Professional Documents

Culture Documents

6g KSB

Uploaded by

Gut BeerliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6g KSB

Uploaded by

Gut BeerliCopyright:

Available Formats

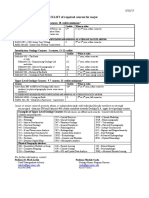

GASITE® 6G

BASIC SPECIFICATION CHEMICAL SPECIFICATION

Abrasion-resistant, nickel-chromium white iron Gasite® 6G is a GIW proprietary metal (manu-

facturing process patent # 4,638,847). This al-

FORM loy conforms in chemistry and physical proper-

Castings and machined castings ties to ASTM Standard A532-93a, Class I, Type

D.

MECHANICAL PROPERTIES

Tensile Strength ..........80-105 KSI ELEMENT ASTM GIW

Hardness ..........650 HBN/59 HRC Carbon..............2.5 - 3.6%..........3.2 - 3.5%

(per ASTM A532) Nickel................4.5 - 7%.............5.5 - 5.8%

Chromium...........7 - 11%.............8.5 - 10%

GIW furnishes chemistry and hardness for mill

test reports upon request. HEAT TREATMENT

Gasite® 6G is heat treated to increase its hard-

MICROSTRUCTURE ness, which results in maximum wear resistance.

Gasite® 6G is a refined Ni-Hard type 4, white-

iron alloy with superior toughness and strength. TEST SPECIMENS AND CERTIFICA-

Its microstructure consists of refined chromium TIONS

carbides and a mostly martensitic matrix. It has A chemical analysis of each heat is conducted

been an effective improvement over general Ni- prior to pouring. For further quality control, GIW

pours test bars randomly. After heat treating, the

tensile strength and hardness of the test bars are

measured and recorded, and the casting is checked

for uniform hardness at several locations.

APPLICATION

With its superior toughness, Gasite® 6G is well

suited for the manufacture of castings, such as

400X

d

gnifie

Ma GIW Industries Inc.

5000 Wrightsboro Road,

Grovetown, GA 30813-9750 USA

Telephone (706) 863-1011

Fax: (706) 863-5637

www.giwindustries.com

A KSB Company ·

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Welding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesFrom EverandWelding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesRating: 1 out of 5 stars1/5 (1)

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- The Essentials of Material Science and Technology for EngineersFrom EverandThe Essentials of Material Science and Technology for EngineersRating: 5 out of 5 stars5/5 (1)

- Customised Incisal GuideDocument3 pagesCustomised Incisal GuideGonçalo Cunha-Coutinho100% (1)

- Is - 1865 - 1991Document13 pagesIs - 1865 - 1991sangitaghaisas50% (2)

- ASTM C90700 - CuSn11 - Tin Bronze AlloysDocument1 pageASTM C90700 - CuSn11 - Tin Bronze Alloysİrem Şebnem SorucuNo ratings yet

- 2019 Usnco Exam Part III PDFDocument18 pages2019 Usnco Exam Part III PDFFernando RiosNo ratings yet

- 29g KSBDocument1 page29g KSBGut BeerliNo ratings yet

- F1886Document4 pagesF1886gaso99No ratings yet

- 34g KSBDocument1 page34g KSBGut BeerliNo ratings yet

- Stellite 6Document2 pagesStellite 6백승훈No ratings yet

- MAT Gasite 28G Dl-DataDocument1 pageMAT Gasite 28G Dl-DataCarlos HernándezNo ratings yet

- 65d KSBDocument1 page65d KSBGut BeerliNo ratings yet

- Synergy CatalogueDocument8 pagesSynergy CatalogueTino JuNo ratings yet

- Wall Colmonoy - Properties of Hard Surfacing Alloy Colmonoy 88 - July 2019Document8 pagesWall Colmonoy - Properties of Hard Surfacing Alloy Colmonoy 88 - July 2019joseocsilvaNo ratings yet

- G I Wire No. 8 & 10Document5 pagesG I Wire No. 8 & 10Dharmendra KumarNo ratings yet

