Professional Documents

Culture Documents

Subcontracting 2

Subcontracting 2

Uploaded by

Ravi Teja0 ratings0% found this document useful (0 votes)

3 views1 pageIn the subcontracting process, a company provides raw materials to a subcontractor to produce finished goods. The company creates a bill of materials for the finished product, records subcontracting information like the vendor, plant, validity period, and price. It then issues a purchase requisition and purchase order to the subcontractor, providing the required raw materials. Upon completion, the subcontractor sends the finished goods back to the company, and the company issues a goods receipt.

Original Description:

Original Title

subcontracting-2

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentIn the subcontracting process, a company provides raw materials to a subcontractor to produce finished goods. The company creates a bill of materials for the finished product, records subcontracting information like the vendor, plant, validity period, and price. It then issues a purchase requisition and purchase order to the subcontractor, providing the required raw materials. Upon completion, the subcontractor sends the finished goods back to the company, and the company issues a goods receipt.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views1 pageSubcontracting 2

Subcontracting 2

Uploaded by

Ravi TejaIn the subcontracting process, a company provides raw materials to a subcontractor to produce finished goods. The company creates a bill of materials for the finished product, records subcontracting information like the vendor, plant, validity period, and price. It then issues a purchase requisition and purchase order to the subcontractor, providing the required raw materials. Upon completion, the subcontractor sends the finished goods back to the company, and the company issues a goods receipt.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 1

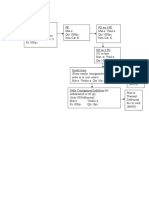

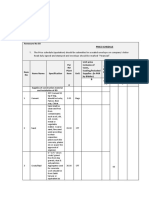

Subcontracting process: In this process material procures from vendor by providing

required component or input materials from our company to vendor.

We can go with subcontracting process due to lack of skilled technicians or lack

of infrastructure or lack of time

Mat-x

(Finished

mat)

Receive end product i.e

Mat-Y Mat-z Mat –z from subcontractor

(Semi finished) (Semi

finished)

Mat-a Mat-b Mat-c Mat-d

(Raw mat) (Raw (Raw (Raw

mat) mat) mat)

Subcon

Provide input materials tractor

i.e mat-c 10 pc

mat-d 10 pc

to subcontractor

Create BOM for Subcontracting Info record Purchase Requistion

End product Mat-z Vend –z Mat-z Qty 10 pc

Mat-z 1pc Plant-z P.org-z In Subcontracting process

Comp qty In Subcontracting process By providing input

Mat-c 2pc Validity period materials i.e mat-c 20pc

Mat-d 3pc 1st apr 19 to 31st mar20 Mat-d 30pc

Rs 100/pc To subcontractor

Purchase Order w.r.t PR

Mat-z Vend-z Qty10pc Rs 100/pc

In Subcontracting process

Providing input materials are

Goods

Mat-cIssue

20pc w.r.t

and PO

Mat-d 30pc

Mat-c 20pc Issue Store-x

Goods Receipt Mat-d 30pc Vedn-Z

IRw.r.t PO for w.r.t PO

Mat-z 10pc Mat-z Qty 10pc

Rs 100/pc +

Service tax 10%

You might also like

- The Cinematic VR Field GuideDocument68 pagesThe Cinematic VR Field GuideGrant Anderson100% (1)

- PDFDocument35 pagesPDFSurya Harta Adi50% (2)

- Assignments PHM2612 Skills Self-Assessment QuizDocument3 pagesAssignments PHM2612 Skills Self-Assessment QuizValentina BibkoNo ratings yet

- Engineering EconomicsDocument3 pagesEngineering EconomicsRaffey Arslan50% (2)

- EMD-003-0 Pre-Used Inspection Checklist For EquipmentsDocument31 pagesEMD-003-0 Pre-Used Inspection Checklist For EquipmentsArjay AlvarezNo ratings yet

