Professional Documents

Culture Documents

Chapter 5

Uploaded by

tùng thanhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 5

Uploaded by

tùng thanhCopyright:

Available Formats

PETROVIETNAM UNIVERSITY

FUNDAMENTAL SCIENCES DEPARTMENT

STRENGTH OF MATERIALS

Chapter 5: Analysis and Design of

Beams for Bending

Instructor: Le Van Sy, PhD

E-mail : sylv@pvu.edu.vn

Analysis and Design of Beams for Bending

Introduction

Shear and Bending Moment Diagrams

Sample Problem 5.1

Sample Problem 5.2

Relations Among Load, Shear, and Bending

Moment

Sample Problem 5.3

Sample Problem 5.5

Design of Prismatic Beams for Bending

Sample Problem 5.8

Le Van Sy, PhD Strength of materials 5-2

Analysis and Design of Beams for Bending

Le Van Sy, PhD Strength of materials 3

Introduction

• Objective - Analysis and design of beams

• Beams - structural members supporting loads at

various points along the member

• Transverse loadings of beams are classified as

concentrated loads or distributed loads

• Applied loads result in internal forces consisting

of a shear force (from the shear stress

distribution) and a bending couple (from the

normal stress distribution)

• Normal stress is often the critical design criteria

My Mc M

x = − m = =

I I S

Requires determination of the location and

magnitude of largest bending moment

Le Van Sy, PhD Strength of materials 5-4

Introduction

Classification of Beam Supports

Le Van Sy, PhD Strength of materials 5-5

Beam Bending

Le Van Sy, PhD Strength of materials 6

Shear and Bending Moment Diagrams

• Determination of maximum normal and

shearing stresses requires identification of

maximum internal shear force and bending

couple.

• Shear force and bending couple at a point are

determined by passing a section through the

beam and applying an equilibrium analysis on

the beam portions on either side of the

section.

• Sign conventions for shear forces V and V’

and bending couples M and M’

Le Van Sy, PhD Strength of materials 5-7

Beam Bending

Le Van Sy, PhD Strength of materials 8

Sample Problem 5.1

SOLUTION:

• Treating the entire beam as a rigid

body, determine the reaction forces

• Section the beam at points near

supports and load application points.

Apply equilibrium analyses on

resulting free-bodies to determine

For the timber beam and loading internal shear forces and bending

shown, draw the shear and bend- couples

moment diagrams and determine

the maximum normal stress due to • Identify the maximum shear and

bending. bending-moment from plots of their

distributions.

• Apply the elastic flexure formulas to

determine the corresponding

maximum normal stress.

Le Van Sy, PhD Strength of materials 5-9

Sample Problem 5.1

SOLUTION:

• Treating the entire beam as a rigid body, determine

the reaction forces

from Fy = 0 = M B : RB = 40 kN RD = 14 kN

• Section the beam and apply equilibrium analyses

on resulting free-bodies

Fy = 0 − 20 kN − V1 = 0 V1 = −20 kN

M1 = 0 (20 kN )(0 m ) + M1 = 0 M1 = 0

Fy = 0 − 20 kN − V2 = 0 V2 = −20 kN

M2 = 0 (20 kN )(2.5 m ) + M 2 = 0 M 2 = −50 kN m

V3 = +26 kN M 3 = −50 kN m

V4 = +26 kN M 4 = +28 kN m

V5 = −14 kN M 5 = +28 kN m

V6 = −14 kN M 6 = 0

Le Van Sy, PhD Strength of materials 5 - 10

Sample Problem 5.1

• Identify the maximum shear and bending-

moment from plots of their distributions.

Vm = 26 kN M m = M B = 50 kN m

• Apply the elastic flexure formulas to

determine the corresponding

maximum normal stress.

S = 16 b h 2 = 16 (0.080 m )(0.250 m )2

= 833.33 10− 6 m3

MB 50 103 N m

m = =

S 833.33 10− 6 m3

m = 60.0 106 Pa

Le Van Sy, PhD Strength of materials 5 - 11

Sample Problem 5.2

SOLUTION:

• Replace the 10 kip load with an

equivalent force-couple system at D.

Find the reactions at B by considering

the beam as a rigid body.

• Section the beam at points near the

support and load application points.

