Professional Documents

Culture Documents

SMAW

Uploaded by

Prince Neil SeraphimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SMAW

Uploaded by

Prince Neil SeraphimCopyright:

Available Formats

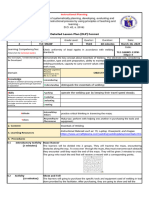

Division Lanao del Norte

School Liangan NHS Grade Level Grade 12

Teacher Marnelle P. Arcay Learning Area SMAW

Time & Dates Quarter Third Quarter Week 1

I. OBJECTIVES

The learner demonstrates an understanding of the concepts and

A. Content Standards

underlying principles in Shielded Metal .Arc Welding (SMAW).

B. Performance The learner independently performs Shielded Metal Arc Welding (SMAW)

Standards processes based on market standards.

LO 3. WELD CARBON STEEL PLATES IN VERTICAL POSITION (3G)

C. Learning TLE_IAAW9-12GWIIIa-IVj-3

Competencies/

Objectives (Write 1. Check root penetration in accordance with acceptable standards

the code for each 2. Identify the five Essentials of welding

LC) 3. Define the five essentials of welding in Checking root penetration in

accordance with acceptable standards.

II. CONTENT Perform Groove welding on Carbon Steel Plate

A. Subject Matter International Welding Codes and Standards

III. LEARNING

RESOURCES

A. References

1. Curriculum Guide Curriculum Guide page 11

Pages

2. Learner’s Material None

Pages

3. Textbook Pages None

4. Additional Materials None

from LR Portal

https://www.esabna.com/us/en/education/blog/welding-codes-and-

B. Other Learning

standards.cfm

Resources

The teacher prepare a PowerPoint presentation

Learner’s Expected

IV. PROCEDURES Teacher’s Activity/ies

Response/s

A. Reviewing previous Prayer ( 1 min) Our previous lesson

lesson or presenting Checking of attendance is all about the

the new lesson Class what was our previous lesson? Essentials of Welding

The Five Essentials

Okay very good! of Welding are

Kindly get ¼ sheet of paper. following:

Give the 5 Essentials of Welding 1. Correct Electrode

Okay class let us check your work Size

2. Correct Current

3. Arc Length

4. Travel Speed

5. Electrode Angle

The Student started

checking their

answer

The Teacher will ask the following

question: Learners answer

Okay class, before we are going to start our may vary based

new lesson let us have some word puzzle on their

activity, to verify if you have some understanding

knowledge on our new topic. about the

Question: Who has an idea what is the International

International Code of Standards? Code of

Standards

What Are Welding Codes and Standards,

When Are They Used, and How Are They

Developed

Many aspects of the design and fabrication of

welded components are governed by documents

known as codes and standards. Other names

used for such documents include guides,

recommended practices, regulations, rules, and

specifications. These documents are often

specified by an end user/purchaser as a

contractual agreement in order to control the

characteristics of the welded fabrication that may

affect its service requirements. They are also

used by the manufacturer to assist in the

B. Establishing a development and implementation of their welding

purpose for the quality system. Many end users of welded

lesson components have developed and issued

specifications that have been compiled by them to

address their specific requirements. Such

specifications may be limited in application and

related only to that customer’s situation and

requirements. National interest in areas such as

public safety and reliability has promoted the

development of welding codes and standards that

command broader recognition both on a national

and industry-specific basis. Numerous committees

have been developed over the years within

national engineering and technical societies that

continue to evaluate the needs of industry and

develop new welding codes and standards. Such

committees are comprised of members who are

technical experts and represent all interested

parties such as manufacturers, end users,

inspection authorities, and government agencies.

The membership of these committees is balanced

in order to prevent any one interest group from

controlling the committee. On completion of a new

or revised document by the specific committee, it

is usually then reviewed and approved by a

review committee, and if accepted, then published

in the name of the applicable engineering society.