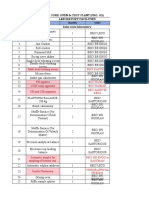

- Description Total Price (Taka) Qty SL No. VAT Amount (Taka) Supply Unit SD (Taka) VAT Rate Total Price (Taka) Per Unit Price (Taka) SDDocument1 pageDescription Total Price (Taka) Qty SL No. VAT Amount (Taka) Supply Unit SD (Taka) VAT Rate Total Price (Taka) Per Unit Price (Taka) SDSaimus SadatNo ratings yet

- ConsignmentDocument1 pageConsignmentkishoreNo ratings yet

- Daily Progress Report: Project MM Lokesh Rao AppartmentDocument2 pagesDaily Progress Report: Project MM Lokesh Rao AppartmentROOPA K PNo ratings yet

- NoidaDocument6 pagesNoidaAvnish KumarNo ratings yet

- Note: Rates of Note: Rates of All Items Should Be Inclusive of All Items Should Be Inclusive of All Supply and Carriage All Supply and Carriage.. Page: 6 of 295 Page: 6 of 295Document1 pageNote: Rates of Note: Rates of All Items Should Be Inclusive of All Items Should Be Inclusive of All Supply and Carriage All Supply and Carriage.. Page: 6 of 295 Page: 6 of 295Narayan Chandra GharamiNo ratings yet

- Equipment ListDocument1 pageEquipment ListRentcon TradingNo ratings yet

- Overall Plan vs. ProductionDocument24 pagesOverall Plan vs. Productionsoyeb60No ratings yet

- Six Sigma Sample PresentationDocument25 pagesSix Sigma Sample Presentationsa_arunkumarNo ratings yet

- MATERIAL Mig ExplanationDocument86 pagesMATERIAL Mig ExplanationGeorgia KyriakidouNo ratings yet

- Unloading Scaling FrequencyDocument1 pageUnloading Scaling FrequencyRezeki SimamoraNo ratings yet

- Directorate General Mis/Fabs: IslamabadDocument7 pagesDirectorate General Mis/Fabs: IslamabadnaveedNo ratings yet

- Formulas MASDocument1 pageFormulas MASRay Allen PabiteroNo ratings yet

- Procurement Analytics - Dashboard TemplateDocument1 pageProcurement Analytics - Dashboard TemplateAiman BoriNo ratings yet

- Types of BusinessDocument1 pageTypes of BusinessSwapnaKarma BhaktiNo ratings yet

- Face To Face Meeting - August 2020 (Sales)Document286 pagesFace To Face Meeting - August 2020 (Sales)aji widiatmokoNo ratings yet

- Batu Bidur Storage - KosongDocument1 pageBatu Bidur Storage - KosongKiky Tri RizkiNo ratings yet

- Cost AccountingDocument16 pagesCost AccountingBellaNo ratings yet

- Roq CceccbdDocument1 pageRoq CceccbdAvisheak PalNo ratings yet

- DSQ04A11Document1 pageDSQ04A11nafurahmanNo ratings yet

- Pantheon Complete Portal MockupDocument1 pagePantheon Complete Portal Mockupharrison.schickNo ratings yet

- Steps of Mfca-7 AgesDocument7 pagesSteps of Mfca-7 AgesErlia AgastyaNo ratings yet

- TNA & Pre-Production StatusDocument10 pagesTNA & Pre-Production StatusMahibur RahmanNo ratings yet

- Page 2 of 3Document2 pagesPage 2 of 3ShahidNo ratings yet

- Wo - 0003 (G)Document1 pageWo - 0003 (G)akbarNo ratings yet

- Daking Propose 1Document1 pageDaking Propose 1KaJong JaclaNo ratings yet

- PG 6Document4 pagesPG 6Prish AnandNo ratings yet

- BLDG Rates 72 73Document55 pagesBLDG Rates 72 73SarinNo ratings yet

- Job Information: Job No Sheet No RevDocument3 pagesJob Information: Job No Sheet No RevJedidiahClementNo ratings yet