The structure shown is constructed Apply equilibrium analyses on

of a W10x112 rolled-steel beam. (a) resulting free-bodies to determine

Draw the shear and bending- internal shear forces and bending

moment diagrams for the beam and couples.

the given loading. (b) determine

normal stress in sections just to the • Apply the elastic flexure formulas to

right and left of point D. determine the maximum normal

stress to the left and right of point D.

Le Van Sy, PhD Strength of materials 5 - 12

Sample Problem 5.2

SOLUTION:

• Replace the 10 kip load with equivalent force-

couple system at D. Find reactions at B.

• Section the beam and apply equilibrium

analyses on resulting free-bodies.

From A to C :

Fy = 0 − 3x − V = 0 V = −3 x kips

M1 = 0 (3x )(12 x )+ M = 0 M = −1.5 x 2 kip ft

From C to D :

Fy = 0 − 24 − V = 0 V = −24 kips

M 2 = 0 24( x − 4) + M = 0 M = (96 − 24 x ) kip ft

From D to B :

V = −34 kips M = (226 − 34 x ) kip ft

Le Van Sy, PhD Strength of materials 5 - 13

Sample Problem 5.2

• Apply the elastic flexure formulas to

determine the maximum normal stress to

the left and right of point D.

From Appendix C for a W10x112 rolled

steel shape, S = 126 in3 about the X-X

axis.

To the left of D :

M 2016 kip in

m = = m = 16.0 ksi

S 126 in 3

To the right of D :

M 1776 kip in m = 14.1ksi

m = =

S 126 in 3

Le Van Sy, PhD Strength of materials 5 - 14

Relations Among Load, Shear, and Bending Moment

• Relationship between load and shear:

Fy = 0 : V − (V + V ) − w x = 0

V = − w x

dV

= −w

dx

xD

VD − VC = − w dx

xC

• Relationship between shear and bending

moment:

M C = 0 : (M + M ) − M − V x + wx x = 0

2

M = V x − 12 w (x )

2

dM

=0

dx

xD

M D − M C = V dx

xC

Le Van Sy, PhD Strength of materials 5 - 15

Sample Problem 5.3

SOLUTION:

• Taking the entire beam as a free body,

determine the reactions at A and D.

• Apply the relationship between shear and

load to develop the shear diagram.

Draw the shear and bending • Apply the relationship between bending

moment diagrams for the moment and shear to develop the bending

beam and loading shown. moment diagram.

Le Van Sy, PhD Strength of materials 5 - 16

Sample Problem 5.3

SOLUTION:

• Taking the entire beam as a free body, determine the

reactions at A and D.

MA = 0

0 = D(24 ft ) − (20 kips )(6 ft ) − (12 kips )(14 ft ) − (12 kips )(28 ft )

D = 26 kips

Fy = 0

0 = Ay − 20 kips − 12 kips + 26 kips − 12 kips

Ay = 18 kips

• Apply the relationship between shear and load to

develop the shear diagram.

dV

= −w dV = − w dx

dx

- zero slope between concentrated loads

- linear variation over uniform load segment

Le Van Sy, PhD Strength of materials 5 - 17

Sample Problem 5.3

• Apply the relationship between bending

moment and shear to develop the bending

moment diagram.

dM

=V dM = V dx

dx

- bending moment at A and E is zero

- bending moment variation between A, B,

C and D is linear

- bending moment variation between D

and E is quadratic

- net change in bending moment is equal to

areas under shear distribution segments

- total of all bending moment changes across

the beam should be zero

Le Van Sy, PhD Strength of materials 5 - 18

Sample Problem 5.5

SOLUTION:

• Taking the entire beam as a free body,

determine the reactions at C.

• Apply the relationship between shear

and load to develop the shear diagram.

Draw the shear and bending • Apply the relationship between

moment diagrams for the beam bending moment and shear to develop

and loading shown. the bending moment diagram.

Le Van Sy, PhD Strength of materials 5 - 19

Sample Problem 5.5

SOLUTION:

• Taking the entire beam as a free body,

determine the reactions at C.

Fy = 0 = − 12 w0 a + RC RC = 12 w0 a

a a

M C = 0 = 12 w0 a L − + M C M C = − 12 w0 a L −

3 3

Results from integration of the load and shear

distributions should be equivalent.

