Professional Documents

Culture Documents

EP Design - 1

EP Design - 1

Uploaded by

raghav abudhabi0 ratings0% found this document useful (0 votes)

26 views17 pagesOriginal Title

EP Design_1

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views17 pagesEP Design - 1

EP Design - 1

Uploaded by

raghav abudhabiCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 17

DESIGN REPORT ON EMBEDDED PARTS

PARTAN

De PEP ip aut nd out

is form irculation= TAPP.384

1.0 Tsdustion =

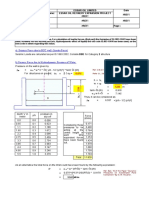

Four nos. of EPs 2 Nos. of EP No. 00224 and 2 Nos. of EP No, 00225) are

Provided in the cali Walt est allt E 98.95m 4 poe the clan inkl oad

‘ut ios for moderator cculaton, These EPs are wale by welding thick forged

‘ings tthe calandra val side and scaling bellows at de other end ie moderator

oom sad. Geel anangement is showa in Dg. No, TAPP-3&4/320000 20060

20 Deseiption of th EP (.P.No, 00228) and 1.ocatin:=

1 penetration EP. and is located at eas wall f salad vault betwoen

pid 23 and grid 3-4 a EL. 98,950m. The sizeof EP, ie $00 NIB, 280mm long.

Pipe sleove. "The axe of thie EP. is paralll 10 the disston ‘of gid 2, and

pexpendicular io giidB, (. ie penewating the Wall perpendvalry). Details of Eps

ste given in Drs. No. TAPP-37421032201 DDR

30 Calelaton for EP No. 00225

31 Lowde

[Range ® [Rate Th aay [a eam) |

Dead weigh ee 65

a st se

i 5 +

‘SSE 521 [450 as 354

{conan iar |e] est oe]

iid consi L

Deng mame de Fy and Sem = Mix By.v 18 = 9885tgem

projecionbeyend conctete face

esdng moments due to Faand 15 em

projection beyend concrete face

70 kgm

[_——-NUSEEAR POWER GoRFORATIC

TARAPUR ATOMIC POWER PRONCT 384 w

DESION REPORT ONEMBEDDED PARTS | KEVNO | 9.

PARTIA Say GF EEN

Hone, resuliant nding moment = VQ; Fhija (Mia > Mag?

>M = 39881 kyem

32 Dimensions of BP

Outi dia of pipe slave = s0.8em

‘(Stiles Stee

‘Wall thickness of pipe steve 1 0983 om

Pua flange = 70cm x Tem x16 em th

(Carbon Steel)

Ed fmge = 80 cm s0¢m x06 om tk.

‘Gainer Ste)

(Cros seesional area ofthe pipe sleeve A = 152.1 ent?

‘Momeat of inertia T= 46360 10! cmt

3 Matralsand sllonable wrens

33.1 - Pipe Sleeve

SS auper ASTM A312 P3041

UTS = 4850 bayon?

YS = 170;pem?

382. End flnge

8.8 as per ASTM A2W0 TP3O¢L

UTS = 4850 igfem?

YS. = 1700ken?

333, Puddle fange

©. per IS 2062 Gr.4

UTS = $100kgim?

YS. = 2300; mt

3.34 Allowable sisse

"For Materist

Allows stress at per ANSI-N6O0-1984 i 0.6 YS in tension

_____ NUCLEAR POWER CORPORATION OF INDIA LID

rARAPLR ATOMIC POWER PROJECT-ARE | AGEN. oF

DESIGN REPORT ON EMBEDDED aRTS Shenlone

-

oc Filet Welt

Allosrable sae soos as por NOO-1584 is 03 x

34 Ses saloulation

“Tenis dae to axial force

Sa * Eq 2489 = 1636 glen

av isa

‘Tense sess due wo bending monet

oo = Mido = 2165 hea?

Total emit tess ~ 0 ~ cq * 0m = 35.29 kglom*

Stearstos due to Fy mndF2 = VEETEE

a

ny MST hem?