- Dhading Rate Summary 9.14.2018Document17 pagesDhading Rate Summary 9.14.2018Vishal VishwakarmaNo ratings yet

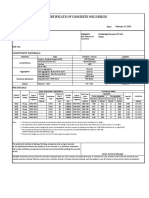

- Certificate of Concrete Mix Design: Strength - Performance - PassionDocument1 pageCertificate of Concrete Mix Design: Strength - Performance - PassionRamesh F SinghNo ratings yet

- Harta Packaging Industries (Perak) Sdn. BHD.: FSC Daily Summary Report (Mock Test)Document2 pagesHarta Packaging Industries (Perak) Sdn. BHD.: FSC Daily Summary Report (Mock Test)Osh 0717No ratings yet

- Break Down Condenser Support A (Rev 1) - 1Document4 pagesBreak Down Condenser Support A (Rev 1) - 1Jekyy GunawanNo ratings yet

- Garcia Alfaro Sergio NepiDocument7 pagesGarcia Alfaro Sergio NepiSergio Garcia AlfaroNo ratings yet

- rptf-191 Top T A Final pfv2Document32 pagesrptf-191 Top T A Final pfv2api-558760998No ratings yet

- July 15 PDFDocument4 pagesJuly 15 PDFShimu ShahrearNo ratings yet

- ST23-2409-3229 Strike-Off Development in Q984 (Evolon)Document1 pageST23-2409-3229 Strike-Off Development in Q984 (Evolon)Zafar IqbalNo ratings yet

- Sistem Perhitungan Biaya Dan Akumulasi BiayaDocument12 pagesSistem Perhitungan Biaya Dan Akumulasi BiayaLidya Hanum KartikaNo ratings yet

- CAF N21 Lec 09Document9 pagesCAF N21 Lec 09Article.vva CNGSNNo ratings yet

- Ega in Ais: 7H Semusterc Final Prog (Paper Course Name) Heeountina RDocument11 pagesEga in Ais: 7H Semusterc Final Prog (Paper Course Name) Heeountina RwajiceNo ratings yet

- ST22-6541-8548 Starch FinishDocument1 pageST22-6541-8548 Starch FinishZafar IqbalNo ratings yet

- Procurement TemplateDocument1 pageProcurement TemplatechethanshivramNo ratings yet

- Escf Bse0007Document5 pagesEscf Bse0007poorneema ramachandranNo ratings yet

- I. Concrete WorksDocument3 pagesI. Concrete WorksCyrene May BueNo ratings yet

- Konsep Menyusun Estimasi Rab Proyek Infrastruktur JalanDocument35 pagesKonsep Menyusun Estimasi Rab Proyek Infrastruktur JalanMuhammad SetyadiNo ratings yet

- Land Port ChargesDocument5 pagesLand Port ChargesMd Robin HossainNo ratings yet

- ITEMS EPCI CTR TO DELIVER TO CC CTR - Rev04Document5 pagesITEMS EPCI CTR TO DELIVER TO CC CTR - Rev04Ik NjokuNo ratings yet

- NotesDocument100 pagesNotesbharatreddy9No ratings yet

- Tarife Constructori Downloaded - FileDocument4 pagesTarife Constructori Downloaded - Filejulian nikoNo ratings yet

- SPL ProcurementDocument49 pagesSPL ProcurementMallu LoharNo ratings yet

- Pricing ProcedureDocument3 pagesPricing Procedurenanigang880No ratings yet

- Kodad Municipality Work SlipDocument2,238 pagesKodad Municipality Work SlipSRIHARINo ratings yet

- CPS EHS Daily Report - MAR 2024-7Document3 pagesCPS EHS Daily Report - MAR 2024-7rraman12347No ratings yet

- Boq 945244Document3 pagesBoq 945244Eng.JIMNo ratings yet

- List of Equipment - Code & Rent: Earth WorksDocument3 pagesList of Equipment - Code & Rent: Earth WorksbolsamirNo ratings yet

