Professional Documents

Culture Documents

Rapid P0001 CCSM Pip SPN 1300 0001 - 1C

Uploaded by

Farghud EismethOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rapid P0001 CCSM Pip SPN 1300 0001 - 1C

Uploaded by

Farghud EismethCopyright:

Available Formats

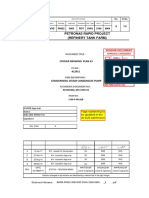

Document Number

Rev. Page

Doc. Unit n°

Project Package Originator Discipline Serial n°

Type

1C 1 / 22

RAPID P0001 CCSM PIP SPN 1300 0001

PETRONAS RAPID PROJECT

(P0001 – RFCC, LTU, PRU UNITS)

PIPING MATERIAL SPECIFICATION

OWNER Approval:

Name:

Date (DD-MMM-YY):

Signature:

Document Class: Z

1C 27-Nov-17 IFC – Issued For Construction

1B 26-Aug-16 IFC – Issued For Construction S.L.Lee Sam Wang

1A 03-MAR-16 IFC – Issued For Construction S.L.Lee Sam Yu Fang

1 11-Sep-15 IFC – Issued For Construction S.L.Lee Sam Yu Fang

0 29-MAY-15 IFD – Issued For Design S.L.Lee Sam Yu Fang

C 28-APR-15 IFA – Issued For Approval S.L.Lee Sam S.N.Sheu/J.C.Hong

B 04-Feb-15 IFA – Issued For Approval S.L.Lee Sam S.N.Sheu/J.C.Hong

A 01-Dec-14 IFA – Issued For Approval S.L.Lee Sam S.N.Sheu/J.C.Hong

DATE WRITTEN BY CHECKED BY APPROVED BY

REV. STATUS – REVISION MEMO

DD-MMM-YY (name & signature) (name & signature) (name & signature)

Sections changed in last revision are identified by a vertical line in the right margin.

Electronic Filename: RAPID-P0001-CCSM-PIP-SPN-1300-0001_1C.docx

Document Number

Rev. Page

Project Package Originator Discipline Doc. Type Unit n° Serial n°

1C 2 / 22

RAPID P0001 CCSM PIP SPN 1300 0001

PIPING MATERIAL SPECIFICATION

(P0001 – RFCC, LTU, PRU UNITS)

HOLD’s

HOLD

REF. § DESCRIPTION ACTIONS

No.

Electronic Filename: RAPID-P0001-CCSM-PIP-SPN-1300-0001_1C.docx

Document Number

Rev. Page

Project Package Originator Discipline Doc. Type Unit n° Serial n°

1C 3 / 22

RAPID P0001 CCSM PIP SPN 1300 0001

PIPING MATERIAL SPECIFICATION

(P0001 – RFCC, LTU, PRU UNITS)

REVISION HISTORY

Rev No Rev Date Page / Row Revision Description

A 01-Dec-‘14 All Page Issue for Approval.

B 04-Feb-‘15 All Page Issue for Approval

Issue for Approval, updated as per RAPID-P0001-CCSM-

C 28-Apr-‘15 All Page

PIP-SPN-1300-0001_B-CRS1.

0 29-May-‘15 All Page Issue for Design

1 11-Sep-‘15 All Page Issue for Construction

Issue for Construction, updated as per RAPID-P0001-CCSM-

1A 03-Mar-’16 All Page

PIP-SPN-1300-0001_1-CRS1.

Issue for Construction, updated as per RAPID-P0001-CCSM-

1B 26-Aug-’16 All Page

PIP-SPN-1300-0001_1A-CRS1.

Issue for Construction, updated F5a to F5 for fitting material

(weldolet/nippolet/flanged pipet) of Piping Class 1L213BS,

1C 27-Nov-’17 All Page

1L213BU, 3L213BS, 3L213BU, 6L213BS, 6L213BU as per

RAPID-P0001-CCSM-PIP-VCR-1300-0016.

Electronic Filename: RAPID-P0001-CCSM-PIP-SPN-1300-0001_1C.docx

Document Number

Rev. Page

Project Package Originator Discipline Doc. Type Unit n° Serial n°

1C 4 / 22

RAPID P0001 CCSM PIP SPN 1300 0001

PIPING MATERIAL SPECIFICATION

(P0001 – RFCC, LTU, PRU UNITS)

Table of Contents

1. PURPOSE.............................................................................................................................................................. 5

2. REFERENCE DOCUMENTS ............................................................................................................................... 5

3. GENERAL REQUIREMENT............................................................................................................................... 10

4. PIPES . .................................................................................................................................................................. 13

5. FITTINGS. ............................................................................................................................................................ 13

6. THREAD .............................................................................................................................................................. 15

7. VALVES . .............................................................................................................................................................. 15

8. FLANGES . ........................................................................................................................................................... 19

9. GASKETS. ........................................................................................................................................................... 20

10. BOLTING . ........................................................................................................................................................ 20

11. GLASS-FIBRE REINFORCED PLASTIC (GRP) . ........................................................................................ 21

12. GALVANIZED PIPING ................................................................................................................................... 21

13. LICENSOR ADDITIONAL REQUIREMENTS .............................................................................................. 22

14. PIPING MATERIAL CLASS SUMMARY . ..................................................................................................... 22

15. PIPE WALL THICKNESS TABLE. ................................................................................................................ 22

16. PIPIING CLASSES DETAIL .......................................................................................................................... 22

Electronic Filename: RAPID-P0001-CCSM-PIP-SPN-1300-0001_1C.docx

Document Number

Rev. Page

Project Package Originator Discipline Doc. Type Unit n° Serial n°

1C 5 / 22

RAPID P0001 CCSM PIP SPN 1300 0001

PIPING MATERIAL SPECIFICATION

(P0001 – RFCC, LTU, PRU UNITS)

1. PURPOSE

This project specification to be used for the Package No 1 - RFCC, LTU, PRU Units of

the PETRONAS RAPID (Refinery And Petrochemical Integrated Development) Project.

The selection of piping construction materials is covered in the following Piping Class

Summary and Piping Class Specification detail, which refer to the PMRC™ system to

specify the piping component.

砀 RAPID-FE1-TPX-PIP-DES-0001-0021 REV.4 Project Specification -Piping Class

Summary -Refinery and Utilities Piping Classes

砀 RAPID-FE1-TPX-PIP-DES-0001-0023 REV.2 Project Specification -Piping Class

Specification For Refinery & Utilities

TM

砀 PMRC (PETRONAS Material Reference Code)

The piping class summary has been developed based on process information from

similar refinery projects and document RAPID-FE1-TPX-PRO-DES-0001-0001 dealing

with utilities conditions and licensor piping material requirements.

2. REFERENCE DOCUMENTS

砀 RAPID PROJECT SPECIFICATION

RAPID-FE1-TPX-PIP-DES-0001-0002, Rev.3 Piping Layout and Installation

RAPID-FE1-TPX-PIP-DES-0001-0021, Rev.4 Piping Class Summary - Refinery and

Utilities Piping Classes

RAPID-FE1-TPX-PIP-DES-0001-0023, Rev.2 Piping Class Specification for Refinery

& Utilities

RAPID-FE1-TPX-PIP-DES-0001-9007, Rev.0 Compilation of a Specification for

Piping Systems(Supplement to PTS

31.38.01.21dated Aug. 2011)

RAPID-FE1-TPX-PIP-DES-0001-9008, Rev.1 Shop and Field Fabrication of

Piping(Supplement to PTS

31.38.01.31 Dated Dec.2010)

RAPID-FE1-TPX-PIP-DES-0001-9012, Rev.1 Interlocking Systems for Safety/Relief

Valves(Supplement to PTS

80.46.30.11 dated Feb.2010)

RAPID-FE1-TPX-PIP-DES-0001-9013, Rev.0 Piping Classes - Basic of

Design(Supplement to PTS

31.38.01.10 dated Aug.2011)

RAPID-FE1-TPX-PIP-DES-0001-9015, Rev.0 Piping Classes - Refining and

Chemical(Supplement to PTS

31.38.01.12 dated OCT. 2011)

Electronic Filename: RAPID-P0001-CCSM-PIP-SPN-1300-0001_1C.docx

Document Number

Rev. Page

Project Package Originator Discipline Doc. Type Unit n° Serial n°

1C 6 / 22

RAPID P0001 CCSM PIP SPN 1300 0001

PIPING MATERIAL SPECIFICATION

(P0001 – RFCC, LTU, PRU UNITS)

RAPID-FE1-TPX-PIP-DES-0001-9023, Rev.0 Glassfibre Reinforced Plastic Pipeline

and Piping Systems(Supplement to

PTS 31.40.10.19 dated Jan.2010)

RAPID-FE1-TPX-PIP-DES-0001-9024, Rev.0 Spoolable Fibre-Reinforced Plastic

Pipes(Supplement to PTS 31.40.10.20

dated Dec.2009)

RAPID-FE1-TPX-MCI-SPN-0001-0002, Rev 2 Project Specification Carbon Steel

Piping And Equipment In "W et H2S"

Service.