- Austempering, A Heat Treating Process Ideal For Many High-Wear Applications, Is Not Just For Ductile IronDocument4 pagesAustempering, A Heat Treating Process Ideal For Many High-Wear Applications, Is Not Just For Ductile IronLizbeth Huerta LarumbeNo ratings yet

- Steel Strength and Hot Dip Galvanising INGALSM3Document6 pagesSteel Strength and Hot Dip Galvanising INGALSM3nasif andriantoNo ratings yet

- Varieties of SG IRONDocument3 pagesVarieties of SG IRONKharade RajendraNo ratings yet

- Letras RandomDocument2 pagesLetras RandomEnrique Paredes MercadoNo ratings yet

- Rockit 606 - 706 Combats Impact and Abrasive Wear - 2019 - 2653HOG PDFDocument2 pagesRockit 606 - 706 Combats Impact and Abrasive Wear - 2019 - 2653HOG PDFgersomNo ratings yet

- Is 10685-1983 (R.a. 2019)Document3 pagesIs 10685-1983 (R.a. 2019)HARIOM INSTRU-LABSNo ratings yet

- Ferrite in Stainless Steel Weld MetalDocument1 pageFerrite in Stainless Steel Weld MetalElizabeth SpenceNo ratings yet

- Stellite 6 DS01-21708 (S R0808)Document2 pagesStellite 6 DS01-21708 (S R0808)bwv1006No ratings yet

- Cast Iron Grades PDFDocument1 pageCast Iron Grades PDFAnurag JainNo ratings yet

- Stainless Steel Grade 630Document6 pagesStainless Steel Grade 630mazaher.ramazaniNo ratings yet

- Flux Cored Wire (FCW) : Typical Chemical Composition of All-Weld Metal (WT%) Product FeaturesDocument1 pageFlux Cored Wire (FCW) : Typical Chemical Composition of All-Weld Metal (WT%) Product FeaturesbudakgemukNo ratings yet

- S G Iron PDFDocument7 pagesS G Iron PDFYogesh AnapNo ratings yet

- pds-cpd-SikaWrap Hex100G-us PDFDocument2 pagespds-cpd-SikaWrap Hex100G-us PDFjohanes b mudaNo ratings yet

- Ees 6.8-1 Hard Chrome PlatingDocument5 pagesEes 6.8-1 Hard Chrome PlatingRobyn NashNo ratings yet

- Steel Shot and Grit To Sae J444, J827 & J1993 Specifications, Ams 2431/1C & 2C Peening Media Granite Cutting MediaDocument1 pageSteel Shot and Grit To Sae J444, J827 & J1993 Specifications, Ams 2431/1C & 2C Peening Media Granite Cutting Mediagowtham_venkat_4No ratings yet

- Hot Dip Galvan Neal EdDocument6 pagesHot Dip Galvan Neal EdEstuardoANo ratings yet

- Chung Hung Steel Corporation: Hot-Dip Galvanized Steel Coil Hot - Rolled Pickled and Oiled CoilDocument16 pagesChung Hung Steel Corporation: Hot-Dip Galvanized Steel Coil Hot - Rolled Pickled and Oiled Coilrahul srivastavaNo ratings yet

- 01 Track 2 - Armaki2 - 019 GDIS-Advantages of Fortiform 980 GI - Superior Weldability PDFDocument17 pages01 Track 2 - Armaki2 - 019 GDIS-Advantages of Fortiform 980 GI - Superior Weldability PDFSilverio AcuñaNo ratings yet

- Data Sheet For FRP Poles - SatyamDocument1 pageData Sheet For FRP Poles - SatyamSwarup NayakNo ratings yet

- Cast Nylon PDFDocument2 pagesCast Nylon PDFrohitdakngNo ratings yet

- 6C High Strength Reinforcement G HalstedDocument36 pages6C High Strength Reinforcement G HalstedRafid RabbaniNo ratings yet

- GGG 40Document1 pageGGG 40Wahyu HidayatNo ratings yet

- Shs 7214 Gmaw: Edefining TeelDocument2 pagesShs 7214 Gmaw: Edefining TeelamitNo ratings yet