• Apply the relationship between shear and load

to develop the shear diagram.

a

x

a x 2

VB − V A = − w0 1 − dx = − w0 x −

2a

0 a 0

VB = − 12 w0 a = − ( area under load curve)

- No change in shear between B and C.

- Compatible with free body analysis

Le Van Sy, PhD Strength of materials 5 - 20

Sample Problem 5.5

• Apply the relationship between bending moment

and shear to develop the bending moment

diagram.

a

a x 2 x 2 x3

M B − M A = − w0 x − dx = − w0 −

2a 2 6a

0 0

M B = − 13 w0 a 2

( )

L

M B − M C = − 12 w0 a dx = − 12 w0 a(L − a )

a

a w0 a

M C = − 16 w0 a(3L − a ) = L−

2 3

Results at C are compatible with free-

body analysis

Le Van Sy, PhD Strength of materials 5 - 21

Design of Prismatic Beams for Bending

• The largest normal stress is found at the surface where the

maximum bending moment occurs.

M max c M max

m = =

I S

• A safe design requires that the maximum normal stress be

less than the allowable stress for the material used. This

criteria leads to the determination of the minimum

acceptable section modulus.

m all

M max

S min =

all

• Among beam section choices which have an acceptable

section modulus, the one with the smallest weight per unit

length or cross sectional area will be the least expensive

and the best choice.

Le Van Sy, PhD Strength of materials 5 - 22

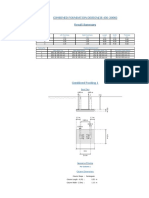

Sample Problem 5.8

SOLUTION:

• Considering the entire beam as a free-

body, determine the reactions at A and

D.

• Develop the shear diagram for the

A simply supported steel beam is beam and load distribution. From the

to carry the distributed and diagram, determine the maximum

concentrated loads shown. bending moment.

Knowing that the allowable normal

stress for the grade of steel to be • Determine the minimum acceptable

used is 160 MPa, select the wide- beam section modulus. Choose the

flange shape that should be used. best standard section which meets this

criteria.

Le Van Sy, PhD Strength of materials 5 - 23

Sample Problem 5.8

• Considering the entire beam as a free-body,

determine the reactions at A and D.

M A = 0 = D(5 m ) − (60 kN )(1.5 m ) − (50 kN )(4 m )

D = 58.0 kN

Fy = 0 = Ay + 58.0 kN − 60 kN − 50 kN

Ay = 52.0 kN

• Develop the shear diagram and determine the

maximum bending moment.

V A = Ay = 52.0 kN

VB − V A = −(area under load curve) = −60 kN

VB = −8 kN

• Maximum bending moment occurs at

V = 0 or x = 2.6 m.

M max = (area under shear curve, A to E )

= 67.6 kN

Le Van Sy, PhD Strength of materials 5 - 24

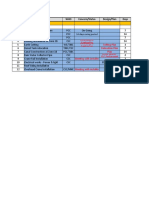

Sample Problem 5.8

• Determine the minimum acceptable beam

section modulus.

M max 67.6 kN m

S min = =

all 160 MPa

= 422.5 10− 6 m3 = 422.5 103 mm3

• Choose the best standard section which meets

this criteria.

Shape S , mm3 W 360 32.9

W410 38.8 637

W360 32.9 474

W310 38.7 549

W250 44.8 535

W200 46.1 448

Le Van Sy, PhD Strength of materials 5 - 25

Le Van Sy, PhD Strength of materials 26

Le Van Sy, PhD Strength of materials 27

Le Van Sy, PhD Strength of materials 28

You might also like

- Strength of Materials: An Introduction to the Analysis of Stress and StrainFrom EverandStrength of Materials: An Introduction to the Analysis of Stress and StrainRating: 5 out of 5 stars5/5 (1)

- Stress Analysis Problems in S.I. Units: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandStress Analysis Problems in S.I. Units: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 2.5 out of 5 stars2.5/5 (4)

- 5 BeamsDocument22 pages5 BeamsataNo ratings yet

- 5 Design of Beams (2022)Document30 pages5 Design of Beams (2022)YAŞAR MERT DOĞANAYNo ratings yet

- CHAPTER 5 BEAM MECHANICS AND STRESSESDocument18 pagesCHAPTER 5 BEAM MECHANICS AND STRESSESEngineering RubixNo ratings yet