- ITEMS EPCI CTR TO DELIVER TO CC CTR Rev05Document5 pagesITEMS EPCI CTR TO DELIVER TO CC CTR Rev05Ik NjokuNo ratings yet

- Daily Prod Report SGB 05 - 07 - 2022Document2 pagesDaily Prod Report SGB 05 - 07 - 2022Said PrayogiNo ratings yet

- Daily Manpower Report FormatDocument1 pageDaily Manpower Report FormatJAZPAKNo ratings yet

- Daily Activity Report Oct 11, 2023Document3 pagesDaily Activity Report Oct 11, 2023rogelio sorianoNo ratings yet

- Tybms Operation ResearchDocument2 pagesTybms Operation ResearchSuhas LawandNo ratings yet

- BOQ Lot 3 RajanpurDocument4 pagesBOQ Lot 3 RajanpurEngr kashifNo ratings yet

- Rahul AadharDocument2 pagesRahul AadharRavi TejaNo ratings yet

- Cover LetterDocument1 pageCover LetterRavi TejaNo ratings yet

- Third Party ProcurementDocument1 pageThird Party ProcurementRavi TejaNo ratings yet

- Indent Note For Mecon BPP Lab EssentialDocument2 pagesIndent Note For Mecon BPP Lab EssentialRavi TejaNo ratings yet

- ContractDocument1 pageContractRavi TejaNo ratings yet

- Indent Note For Mecon BPP GlasswareDocument1 pageIndent Note For Mecon BPP GlasswareRavi TejaNo ratings yet

- Tar Silicaware & Accessories 040523-2Document2 pagesTar Silicaware & Accessories 040523-2Ravi TejaNo ratings yet

- Annexure - 2Document12 pagesAnnexure - 2Ravi TejaNo ratings yet

- Invoice 7214276INDocument1 pageInvoice 7214276INRavi TejaNo ratings yet

- Organizational LevelsDocument1 pageOrganizational LevelsRavi TejaNo ratings yet

- Coke Oven LabDocument3 pagesCoke Oven LabRavi TejaNo ratings yet

- NMDCDocument31 pagesNMDCRavi TejaNo ratings yet

- Technical RequirementsDocument5 pagesTechnical RequirementsRavi TejaNo ratings yet

- Standard Mark: Bureau of Indian Standards Act, 1986Document1 pageStandard Mark: Bureau of Indian Standards Act, 1986Ravi TejaNo ratings yet

- Dept Name - CRCL Status of Spares & ContractsDocument5 pagesDept Name - CRCL Status of Spares & ContractsRavi TejaNo ratings yet

- Disclosure To Promote The Right To Information: IS 13502 (1992) : Pig Iron (MTD 6: Pig Iron and Cast Iron)Document11 pagesDisclosure To Promote The Right To Information: IS 13502 (1992) : Pig Iron (MTD 6: Pig Iron and Cast Iron)Ravi TejaNo ratings yet

- Sub: Sampling and Chemical Testing of Coal by CRCL Department in NISP, NagarnarDocument1 pageSub: Sampling and Chemical Testing of Coal by CRCL Department in NISP, NagarnarRavi TejaNo ratings yet

- Udata Bhaskara RavitejaDocument1 pageUdata Bhaskara RavitejaRavi TejaNo ratings yet

- SMS ASTM 187 192 KrollsDocument5 pagesSMS ASTM 187 192 KrollsRavi TejaNo ratings yet

- Nitish Kpa 1Document4 pagesNitish Kpa 1Ravi TejaNo ratings yet

- Udata Bhaskara RavitejaDocument1 pageUdata Bhaskara RavitejaRavi TejaNo ratings yet

- Theoretical Calculation of Strain Hardening ExponentDocument4 pagesTheoretical Calculation of Strain Hardening ExponentRavi TejaNo ratings yet