Documents that have significant influence upon

public health and safety are sometimes adopted

by legislative bodies or by federal regulating

agencies. In those jurisdictions, such documents

become law and are often referred to as Codes or

Regulations.

The welding inspector should be aware of what

codes or standards are applicable within their

jurisdiction, understand the requirements of the

relevant documents and perform their inspection

accordingly.

The Teacher will discuss the on what the Welding Learners answer

Code and Standard Generally Provides. may vary based

on their

The Scope and General Requirements:

C. Presenting examples/ Design observations

instances of the new Qualification about the images

lesson Fabrication presented by the

Inspection teacher.

The Teacher will discuss the two out of Learners will

listen carefully

4 Welding Codes and Standards and Jot down the

generally provides, important words

The Scope and General Requirements: discussed by the

This is found at the beginning of the teacher.

document and is important as it will

normally provide a description as to the

type and extent of welding fabrication for

which the document was developed and

intended to be used.

Design: If the document provides a The first two

section for design, it may refer the user to welding codes

D. Discussing new a secondary source of information, or it Generally provides

concepts and may contain minimum requirements for are,

practicing new skills the design of specific welded connections. The Scope and

#1 Inspection: This section of the document

General

will typically address the welding

Requirements

inspector’s qualification requirements and

responsibilities, acceptance criteria for Design

discontinuities, and requirements relating Inspection

to procedures for nondestructive testing. To assist in the

Okay class answer the Following question development

1. Welding Codes and Standard and

Generally Provides? Give at least 2 implementation

2. What do you think, why we need to of their welding

follow the Welding Codes and quality

Standards? systems.

Okay very good

Class!

A. Today, we are going discuss the Learners will

remaining listen carefully and

Jot down the

B. Qualification: This section of the important

document will typically outline the wordsdiscussed by

requirements for qualification testing of the teacher

welding procedure specifications (WPS) The students from the

and also those requirements for different groupswill

qualification of welding personnel. It may elaborate their answer

provide the essential variables, these in front of the class

being the change limitations that govern

the extent of qualification.

C. Fabrication: This section, when included

E. Discussing new in the document, will typically provide

concepts and information associated with the

practicing new skills fabrication methods and/or workmanship

#2 standards. It may contain information and

requirements on such items as base

materials, welding consumable

classification requirements, shielding gas

quality, heat treatment requirements,

preparation and care of base material,

and other welding fabrication r

D. Inspection: This section of the document

will typically address the welding

inspector’s qualification requirements and

responsibilities, acceptance criteria for

discontinuities, and requirements relating

to procedures for nondestructive

testing.equirements.

Assessment of the Students Their outputs will be

Points Earned

17-20

Numeral rating

96-100

Descriptive rating

outstanding

scored based on the

13-16 90-95 Very satisfactory rubrics given.

F. Developing mastery 9-12

5-8

85-89

80-84

Satisfactory

Fair

1-4 75-79 Needs improvement

0 70-74 poor

The Teacher will ask the following questions to

the learner: Learners answer

G. Finding practical

1. How will you apply the following Welding may vary on how they

applications of

Codes and Standards are going to answer

concepts and skills in

2. What do you think will happen if you will the following

daily living

not follow the Welding codes and questions.

Standard?

H. Making generalization The teacher will call someone in the class to

and abstractions summarize what they have learned The learners will give

about the lesson 1. What are the following Welding codes the important points

and Standards to remember about

2. Essential variables typically include: the welding codes

and SThe welding

process

Base metal type and

thickness

Filler metal type

Electrical parameters

Joint design

Welding position

Standards

Assessment: The Scope and

5 item Quiz. General Requirements

1. List the Welding Codes and Standards Designs

in order Inspections

I. Evaluating Qualification

learning Fabrication

Inspection

With corresponding

explanation

Assignment : The student will

J. Additional activities for

Research the Acceptable Weld Profiles research about the

application or

Acceptable Weld

remediation

Profiles

IV.REMARKS

V. REFLECTION

A. No. of learners who

earned 80% on the

formative assessment

B. No. of learners who

require additional

activities for

remediation

C. Did the remedial

lessons work? No. of

learners who have

caught up with the

lesson.