Shear sree due to argue ts = Mado

a

= son00x 508

414.6369 104)

= sige"

‘Total Show Sess 7

= Boathgen!

Stes intensiy = Vor aE

= 8592 kyla

35 Buckling capacity

Pe = B (ity! [Reference It)

4

Danco! fossaxsoRy

4

2173 Aalem*

3.6 Consrets Presure

Extend pressre on embedded part ding concreting. = 0.9 kgf?

TARAPUR ATOMIC POWER PROMECT-Ned | PACENG apoF

DESIGN REPORT ON FMBEDDED PARTS. |REVNO 0

PARTAA eS MEE MNO No.

3.7 Caleasion of fanges of BE

37.1 Qualification of Weld

Shear sts on the weld of 2489 glen?

the end flange and —

ude ange HxS0.5x 04x07

= S87 kyon

3.72 Qualifieaion of end ange

‘Considering 1 cz wid poton of ond Mange

= 200m

W = tanec force

Per unit perimeter

= 89 = 1S.6hwmn

508

M = Moment a the fixed end

= 2kgemem

Bening sues = Gh

M

= 351 gent

4.0 Calslation for concrete stent

41 Propetct of concrete { Reference — 1]

3] Grade eames

| Character ompeaive sh |

bebe ar 78 ays fen

Tih} Graces compressive ais

| of pliner afer 28 days Fay =

ost.

a) Teese

Peryiss

| Permissible barging) kaa

stength fe 0.6 _|

WH Permusible bond ares Silent

ouag,

aa

42

so

60

TARAPUR A

——HUELEAR POWER CORPORA

POWER PROIECT Nt

DESIGN RAVORT ON EMBEDDRD PARTS

Reyne

Steunsite

0 aes = nl

EEStE a 7

346x108 ke

i) Pullout strength — 1.06% Vie, [Projected arse of the cone } fRefTV]

aaa ds "eins

4.06 8.0.85 x ¥200 x [2(350 + 125)'-70*)

2 Cmingsngh = sr

Si So~ 5

1528310" ky

conn

ee ty) opening payin

mere elon ft oa ein

Eelcomcen hd Howe eee

frown pst or deat a ns

eee nena ar ee

nee

1 Lette No. TAPP-384 /32119/ 98/ MY 1576 dated 15% Tine 1998,

L_ Theory and Design of pressure weasels - Job F Hsey

It DAR onre-mginecring of IC dome of Kaig2 and RAPP-384

TV. Ametican Concrete Tastings - ACL-H9-85

en

10

20

30

34

32

328

322

JCLEAR POWER CORFORATION OF INDIA LTD.

WER PROMECT

DESIGN REPORT ON EMBEDDED PARTS | FRETO 6

PARIIA :

DATE 3

silandelg Vail -TAPP.384

Introduction :-

EP No, 01008 provided onthe almaia vault west wall it meet to Bowe the

ligament cam shiokding sleeve and the iezejecket. Light water and heavy Water

bellows anangements are provided on citer ede of the calanrin vaule weet Ball in

fords to seal te salndsis vault ght water & calm beavy water. The Reavy

ater bellows alen provides presensioning load of 1250 ky 10 the injation tit

‘which mum applies on axial tensile lad fo the pipe steve ofthe EP. -Genetal

rangement shown in fig. 1

Desription af the EP (EP No, 01008) and Location =

‘The ED. in Iocated at West wall of calndsiavaut, The FP. is sepped 8.5.

sleeve having intemal diameters a 122-24mm and 2027 respectively. The axe

of EP. is panel vo grid 3 and long ofthe EP. is 2540nam. The ED. is fished

withthe wal, Fer futher detail refer fi 2,

‘Salutation for EP No. 210000}008

onde on EP and EP dimensions

Fe = 1260g | [Pretension lad )

ter lade are insignificantly small and wo nelostd.

Min eros setional area

A= 394Scm"

Material & allosable stress

Pe Sleeve

SS as per ASTM A312 TP 3041,

UTS, = 4850 }g/emt

YS = 1o0kgem?