- Do It With Electrons ! IIDocument37 pagesDo It With Electrons ! IIRavi TejaNo ratings yet

- Independent Slip Systems in CrystalsDocument12 pagesIndependent Slip Systems in CrystalsRavi Teja100% (1)

- Ice E083-E-Pjw-101-3a - Electrical Single Line Diagram - Sheet 3 - Mv-t2, Mvsb-t3, Mvsb-pb1, Mvsb-pb2, Mvsb-T4a, Mvsb-t4bDocument1 pageIce E083-E-Pjw-101-3a - Electrical Single Line Diagram - Sheet 3 - Mv-t2, Mvsb-t3, Mvsb-pb1, Mvsb-pb2, Mvsb-T4a, Mvsb-t4bAn BuiNo ratings yet

- Marine BiologyDocument46 pagesMarine Biologyoytun100% (1)

- Leadership and ManagementDocument2 pagesLeadership and ManagementMuhammad Hashim MemonNo ratings yet

- Lecture 2 Engineering EconomicsDocument30 pagesLecture 2 Engineering Economicsahmer100% (1)

- Ucmp NotesDocument46 pagesUcmp NotesAnonymous fowICTKNo ratings yet

- Propia PokedexDocument64 pagesPropia PokedexCesaromar RuedaNo ratings yet

- ISO SymbolsDocument167 pagesISO SymbolskillimakilliNo ratings yet

- Building Management ElectricalDocument51 pagesBuilding Management Electricalmanikyam begariNo ratings yet

- Design: IdeasDocument5 pagesDesign: Ideasdcastrelos2000No ratings yet

- Math Formula Chapter 07trigonometryDocument4 pagesMath Formula Chapter 07trigonometryTanvirul IslamNo ratings yet

- W340EU Service ManualDocument110 pagesW340EU Service ManualFabricio BlosNo ratings yet

- 05b4 - E70 Adaptive Headlight SystemDocument28 pages05b4 - E70 Adaptive Headlight SystemAthira Sobhana Ramachandran100% (1)

- Wang CSPNet A New Backbone That Can Enhance Learning Capability of CVPRW 2020 PaperDocument10 pagesWang CSPNet A New Backbone That Can Enhance Learning Capability of CVPRW 2020 PaperSerxio GarcíaNo ratings yet

- Textiles in The World of SealingDocument2 pagesTextiles in The World of Sealingvadiraj2002No ratings yet

- Customer Services: Meaning of Customer ServiceDocument5 pagesCustomer Services: Meaning of Customer ServiceBoobalan RNo ratings yet

- Concept Six: Themes For Cockos REAPERDocument18 pagesConcept Six: Themes For Cockos REAPERLustmordNo ratings yet

- Ubd-Udl Curriculum DesignDocument19 pagesUbd-Udl Curriculum Designapi-341959014No ratings yet

- Request For Proposal Writing GuideDocument3 pagesRequest For Proposal Writing GuideSunilBhandari100% (1)

- Jupiter's Great Red SpotDocument1 pageJupiter's Great Red Spotkareen00No ratings yet

- Mobile Operating System SlidesDocument12 pagesMobile Operating System SlidesDaniyal AliNo ratings yet

- Timetable Route BMTDocument9 pagesTimetable Route BMTAimi SyafiqahNo ratings yet

- Ducati Diavel ABS WiringDocument1 pageDucati Diavel ABS WiringKhoảng LặngNo ratings yet

- Trends in Degradation Diagnostic Technique For XLPE Cables in Japan A. Toya, M. Nakade, Y. Okuyama, K. Uchida, H. Tanaka, K. WatanabeDocument7 pagesTrends in Degradation Diagnostic Technique For XLPE Cables in Japan A. Toya, M. Nakade, Y. Okuyama, K. Uchida, H. Tanaka, K. WatanaberamsesiNo ratings yet

- BigJoe S22Document162 pagesBigJoe S22martinNo ratings yet