D. No. of learners who

continue to require

remediation

E. Which of my teaching

strategies worked

well? Why did these

work?

F. What difficulties did I

encounter which my

principal or supervisor

can help me solve?

G. What innovation or

localized materials did

I use / discover which

I wish to share with

other teachers?

PREPARED BY: MARNELLE P. ARCAY

You might also like

- Smaw 12 ArcayDocument6 pagesSmaw 12 ArcayPrince Neil SeraphimNo ratings yet

- TVL-SMAW 12 - Week 4 - Lesson 1 - Concept of Welding Codes and StandardsDocument9 pagesTVL-SMAW 12 - Week 4 - Lesson 1 - Concept of Welding Codes and StandardsNelPalalonNo ratings yet

- SMAW 10 - Q1 - W2 - Mod2Document16 pagesSMAW 10 - Q1 - W2 - Mod2Romeo Dela RosaNo ratings yet

- Practical Application of ASME BPV Code Section VIII Division 1Document5 pagesPractical Application of ASME BPV Code Section VIII Division 1hardikpandya20No ratings yet

- June 18-22, 2018Document3 pagesJune 18-22, 2018Oliver C SilvanoNo ratings yet

- DLL 12smawDocument7 pagesDLL 12smawHerbert Quimada Reblora100% (2)

- COT LESSON LOG BendingDocument5 pagesCOT LESSON LOG BendingCourei-FxAlcazarNo ratings yet

- 1 Apply Safety PracticesDocument103 pages1 Apply Safety PracticesRobinson ConcordiaNo ratings yet

- MCD523 Engineering Workshop Practice Course GuideDocument7 pagesMCD523 Engineering Workshop Practice Course Guideak4952961No ratings yet

- 2 Interpret Drawings and SketchesDocument93 pages2 Interpret Drawings and SketchesRobinson ConcordiaNo ratings yet

- 7 Set-Up Welding Equipment SMAWDocument45 pages7 Set-Up Welding Equipment SMAWRobinson ConcordiaNo ratings yet

- Parts of A Competency-Based Learning Material PackageDocument19 pagesParts of A Competency-Based Learning Material PackageRoedfrey OrtizNo ratings yet

- NRC QA TrainingDocument211 pagesNRC QA Trainingchandra shekharNo ratings yet

- SMAW (5) EditedDocument8 pagesSMAW (5) EditedPrince Neil SeraphimNo ratings yet

- 6 Prepare Weld MaterialsDocument80 pages6 Prepare Weld MaterialsRobinson Concordia50% (2)

- 4 Quality System 4Document30 pages4 Quality System 4International Technology Center IncNo ratings yet

- Mce03 WTPDocument142 pagesMce03 WTPalfieNo ratings yet

- K To 12 Basic Education CurriculumDocument133 pagesK To 12 Basic Education CurriculumviptoneytNo ratings yet

- Module 4 GR 12Document14 pagesModule 4 GR 12WilmerNo ratings yet

- PLM NC II CommonDocument133 pagesPLM NC II CommonRegie Dumaran CubaNo ratings yet

- Smaw NC IIDocument42 pagesSmaw NC IILloyd Arnold Catabona100% (1)

- EE 424 Integrated Circuits FabricationDocument7 pagesEE 424 Integrated Circuits FabricationKhalil AlluhaybiNo ratings yet

- Welding Module 2-1Document21 pagesWelding Module 2-1Marwin NavarreteNo ratings yet

- Grade 11 SMAW - q2 w7Document6 pagesGrade 11 SMAW - q2 w7Jhon Vernie Reponte GambitoNo ratings yet