Entlanaes,

8.838 per ASTM A240 TP 304L

UTS > 4850 kgm!

YS = 1700 keen

~—— WUGLEAR POWER CORPORATION OF NDIA LTD.

TARAPUR ATOMIC POWER FROMCT:AGT PACINO ago" 3

DESIGN HIVORT ON EMBEDDED Pass

PARTIA

Ear Materia

Allowable Stes in por ANSLNGOD 1984 80.6 x. in tosion,

{Under extreme condition, th allowable tes cn he ireasod by 9 factor of 1.6

For ile Weld

Allowable sear sess as per N-€00-1984 0.3 x 8

33 cuttin

‘easiest duc to axial force

= By = U7 kgtemt

a

‘Since there i no shear stro the ates intensity (SI) = 31,7 kglent

34 Bushing capacity

Pe = B (en [Reference ty

4

Forsmalldiasieeve Py = 24510° (09su0d.32)7

4

= 1288.$Sigiem? F

For lange dla sleeve Pe = 21x10! [oxis@I9aF

4

= 218.56kglen?

3S Congrete Pressure

External pressure on embed prt during concreting

3.6 Caleulavion far anges of BP

‘Shear tres on the weld ofthe end lange

"TARAPUR ATOMIC POWER PROJECT-Atei | FAGENO oF Je

DESIGN REPORT ON EMBEDDED PARTS

‘AR POWER CORPORATION OF INDIA LTD,

REVINO a

ese BEN NO.

i PARTIA Bias OF MEETING.

40 Calulion forconete stent

41 Propaties fms Peference 1}

———

Ay eancrie pasioe

ema ofeite ae 2 dae

| Gases aieave 200g]

srengh of esindr ae 28

diye fy OF fae

By | Teme th Tiga

fe Gra0st.

[| Peminbe beaiag rulngy | TOTS

seength f= 05

“ay | Pennie bad sas

Lleemaasg

42 Concrete sang calsation

Bond strength = ado. fis

forts seve A219 00x78

= Baxi

Bond seat ASMUtxIS3192

forall sleeve Sara" 6

Frlloutaength = 1.06 Vee [Projet area fhe ome} (REET

‘comsiering cone fas) = :

Oss 0854 1300 x (R414 +1007" ¥0.144)

sAsaI0 ig

£0 Concsion

The ses intensity (S1) concaponding othe given lad gory an inension i

such ess tha the alowabte alse. The bacing rent rao sich more ane

‘cal compresive lod an EP dug contetng. Merv: pullout sgibond

‘seengthconiiteahy more than as loud ating os tem.

60 Reference,

4 ‘Thoory and Design of pressure veel ~ Job Farry

DBR on resngincenng of IC dome of Kaige? and RAPP-R4

TL American Caseree Inte —ACI-I9-85

DESIGN REPORT ON EAGIEDDSD PARTS.

= Be

NUCLEAR POWER CO!

PARTAA,

Be)

SgoTion s-s

froors Total (euros)

OL 90012) TIVM IS3M AO NO “dS woh

mo WSISKS WOLSINN WOSOT aE

IF 3

ee

ise

eae

sn | 7

z is

i 7

es le

as LE

iss 5

Ee | “ses oog

Bz No aza¥asiNOs

2g 2 a330%00n

eg SH0H dade 3

BE

POWER CORPORATION OF INDIA LID.

| eer ‘ATOMIC POWER PROJECT-383 | PAGENG “W9OF

DESIGN REPORT ON EMBEDDED PARTS | REVO.

esc seers No:

1 iL PARTIA ___| BSiebeweEnNg. J

Report eam, ion EPs

irs idlug~ TAPP 384

2.0 Inaction +

‘Ti so main steamy lines (No. 361-140 and 1003) pa though

oth the ICW and the OCW fo cater the turbine bulking, Each line ie conacced fo

‘he penetration EPs inthe containment walls tough telows expansion joints Tae

twflows help in stnoth absorption of the pipe movement uring normal operation duc

to themal efsets and postulated seismic events. Gencalamangetci i shown it

‘he Dg. No. TAPP-3843600022008108.