- G60X00Document8 pagesG60X00Rafael Atayde GlaussNo ratings yet

- Spheroidal Graphite (SG) Acicular / MartensiticDocument2 pagesSpheroidal Graphite (SG) Acicular / MartensiticTarun ChakrabortyNo ratings yet

- EN-GJS-450-10, ASTM A536 65-45-12, Ductile Iron, SG Iron Chemical Composition, Mechanical and Physical PropertiesDocument2 pagesEN-GJS-450-10, ASTM A536 65-45-12, Ductile Iron, SG Iron Chemical Composition, Mechanical and Physical PropertiesBbiettg AndiarNo ratings yet

- GT E 201808 LowDocument32 pagesGT E 201808 Lowwataneta valveNo ratings yet

- Bisalloy Bisplate Technical ManualDocument90 pagesBisalloy Bisplate Technical Manualshaun_saggersNo ratings yet

- Iron Castings With Spheroidal or Nodular Graphite - Specification (Document13 pagesIron Castings With Spheroidal or Nodular Graphite - Specification (Lipika GayenNo ratings yet

- Hot Dip Galvanizing The Best Protection Inside and OutDocument8 pagesHot Dip Galvanizing The Best Protection Inside and OuttabacauNo ratings yet

- CZ120 (CW612N) : Technical DatasheetDocument1 pageCZ120 (CW612N) : Technical DatasheetAmrut KanungoNo ratings yet

- Galvanizing500Ngradereinforcingbar INGALSM3Document7 pagesGalvanizing500Ngradereinforcingbar INGALSM3Adhie RakhmadiNo ratings yet

- Duraform Pa Plastic: General Properties FeaturesDocument2 pagesDuraform Pa Plastic: General Properties FeaturesMarouane MbarkiNo ratings yet

- 06 SteelDocument3 pages06 SteelEmre TorunNo ratings yet

- Geomembrane Technical DataDocument1 pageGeomembrane Technical DataYusufAliMuktiNo ratings yet

- BIS0073-Technical Guide Update-April 2015Document104 pagesBIS0073-Technical Guide Update-April 2015Samial HasnatNo ratings yet

- Case Study Papers On Practical Guidelines For The Inspection and Repair of Hot Dip Galvanized CoatingsDocument14 pagesCase Study Papers On Practical Guidelines For The Inspection and Repair of Hot Dip Galvanized Coatingstekno foniNo ratings yet

- GTD 111 AlloyDocument7 pagesGTD 111 AlloyJJNo ratings yet

- 3 & 4 Point Flexural Bend Fixtures: Modular & ConfigurableDocument4 pages3 & 4 Point Flexural Bend Fixtures: Modular & ConfigurableMuhammad Bin RiazNo ratings yet

- Whitmore BMG-6000 Open Gear LubricantDocument1 pageWhitmore BMG-6000 Open Gear LubricantDon HowardNo ratings yet

- Applications of Austempered Cast IronsDocument10 pagesApplications of Austempered Cast IronsSatya PalNo ratings yet

- AKG Bearings - SRBDocument2 pagesAKG Bearings - SRBWahyu HadiNo ratings yet

- Hydro Aluminium - AlSi7Mg0 3Document2 pagesHydro Aluminium - AlSi7Mg0 3Raj PrasanthNo ratings yet

- Proceedings of the 8th International Symposium on Superalloy 718 and DerivativesFrom EverandProceedings of the 8th International Symposium on Superalloy 718 and DerivativesNo ratings yet

- Newton's Law of ViscosityDocument8 pagesNewton's Law of ViscosityAn FakeihahNo ratings yet

- Plantacare Line (OPP)Document1 pagePlantacare Line (OPP)paromanikNo ratings yet

- Aggregates - Relative Density For StudentsDocument35 pagesAggregates - Relative Density For StudentsRania FitouriNo ratings yet

- Xypex ConcDocument4 pagesXypex ConcDariel Cedeño CastilloNo ratings yet

- Enzymology Exam 2020-2021Document2 pagesEnzymology Exam 2020-2021Marco CalixtoNo ratings yet