RAPID-FE1-TPX-PRO-DES-0001-0001, Rev.1 Design Basis–Utilities Conditions

砀 PETRONAS TECHNICAL STANDARDS

PTS 31.38.01.10, Aug.2011 Piping Classes - Basic Of Design

PTS 31.38.01.12, OCT. 2011 Piping Classes – Refining And

Chemicals

PTS 31.38.01.21, Aug 2011 Compliation Of A Specification For

Piping Systems

PTS 31.38.01.31, Dec.2010 Shop And Field Fabrication Of Piping

PTS 31.40.10.19, Jan.2010 Glass-Fibre Reinforced Plastic

Pipeline And Piping Systems

PTS 31.40.10.20, Dec 2009 Spoolable Fibre Reinforced Plastic

Pipes

PTS 80.46.30.11, Feb.2010 Interlocking System For Safety Relief

Valves

砀 LICENSOR’s SPECIFICATION

UOP:

SPN-UOP-1320-0008, 11-Apr-2011 Standard Specifications - Piping &

Piping Class

AXENS:

RAPID-LR2-AXN-PRO-DES-0001-0001, Rev.0 General Process Data Book

RAPID-LR2-AXN-PRO-SPN-0001-0005, Rev.1 Standard Material Specifications

For Wet H2S Services Application

to Carbon Steels

砀 CCSM PROJECT SPECIFICATIONS AND STANDARDS

Electronic Filename: RAPID-P0001-CCSM-PIP-SPN-1300-0001_1C.docx

Document Number

Rev. Page

Project Package Originator Discipline Doc. Type Unit n° Serial n°

1C 7 / 22

RAPID P0001 CCSM PIP SPN 1300 0001

PIPING MATERIAL SPECIFICATION

(P0001 – RFCC, LTU, PRU UNITS)

RAPID-P0001-CCSM-PIP-STD-1300-0001, Rev.A Above Ground Piping Standard

(Refer to RAPID-FE1-TPX-PIP-

STD-0001-0001, Rev.2 and

RAPID-FE1-TPX-PIP-STD-0001-

0002, Rev.0)

RAPID-P0001-CCSM-PIP-STD-1300-0003, Rev.A Steam Tracing Standard (Refer

to RAPID-FE1-TPX-PIP-DES-

0001-0003, Rev.1)

RAPID-P0001-CCSM-PIP-SPN-1300-0003, Rev.A Specification for Coating and

Wrapping

砀 CODES AND STANDARDS

ASME (American Society of Mechanical Engineers)

B31.1 2012 Power Piping

B31.3 2012 Process Piping

B1.1 2003 Unified Inch Screw Threads

B1.20.1 2013 Pipe Threads, General Purpose (Inch)

B16.1 2010 Gray Iron Pipe Flanges and Flanged Fittings Classes 25, 125,

and 250

B16.3 2011 Malleable Iron Threaded Fittings Classes 150 and 300

B16.5 2013 Pipe Flanges and Flanged Fittings NPS 1/2 Through

NPS 24 Metric/Inch Standard

B16.9 2012 Factory-Made Wrought Buttwelding Fittings

B16.10 2009 Face to Face and End to End Dimensions of Valves

B16.11 2011 Forged Fittings, Socket-Welding and Threaded

B16.14 2013 Ferrous Pipe Plugs, Bushings, and Locknuts with Pipe

Threads

B16.20 2012 Metallic Gaskets for Pipe Flanges Ring-Joint, Spiral-Wound,

and Jacketed

B16.21 2011 Nonmetallic Flat Gaskets for Pipe Flanges

B16.25 2012 Butt welding Ends

B16.34 2013 Valves - Flanged, Threaded, and Welding End

B16.36 2009 Orifice Flanges

B16.42 2011 Ductile Iron Pipe Flanges and Flanged Fittings Classes 150

And 300

B16.47 2011 Large Diameter Steel Flanges NPS 26 Through NPS 60

Electronic Filename: RAPID-P0001-CCSM-PIP-SPN-1300-0001_1C.docx

Document Number

Rev. Page

Project Package Originator Discipline Doc. Type Unit n° Serial n°

1C 8 / 22

RAPID P0001 CCSM PIP SPN 1300 0001

PIPING MATERIAL SPECIFICATION

(P0001 – RFCC, LTU, PRU UNITS)

Metric/Inch Standard

B16.48 2010 Line Blanks

B18.2.2 2010 Nuts for General Applications: Machine Screw Nuts, Hex,

Square, Hex Flange, and Coupling Nuts (Inch Series)

B36.10M 2004 Welded and Seamless Wrought Steel Pipe

B36.19M 2004 Stainless Steel Pipe

B46.1 2009 Surface Texture (Surface Roughness, Waviness and Lay)

PCC-1 2013 Guidelines for Pressure Boundary Bolted Flange Joint

Assembly.

Sec. I 2013 Rules for Construction of Power Boilers

Sec. IX 2013 Qualification Standard for Welding and Brazing and Brazing

Procedures, Welders, Brazers, and Weldings and Brazing

Operators Welding and Brazer Qualifications

API (American Petroleum Institute)

5L 2012 Specification for Line Pipe

6D 2008 Specification for Pipeline Valves

594 2010 Check Valves: Flanged, Lug, Wafer, and Butt-welding

598 2009 Valve Inspection and Testing

599 2013 Metal Plug Valves—Flanged, Threaded and Welding Ends

600 2009 Steel Gate Valves-Flanged and Butt-welding Ends, Bolted

Bonnets

602 2009 Steel Gate, Globe, and Check Valves for Sizes NPS 4 (DN

100) and Smaller for Petroleum and Natural Gas Industries

603 2013 Corrosion resistant, Bolted Bonnet Gate Valves-Flanged

and Butt-welding Ends

607 2010 Fire Test for Quarter-turn Valves and Valves Equipped with

Nonmetallic Seats

608 2012 Metal Ball Valves - Flanged, Threaded, and Welding Ends

609 2009 Butterfly Valves: Double-flanged, Lug- and Wafer-type

6FA 2011 Specification for Fire Test for Valves

941 2008 Steels for Hydrogen Service at Elevated Temperatures and

Pressures in Petroleum Refineries and Petrochemical plants

BS (British Standard)

Electronic Filename: RAPID-P0001-CCSM-PIP-SPN-1300-0001_1C.docx

Document Number

Rev. Page

Project Package Originator Discipline Doc. Type Unit n° Serial n°

1C 9 / 22

RAPID P0001 CCSM PIP SPN 1300 0001

PIPING MATERIAL SPECIFICATION

(P0001 – RFCC, LTU, PRU UNITS)

1868 1975 Specification for Steel Check Valves (Flanged and Butt

welding Ends) for The Petroleum, Petrochemical and Allied

Industries.

1873 1975 Steel Globe and Globe Stop and Check Valves (Flanged and

Butt- Welding Ends) for the Petroleum, Petrochemical and

Allied Industries

6364 1984 Specification for Valves for Cryogenic Service

6755-2 1984 Testing of Valves Specification for Fire Type

5157 1989 Specification for Steel Gate (Parallel Slide) Valves

EN (European Norm)

10204 2004 Metallic products. Types of Inspection Documents

ISO (International Standardization Organization)

5208 2008 Industrial Valves - Pressure Testing of valves

9000 2005 Quality Management Systems - Fundamentals and

Vocabulary

10474 2013 Steel and Steel Products - Inspection Documents

10497 2010 Testing of Valves – Fire Type Testing Requirements

15761 2002 Steel Gate, globe and Check Valves For Sizes DN100 and

Smaller, for the Petroleum and Natural Gas Industries

15848-1 2006 Industrial Valves - Measurement, Test and Qualification

Procedures for Fugitive Emissions Part 1:Classification

System and Qualification Procedures for Type Testing of

Valves

15848-2 2006 Industrial Valves - Measurement, Test and Qualification

Procedures for Fugitive Emissions – Part 2: Production

Acceptance Test of Valves

17292 2004 Metal Ball Valves for Petroleum, Petrochemical and

Allied Industries

MSS (Manufacturer's Standardization Society)

SP-25 2013 Standard Marking System for Valves, Fittings, Flanges and

Unions

SP-43 2013 Wrought and Fabricated Butt-Welding Fittings for Low

Pressure, Corrosion Resistant Applications

SP-44 2010 Steel Pipeline Flanges

Electronic Filename: RAPID-P0001-CCSM-PIP-SPN-1300-0001_1C.docx

Document Number

Rev. Page

Project Package Originator Discipline Doc. Type Unit n° Serial n°

1C 10 / 22

RAPID P0001 CCSM PIP SPN 1300 0001

PIPING MATERIAL SPECIFICATION

(P0001 – RFCC, LTU, PRU UNITS)

SP-45 2003 Bypass and Drain Connections

SP-53 2012 Quality Standard for Steel Castings and Forgings for Valves,

Flanges, Fittings, and Other Piping Components.

SP-54 2007 Quality Standard for Steel Castings for Valves Flanges

Fittings and Other Piping Components Radiographic

Examination Method.

SP-55 2011 Quality Standard for Steel Castings for Valves, Flanges,

Fittings and Other Piping Components – Visual Method for

Evaluation of Surface Irregularities.

SP-80 2013 Bronze Gate, Globe, Angle and Check Valves

SP-95 2014 Swage(d) Nipples and Bull Plugs

SP-97 2012 Integrally Reinforced Forged Branch Outlet Fittings – Socket

Welding, Threaded, and Buttwelding Ends

NACE (National Association of Corrosion Engineers)

MR0175/ 2009 Petroleum and Natural Gas Industries – Materials for use in

ISO15156 H2S containing environments in Oil & Gas Production

MR0103 2012 Materials Resistant to Sulfide Stress Cracking in Corrosive

Petroleum Refining Environments

ASTM Material Standard applicable, shall be specified in the Material

Requisitions

UL/FM Underwriters Laboratories/Factory Mutual

3. GENERAL REQUIREMENT

砀 RESTRICTED PIPE SIZE

Following diameters up to DN600 will be prescribed except process requirements

and/or equipment connections: DN8, DN10, DN32, DN65, DN90, DN125, DN175,

DN275, DN550.

Unless economically justified otherwise, the range of pipe sizes above DN600

shall be restricted to the following, in order to avoid the purchase of many different

sizes of pipes and fittings: DN750, DN900, DN1050, DN1200, DN1400, DN1600,

DN1800 and DN2000. DN2250, DN2500, DN2750, DN3000, DN3250, DN 3500…

砀 JOINTS FOR METALLIC PIPING

砀 Welded joints

Electronic Filename: RAPID-P0001-CCSM-PIP-SPN-1300-0001_1C.docx

Document Number

Rev. Page

Project Package Originator Discipline Doc. Type Unit n° Serial n°

1C 11 / 22

RAPID P0001 CCSM PIP SPN 1300 0001

PIPING MATERIAL SPECIFICATION

(P0001 – RFCC, LTU, PRU UNITS)

- The piping classes RAPID-FE1-TPX-PIP-DES-0001-9015 for Refining

and Chemical Plant are standardized on butt-welding.

- Preparation shall be in accordance with ASME B16.25. Permanent

backing rings shall not be used.

- Whenever welds are to be PWHT, the acceptance of NDT for the welds

shall be after the PWHT.

砀 Socket welding

砀 The piping classes RAPID-FE1-TPX-PIP-DES-0001-9015 for Refining

and Chemical Plant are standardized on butt-welding, not socket-welding,

components.

砀 Socket-welded construction is not permitted in the following services:

· Services in which crevice corrosion can occur;

· ASME rating class above 900

· Lower design temperature below 0 °C;

· Very toxic service;

· Hydrogen service.