2.0 Desorption af the EPs (EE, Nos, 0009? and 000095) syd Location -

| Th penetration EPs are sleeve HPs and fsiiomed non-raially with

‘pect to RB, These EPs are cad at East area Noth ecton and Fast ago South

Section at F, 134.5: of containment vals, The ae of fe EPs are 914.4 OD. wih

fengsh of EP. No, 00009 P is 1717mm and kngth of E2. No, 000098 is 148mm.

For furer desl refee Dip, No. TAPP-38:1/21032/2025DD/R0,

3.0 Calculation of .P.No, 2000931000008

‘The above mentioned EP hus Been contidered conservatively for

caeultion besauve ite Hosted on OCW and thisknaes of OCW (6mm) i eas

| than CW (7S0mm). Moreove, the sength af the concrae used in OCW (M25)

less tha dat of ICW (M35,

Load on ER

| [Reterenee =}

Tipe of oad Mi igen | Mga ea)

“Preraai [10 28

SSE | 2000 So000

‘Ceinbined Woad | 30001800 75600}

3.2 Dimensions of fp

ite ain we

Wal tices t

‘Crom Sectional area, =

—

iR ATOMIC NECT-384 | PAGENO BOF 2

DESION REPORT ONEMBEDDED PARTS | RENO. 0

PART-IA

Moment ofinera Ras

33° Stes calculation

‘Temi stress dive to axial foad .

T8000 x 91.44

= 62 kglem?

26x10

‘Total Shear Stress = wut t, = 155 kgtent

Ses intensity (1)

3.4, Malerials nd Allowabfs teas

3.41 Pipe Steve

CS spor 197818 3589

UTS = 3100 ksiem

YS = 1700kyen

3.42 Puddle fhnge

8.8 ports 2062

UTS = 4100 fom

YS. = 2300Kgleu?

Baa

Allowable Suess as per ANSENSIO 1966 60.6% YS tension,

Fortes Weld

‘Alloa shear sess a per ANST-NO9O 1984 i 0.3 x ¥.S

PAGeNO wor H |

|

|

Tivaionotmanieseaes! [Saas

iether

Po = Bitty = 24x10 (09Si9148/2))° {Reference =I}

: :

= Att

‘Ext Pressure on embedded part during concreting = py 0.9 kglam?

3.7 Blangs of BR

She Sain allege =n

shat

4.1. Bropertion of sonerste [Reference «11

Zs Sew

‘Grate of conareis M35 M25]

eee eee — abla alse

oesart tarde

So

Sosiice aa TS

sgh giana

_ days fg = 0.8 Tote eae

{tara igi | eae

eae

iit amma Ponta frie |

\73 Page|

ol fe

wx9Lde361

7 138x10" kg

1 x 7928

Pullout strength = 1.66 ¢ Vfae[Projecte are ofthe cone] FReETV

(considering cove fails)

06 x 083 x VT

1x ig,

[3463 + 30.5" 12058 126)

or

10

30

aa

DESIGN REPORT ON EMBEDDED PARTS

PARTIA

esa sation

oa i Rea

Inradactin =

Emergency core cooling sytem (ECCS) is one of the enpinered

tulsty ystems proved to mitre the consecuencas of & Loss of Coolant

Accident (LOCA) inthe event of break inthe Primary Ckult Preesre

‘Boundary: Tn BOCS water fom suppression pook injcted fo coe afer

cooling. i through Heat Exchangers. To tous these pipe lines penetration

{EPs ae provided in sonsinmeat walls, Above mentioned EP i obe of those

EPs. General arangement is shown in hed, Ho. TAPP=#/33350'2107/G,

‘Dessinvion ofthe EP (EP No, c00018) ant

1 fe located at EL. 86,6504 in West Area South Seton inthe outer

‘onisinment wall and ata distance of 886mm fom grid CR-CH, Size of the

[EP it SOONB dia 920mm length and 9.SWT. For father dete refer dry

No, TAPP-364/210322020DD:R0,

‘ECCS ine pansion EP 200015000018

‘The shove mentioned BP has been considered conservatively

for caetlation because itis oeated on OCW and ihskaess of OCW (610m)

is ess thin ICW (750mm). Moreover, the strength of the conatte sed in

‘OCW (M25) isles than ha oF OW (HES,

ag

Loads on BP

T Refeence = 1]

