - Wellheads and Xmas TreesDocument100 pagesDPT1 - 01 - Wellheads and Xmas TreesMohammed Moulay100% (1)

- David Tarboton, Dan Watson, Rob Wallace: Dtarb@usu - EduDocument49 pagesDavid Tarboton, Dan Watson, Rob Wallace: Dtarb@usu - EdurovallecNo ratings yet

- Neugroschl 2017Document31 pagesNeugroschl 2017Ujjwal SinghNo ratings yet

- Casing Design GHBDocument59 pagesCasing Design GHBahoua100% (1)

- Introduction To Rock Mechanics: Geological Exploration (Coring)Document39 pagesIntroduction To Rock Mechanics: Geological Exploration (Coring)Umair AshrafNo ratings yet

- Resolve VP ApacDocument20 pagesResolve VP ApacHoang-Vu BuiNo ratings yet

- Viraj N SLB-IIDocument45 pagesViraj N SLB-IIViraj NevrekarNo ratings yet

- Pipeline Optimization TechniquesDocument7 pagesPipeline Optimization Techniquesbiswajit biswalNo ratings yet

- ABP Fluent 2021R2 External Aero Automotive v0Document94 pagesABP Fluent 2021R2 External Aero Automotive v0PrabhakaranGopalNo ratings yet

- QAQC For Dynamic Ground SupportDocument17 pagesQAQC For Dynamic Ground SupportTúlio AbduaniNo ratings yet

- Pro To TypingDocument6 pagesPro To TypingSomesh KshirsagarNo ratings yet

- Prototyping PDFDocument6 pagesPrototyping PDFSomesh KshirsagarNo ratings yet

- Cost Effective For Soil Nail Wall Designs - Fast Installation and Immediate Loading - Predictable Capacity - Limited Access Areas - Pre-Engineered SystemDocument4 pagesCost Effective For Soil Nail Wall Designs - Fast Installation and Immediate Loading - Predictable Capacity - Limited Access Areas - Pre-Engineered SystemVerenice CentenoNo ratings yet

- What'S in Your Coiled Tubing?: Roderic K. Stanley, PH D, I. EngDocument30 pagesWhat'S in Your Coiled Tubing?: Roderic K. Stanley, PH D, I. EngAriel TerrensNo ratings yet

- Ohiodot - Skewed Bridges Overview of New Practices & PolicyDocument41 pagesOhiodot - Skewed Bridges Overview of New Practices & PolicyOlivier GauthierNo ratings yet

- D-Cable: Improving Mine Safety and Productivity For Over 10 YearsDocument4 pagesD-Cable: Improving Mine Safety and Productivity For Over 10 YearsSen HuNo ratings yet

- NR-L3-MTC-RCS0216-GA08 - Tack Risk Control Sheet - Ground Penetration and ExcavationsDocument2 pagesNR-L3-MTC-RCS0216-GA08 - Tack Risk Control Sheet - Ground Penetration and ExcavationsnigelNo ratings yet

- BHA 04 Logging PDFDocument1 pageBHA 04 Logging PDFayhamNo ratings yet

- CHK3 Choke Manifold Test Rev 1Document1 pageCHK3 Choke Manifold Test Rev 1ayhamNo ratings yet

- Curs#1 CatalizaDocument25 pagesCurs#1 CatalizaayhamNo ratings yet

- Operating Instructions: User Manual No.: T4802-Z-MA-001, Rev. 0 Equipment: Top Drive 1 38Document38 pagesOperating Instructions: User Manual No.: T4802-Z-MA-001, Rev. 0 Equipment: Top Drive 1 38ayhamNo ratings yet

- GSP-SATURN-MR-205-2018-DRL-0561 - Tubing Head To BOP Adaptors Spool & Ring GasketsDocument2 pagesGSP-SATURN-MR-205-2018-DRL-0561 - Tubing Head To BOP Adaptors Spool & Ring GasketsayhamNo ratings yet

- Gsp-Saturn-Mr-205-2018-Drl-0460 - Lifting CapsDocument1 pageGsp-Saturn-Mr-205-2018-Drl-0460 - Lifting CapsayhamNo ratings yet

- UntitledDocument1 pageUntitledayhamNo ratings yet

- Operating Instructions: User Manual No.: T4854-Z-Ma-001, Rev. 0 Equipment: Hydraracker X-Y 1 of 89Document89 pagesOperating Instructions: User Manual No.: T4854-Z-Ma-001, Rev. 0 Equipment: Hydraracker X-Y 1 of 89ayhamNo ratings yet

- BbprocedureDocument3 pagesBbprocedureayhamNo ratings yet

- Operation Manual: Drawworks Control SystemDocument49 pagesOperation Manual: Drawworks Control Systemayham0% (1)

- GSP-SATURN-MR-205-2018-DRL-0559 - Personnel For Installing Top DerrickDocument1 pageGSP-SATURN-MR-205-2018-DRL-0559 - Personnel For Installing Top DerrickayhamNo ratings yet

- GSP-SATURN-MR-205-2018-DRL-0564 - Valve Seat Puller For API 7 Valve Seat 4 Web StyleDocument2 pagesGSP-SATURN-MR-205-2018-DRL-0564 - Valve Seat Puller For API 7 Valve Seat 4 Web StyleayhamNo ratings yet