- Grand DemoDocument4 pagesGrand DemoAngel Mae Valdez ArnaizNo ratings yet

- Preface: New To This EditionDocument31 pagesPreface: New To This EditionWohs EdilsNo ratings yet

- Smaw 9 Prepare Weld Materials LC 123Document3 pagesSmaw 9 Prepare Weld Materials LC 123RoanBronolaSumalinog0% (1)

- Love 18 DaylieDocument12 pagesLove 18 DayliePradel FamilyNo ratings yet

- Smaw 11 LP Mar. 7 2019Document2 pagesSmaw 11 LP Mar. 7 2019ronald curayag100% (2)

- Grade 11 SMAW - q2 w5Document7 pagesGrade 11 SMAW - q2 w5Jhon Vernie Reponte GambitoNo ratings yet

- Basic Principles of Welding Is A Course in Which Students Will Learn Basics Skills and KnowledgeDocument15 pagesBasic Principles of Welding Is A Course in Which Students Will Learn Basics Skills and Knowledgeகோகுல் இராNo ratings yet

- SHS DLL Q2 - w3Document3 pagesSHS DLL Q2 - w3MELAIDA CASTANAR GARIBAYNo ratings yet

- Course Basic Welding Skills PurposeDocument11 pagesCourse Basic Welding Skills PurposeDil Chandra PandeyNo ratings yet

- Electrical Safety (NFPA 70E 2021) : Course Name Credit Hours Course DescriptionDocument10 pagesElectrical Safety (NFPA 70E 2021) : Course Name Credit Hours Course DescriptionciskalauraNo ratings yet

- IM ECEN 3453 Safety Engineering and ManagementDocument89 pagesIM ECEN 3453 Safety Engineering and ManagementEm ReyesNo ratings yet

- Lesson Plan SMAW 12Document8 pagesLesson Plan SMAW 12Jymaer GeromoNo ratings yet

- TVL-Shielded Metal Arc Welding 12 Third: PanimulaDocument3 pagesTVL-Shielded Metal Arc Welding 12 Third: PanimulaFlorinda Gagasa100% (1)

- SHS DLL Q2 - w9Document5 pagesSHS DLL Q2 - w9MELAIDA CASTANAR GARIBAYNo ratings yet

- CBLM Smaw NciiDocument44 pagesCBLM Smaw NciiJacaskills Jstac50% (2)

- TVL-SMAW 12 - Week 6 - Lesson 1 - Welding Procedure SpecificationDocument10 pagesTVL-SMAW 12 - Week 6 - Lesson 1 - Welding Procedure SpecificationNelPalalonNo ratings yet

- DLP 3 SmawDocument4 pagesDLP 3 SmawNiña Gel Gomez AparecioNo ratings yet

- G10 Selfpace Module Repair Weld DefectsDocument23 pagesG10 Selfpace Module Repair Weld DefectsJackyJane PagalingNo ratings yet

- 2017 Sem 1 ENG467 Unit InformationDocument5 pages2017 Sem 1 ENG467 Unit InformationAmrit AcharyaNo ratings yet

- Course Unit: Bachelor of Science in Mechanical Engineering: Mechanical Engineering Laboratory 1Document4 pagesCourse Unit: Bachelor of Science in Mechanical Engineering: Mechanical Engineering Laboratory 1Sandra Abancio HollmanNo ratings yet

- Ia - Smaw CGDocument4 pagesIa - Smaw CGArlyn AgustinNo ratings yet

- Smaw DLP - DivisionDocument37 pagesSmaw DLP - DivisionJoel SoreñoNo ratings yet

- Engineering Physics Lab: Course ObjectivesDocument2 pagesEngineering Physics Lab: Course ObjectivesDarren NehNo ratings yet

- Broadband m2 l1234Document70 pagesBroadband m2 l1234Cyrelle Jay MantalabaNo ratings yet