· Cyclic condition

砀 For other services, socket-welded construction is permitted in carbon

steel systems if economically justified. Economic assessment should

take account of the fact that more welds are required in socket-welded

systems because socket-welding components cannot be welded directly

to each other. Typically, there are 25 % more welds in a socket-welded

system than in an equivalent butt welded system.

砀 In some condition, socket weld may be permitted for small diameter

piping (less than DN50) for certain utility services (Category D) specified

in RAPID-FE1-TPX-PIP-DES-0001-0023 Rev 2 and subject to OWNER

approval.

砀 Manufacturer's "package" units often include socket-welded small bore

piping as a standard. Departing from that standard may have a

significant cost impact. In these package units, socket welded

construction may be considered acceptable except where defined above.

砀 Socket welded connections cannot be properly radiographed to verify

weld quality; they can only be inspected by surface techniques such as

magnetic particle or liquid penetrant. Radiography may be selectively

applied to check that a fit-up gap remains after the weld has been made.

For inspection requirements as per RAPID- FE1-TPX-PIP-DES-0001-

9008.

Electronic Filename: RAPID-P0001-CCSM-PIP-SPN-1300-0001_1C.docx

Document Number

Rev. Page

Project Package Originator Discipline Doc. Type Unit n° Serial n°

1C 12 / 22

RAPID P0001 CCSM PIP SPN 1300 0001

PIPING MATERIAL SPECIFICATION

(P0001 – RFCC, LTU, PRU UNITS)

砀 MATERIALS

The additional material requirement specified in Section 10 of RAPID-FE1-TPX-

PIP-DES-0001-0021 Piping Class Summary document shall be applied. All piping

components of piping classes are covered by PMRC™ (PETRONAS Material

Reference Coding).

The pressure and temperature given in each Piping Class are the limits of use and

the design conditions of the lines referenced shall not exceed these limits. All

piping components and pipe wall thickness shown in each piping class are based

on these limits.

砀 Carbon Steel & Alloy Steel

Materials shall conform to all the Project Specification and applicable Codes

and Standards.

砀 Carbon Steel for wet H2S service

Wet H2S service (Carbon steel) shall be conformed to specification RAPID-

FE1-TPX-MCI-SPN-0001-0002 for Refinery piping classes (PTS, Derived

and Project piping Class). For Licensor AXENS piping classes, the wet H2S

service shall be compliant with specification RAPID-LR2-AXN-PRO-SPN-

0001-0005.

砀 Austenitic Stainless Steel

Materials shall be furnished in the solution heat treated condition and free of

subsequent cold work. Stainless steel 304 and 316 are dual certified

(304/304L and 316/316L).

砀 Austenitic Stainless Steel for wet H2S service

Stainless steel selected in wet H2S service piping classes shall be compliant

with requirements given in the NACE MR 0103.

砀 PWHT

Unless otherwise specified, PWHT shall be in accordance with ASME B31.3

based on material groupings and thickness ranges. When PWHT is specified in

individual piping class, PWHT is to be performed for all thicknesses. All welded

connection of testing requirements as per RAPID- FE1-TPX-PIP-DES-0001-9008.

砀 UNDERGROUND PIPING SYSTEMS

External coating for underground piping shall be in accordance with RAPID-

P0001-CCSM-PIP-SPN-1300-0003, Specification for Coating and Wrapping.

Electronic Filename: RAPID-P0001-CCSM-PIP-SPN-1300-0001_1C.docx

Document Number

Rev. Page

Project Package Originator Discipline Doc. Type Unit n° Serial n°

1C 13 / 22

RAPID P0001 CCSM PIP SPN 1300 0001

PIPING MATERIAL SPECIFICATION

(P0001 – RFCC, LTU, PRU UNITS)

4. PIPES

砀 GENERAL WORKS

Thickness calculations shall conform to ASME B31.3, § 304.1.2. and ASME B31.1

when applicable.

For stainless steel, wall thicknesses shall conform to ASME B36.19 where

applicable otherwise ASME B36.10 is applicable.

When pipes are ordered beveled ends, bevel shall conform ASME B16.25 unless

standard to which refers the pipe asks for specific bevel.

砀 MILL TOLERANCE (Thickness Calculation)

ASTM carbon steel: 12.5% up to DN600 and 0.3mm for DN650 and above.

ASTM alloy steel: 12.5% up to DN400 and 0.3mm for DN450 and above.

For seamless materials used up to DN600 12.5% is applied.

ASTM stainless steel: 12.5% up to DN300 and 0.3mm for DN350 and above.

砀 SEAMLESS PIPE

For carbon, the seamless pipe is specified up to DN600.

For alloy steels, the seamless pipe is specified up to DN400.

For stainless steels, the seamless pipe is specified up to DN300.

砀 WELDED PIPE

All ASTM A 358 material shall be Class 1 which pipe shall be double welded by

processes employing filler metal in all passes and shall be completely

radiographed.

5. FITTINGS

砀 GENERAL WORKS

Butt welding fittings up to DN1200 shall be conformed to ASME B16.9.

Forged fittings shall be conformed to ASME B16.11.

砀 FITTINGS WITH DIAMETER OVER DN1200

Electronic Filename: RAPID-P0001-CCSM-PIP-SPN-1300-0001_1C.docx

Document Number

Rev. Page

Project Package Originator Discipline Doc. Type Unit n° Serial n°

1C 14 / 22

RAPID P0001 CCSM PIP SPN 1300 0001

PIPING MATERIAL SPECIFICATION

(P0001 – RFCC, LTU, PRU UNITS)

For diameters, not covered by ASME B16.9, the design of fittings shall be

established according to ASME B16.9 paragraph 2.2 (mathematical analysis or

proof test).

砀 BRANCH CONNECTIONS

A branch fitting connects a branch pipe to the run pipe. Branches should be

connected at 90 Deg to the run pipe. Branch fitting selection shall be as per

branch selection table provided in each piping class.

- Butt-welding tees should be used for branches equal in diameter to the run

pipe. Butt-welding tees with equal or reducing outlets should be used for

services where flow disturbance is to be minimized.

- Economic aspects and service conditions shall be considered in the selection

of the reinforcing method.

- Where available, butt-welding tee fittings shall be used in severe cyclic service

(as defined in ASME B31.3).

- Branch connections shall not be made on elbows or concentric reducers.

Branch connections should not be made on eccentric reducers or tees but may

be made if the branch is maximum DN 40 and the run-size of the fitting at the

branch position is minimum DN 150. On eccentric reducers the branch shall be

located at the flat side of the reducer. On tees the branch shall be located

opposite the main branch of the tee.

- Welded branch connections shall be full penetration type. If any, pipe to pipe

connection should be reinforced with pads.

- For 90 degree branch connection size DN 40 and below in non-coated or lined

carbon steel piping classes, flanged branch fitting outlets shall be utilized in

lieu of bevel end branch outlet fittings.

砀 REDUCERS

Concentric or eccentric reducers shall be used:

- In case of a great difference between diameters the use of more than 2

reducers in line shall be avoided.

- Special items, "Divergent type" with 14 Deg or 22 Deg angle, could be used

when they are indicated on P&ID's. These special 14 and 22 Deg reducers are

to be used on piping which required minimum pressure drop or minimum

turbulent flow only (as per process requirement), and are subject to OWNER

approval.

Electronic Filename: RAPID-P0001-CCSM-PIP-SPN-1300-0001_1C.docx

Document Number

Rev. Page

Project Package Originator Discipline Doc. Type Unit n° Serial n°

1C 15 / 22

RAPID P0001 CCSM PIP SPN 1300 0001

PIPING MATERIAL SPECIFICATION

(P0001 – RFCC, LTU, PRU UNITS)

6. THREAD

砀 Threads for threaded pipes, fittings, flanges and valves shall be in accordance with

ASME B1.20.1 taper threads.

砀 Threaded joints shall not be used in any piping system handling flammable, toxic

fluid, process fluid, or cyclic service condition.

砀 Threaded steam traps may be used if it is located downstream of a piping valve.

砀 Threaded joints may be used only in galvanized piping (e.g. for fire water,

instrument air systems) DN 50 and smaller. The minimum wall thickness for these

shall be Schedule 80.

砀 Seal welding of threaded connections shall not be permitted.

7. VALVES

砀 DIMENSIONS (FACE TO FACE)

Unless otherwise specified, the face to face dimensions shall conform to ASME

B16.10.

砀 TRIM DEFINITION

Valve internals are defined in Attachment 1 in Trim column.

For ball valves, it includes stem, ball and seats materials.

For gate, globe and check valves, when a number is indicated, it refers to the trim

combination number defined in API Std 600, 602.

Alternative trim of valves shall be specified by EPCC Contractor, CCSM when

design temperature is not in accordance with the materials. Trim Duplex is limited

to 315°C max. For temperature more than 315°C, it is recommended to use SS

316 as a minimum.

砀 SELECTION OF GEAR OPERATOR

Type of Valve Rating NPS

150#

脂DN350

Gate Valves 300#

脂DN300

600#

脂DN150

Electronic Filename: RAPID-P0001-CCSM-PIP-SPN-1300-0001_1C.docx

Document Number

Rev. Page

Project Package Originator Discipline Doc. Type Unit n° Serial n°

1C 16 / 22

RAPID P0001 CCSM PIP SPN 1300 0001

PIPING MATERIAL SPECIFICATION

(P0001 – RFCC, LTU, PRU UNITS)

900# & 1500# 脂 DN100

2500#

脂DN80

150#, 300# & 600#

脂DN200

Globe Valves 900#

脂DN150

1500# & 2500#

脂DN80

150#

脂DN200 (FB)

脂DN250 (RB)

300#

脂DN150 (FB)

脂DN200 (RB)

Ball Valves

600# & 900# 脂DN100 (FB)

脂DN150 (RB)

1500# & 2500#

脂DN80 (FB)

脂DN100 (RB)

Butterfly Valves 150# & 300# 脂DN200

(except torque seated

valves "triple offset")

Plug Valves 150# 脂DN150

All Butterfly torque seated valves “Triple Offset” shall have a gear operator.