- Gsp-Saturn-Mr-205-2018-Drl-0375 - 13 .625 Cameron Bop Critical Spare PartsDocument2 pagesGsp-Saturn-Mr-205-2018-Drl-0375 - 13 .625 Cameron Bop Critical Spare PartsayhamNo ratings yet

- GSP-SATURN-MR-205-2018-DRL-0417 - BOLTS AND WASHERS TO REPAIR For 13 58 X 10k CAMERON BOP RevisedDocument2 pagesGSP-SATURN-MR-205-2018-DRL-0417 - BOLTS AND WASHERS TO REPAIR For 13 58 X 10k CAMERON BOP RevisedayhamNo ratings yet

- GSP-SATURN-MR-205-2018-DRL-0373 - Third Party Inspection For TDS 8S & Solid Control SystemDocument1 pageGSP-SATURN-MR-205-2018-DRL-0373 - Third Party Inspection For TDS 8S & Solid Control Systemayham100% (1)

- Subiecte Bazele SimulariiDocument5 pagesSubiecte Bazele SimulariiayhamNo ratings yet

- GSP-SATURN-MR-205-2018-DRL-0375 - 13 .625 CAMERON BOP CRITICAL SPARE PARTS - Revised 2Document2 pagesGSP-SATURN-MR-205-2018-DRL-0375 - 13 .625 CAMERON BOP CRITICAL SPARE PARTS - Revised 2ayhamNo ratings yet

- 01 MEC Catalogo Tecnico Agricolo 2017 PDFDocument16 pages01 MEC Catalogo Tecnico Agricolo 2017 PDFKouki JihedNo ratings yet

- WMS For Pipe Supports ErectionDocument17 pagesWMS For Pipe Supports ErectionRamaraju RNo ratings yet

- Bill of Quantities: Prepared By: Checked By: Approved byDocument82 pagesBill of Quantities: Prepared By: Checked By: Approved byRoshan KejariwalNo ratings yet

- Geyser Hybrid PumpDocument2 pagesGeyser Hybrid PumpnmrsNo ratings yet

- BS EN 736-3 Valves Terminology - Definition TermsDocument12 pagesBS EN 736-3 Valves Terminology - Definition TermsLuis Daniel ContrerasNo ratings yet

- Residential Owners ManualDocument11 pagesResidential Owners ManualMSILVAJRNo ratings yet

- Vista Explodida Thermoking ContainerDocument139 pagesVista Explodida Thermoking ContainerCaio CesarNo ratings yet

- Pipeline Tie - inDocument2 pagesPipeline Tie - inanishsr75% (4)

- High-Speed Mill System Z Type LMZ: Grinding & DispersingDocument12 pagesHigh-Speed Mill System Z Type LMZ: Grinding & DispersingDipesh100% (1)

- Ms 20832 PDFDocument114 pagesMs 20832 PDFNaqqash SajidNo ratings yet

- Astm-D3567 - 97Document4 pagesAstm-D3567 - 97Bipin Sp100% (1)

- Pool Circulation PDF Document Aqua Middle East FZCDocument18 pagesPool Circulation PDF Document Aqua Middle East FZCAdolfsmith69No ratings yet

- BS en Iso 13783 - 1998Document12 pagesBS en Iso 13783 - 1998Kim WongNo ratings yet

- Notes For Road and Infrastructure - Doc-6Document54 pagesNotes For Road and Infrastructure - Doc-6aamirNo ratings yet

- As A09-12lkc DTR As039e 01Document38 pagesAs A09-12lkc DTR As039e 01Omu AntenaNo ratings yet

- Design of TankDocument12 pagesDesign of Tanksksiddique100% (1)

- Design Standard Ds 31-01: Pipework - MechanicalDocument41 pagesDesign Standard Ds 31-01: Pipework - Mechanical4usangeetNo ratings yet

- Ancillary Scaffolding Components Not Covered by British StandardsDocument4 pagesAncillary Scaffolding Components Not Covered by British StandardsMatthew PowellNo ratings yet

- Diager Catalog Export Eng 2022 d00362Document240 pagesDiager Catalog Export Eng 2022 d00362Cristian MoraNo ratings yet

- E170E2 IQ Mk2 Installation Maintenance Instructions 01-05Document86 pagesE170E2 IQ Mk2 Installation Maintenance Instructions 01-05apisituNo ratings yet

- Vds - 2132en Aproval of Installers of Fire Extinguishing SystemsDocument44 pagesVds - 2132en Aproval of Installers of Fire Extinguishing SystemsCristianLeotescu100% (2)

- 15SY0136C9578Document486 pages15SY0136C9578electricista85No ratings yet

- BM 21Document2 pagesBM 21ghostinshellNo ratings yet

- Nordson EFD 752V Maintenance GuideDocument4 pagesNordson EFD 752V Maintenance GuidePedro Abregú100% (1)

- RWPL TG LP Rotor Replacement Scope of JobDocument5 pagesRWPL TG LP Rotor Replacement Scope of JobSreekanthMylavarapuNo ratings yet

- Claas Dominator 108vx 98vx 88vx Operation Mantenance ManualDocument20 pagesClaas Dominator 108vx 98vx 88vx Operation Mantenance Manualwillie100% (54)

- PIPING GUIDE - Typical Questions For Piping Engineer's Knowledge Testing (With Answers)Document10 pagesPIPING GUIDE - Typical Questions For Piping Engineer's Knowledge Testing (With Answers)Kurian JoseNo ratings yet

- Lxe10e A36 ADocument62 pagesLxe10e A36 AСергей ПетровNo ratings yet