— [Fete

1000,

2000

5000

BLY)

"TARAPOR ATOMIC POWER PROMECT-A84 | PACENO a40F 27

DESIGNREPORTONEMBEDDED PARTS | ENO 0

se MEETING NO

L PARTIA

32, Dimension of,

Outside darter = do = S0imm = 08cm

Wallthisiness = t= Sam = 095m

Gros Section Arca = AS aston

Moment af ners SPs 2 Gea

= 3172028 emt

= Sits ttant

3.3. Sip culuation

Tense sess duet aciat load = = gy

Shear Stes deo shear fee = y= {

16.48 halon?

‘Shear Stress dust torus zon

Tova Shear Sone toe Ise 1842

3450 kyom®

Stes intensity (81) = VaETEE = 2245 kein?

CS asper 18 197818 3569,

O18 = 3100

YS 5 1700 kgm

34.2 Puddle age

C.S.asperIS 2062 Grade “A?

UTS = s10dkyem?

YS. = 2300 kgm

oeMateish

‘Allowable Stress us por ANST-NG9O 1984 is 06x Y.8 in tension,

|_.__N POWER CORPORATION OF INDIA

‘TARAPUR ATOMIC POWER PROIECT-384 | PAGENO 230?

DESIGN REPORT ONEMBEDDED PARTS [REVO : 0

PARTIA SATEOP MENTING.

Thebuckling siengthof = Py ™ E(u)? Refrence = 11)

ee a gaa tesstsapy

= Big?

36 Conte Resse

stem posts on embeded pt daring conrtng. = Oyen?

37 Bac ots

3.7. Shear Stress inthe weld ofthe puddle flange ~

40

441 Propinion ofconsrete [ Reference =I }

Se ew

bij Frade ofomees

|iy ~Chaictesaiscompiemiva | asc

strength of cade afer 28 days

a

il) | Canscistnic conprenive | 0 gant | Dorkga

Srongth of liner after 28

‘08 fete

Di igen

f= 64 O08", aan

[W)] Perms berg ring) | 168 Balen

ba—(stenuth fe=06ty |

Vi | Femnisible ond sae Ta gaa | THT

f= 044 go

$2 Conese wena

9) Bondstengh = dol fy

ReSO8 FO 72g

~ me kg

LEST)

|

so

so

_ NUCLEAR POWE

OF INDIA 1

TRAGEND aka

"TARAPUR ATOMIC POWER PROJECT-384

DISIGN REPORT ONEMBEDDED PARIS | EVNG "3

PART bare Oe MeenING |

if) Palloutsrengtt = 1.06 @ Vous [Projected area of the cone} [ReFIV}

(considering sone file)

1.06% 0.88 x V6 x [2 (3554 308)? = 71x71]

= 985% 10" kg

ii Crushing seen alee

= 08x61x96K3

TIES x10 he

‘Conclusion

The sos intensity (ST) corresponding tothe given tsk, geomet snd dimension is

mach fs hum th allowable val. The bukling eng also much more the the

cual compressive loads EP during concreting. Mover pulhoutstenthbond

strength consider more than axial fad acting om them snd sp crushing sfeath

‘is more han crushing load ating on conor.