砀 BONNET TYPE SELECTION

For Gate, Globe, Check valves:

Type of Bonnet Rating NPS

Bolted Bonnet 150# to 600# All Diameters

900# Up to DN150

1500# Up to DN50

Pressure Seal Bonnet 900# 脂DN200

1500# 脂DN80

2500# 脂DN50

Welded Bonnet 2500# Up to DN40

砀 GATE VALVES

Electronic Filename: RAPID-P0001-CCSM-PIP-SPN-1300-0001_1C.docx

Document Number

Rev. Page

Project Package Originator Discipline Doc. Type Unit n° Serial n°

1C 17 / 22

RAPID P0001 CCSM PIP SPN 1300 0001

PIPING MATERIAL SPECIFICATION

(P0001 – RFCC, LTU, PRU UNITS)

Gate valves shall conform to:

API Std 602 / ISO 15761 for classes 150 to 1500 for diameters up to DN 40

included,

API Std 600 for classes 150 to 2500 (for valves above DN 600, ASME B16.34

shall be followed),

MSS SP-80 for nickel and nickel-copper valves,

The parallel slide Gate valves shall conform to BS 5157,

ASME B16.34 for Pressure Bonnet valves,

砀 GLOBE VALVES

Globe valves shall conform to:

API Std 602 / ISO 15761 for classes 150 to 1500 for diameters up to DN 40

included,

BS 1873 (+ ASME B16.34) for classes 150 to 2500 for diameters above DN 40.

砀 CHECK VALVES

Check valves shall conform to:

API Std 602 / ISO 15761 for classes 150 to 1500 for diameters up to DN 40

included,

API Std 594 for classes 150 to 2500 for dual plate check valves (Flanged and Lug

only),

BS 1868 (+ ASME B16.34) for classes 150 to 2500 for swing check,

MSS SP80 for nickel and nickel-copper valves,

Piston type check valves (DN15~40) for horizontal mounting only,

砀 BALL VALVES

Ball Valves shall conform to ISO 17292.

砀 PLUG VALVES

Plug Valves shall conform to API 599.

砀 BUTTERFLY VALVES

Electronic Filename: RAPID-P0001-CCSM-PIP-SPN-1300-0001_1C.docx

Document Number

Rev. Page

Project Package Originator Discipline Doc. Type Unit n° Serial n°

1C 18 / 22

RAPID P0001 CCSM PIP SPN 1300 0001

PIPING MATERIAL SPECIFICATION

(P0001 – RFCC, LTU, PRU UNITS)

Butterfly Valves shall conform to API 609 up to 600#,

Butterfly Valves shall conform to API 609 + ASME B16.34 for 900#.

砀 VALVE TESTS

Unless otherwise specified, valves shall be tested as per API 598

For Cryogenic service, valves shall conform to BS 6364.

For Firewater services, valves shall have the UL/FM Certification and additionally

Malaysian Laws and applicable regulatory requirements for all fire water piping

components for cast iron, bronze and plastic materials.

Testing of Fugitive Emission Tightness Class shall conform to PMRC MAR VA/124.

On hydrocarbon services, soft seat valves or valves incorporating soft seal shall

be fire tested and certified in accordance with ISO 10497, BS 6755 part 2, API 607

or API 6FA.

砀 SPECIFIC SERVICE

For steam services, valves DN150 and larger in ASME rating class 600 and higher

shall have a bypass valve for preheating and pressure balancing. The Bypass

valve shall be as follows which is shown on P&ID:

Bypass valve

For warming up of pipe

Main Valve For pressure

and for pressure

balancing of other

balancing of pipes with

pipes

limited volumes

DN150 DN20 DN25

DN200 DN20 DN40

DN250 DN25 DN40

DN300 DN25 DN50

DN350 DN25 DN50

DN400 DN25 DN80

DN450 DN25 DN80

DN500 DN25 DN80

DN600 DN25 DN100

Electronic Filename: RAPID-P0001-CCSM-PIP-SPN-1300-0001_1C.docx

Document Number

Rev. Page

Project Package Originator Discipline Doc. Type Unit n° Serial n°

1C 19 / 22

RAPID P0001 CCSM PIP SPN 1300 0001

PIPING MATERIAL SPECIFICATION

(P0001 – RFCC, LTU, PRU UNITS)

Valves for pure hydrogen or fluids containing hydrogen in piping classes 600 and

higher should be butt welded except for check valves and instrument isolation

valves which may be flanged.

8. FLANGES

砀 DIMENSIONS

Flanges specified with NPS 鐀 DN600 shall conform to ASME B16.5.

Flanges specified with DN650 鐀 NPS 鐀 DN1500 shall conform to ASME B16.47,

series A.

Flanges specified with NPS > DN1500 shall be calculated as per ASME B31.3 &

ASME VIII.

砀 FLANGE SURFACE FINISH

Unless otherwise specified, machining shall be in accordance with the referenced

standard.

Facing of flanges:

RF = Raised Face- Roughness (Ra) = 3,2 to 6,3 µm

FF = Flat Face- Roughness (Ra) = 6,3 to 12.5 µm

RTJ = Ring Joint -Roughness (Ra) = 1,6 µm maxi.

Galvanized Flanges:

After galvanizing, facing will show a regular aspect without any over thicknesses.

Serrated aspect will remain visible.

砀 HARDNESS OF FLANGE FACING

Flange facing which are to receive ring type joints (RTJ) shall feature the following

minimum hardness values :

Carbon steel = 120 HB

Austenitic stainless steel AISI 304L, 316L = 150 HB

Austenitic stainless steel AISI 304, 316, 321, 347 = 160 HB

Low temperature carbon steel (down to –46°C) = 160 HB

Alloy Steel (Cr < = 5%) = 150 HB

砀 ORIFICE FLANGES

Orifice flanges shall conform to ASME B16.36.

Electronic Filename: RAPID-P0001-CCSM-PIP-SPN-1300-0001_1C.docx

Document Number

Rev. Page

Project Package Originator Discipline Doc. Type Unit n° Serial n°

1C 20 / 22

RAPID P0001 CCSM PIP SPN 1300 0001

PIPING MATERIAL SPECIFICATION

(P0001 – RFCC, LTU, PRU UNITS)

9. GASKETS

Compressed Asbestos Fiber (CAF) and Man Made Mineral Fibers (MMMF) shall not

be used.

砀 FLAT GASKETS

Flat Gasket shall conform to ASME B16.21.

Graphite tanged insert gaskets shall be used instead of compressed asbestos

fiber (CAF) gaskets.

Where a flat face flange is required, the counter-flange shall also have a flat face

and full face gaskets shall be applied.

砀 METAL GROOVE GASKETS

For flanged connections above DN600, and for equipment shell flanges, metal

grooved AISI 316L/ graphite gaskets with a "lateral" profile height shall be selected.

Metal grooved gaskets with a convex profile shall only be used in special cases,

e.g. if metal grooved gaskets with a lateral profile cannot provide an adequate seal

(e.g. in weak flanges or where the flange facing is not perpendicular to the design

plane). Metal grooved gaskets with a convex profile may be used only if approved

by the OW NER.

砀 SPIRAL WOUND GASKETS

- Spiral wound gaskets shall confirm to ASME B16.20.

- For raised face flanges, spiral wound, AISI 304/316/321(As per piping class),

graphite-filled gaskets with inner and outer rings shall be used.

- The inner and outer ring material shall be suitable to the fluid it exposed to.

- Spiral wound / Monel 400 gaskets may be used up to a design temperature of

400 圂 .

- Spiral wound / lnconel 600/graphite gaskets may be used up to a design

temperature of 650 圂 .

- Spiral wound gaskets shall have a colour code in accordance with ASME

B16.20.

- Spiral wound gaskets shall not be used in sizes DN1000 and larger.

10. BOLTING

砀 GENERNAL

- Thread shall conform to ASME B1.1 (UNC up to 1”, 8UN 1-1/8” and larger).

Electronic Filename: RAPID-P0001-CCSM-PIP-SPN-1300-0001_1C.docx

Document Number

Rev. Page

Project Package Originator Discipline Doc. Type Unit n° Serial n°

1C 21 / 22

RAPID P0001 CCSM PIP SPN 1300 0001

PIPING MATERIAL SPECIFICATION

(P0001 – RFCC, LTU, PRU UNITS)

- Nuts shall conform to ASME B18.2.2.

- All alloy steel stud bolts and nuts shall be fluorocarbon coated for corrosion

protection when the temperature is less than 285°C.

砀 HYDRAULIC BOLT TENSION

- Hydraulic bolt tensioning shall be applied in the following cases:

SERVICE ASME RATING BOLT

CLASS

DIAMETER

All All

销50 mm

All 销1500

销38 mm

Hydrogen 销600 销38 mm

Critical applications (to be agreed All 销25 mm

between the Contractor and the

OWNER).

- Bolt tensioning shall be in accordance with ASME PCC1.

- All pressure bolting shall be per respecting piping class (stud bolt with 2 heavy

hex nuts)

11. GLASS-FIBRE REINFORCED PLASTIC (GRP)

GRP materials shall conform to:

PTS 31.40.10.19, Jan-2010, Glass-Fibre Reinforced Plastic Pipeline & Piping System

PTS 31.40.10.20, Dec 2009, Spoolable Fibre Reinforced Plastic Pipes

RAPID-FE1-TPX-PIP-DES-0001-9023_0, Project Specification – Glass Fibre

Reinforced Plastic Pipeline & Piping Systems (Supplement to PTS 31.40.10.19 dated

Jan. 2010)

RAPID-FE1-TPX-PIP-DES-0001-9024_0, Project Specification - Spoolable Fibre-

Reinforced Plastic Pipes (Supplement to PTS 31.40.10.20 dated Dec. 2009)

12. GALVANIZED PIPING

Galvanized piping in sizes DN15 up to DN50 should be constructed from pre-

galvanized screwed pipe and fittings according to piping classes 1G100(18011),

1G212(18012) and 1G211(18600).

Electronic Filename: RAPID-P0001-CCSM-PIP-SPN-1300-0001_1C.docx

Document Number

Rev. Page

Project Package Originator Discipline Doc. Type Unit n° Serial n°

1C 22 / 22

RAPID P0001 CCSM PIP SPN 1300 0001

PIPING MATERIAL SPECIFICATION

(P0001 – RFCC, LTU, PRU UNITS)

Galvanized piping DN80 up to DN100 should be made from pre-fabricated pipe spools

according to piping class 1G100(18011). These spools shall be flanged and shall be

restricted to shapes that permit hot dip galvanizing after fabrication. The maximum size

of these spools is limited by the available galvanizing bath and by the means of

transport.