- Wearing On Her Nerves Case Study - Werner Williams Mccool Floyd AhmadDocument50 pagesWearing On Her Nerves Case Study - Werner Williams Mccool Floyd Ahmadapi-320365850100% (2)

- MicrobiologyDocument115 pagesMicrobiologyNitish Kumar MVNo ratings yet

- Fermentation Kinetics For The Production of Ethanol by ImmobilizeDocument278 pagesFermentation Kinetics For The Production of Ethanol by ImmobilizeFitria Nur LailyNo ratings yet

- Accepted Manuscript: Microporous and Mesoporous MaterialsDocument29 pagesAccepted Manuscript: Microporous and Mesoporous MaterialsbhrNo ratings yet

- Talanta: Noemí León-Roque, Mohamed Abderrahim, Luis Nuñez-Alejos, Silvia M. Arribas, Luis Condezo-HoyosDocument9 pagesTalanta: Noemí León-Roque, Mohamed Abderrahim, Luis Nuñez-Alejos, Silvia M. Arribas, Luis Condezo-HoyosDino J. Flores BasilioNo ratings yet

- TITAS-383-PCT-ITP-0001 Rev.0 - CoatingDocument7 pagesTITAS-383-PCT-ITP-0001 Rev.0 - Coatingismail batinNo ratings yet

- Pesticide in FoodDocument14 pagesPesticide in FoodSajib RezaNo ratings yet

- MSDS For CorbolineDocument11 pagesMSDS For Corbolinesudeesh kumarNo ratings yet

- Microwave Assisted Solid Phase Microextraction For Extraction and Selective Enrichment of Four Alkaloids in Lotus LeafDocument8 pagesMicrowave Assisted Solid Phase Microextraction For Extraction and Selective Enrichment of Four Alkaloids in Lotus LeafAndres Fernando Silvestre SuarezNo ratings yet

- Ford f150 2019 Electrical Wiring DiagramDocument22 pagesFord f150 2019 Electrical Wiring Diagramsamuelwilliams190691rmw99% (99)

- Plain and Steel-Laminated Elastomeric Bearings For BridgesDocument1 pagePlain and Steel-Laminated Elastomeric Bearings For BridgesMirza SakibNo ratings yet

- Writable Uploads Resources Files GEAS 03-01 To GEAS 03-13 QuestionnaireDocument4 pagesWritable Uploads Resources Files GEAS 03-01 To GEAS 03-13 QuestionnaireRose Ann CalloNo ratings yet

- Fosroc Dekguard S: Constructive SolutionsDocument4 pagesFosroc Dekguard S: Constructive SolutionsshazibNo ratings yet

- G2 Atenas, Charlene - Experiment PaperDocument9 pagesG2 Atenas, Charlene - Experiment PaperRance LozanoNo ratings yet

- 1 Secondary - Homework Sheet: H Oh Academy For ChemistryDocument7 pages1 Secondary - Homework Sheet: H Oh Academy For ChemistryMark FahimNo ratings yet

- Contoh Pengiraan Masma PDFDocument4 pagesContoh Pengiraan Masma PDFMohd AzwanNo ratings yet

- 12090sd - GRANIT MAXIMUM 15W-40 (GB)Document8 pages12090sd - GRANIT MAXIMUM 15W-40 (GB)TAREK HAMADNo ratings yet

- Physical Sciences P2 Memo A EDocument9 pagesPhysical Sciences P2 Memo A Erowan chibiNo ratings yet

- Thermo Spectronic Genesys 6 Manual: Read/DownloadDocument3 pagesThermo Spectronic Genesys 6 Manual: Read/DownloadaseelNo ratings yet

- Application Note No. 065/2011: Total SO in WineDocument14 pagesApplication Note No. 065/2011: Total SO in WineLina Budi RahayuNo ratings yet

- Geology BA Checklist PDFDocument1 pageGeology BA Checklist PDFSami AjNo ratings yet

- The Reaction Between Methyl Benzene and ChlorineDocument7 pagesThe Reaction Between Methyl Benzene and ChlorineJessiee YeoNo ratings yet