- Course Title: Mechanics of Materials Course Code: MM-205 Year: S.EDocument21 pagesCourse Title: Mechanics of Materials Course Code: MM-205 Year: S.ESahar Batool QaziNo ratings yet

- Bending of Straight Beams 1: Amir Radzi Ab. GhaniDocument37 pagesBending of Straight Beams 1: Amir Radzi Ab. GhaniMohdNorAzmiNo ratings yet

- SHEAR AND BENDINGDocument9 pagesSHEAR AND BENDINGSyamil TamlikhaNo ratings yet

- Jhonson Beer Beams PDFDocument25 pagesJhonson Beer Beams PDFluis peixotoNo ratings yet

- Shear Force and Bending Moment Diagrams ZP 14 PDFDocument17 pagesShear Force and Bending Moment Diagrams ZP 14 PDFZdenkoNo ratings yet

- Shear Force and Bending Moment Diagrams ZP 14Document17 pagesShear Force and Bending Moment Diagrams ZP 14ZdenkoNo ratings yet

- Mechanics of Solids: Analysis and Design of Beams For BendingDocument23 pagesMechanics of Solids: Analysis and Design of Beams For BendingZabid UllahNo ratings yet

- Department of Mechanical EngineeringDocument16 pagesDepartment of Mechanical EngineeringarulmuruguNo ratings yet

- BTE 1013 Engineering Sciences: 8. Shear Force and Bending MomentDocument32 pagesBTE 1013 Engineering Sciences: 8. Shear Force and Bending MomentAli HassenNo ratings yet

- Statics and Mechanics of MaterialsDocument22 pagesStatics and Mechanics of MaterialsAli HassenNo ratings yet

- Text Book: "Advanced Mechanics of Materials"Document22 pagesText Book: "Advanced Mechanics of Materials"developmental biologyNo ratings yet

- BendingDocument92 pagesBendingardiyansyah189No ratings yet

- Chapter 4Document49 pagesChapter 4tùng thanhNo ratings yet

- Analysis and Design Of: Beams For BendingDocument32 pagesAnalysis and Design Of: Beams For BendingGabbar SinghNo ratings yet

- Forces in BeamDocument28 pagesForces in BeamEdward NamoraNo ratings yet

- Mo M1 Chap 5Document32 pagesMo M1 Chap 5Jeff HardyNo ratings yet

- Mom 1Document25 pagesMom 1Husnain ShahidNo ratings yet

- Chapter 1-2Document29 pagesChapter 1-2Tech&EngUniversity ITdepartmentNo ratings yet

- Shear ForceDocument9 pagesShear ForceMuhamed ZaimNo ratings yet

- Structural Analysis (FINALS) PDFDocument45 pagesStructural Analysis (FINALS) PDFJunel Torrejos100% (1)

- MCHT 213 - Section 3 Strength of Materials: Section 3 - 7:00 - 8:15 PM Tue/ThurDocument36 pagesMCHT 213 - Section 3 Strength of Materials: Section 3 - 7:00 - 8:15 PM Tue/Thurkronik_insanNo ratings yet

- Chapter 3Document35 pagesChapter 3tùng thanhNo ratings yet

- ENGR6005 Mechanics of Materials Course OverviewDocument47 pagesENGR6005 Mechanics of Materials Course Overviewlola angela teterissaNo ratings yet

- Lecture 7 - Shear Force and Bending Moment Diagram 1Document32 pagesLecture 7 - Shear Force and Bending Moment Diagram 1imranjami100% (2)

- Analysis and Design of Beams For Bending: MEE 320: Strength of MaterialsDocument36 pagesAnalysis and Design of Beams For Bending: MEE 320: Strength of Materialskamalnath100% (1)

- Lec 03, Rectangular Components of ForceDocument21 pagesLec 03, Rectangular Components of ForceAli Raza100% (1)

- 1. Mechanical TestingDocument21 pages1. Mechanical TestingMING LIAONo ratings yet

- Beam Loading Types and EffectsDocument62 pagesBeam Loading Types and EffectsalexNo ratings yet

- Mechanics of Materials IntroductionDocument29 pagesMechanics of Materials IntroductionengrrrrNo ratings yet

- Shri Chakra 4 16Document13 pagesShri Chakra 4 16Vasupilli VennelaNo ratings yet