Galvanizing shall be in accordance with ASTM A153 Grade B.

13. LICENSOR ADDITIONAL REQUIREMENTS

砀 UOP:

The concerned piping classes shall conform to SPN-UOP-1320-0008 - Standard

Specifications - Piping & Piping Class

砀 AXNENS:

The concerned piping classes shall conform to:

RAPID-LR2-AXN-PRO-DES-0001-0001-General Process Data Book

14. PIPING MATERIAL CLASS SUMMARY

Refer to ATTACHMENT-1

15. PIPE WALL THICKNESS TABLE

Refer to ATTACHMENT-2

16. PIPIING CLASSES DETAIL

Refer to ATTACHMENT-3

Electronic Filename: RAPID-P0001-CCSM-PIP-SPN-1300-0001_1C.docx

Document Number Rev. Page

Doc.

Project Package Originator Discipline Unit nº Serial nº

Type

RAPID P0001 CCSM PIP SPN 1300 0001 1C 1 / 8aaaaaaaaaaaa

ATTACHMENT - 1 PIPING MATERIAL CLASS SUMMARY

LICENSORS PIPING

DESIGN

RATING FACE MATERIAL

BLOCK VALVE

CLASS REFERENCES

RAPID PMRC

CONDITIONS

Symbol HEAT Fluid Cat DN

Remarks

SERVICE

&

CLASS CLASS AXENS UOP GASKET

CORROSION

P T TREATMENT type trim max

Modifications

ALLOWANCE

BOLTING (barg) (°C) (DN) (mm)

150 # RF

ABOVEGROUND SYSTEM

GATE (15-600)

Derived pipe class

Ra=3.2 to 6.3µm

LOW TEMPERATURE CARBON STEEL

316, Stellite 6

11001A-KS 1C101BQ-KS F BUTTERFLY TRIP OFFSET

1400

Valve type

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 3 mm

LTCS, Duplex, Stellite 6

3.5 -45 / 120 295

Flare Service (Flashing LPG)

(650-950)

CA=3mm

A320-L7 / A194-4

ABOVEGROUND SYSTEM

150 # RF

KILLED CARBON STEEL

Derived pipe class

Ra=3.2 to 6.3µm

316, Stellite 6 up to DN40

11003A 1C103BQ C.A.= 3 mm

17.7

80

10% Spent Caustic Soda

CCS PWHT GATE (15-450) 450

Valve type

Spiral Wound Graphite / 316/center CS/inner 316

13% Cr, Stellite 6 above DN40

HV @ 150°C

3.5

80

47% Fresh Caustic

Add PWHT

A193-B7 / A194-2H

3.5

75

Caustic Drain

-0.5

150

150 # RF

Derived pipe class

KILLED CARBON STEEL PE COATED

UNDERGROUND SYSTEM

Ra=3.2 to 6.3µm

316, Stellite 6 up to DN40

Valve type

11003B 1C103BR C.A.= 3 mm

CAD PWHT GATE (15-200) 200

Spiral Wound Graphite / 316/center CS/inner 316

13% Cr, Stellite 6 above DN40

Undeground

HV @ 150°C 3.5

75

Caustic Drain

A193-B7 / A194-2H

Add PWHT

-0.5

150

ABOVEGROUND SYSTEM

150 # RF

KILLED CARBON STEEL

Derived pipe class

Ra=3.2 to 6.3µm

Wet H2S Service - HIC

11007A 1C105BQ 17.8

75

Amine wet H2S service

PWHT GATE (15-350) 316, Stellite 6 350

Valve type

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 3 mm

3.9

80

Sour Gas (Amine service) wet H2S service

High Sour Service

A193-B7M / A194-2HM

HV @ 150°C

-0.5

150

Lean/Rich Amine Close Drain

ABOVEGROUND SYSTEM

150 # RF

GATE (15-600)

316, Stellite 6 up to DN40

PTS pipe class

KILLED CARBON STEEL

-0.5 / 4.7

150 / 65

Cold Fresh Crude non corrosive

Ra=3.2 to 6.3µm

13% Cr, Stellite 6 above DN40

900

Calculated as per

11011 1C108 C.A.= 1 mm

13

80

Low Pressure Nitrogen, Plant Air

LPN, IA, PA

Spiral Wound Graphite / 316/center CS/inner 316

BUTTERFLY TRIP OFFSET

CS, Duplex, Stellite 6

design condition for DN650

HV @ 150°C

15

75

Sweet Naphta

A193-B7 / A194-2H

(650-900)

and above

19.6 / 15.8

-9 / 150

Plant Air, Nitogen, Flue Gas, Fuel gas, Natural Gas, Combustion

ABOVEGROUND SYSTEM

15.5

75

Stripped Water

150 # RF

15

75

Sweet Hydrocarbon (liquid)

GATE (15-600)

316, Stellite 6 up to DN40

KILLED CARBON STEEL

PTS pipe class

Ra=3.2 to 6.3µm

H2O condensates

13% Cr, Stellite 6 above DN40

11031 1C114 C.A.= 3 mm

S,FOR,FLR,HHD 700

Calculated as per

Spiral Wound Graphite / 316/center CS/inner 316

3.5

75

Air Process (SGP)

BUTTERFLY TRIP OFFSET

CS, Duplex, Stellite 6

FV @ 160°C

design condition for DN650 and above

A193-B7 / A194-2H

9

135

Sweet Gas HC

(650-700)

-1 / 11.7

160 / 80

Fuel Gas, Fuel Oil, Flushing Oil

3.5

200

Heavy HC closed drain

15.9

95

Brine salt corrosion

ABOVEGROUND SYSTEM

Derived pipe class

11

85

Valve type

150 # RF

KILLED CARBON STEEL

15.6 / 16.7

120 / 80

Stabilizer Overhead wet H2S service

GATE (15-600)

Add PWHT

Ra=3.2 to 6.3µm

Wet H2S Service - HIC

316, Stellite 6

11036A 1C116BQ 15.6

75

Sour Gas wet H2S service

HHD,LHD PWHT BUTTERFLY TRIP OFFSET

800

DN to be Extended

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 3 mm

CS, Duplex, Stellite 6

15.7

75

Sour Hydrocarbon (liquid) wet H2S service

(650-800)

SS316 is required instead

A193-B7M / A194-2HM

HV @ 150°C

-0.5

150

Skim Oil

of Duplex for Temp

3.5

365

Heavy HC closed drain (ARDS & RFCC)

above 315°C

3.5

150

Light HC closed drain

ABOVEGROUND SYSTEM

16

75

Sour Water wet H2S service

150 # RF

KILLED CARBON STEEL

Derived pipe class

16.6

115

Sour Water

Ra=3.2 to 6.3µm

Wet H2S Service - HIC

Valve type

11036B 1C116BR 7

165

Acid Gas

SWD PWHT GATE (15-600) 316, Stellite 6 600

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 6 mm

Add PWHT

15.7

75

Sour Gas wet H2S service

A193-B7M / A194-2HM

HV @ 150°C

Corrosion 6mm

15.3

116

Sour Gas + Sour water wet H2S service (mixed phase)

-0.5

150

3.5

75

Sour water closed drain

UNDERGROUND SYSTEM

150 # RF

KILLED CARBON STEEL PE COATED

Derived pipe class

Ra=3.2 to 6.3µm

Wet H2S Service - HIC

Valve type

11036D 1C116BT 3.5

150

Light HC closed drain

LHD,HHD PWHT GATE (15-350) 316, Stellite 6 350

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 3 mm

Add PWHT

3.5 / -0.5

365 / 150

Heavy HC closed drain

A193-B7M / A194-2HM

HV @ 150°C

Undeground

17.8

75

Lean/Rich Amine Close Drain

ABOVEGROUND SYSTEM

Derived pipe class

150 # RF

KILLED CARBON STEEL

GATE (15-600)

Add PWHT

Ra=3.2 to 6.3µm

316, Stellite 6

11055A-20 1C119BQ-20 Wet H2S Service - HIC

3.5 -29 / 315 Acid Flare wet H2S service

AF,F PWHT BUTTERFLY TRIP OFFSET

2300

SS316 is required instead

Spiral Wound Graphite / 316/center CS/inner 316

CS, Duplex, Stellite 6

C.A.= 3 mm

Normal Flare

(650-900)

of Duplex for Temp

A193-B7M / A194-2HM

above 315°C

150 # RF

Project Piping Class

KILLED CARBON STEEL

ABOVEGROUND SYSTEM

Ra=3.2 to 6.3µm

High Sour Service

11073B 1C122BR Wet H2S Service - HIC

PWHT GATE (15-500) 316, Stellite 6 500

Spiral Wound Graphite / 316/center CS/inner 316

Add PWHT

C.A.= 6 mm 15.3 116

Sour Gas + Sour water wet H2S service (H2 service mixed phase)

A193-B7M / A194-2HM

Corrosion 6mm

ABOVEGROUND SYSTEM

Derived pipe class

Valve type

150 # RF

GATE (15-50)

316, Stellite 6 up to DN40

KILLED CARBON STEEL

Fresh Cooling Water supply,return

DN to be Extended

Ra=3.2 to 6.3µm

-1 / 14

75

CWS,CWR,AOC,SWS,RW,CHWS,

13% Cr, Stellite 6 above DN40

11201A 1C136BQ C.A.= 3 mm

Accidentaly Contamined Water, Sanitary Water

1600

Corrosion 3mm

Spiral Wound Graphite / 316/center CS/inner 316

16

75

CHWR,VA,STW,SW,UE,FW

BUTTERFLY Concent.

316, EPDM

FV @ 75°C

Raw Water, Chilled Water, Treated Water, Vent to ATM,

Calculated as per

A193-B7 / A194-2H

18.4

75

(80-3450)

Service Water, Storm Water, Fire Water Wet System, Tempered Water

design condition for DN650

17.7

100

Utilities Effluent

and above

15

100

Derived pipe class

Valve type

UNDERGROUND SYSTEM

150 # RF

GATE (15-50)

316, Stellite 6 up to DN40

DN to be Extended

Ra=3.2 to 6.3µm

KILLED CARBON STEEL PE COATED

13% Cr, Stellite 6 above DN40

Underground

11201B 1C136BR 14

75

Fresh Cooling Water supply,return

CWS,CWR,RW,WT,SW,COC 1600

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 3 mm

BUTTERFLY Concent.