- Arnold Can Run 4 Laps in 12 MinutesDocument68 pagesArnold Can Run 4 Laps in 12 MinutesMphilipTNo ratings yet

- EWF-544-01, Europski Specialist Za Zavarivanje Čelika Za Armiranje BetonaDocument7 pagesEWF-544-01, Europski Specialist Za Zavarivanje Čelika Za Armiranje BetonaMarija IvanovskaNo ratings yet

- 0 Course IntroductoryDocument21 pages0 Course IntroductorySuhail Al-serriNo ratings yet

- Specific Contracts-Course OutlineDocument5 pagesSpecific Contracts-Course OutlineAyush SinghNo ratings yet

- Repair WeldDocument9 pagesRepair WeldEvan Jared L. GalvezNo ratings yet

- CSN10107 Coursework v3Document6 pagesCSN10107 Coursework v3Anonymous gbJHD9IjvNo ratings yet

- We 7012Document3 pagesWe 7012linsonNo ratings yet

- SMAW (2) EditedDocument5 pagesSMAW (2) EditedPrince Neil SeraphimNo ratings yet

- 3 Perform Industry CalculationsDocument90 pages3 Perform Industry CalculationsRobinson ConcordiaNo ratings yet

- AEEE450 - IET Wiring Regulations IDocument3 pagesAEEE450 - IET Wiring Regulations Imohammadali.rezaeifNo ratings yet

- Reliability of Semiconductor Lasers and Optoelectronic DevicesFrom EverandReliability of Semiconductor Lasers and Optoelectronic DevicesNo ratings yet

- SMAW (8) EditedDocument6 pagesSMAW (8) EditedPrince Neil SeraphimNo ratings yet

- SMAW (5) EditedDocument8 pagesSMAW (5) EditedPrince Neil SeraphimNo ratings yet

- Parts of Lesson Plan BUHIANDocument5 pagesParts of Lesson Plan BUHIANPrince Neil SeraphimNo ratings yet

- Lesson Plan MomoDocument2 pagesLesson Plan MomoPrince Neil SeraphimNo ratings yet

- SMAWDocument5 pagesSMAWPrince Neil SeraphimNo ratings yet

- Detailed Lesson Plan Ecological Literacy UnfinishedDocument6 pagesDetailed Lesson Plan Ecological Literacy UnfinishedPrince Neil Seraphim100% (1)

- CBLM FooterDocument34 pagesCBLM FooterPrince Neil SeraphimNo ratings yet

- Understanding CultureDocument3 pagesUnderstanding CulturePrince Neil SeraphimNo ratings yet

- Elc 102 Activity Ia HeDocument1 pageElc 102 Activity Ia HePrince Neil SeraphimNo ratings yet

- ELC 101 ActvityDocument2 pagesELC 101 ActvityPrince Neil SeraphimNo ratings yet

- Detailed Lesson Plan in Science 7 GradeDocument11 pagesDetailed Lesson Plan in Science 7 GradePrince Neil SeraphimNo ratings yet

- Front Office Reservation Department: Telephone EtiquetteDocument50 pagesFront Office Reservation Department: Telephone EtiquettePaola Quintos100% (1)

- Questions About Murder and HistoryDocument19 pagesQuestions About Murder and HistoryIris Kaye AbelleraNo ratings yet

- 2 The Therapeutic Nurse-Client RelationshipDocument30 pages2 The Therapeutic Nurse-Client Relationshipsri endriyaniNo ratings yet

- Statistics 3rd Edition Agresti Solutions ManualDocument25 pagesStatistics 3rd Edition Agresti Solutions ManualMarcusCarlsonerps100% (48)

- Communal LandDocument17 pagesCommunal Landermias dersehNo ratings yet

- Taska Energy Resources LimitedDocument6 pagesTaska Energy Resources Limitedkareem hassan olatundeNo ratings yet