- CH1 Intro&StaticsDocument42 pagesCH1 Intro&Staticsgelber clintonNo ratings yet

- Mechanics of Materials: Analysis and Design of Beams For BendingDocument22 pagesMechanics of Materials: Analysis and Design of Beams For Bendingfaizan260690No ratings yet

- Mechanics of Materials: Introduction - Concept of StressDocument10 pagesMechanics of Materials: Introduction - Concept of StressMelbert BonotanNo ratings yet

- Mechanics of Materials: Chapter 5: Analysis of Beams For BendingDocument44 pagesMechanics of Materials: Chapter 5: Analysis of Beams For Bendingاحمد يوسفNo ratings yet

- Week 12 Method of Consistent Deformation (1)Document20 pagesWeek 12 Method of Consistent Deformation (1)Axle LadimNo ratings yet

- Course Title: Mechanics of Materials Course Code: MM-205 Year: S.EDocument14 pagesCourse Title: Mechanics of Materials Course Code: MM-205 Year: S.ESahar Batool QaziNo ratings yet

- Lec9 PDFDocument5 pagesLec9 PDFDilip KumarNo ratings yet

- Kesetimbangan Partikel Dan Keseimbangan Benda TegarDocument25 pagesKesetimbangan Partikel Dan Keseimbangan Benda TegarEka NugrahaNo ratings yet

- Mechanics of Materials: Analysis and Design of Beams For BendingDocument22 pagesMechanics of Materials: Analysis and Design of Beams For BendingRashmi SahooNo ratings yet

- Presentation On Beams (Part I)Document36 pagesPresentation On Beams (Part I)nagoori amanullaNo ratings yet

- CIVIL ENGINEERING MODULE ON MECHANICS OF DEFORMABLE BODIESDocument31 pagesCIVIL ENGINEERING MODULE ON MECHANICS OF DEFORMABLE BODIESWalwal WalwalNo ratings yet

- Mechanics of Materials: Analysis and Design of Beams For BendingDocument22 pagesMechanics of Materials: Analysis and Design of Beams For BendingLife hacksNo ratings yet

- Theory of Structure I: Engr. Gabriel GamanaDocument14 pagesTheory of Structure I: Engr. Gabriel Gamanamichael jayNo ratings yet

- Friction: Vector Mechanics For Engineers: StaticsDocument22 pagesFriction: Vector Mechanics For Engineers: StaticsrushdiNo ratings yet

- Lec 3Document22 pagesLec 3Maya TareqNo ratings yet

- Me2003d Solid Mechanics - 16-11Document164 pagesMe2003d Solid Mechanics - 16-11Vidhya NairNo ratings yet

- Fundamentals of Strength of Materials Examples of Questions For Test #2Document2 pagesFundamentals of Strength of Materials Examples of Questions For Test #2Oumaima La RebelleNo ratings yet

- Stiffness Method For BeamsDocument39 pagesStiffness Method For BeamsluisalvesqueirozNo ratings yet

- Structural Analysis NotesDocument166 pagesStructural Analysis NotesdunyNo ratings yet

- STATIC NOTES Notes 4Document29 pagesSTATIC NOTES Notes 4nfatihahNo ratings yet

- 1 IntroductionDocument25 pages1 IntroductionGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Introduction - Concept of StressDocument25 pagesIntroduction - Concept of StressTony HuangNo ratings yet

- Chapter 11 BendingDocument27 pagesChapter 11 BendingSofwan JuewekNo ratings yet

- Mechanics of Materials - 3Document24 pagesMechanics of Materials - 3awanNo ratings yet

- Chapter 4Document49 pagesChapter 4tùng thanhNo ratings yet

- Chapter 3Document35 pagesChapter 3tùng thanhNo ratings yet

- Chapter 2Document35 pagesChapter 2tùng thanhNo ratings yet

- Chapter 5Document28 pagesChapter 5tùng thanhNo ratings yet

- Technical - Manual El - Zinc MetalTech 2012Document158 pagesTechnical - Manual El - Zinc MetalTech 2012RICARDO GIERKENo ratings yet

- 2239 - Specification of Brick Work and Plastering WorkDocument12 pages2239 - Specification of Brick Work and Plastering Workvelmurug_bala100% (2)