316, EPDM

Corrosion 3mm

17.5

75

Raw Water, Treated Water, Service Water,

A193-B7 / A194-2H

(80-3450)

Calculated as per

ATM

100

Continuously Oily Contamined Water

design condition for DN650

and above

Document Number Rev. Page

Doc.

Project Package Originator Discipline Unit nº Serial nº

Type

RAPID P0001 CCSM PIP SPN 1300 0001 1C 2 / 8aaaaaaaaaaaa

ATTACHMENT - 1 PIPING MATERIAL CLASS SUMMARY

LICENSORS PIPING

DESIGN

RATING FACE MATERIAL

BLOCK VALVE

CLASS REFERENCES

RAPID PMRC

CONDITIONS

Symbol HEAT Fluid Cat DN

Remarks

SERVICE

&

CLASS CLASS AXENS UOP GASKET

CORROSION

P T TREATMENT type trim max

Modifications

ALLOWANCE

BOLTING (barg) (°C) (DN) (mm)

ABOVEGROUND SYSTEM

Derived pipe class

150 # RF

KILLED CARBON STEEL

GATE (15-600)

DN to be Extended

Ra=3.2 to 6.3µm

-1 / 9

295

Low Pressure Steam. Blowdown

316, Stellite 6

11261A 1C139BQ C.A.= 1 mm

SL,BB,LCC,LCP,CCC,STC,BB BUTTERFLY TRIP OFFSET

1500

Valve types

Spiral Wound Graphite / 316/center CS/inner 316

13

150

Low Pressure Steam Condensate

CS, Duplex, Stellite 6

FV @ 295°C

(650-1500)

Calculated as per

A193-B7 / A194-2H

Cold Condensate

design condition for DN650 and above

15

150

Blowdown

150 # RF

ABOVEGROUND SYSTEM

AXENS pipe class

KILLED CARBON STEEL

Ra=3.2 to 6.3µm

11500 1C211 A0-1F C.A.= 0 mm

GATE (15-200) 316, Stellite 6 300

Spiral Wound Graphite / 316/center CS/inner 316

12 80

Catalyst

Calculated as per

FV @ 425°C

A193-B7 / A194-2H

design condition

ABOVEGROUND SYSTEM

AXENS pipe class

5.5

296(500)

Combustion Air

SS316 is required instead

13

75

Cooling Water Return

of Duplex for Temp

13

75

Cooling Water Supply

above 315°C

3.5

315

Normal Flare

Transient temperatures

7

80

HP&LP Fuel Gas

are defined in brackets

150 # RF

12

80

Instrument Air

KILLED CARBON STEEL

GATE (15-600)

Ra=3.2 to 6.3µm

12

80

LP Nitrogen

316, Stellite 6

11501 1C211BS A3-1F C.A.= 3 mm

BUTTERFLY

1900*

**Design conditions shall be

Spiral Wound Graphite / 316/center CS/inner 316

12

80

Plant Air

CS, Duplex, Stellite 6

FV @ 425°C

(650-1900)

confirmed by EPCC Contractor

A193-B7 / A194-2H

17.3

75

Process Gas

8.7 / 26.6

90 / 75

Hydrogen Gas

* Maximum diameter

18.1 / 13.8 / 17

75 / 210 / 75

Process Liquid

shall be confirmed during

7.2

125

Close Drain

EPCC Phase

17.8

75

Process Mixture

Calculated as per

9

295

LP steam

design condition

13

120

Cold condensate

3.5

400

Atmospheric Vent

ABOVEGROUND SYSTEM

150 # RF

3.5

150

Dry Flare

LOW TEMPERATURE CARBON STEEL

GATE (15-600)

Ra=3.2 to 6.3µm

9.1

80

HP&LP Fuel Gas

316, Stellite 6

AXENS pipe class

11504 1C221BS B3-1F C.A.= 3 mm

BUTTERFLY TRIP OFFSET

1200

Spiral Wound Graphite / 316/center CS/inner 316

18.2

80

Process Gas

LTCS, Duplex, Stellite 6

FV @ 80°C

(650-1050)

A320-L7/A194-4

18.2

75

Process Liquid

18.2

75

Process Mixture

13.5

75

Sour Water

ABOVEGROUND SYSTEM

13.6

165

Normal Flare

AXENS pipe class

7

80

HP&LP Fuel Gas

Rating problem

150 # RF

KILLED CARBON STEEL

13.6

165

Process Gas

GATE (15-600)

Ra=3.2 to 6.3µm

Severe service "HIC resistant steel"

16.8

75

Process Liquid

316, Stellite 6

* Maximum diameter

11505 1C213BU A6H-1F PWHT BUTTERFLY TRIP OFFSET

1200*

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 6 mm

16.54

75

Process Mixture

CS, Duplex, Stellite 6

shall be confirmed during

(650-1200)

A193-B7M / A194-2HM

FV @ 214°C

7.3

240

Process Mixture

EPCC Phase

3.5

145

Acid Flare

Calculated as per

4.3

145

Closed drain

design condition

14.2

75

Sour Water

10

75

MDEA solution

AXENS pipe class

ABOVEGROUND SYSTEM

* Maximum diameter

150 # RF

KILLED CARBON STEEL

shall be confirmed during

Ra=3.2 to 6.3µm

Moderate service "wet H2S resistant steels"

7

75

Process Gas

11506 1C212BU A65-1F PWHT GATE (15-400) 316, Stellite 6 400*

EPCC Phase

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 6 mm

16.6

120

Process Liquid

A193-B7M / A194-2HM

FV @ 214°C

16.4

75

Process Mixture

Calculated as per

7.3

240

Process Mixture

design condition

AXENS pipe class

150 # RF

LOW TEMPERATURE CARBON STEEL

* Maximum diameter

ABOVEGROUND SYSTEM

Ra=3.2 to 6.3µm

Moderate service "wet H2S resistant steels"

shall be confirmed during

11507 1C222BS B3S-1F PWHT GATE (15-300) 316, Stellite 6 300*

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 3 mm

EPCC Phase

8.3 325

N2

A193-B7M / A194-2HM

FV @ 325°C

LTCS with in the range -18 oC and -45 oC. Impact testing at -48 圂 is

mandatory.

150 # RF

KILLED CARBON STEEL

ABOVEGROUND SYSTEM

UOP pipe class

B1A2- Ra=3.2 to 6.3µm

11600 1C214BS Wet H2S Service - HIC

PWHT GATE (15-100) 316, Stellite 6 100

Valves with MN on p&ID

NACE

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 3 mm 19.6 / 11.72 -29 / 260

Process with Hydrogen and wet Hydrogen sulfide

must have Alloy 400 trim

A193-B7M / A194-2HM

150 # RF

ABOVEGROUND SYSTEM

Ra=3.2 to 6.3µm

KILLED CARBON STEEL

11601 1C211BX B1A2 PWHT GATE (15-100) 13% Cr, Stellite 6 150 UOP pipe class

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 3 mm 19.6 / 7.4 -29 / 370

Caustic Soda, Rich Caustic, COS Solvent Spent Air

A193-B7 / A194-2H

Wash Oil/Disulphide Oil

150 # RF

ABOVEGROUND SYSTEM

Ra=3.2 to 6.3µm

KILLED CARBON STEEL

11602 1C211BR B1A1 GATE (15-50) 13% Cr, Stellite 6 150 UOP pipe class

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 1.5 mm 19.6 / 7.4 -29 / 370

Nitrogen, Hydrocarbons(Aromatics, Kero, Naphta)

A193-B7 / A194-2H

Disulphide Oil, Wash Oil

150 # RF

ABOVEGROUND SYSTEM

UOP pipe class

Ra=3.2 to 6.3µm

KILLED CARBON STEEL

11602 1C216 B1A1 GATE (15-50) 13% Cr, Stellite 6 150

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 1.5 mm 19.6 / 7.4 -29 / 370

Nitrogen, Hydrocarbons(Aromatics, Kero, Naphta)

(Interface Piping Class)

A193-B7 / A194-2H

Disulphide Oil, Wash Oil

150 # RF

ABOVEGROUND SYSTEM

Ra=3.2 to 6.3µm

KILLED CARBON STEEL

11603 1C211BV MS-11 GATE (15-40) 13% Cr, Stellite 6 40 UOP pipe class

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 1.5 mm

19.6 / 7.6 -29 / 370

Steam, Condensate and Boiler Feed Water

A193-B7 / A194-2H

150 # RF

ABOVEGROUND SYSTEM

Ra=3.2 to 6.3µm

KILLED CARBON STEEL

11604 1C211BW MS-1 GATE (15-150) Bronze 150 UOP pipe class

Asbestos free composition

C.A.= 1.5 mm

19.6 / 15.8 -29 / 150

Refinery Air and water

A307 Gr.B

Document Number Rev. Page

Doc.

Project Package Originator Discipline Unit nº Serial nº

Type

RAPID P0001 CCSM PIP SPN 1300 0001 1C 3 / 8aaaaaaaaaaaa

ATTACHMENT - 1 PIPING MATERIAL CLASS SUMMARY

LICENSORS PIPING

DESIGN

RATING FACE MATERIAL

BLOCK VALVE

CLASS REFERENCES

RAPID PMRC

CONDITIONS

Symbol HEAT Fluid Cat DN

Remarks

SERVICE

&

CLASS CLASS AXENS UOP GASKET

CORROSION

P T TREATMENT type trim max

Modifications

ALLOWANCE

BOLTING (barg) (°C) (DN) (mm)

AXENS pipe class

150 # RF

ABOVEGROUND SYSTEM

Rating problem

Ra=3.2 to 6.3µm

LOW ALLOY STEEL 1.25Cr - 0.5Mo

12500 1L211BS E3-1F PWHT GATE (15-500) 316, Stellite 6 500

Design conditions shall be

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 3 mm 6.6

340

Process Liquid

confirmed by EPCC

A193-B16 / A194-4

5.7

410

Hydrogen Gas

Contyractor

150 # RF

ABOVEGROUND SYSTEM

Ra=3.2 to 6.3µm

LOW ALLOY STEEL 5Cr - 0.5Mo

12501 1L213BU H6-1F PWHT GATE (15-600) 316, Stellite 6 600 AXENS pipe class

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 6 mm

6.6 370

Process Liquid

A193-B16 / A194-4

ABOVEGROUND SYSTEM

150 # RF

Ra=3.2 to 6.3µm

LOW ALLOY STEEL 5Cr - 0.5Mo

3.5

315

Normal Flare

12502 1L213BS H3-1F PWHT GATE (15-500) 316, Stellite 6 500 AXENS pipe class

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 3 mm

7

80

HP&LP Fuel Gas

A193-B16 / A194-4

3.9

320

Process Gas

5.2 / 9.3

340 / 315

Process Liquid

AXENS pipe class

150 # RF

Rating shall be confirmed by

ABOVEGROUND SYSTEM

GATE (15-600)