Referees

Teter No. TARP-364 /33000/ 98/34/1712 dated 0 Joy 1996,

21032

Theory and Design of presse ves

Soin F Homey

LIBR on re-incating of IC dome of Kain? and RAPP-A&4

TV. American Concrete Institute ~ ACI-9-85,

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Storm Water Drain Tce.6059a-100-Si-SwdDocument17 pagesStorm Water Drain Tce.6059a-100-Si-Swdraghav abudhabiNo ratings yet

- Matix GeocalculationsDocument8 pagesMatix Geocalculationsraghav abudhabiNo ratings yet

- Design of ConnectionsDocument22 pagesDesign of Connectionsraghav abudhabi100% (1)

- HousnerDocument8 pagesHousnerraghav abudhabiNo ratings yet

- Rainwater Sump - 21 - 1 - 11Document19 pagesRainwater Sump - 21 - 1 - 11raghav abudhabiNo ratings yet

- Manhole DesignDocument7 pagesManhole Designraghav abudhabiNo ratings yet

- Steel Design PresentationDocument90 pagesSteel Design Presentationraghav abudhabiNo ratings yet

- AP303 A, B C - FoundationDocument38 pagesAP303 A, B C - Foundationraghav abudhabiNo ratings yet

- Scope of Work For Geotechnical Survey: Abu Dhabi Polymers Co. Ltd. (Borouge)Document43 pagesScope of Work For Geotechnical Survey: Abu Dhabi Polymers Co. Ltd. (Borouge)raghav abudhabiNo ratings yet

- 4230-127-Pvc-U-009-Sh 1-03Document9 pages4230-127-Pvc-U-009-Sh 1-03raghav abudhabiNo ratings yet

- Survey LogDocument1 pageSurvey Lograghav abudhabiNo ratings yet

- 40-007-CS-8180-03043 - Rev 02CDocument105 pages40-007-CS-8180-03043 - Rev 02Craghav abudhabiNo ratings yet

- EP Design - 2Document27 pagesEP Design - 2raghav abudhabiNo ratings yet

- 2-Load Carrying Capacity of Column - 400 X 400-FinalDocument1 page2-Load Carrying Capacity of Column - 400 X 400-Finalraghav abudhabiNo ratings yet

- MALB RPTDocument27 pagesMALB RPTraghav abudhabiNo ratings yet

- Member ComparisionDocument2 pagesMember Comparisionraghav abudhabiNo ratings yet

- E-105b Fix - Pile Capacity & OutputDocument19 pagesE-105b Fix - Pile Capacity & Outputraghav abudhabiNo ratings yet

- E-105b Fix - Load Calc For F3DDocument6 pagesE-105b Fix - Load Calc For F3Draghav abudhabiNo ratings yet

- Bolt CheckDocument1 pageBolt Checkraghav abudhabiNo ratings yet

- 4 - Stair Case - Dead LoadsDocument4 pages4 - Stair Case - Dead Loadsraghav abudhabiNo ratings yet

- 4-Design of StaircaseDocument5 pages4-Design of Staircaseraghav abudhabiNo ratings yet

- Summary Report For E-105-B Fixed Saddle Project Information: Page 1 of 33Document33 pagesSummary Report For E-105-B Fixed Saddle Project Information: Page 1 of 33raghav abudhabiNo ratings yet

- PropDocument1 pagePropraghav abudhabiNo ratings yet

- 4-Pages From Design of Water Retaining Structure - Ian Batty-3Document25 pages4-Pages From Design of Water Retaining Structure - Ian Batty-3raghav abudhabiNo ratings yet

- 116 AbDocument23 pages116 Abraghav abudhabiNo ratings yet

- 110-123-116 SettlementDocument52 pages110-123-116 Settlementraghav abudhabiNo ratings yet

- MATIX SumpDocument1 pageMATIX Sumpraghav abudhabiNo ratings yet

- Dynamic Soil PressureDocument5 pagesDynamic Soil Pressureraghav abudhabiNo ratings yet

- Summary Report For 10-E-123Fixed Project InformationDocument19 pagesSummary Report For 10-E-123Fixed Project Informationraghav abudhabiNo ratings yet

- Summary Report For 10-V-127 Project InformationDocument19 pagesSummary Report For 10-V-127 Project Informationraghav abudhabiNo ratings yet