- Project No. 20361 BAA Retail Development Lot 32-37, 271 - 311 Garth RD, JohnswoodDocument12 pagesProject No. 20361 BAA Retail Development Lot 32-37, 271 - 311 Garth RD, JohnswoodBennet LawNo ratings yet

- Geotechnical EngineeringDocument33 pagesGeotechnical EngineeringXkarr RastaNo ratings yet

- E Spec Guide BCI and VL PDFDocument36 pagesE Spec Guide BCI and VL PDFcphammond83No ratings yet

- Northern Railway Line Doubling Project DetailsDocument6 pagesNorthern Railway Line Doubling Project DetailsPrasanta ParidaNo ratings yet

- BRIDGE DESIGN MANUALDocument49 pagesBRIDGE DESIGN MANUALdulancivil100% (11)

- Hydraulics 1 Lec 2 20 21 PDFDocument28 pagesHydraulics 1 Lec 2 20 21 PDFAngelo Luis RosNo ratings yet

- JKR ProbeDocument6 pagesJKR ProbeAinur NasuhaNo ratings yet

- DM Exam OnlyDocument7 pagesDM Exam OnlyHamza AhmadNo ratings yet

- %DWK - FLUFXODWLRQ Water Bath: Iq - OqDocument1 page%DWK - FLUFXODWLRQ Water Bath: Iq - OqnyanaungNo ratings yet

- Plumbing BOQDocument3 pagesPlumbing BOQMuhammad KhubaibNo ratings yet

- Casing and TubingDocument6 pagesCasing and TubingWulandari Tri Maharani100% (1)

- Behavior of Q690 High-Strength Steel Columns - Part 2 - Can - Be - UsedDocument16 pagesBehavior of Q690 High-Strength Steel Columns - Part 2 - Can - Be - UsedSeymur AkbarovNo ratings yet

- The Effect of Aggregate Properties On Concrete: Strength, Workability DurabilityDocument2 pagesThe Effect of Aggregate Properties On Concrete: Strength, Workability DurabilityBasleal SemachewNo ratings yet

- Arunachal AE Civil Study MaterialDocument1 pageArunachal AE Civil Study MaterialNarundra modiNo ratings yet

- Civil Surveying and Drawing - A1Document8 pagesCivil Surveying and Drawing - A1Parangat SharmaNo ratings yet

- Week 7 Truss DesignDocument39 pagesWeek 7 Truss DesignFoo He XuanNo ratings yet

- St. Anthony Falls (I-35W) BridgeDocument48 pagesSt. Anthony Falls (I-35W) BridgesalmanNo ratings yet

- Silica Fume and Fly AshDocument14 pagesSilica Fume and Fly AshGeetesh MakadiaNo ratings yet

- Risk Assessment of Culvert Blockage and FloodingDocument5 pagesRisk Assessment of Culvert Blockage and Floodingrajal11No ratings yet

- Advanced Fluid Mechanics PartDocument9 pagesAdvanced Fluid Mechanics PartkishorebabubhumulaNo ratings yet

- JAPANESE INDUSTRIAL STANDARD FOR PRESTRESSED CONCRETE PILESDocument15 pagesJAPANESE INDUSTRIAL STANDARD FOR PRESTRESSED CONCRETE PILESVõ Quang Kiệt100% (2)

- NHAI bearing inspectionDocument6 pagesNHAI bearing inspectionrohitNo ratings yet

- Tribhuvan University Fluid Mechanics ExamDocument11 pagesTribhuvan University Fluid Mechanics ExamAbishek AdhikariNo ratings yet

- AISI S200-07 Standard and Commentary (1st Printing) PDFDocument46 pagesAISI S200-07 Standard and Commentary (1st Printing) PDFthjozsefNo ratings yet

- Zone1B construction project timeline and tasksDocument8 pagesZone1B construction project timeline and tasksAlfric AbinsayNo ratings yet

- Concrete Slump TestDocument3 pagesConcrete Slump TestShaan LalwaniNo ratings yet

- Esr 3269 PDFDocument19 pagesEsr 3269 PDFMauricio RiquelmeNo ratings yet

- Combined Foundation Design (Is 456-2000) Result SummaryDocument30 pagesCombined Foundation Design (Is 456-2000) Result Summaryarchetype designNo ratings yet