321, Stellite 6

Ra=3.2 to 6.3µm

LOW ALLOY STEEL 1.25Cr - 0.5Mo

EPCC Contractor

12507 1L211BR E2-1F PWHT

BUTTERFLY TRIP OFFSET

1,25Cr-0,5Mo, 321, Stellite 6 750

Spiral Wound Graphite / 321/center 321/inner 321

C.A.= 1.5 mm

Design conditions shall be

8.7 544

Process Gas

(650-750)

EN 10269 - 20CrMoVTiB4-10

confirmed, currently

used 300# for flange

ABOVEGROUND SYSTEM

150 # RF

STAINLESS STEEL 316/316L

GATE (15-600)

Ra=3.2 to 6.3µm

Wet H2S Service

316, Stellite 6

13021 1S105 13

75

Demineralised Water

DMW BUTTERFLY TRIP OFFSET

950 PTS pipe class

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 0 mm

316, Duplex, Stellite 6

9.8

120

Rich Amine service

(650-950)

A193-B7M / A194-2HM

FV @ 125°C

-1 / 3.5

125

Sour Gas

150 # RF

STAINLESS STEEL 316/316L

ABOVEGROUND SYSTEM

Ra=3.2 to 6.3µm

BALL (15-250)

PTFE Trim

13032 1S108 C.A.= 0 mm

LO 600 PTS pipe class

Spiral Wound Graphite / 316/center CS/inner 316

-0.01

64.4

BUTTERFLY (300-600)

SS, ALLOY 625, PTFE

FV @ 122°C

Lube Oil

A193-B7 / A194-2H

12.5

122

ABOVEGROUND SYSTEM

150 # RF

STAINLESS STEEL 316/316L

Ra=3.2 to 6.3µm

Wet H2S Service

13034 1S216 M1A1 -0.5 / 12.5

150 / 122

Spent Caustic (Neutralization Loop)

GATE(15-300) 316, Stellite 6 300 Project Piping Class

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 0 mm

Licensor Fluids :

A193-B8 Cl2 / A194-8

HV @ 150°C

19.0 / 7.4

-45 / 370

Water (CausticWater), Disulphide Oil(UOP)

150 # RF

ABOVEGROUND SYSTEM

STAINLESS STEEL 304/304L

Ra=3.2 to 6.3µm

13500 1S212BQ M11S-1F Moderate service "wet H2S resistant steels"

GATE (15-100) 316, Stellite 6 100 AXENS pipe class

Spiral Wound Graphite / 316/center CS/inner 316

8

65

Process Gas

C.A.= 0.75 mm

A193-B7M / A194-2HM

12

80

150 # RF

ABOVEGROUND SYSTEM

Ra=3.2 to 6.3µm

STAINLESS STEEL 316/316L

13501 1S215BQ K1-1F GATE (15-600) 316, Stellite 6 250 AXENS pipe class

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 0.75 mm 3.5

155

Process Gas

A193-B7 / A194-2H

3.5

155

Process Mixture

ABOVEGROUND SYSTEM

*

*

150 # RF

Sodium Hydroxide

13

75

Ra=3.2 to 6.3µm

STAINLESS STEEL 304/304L

Demineralised Water

AXENS pipe class

13502 1S211BQ M11-1F 12

80

GATE (15-250) 316, Stellite 6 250

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 0.75 mm

LP Nitrogen

*Design conditions can be confirmed by EPCC Contractor

*

*

A193-B7 / A194-2H

CCR Perchloroethylene

6.75

75

Process Gas

10.3

160

Process Liquid

3.5

75

150 # RF

ABOVEGROUND SYSTEM

Ra=3.2 to 6.3µm

STAINLESS STEEL 321

13503 1S217BQ N1-1F GATE (15-200) 321, Stellite 6 200 AXENS pipe class

Spiral Wound Graphite / 321/center 321/inner 321

C.A.= 0.75 mm

8.05 260

Process Gas

A193-B7 / A194-2H

150 # RF

Ra=3.2 to 6.3µm

STAINLESS STEEL 304/304L

ABOVEGROUND SYSTEM

13504 1S211BR 13 -30/100 GATE (15-100) 316, Stellite 6 900 Package BELCO pipe class B304LS

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 0.75 mm

Water W/ Catalyst

A193-B7 / A194-2H

150 # RF

ABOVEGROUND SYSTEM

Ra=3.2 to 6.3µm

STAINLESS STEEL 316/316L

13600 1S215BR L1A1 GATE (15-100) 316, Stellite 6 150 UOP pipe class

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 1.5 mm

15.9 / 7.4 -29 / 370

Demineralised Water

A193-B7 / A194-2H

150 # FF

Derived pipe class

GRP

UNDERGROUND SYSTEM

Ra=3.2 to 6.3µm

Ball 鐀 DN50

PTFE Trim

Valve type

17102A 1N103BQ Biphenol A

FW 600

Flat Face EPDM Gasket

Butterfly DN 80 to DN600

Alu-Brz/EPDM

17,5barg/75°C

C.A.= 0 mm 18.4 75

Fire Water Wet System

A193-B7 / A194-2H

Resin shall be confirmed by Supplier

150 # FF

UNDERGROUND SYSTEM

GRP

Derived pipe class

Ra=3.2 to 6.3µm

Ball 鐀 DN50

FRP/PTFE

17102B 1N103BR Atmospheric Pressure

FWR,AOC 1200

Valve type

Flat Face EPDM Gasket

ATM

60

Fire Water Return Off

Butterfly DN 80 to DN600

FRP/TFE

C.A.= 0 mm

Resin shall be confirmed by Supplier

A193-B7 / A194-2H

ATM

60

Accidently Oily Contamined Water

ABOVEGROUND SYSTEM

150 # RF

BALL(15-50), THR

PTS pipe class

Ra=3.2 to 6.3µm

KILLED CARBON STEEL GALVANIZED

1.5

75

Oil Mist

Alu Bronze, PTFE

18011 1G100 PW,FW,FS BUTTERFLY Lug

250

Thread Connection

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 0 mm

16

75

Potable Water

Alu Bronze, EPDM

(80-250)

up to DN50

A193-B7 / A194-2H

16

75

Fire Water Dry System

17.3

75

Foam Solution Dry System

Document Number Rev. Page

Doc.

Project Package Originator Discipline Unit nº Serial nº

Type

RAPID P0001 CCSM PIP SPN 1300 0001 1C 4 / 8aaaaaaaaaaaa

ATTACHMENT - 1 PIPING MATERIAL CLASS SUMMARY

LICENSORS PIPING

DESIGN

RATING FACE MATERIAL

BLOCK VALVE

CLASS REFERENCES

RAPID PMRC

CONDITIONS

Symbol HEAT Fluid Cat DN

Remarks

SERVICE

&

CLASS CLASS AXENS UOP GASKET

CORROSION

P T TREATMENT type trim max

Modifications

ALLOWANCE

BOLTING (barg) (°C) (DN) (mm)

150 # RF

KILLED CARBON STEEL GALVANIZED

Project Piping Class

ABOVEGROUND SYSTEM

BALL(15-50) FLG

Alu Bronze, PTFE

Ra=3.2 to 6.3µm

KILLED CARBON STEEL

50

Welded Galva upto DN50

18012 1G212

BUTTERFLY LUG

316, EPDM

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 0 mm

400

KCS for 3" &

13 80

Air Instrument

(80-400)

A193-B7 / A194-2H

C.A.= 1 mm

Above

AXENS pipe class

Pressure Vessel Scope

Transient temperatures

150 # RF

ABOVEGROUND SYSTEM

321H, Stellite 6

GATE (15-600)

are defined in

Ra=3.2 to 6.3µm

KILLED CARBON STEEL Refractory lining

Refractory Lining

18500 1G215BS A3L-1F BUTTERFLY TRIP OFFSET

*ID1000

brackets

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 3 mm 5.5

770(843)

Combustion Air

321H, Stellite 6

(650-*)

*ID is referring to Internal

A193-B7 / A194-2H

5.5

843

Refractory Lining

Diameter

The Refactory lining material shall be select during EPCC phase with

OWMER approval

ABOVEGROUND SYSTEM

300 # RF

KILLED CARBON STEEL

Derived pipe class

GATE(15-600)

Ra=3.2 to 6.3µm

Wet H2S Service - HIC

316, Stellite 6

Valve type

31007A 3C105BQ 47.5

75

Amine wet H2S service

PWHT BUTTERFLY TRIP OFFSET

900

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 3 mm

CS, Duplex, Stellite 6

High Sour Service

34.4

75

Sour Gas (Amine service) wet H2S service

(650-900)

A193-B7M / A194-2HM

HV @ 150°C

DN to be Extended

47.5

75

Rich Amine service

ABOVEGROUND SYSTEM

300 # RF

GATE (15-600)

316, Stellite 6 up to DN40

KILLED CARBON STEEL

Ra=3.2 to 6.3µm

-0.5 / 39

150 / 75

Cold Fresh Crude non corrosive

13% Cr, Stellite 6 above DN40

31011 3C108 C.A.= 1 mm

HPN, PA 900 PTS pipe class

Spiral Wound Graphite / 316/center CS/inner 316

40

80

HP Nitogen, Hot Air, Plant Air

BUTTERFLY TRIP OFFSET

CS, Duplex, Stellite 6

HV @ 150°C

A193-B7 / A194-2H

34.9

205

Sweet naphta

(650-800)

44

175

MP Boiler Feed Water

ABOVEGROUND SYSTEM

300 # RF

LOW TEMPERATURE CARBON STEEL

BALL (15-250)

Ra=3.2 to 6.3µm

Wet H2S Service - HIC

31.1

-35 / 75

Sour LPG wet H2S service (The minimum temperature is outside PTS piping class 31026-KS

316, Stellite 6

31026-KS 3C113-KS PWHT BUTTERFLY TRIP OFFSET

300 PTS pipe class

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 3 mm

range)