- Electro-Diesels v6Document14 pagesElectro-Diesels v6Nuh AinuhaNo ratings yet

- Rapid Game Development Using Cocos2d JS An End To End Guide To 2DDocument135 pagesRapid Game Development Using Cocos2d JS An End To End Guide To 2DlordinicusNo ratings yet

- Acp 113 (Ah) Call Sign Book PDFDocument224 pagesAcp 113 (Ah) Call Sign Book PDF王大明No ratings yet

- Lecture 1 - Part 1 - Introduction To ECE 105Document12 pagesLecture 1 - Part 1 - Introduction To ECE 105homamhomarNo ratings yet

- Decision Pardo, J.:: Marissa A. Mossesgeld, Petitioner, vs. Court of Appeals and Civil Registrar General, RespondentsDocument2 pagesDecision Pardo, J.:: Marissa A. Mossesgeld, Petitioner, vs. Court of Appeals and Civil Registrar General, RespondentsThrees SeeNo ratings yet

- Skin Studio Powerpoint RevisedDocument8 pagesSkin Studio Powerpoint RevisedAngelo Jay MacaraegNo ratings yet

- HarpDocument9 pagesHarpSergio Miguel MiguelNo ratings yet

- Patenting and Copy Righting Procedures in KenyaDocument6 pagesPatenting and Copy Righting Procedures in KenyaKhayeka AlexNo ratings yet

- NCOB Solidarity Report FINAL PDFDocument135 pagesNCOB Solidarity Report FINAL PDFRes2001No ratings yet

- Print Chapter 6 Mcqs BankDocument8 pagesPrint Chapter 6 Mcqs BankMohammedAlmohammedNo ratings yet

- Nutrition Choice BingoDocument1 pageNutrition Choice BingoJenonymouslyNo ratings yet

- ASSIGNMENT Marketing Coca ColaDocument11 pagesASSIGNMENT Marketing Coca ColaFazal MuhammedNo ratings yet

- NJP 1200 Series Automatic Capsule Filling Machine PDFDocument53 pagesNJP 1200 Series Automatic Capsule Filling Machine PDFElena VardanyanNo ratings yet

- Dialight CE Catalogue 2016 2Document60 pagesDialight CE Catalogue 2016 2KABRENo ratings yet

- 5 Coolest Pinoy Inventions You HavenDocument6 pages5 Coolest Pinoy Inventions You HavenChiela BagnesNo ratings yet

- Invoice 2 PDFDocument1 pageInvoice 2 PDFPurva TiwariNo ratings yet

- BAFINAR - Midterm Draft (R) PDFDocument11 pagesBAFINAR - Midterm Draft (R) PDFHazel Iris Caguingin100% (1)

- Neil Keenan Born To Be WildDocument50 pagesNeil Keenan Born To Be WildGroup K100% (6)

- Q2 Grade 8 Music DLLDocument13 pagesQ2 Grade 8 Music DLLBee Gee GeeNo ratings yet

- (New Directions in Theorizing Qualitative Research) Norman K. Denzin (Editor), James Salvo (Editor) - New Directions in Theorizing Qualitative Research_ Theory as Resistance-Myers Education Press (202Document148 pages(New Directions in Theorizing Qualitative Research) Norman K. Denzin (Editor), James Salvo (Editor) - New Directions in Theorizing Qualitative Research_ Theory as Resistance-Myers Education Press (202josezawadskyNo ratings yet

- The Angel Next Door Spoils Me Rotten - 01 (Yen Press)Document228 pagesThe Angel Next Door Spoils Me Rotten - 01 (Yen Press)Gilbert ValenzuelaNo ratings yet

- Charcot JointDocument8 pagesCharcot JointAtika SugiartoNo ratings yet

- Insurance Analysis ReportDocument12 pagesInsurance Analysis ReportMazharul KarimNo ratings yet

- Group 1-Activity 4Document12 pagesGroup 1-Activity 4Dũng NguyễnNo ratings yet