LTCS, Duplex, Stellite 6

(300)

A193-B7M / A194-2HM

HV @ 150°C

-0.5

150

Sour LPG (Caustic Service) wet H2S service

Sour Hydrocarbon Wet H2S (LPG)

ABOVEGROUND SYSTEM

25.4

125

Stripped Water

39

170

Hot Fresh Crude non corrosive

300 # RF

GATE (15-600)

316, Stellite 6 up to DN40

PTS pipe class

KILLED CARBON STEEL

-0.5

150

Ra=3.2 to 6.3µm

13% Cr, Stellite 6 above DN40

SS316 is required instead

31031 3C114 C.A.= 3 mm

34.9

205

Sweet Hydrocarbon (liquid)

S,FOR,FLR 750

Spiral Wound Graphite / 316/center CS/inner 316

BUTTERFLY TRIP OFFSET

CS, Duplex, Stellite 6

of Duplex for Temp

HV @ 150°C

34.3

75

Sweet Gas

A193-B7 / A194-2H

(650-700)

above 315°C

29.5

75

H2O condensates

44.1

100

Heavy Slops (cold)

29

130

Fuel Gas, Fuel Oil, Flushing Oil

15.9

165

Brine salt corrosion

300 # RF

KILLED CARBON STEEL

Derived pipe class

ABOVEGROUND SYSTEM

Ra=3.2 to 6.3µm

Wet H2S Service - HIC

Valve type

31036A 3C116BQ PWHT GATE (15-200) 316, Stellite 6 200

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 6 mm

Add PWHT

35.9 75

Sour Water wet H2S service

A193-B7M / A194-2HM

HV @ 150°C

Corrosion 6mm

ABOVEGROUND SYSTEM

300 # RF

KILLED CARBON STEEL

-0.5 / 32.9

150 / 75

Sour Gas wet H2S service

GATE (15-600)

Ra=3.2 to 6.3µm

Wet H2S Service - HIC

16.7 / 35.9

205 / 75

Sour Hydrocarbon (liquid) wet H2S service

316, Stellite 6

Derived pipe class

31055A 3C119BQ PWHT BUTTERFLY TRIP OFFSET

700

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 3 mm

21.6

180

Stripped Water (Sour service)

CS, Duplex, Stellite 6

Add PWHT

(600-700)

A193-B7M / A194-2HM

HV @ 150°C

29.4

150

Light Slops

44.1

100

Heavy Slops (cold)

25.3

165

Unst. Naphtha wet H2S service

300 # RF

Project Piping Class

KILLED CARBON STEEL

ABOVEGROUND SYSTEM

Ra=3.2 to 6.3µm

High Sour Service

31073B 3C122BR Wet H2S Service - HIC

PWHT GATE (15-400) 316, Stellite 6 400

Spiral Wound Graphite / 316/center CS/inner 316

Add PWHT

C.A.= 6 mm 36.2 113

Sour Gas + Sour water wet H2S service ( H2 service mixed phase)

A193-B7M / A194-2HM

Corrosion 6mm

300 # RF

LOW TEMPERATURE CARBON STEEL

ABOVEGROUND SYSTEM

BALL (15-250)

Ra=3.2 to 6.3µm

316, PTFE

31085 3C124 C.A.= 1 mm

BUTTERFLY TRIP OFFSET

400 PTS pipe class

Spiral Wound Graphite / 316/center CS/inner 316

LTCS, Duplex, Stellite 6

HV @ 150°C 31.1

-35 / 75

Sweet LPG

(300-400)

A320-L7/A194-4

-0.5

150

300 # RF

ABOVEGROUND SYSTEM

GATE (15-600)

316, Stellite 6 up to DN40

KILLED CARBON STEEL

Ra=3.2 to 6.3µm

13% Cr, Stellite 6 above DN40

31201A 3C211BV C.A.= 3 mm

CWS,CWR 900 Project pipe class

Spiral Wound Graphite / 316/center CS/inner 316

36.6

75

Cooling Water supply, return

BUTTERFLY TRIP OFFSET

CS, Duplex, Stellite 6

FV @ 75°C

A193-B7 / A194-2H

31.3

100

Tempered Water

(650-900)

Derived pipe class

Valve type

DN to be Extended

300 # RF

ABOVEGROUND SYSTEM

KILLED CARBON STEEL

GATE (15-600)

SS316 is required instead

Ra=3.2 to 6.3µm

316, Stellite 6

31261A 3C139BQ C.A.= 1 mm

SM,MCC,MCP,PCC BUTTERFLY TRIP OFFSET

1500

of Duplex for Temp

Spiral Wound Graphite / 316/center CS/inner 316

25

350

Medium Pressure Steam

CS, Duplex, Stellite 6

FV @ 100°C

(650-1500)

above 315°C

A193-B7 / A194-2H

-1

100

Medium Pressure Steam Condensate

Calculated as per

design condition for DN650

and above

300 # RF

KILLED CARBON STEEL

ABOVEGROUND SYSTEM

Ra=3.2 to 6.3µm

AXENS pipe class

31500 3C211 A0-3F C.A.= 0 mm

GATE (15-200) 316, Stellite 6 300

Spiral Wound Graphite / 316/center CS/inner 316

FV @ 425°C 12 425

Catalyst

A193-B7 / A194-2H

Document Number Rev. Page

Doc.

Project Package Originator Discipline Unit nº Serial nº

Type

RAPID P0001 CCSM PIP SPN 1300 0001 1C 5 / 8aaaaaaaaaaaa

ATTACHMENT - 1 PIPING MATERIAL CLASS SUMMARY

LICENSORS PIPING

DESIGN

RATING FACE MATERIAL

BLOCK VALVE

CLASS REFERENCES

RAPID PMRC

CONDITIONS

Symbol HEAT Fluid Cat DN

Remarks

SERVICE

&

CLASS CLASS AXENS UOP GASKET

CORROSION

P T TREATMENT type trim max

Modifications

ALLOWANCE

BOLTING (barg) (°C) (DN) (mm)

ABOVEGROUND SYSTEM

48.3

75

Hydrogen Gas

AXENS pipe class

44

175

Medium Pressure Boiler Feed Water

Transient temperatures

5.5

565(650)*

Process Gas

are defined in brackets

47.7

75

Process Liquid

Temperature for Process

300 # RF

KILLED CARBON STEEL

47.7

80

Process Mixture

GATE (15-600)

321H, Stellite 6

Gas up to 565 shall be

Ra=3.2 to 6.3µm

31501 3C211BS A3-3F

C.A.= 3 mm

9

295

LP Steam

BUTTERFLY TRIP OFFSET

321H, Stellite 6 1050*

confirmed during EPCC

Spiral Wound Graphite / 316/center CS/inner 316

FV @ 350°C

25

350

MP Steam

(650-1050)

Phase

A193-B7 / A194-2H

29.9

75

Sour Water

* Maximum diameter

22.8

75

Continious Oily Contamined

shall be confirmed during

10 / 35.5

400 / 200

LP Nitrogen

EPCC Phase

37.1

150

Process Gas

30.4

210

Process Gas

26.3

425

Process Gas

ABOVEGROUND SYSTEM

AXENS pipe class

48.3

75

Hydrogen Gas

Transient temperatures

44

175

Medium Pressure Boiler Feed Water

are defined in brackets

5.5

565(650)*

Process Gas

Temperature for Process

47.7

75

Process Liquid

300 # RF

Gas up to 565 shall be

KILLED CARBON STEEL

47.7

80

Process Mixture

GATE (15-600)

321H, Stellite 6

Ra=3.2 to 6.3µm

confirmed during EPCC

31501 3C215 A3-3F

C.A.= 3 mm

9

295

LP Steam

BUTTERFLY TRIP OFFSET

321H, Stellite 6 1050*

Spiral Wound Graphite / 316/center CS/inner 316

Phase

FV @ 350°C

25

350

MP Steam

(650-1050)

A193-B7 / A194-2H

* Maximum diameter

29.9

75

Sour Water

shall be confirmed during

22.8

75

Continious Oily Contamined

EPCC Phase

10 / 35.5

400 / 200

LP Nitrogen

37.1

150

Process Gas

(Interface Piping Class)

30.4

210

Process Gas

26.3

425

Process Gas

ABOVEGROUND SYSTEM

300 # RF

KILLED CARBON STEEL

AXENS pipe class

40.5

75

Amine(rich and lean)

GATE (15-600)

Ra=3.2 to 6.3µm

Severe service "HIC resistant steel"

316, Stellite 6

* Maximum diameter

31504 3C213BU A6H-3F 35.4

245

Process Gas

PWHT BUTTERFLY TRIP OFFSET

1200

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 6 mm

CS, Duplex, Stellite 6

shall be confirmed during

41.9

120

Process Liquid

(650-750)

A193-B7M / A194-2HM

FV @ 75°C

EPCC Phase

35.4

245

Process Mixture

35.4

75

Sour Water

ABOVEGROUND SYSTEM

300 # RF

KILLED CARBON STEEL

12

80

LP Nitrogen

AXENS pipe class

Ra=3.2 to 6.3µm

Moderate service "wet H2S resistant steels"

33.4

245

Process Gas

* Maximum diameter

31505 3C212BU A6S-3F PWHT GATE (15-500) 316, Stellite 6 600

Spiral Wound Graphite / 316/center CS/inner 316

C.A.= 6 mm

37.7

120

Process Liquid

shall be confirmed during

A193-B7M / A194-2HM

FV @ 75°C

37.1

275

Process Mixture

EPCC Phase

34.1

310

Process Mixture

29.9

75

Sour Water

AXENS pipe class

SS316 is required instead

ABOVEGROUND SYSTEM

300 # RF

of Duplex for Temp

LOW TEMPERATURE CARBON STEEL

GATE (15-600)

Ra=3.2 to 6.3µm

316, Stellite 6

above 315°C

31506 3C221BS B3-3F C.A.= 3 mm

32

340

Process Gas

BUTTERFLY TRIP OFFSET

1400

Spiral Wound Graphite / 316/center CS/inner 316

LTCS, Duplex, Stellite 6

* Maximum diameter

FV @ 340°C

35.5

75

Process Mixture

(650-1050)

A320-L7 / A194-4

shall be confirmed during

23

75

Sour Water

EPCC Phase

ABOVEGROUND SYSTEM

300 # RF

LOW TEMPERATURE CARBON STEEL