Professional Documents

Culture Documents

Steam Turbine Testing During Shut-Down Maintenance

Uploaded by

MELCO JITPLOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steam Turbine Testing During Shut-Down Maintenance

Uploaded by

MELCO JITPLCopyright:

Available Formats

Steam Turbine Testing during Shut-down

Maintenance

Introduction Test performance

Tests that demonstrate the proper functioning of Take care to avoid any risks to people or machines while

important components must be performed during shut performing tests.

down of the turbine generator unit.

Any simulated condition necessary for the tests must be

The scope of the tests performed is listed in the Test cancelled after completion of tests.

interval instruction [1].

Steam inlet valves may only be opened for test purposes

if the piping system upstream of those valves is not under

Test Procedures pressure and the system concerned have been cleared

for testing.

Test prerequisites, test activities and criteria in tabular

form are intended to simplify testing. Test performance must be recorded.

The tables can also be used as checklists. When no If incorrect operation of the equipment being tested

specific instructions are given for any test, the test occurs, take action establishing full operational reliability

sequences shown in the table must be followed. of the turbine generator unit immediately.

A number of tests require certain components be in a Pay attention to fault tracing instructions.

definite position (e.g. main trip valves in operating

position, stop valves closed, etc.).

The operating sequence establishing certain operating

conditions is given in the form of general instructions to

avoid constant repetition in the tables of test sequences. Also refer to the following sections:

[1] 6.2-002. : Testing of turbine components

[2] 6.3-0061 : Testing during standstill

Equipment tested o Preconditions Date

() Test Step Result

o Type of test

• Result Tested by

Main trip valves in operating

position

{ Stop valves closed o Starting and load limit device not in 0%

position

o Test valves of stop valves in left-hand

end position ( = stop valves open)

(1) Move test valve pilot into right-hand

end position ( = stop valves closed)

using hand wheel

(2) Bring starting and load limit device

into 0 % position

• Main trip valves in operating position

(3) Bring starting and load limit device

into 40 % position

BHEL, Hardwar 6.3-0060-01/1

Equipment tested o Preconditions Date

o Type of test () Test Step Result

• Result Tested by

• Main trip valves in operating position

and ready to trip

• Stop valves closed

o Stop valves open o Starting and load limit device not in 0%

position

o Test valves of stop valves in left-hand

end position

(1) Bring starting and load limit device

into 0 % position

• Main trip valves in operating position

(2) Bring starting and load limit device

into 40 % position

• Main trip valves in operating position

and ready to trip

• Stop valves open

Overspeed trip

o Overspeed test after test interval o Generator not synchronized

or after inspections and repairs o Turbine generator unit at rated speed

(See also instruction 6.3-0030)

o Turbine at operating temperature

(1) Raise speed reference to maximum

• Speed approx. 107%

(2) Switch off Electro-hydraulic controller

(3) Run up to trip speed by pressing

mechanical push button on hydraulic

speed governor

(4) Verify operation of overspeed trip

• Trip speed

• Stop and control valves closed

Control valves and reverse power

protection relay

o Leak test valves o Generator synchronized

and o Load > 0 %

o Functional test (reverse power o Speed governor effective

relay)

(1) Lower speed set point

BHEL, Hardwar 6.3-0060-01/2

Equipment tested o Preconditions Date

o Type of test () Test Step Result

• Result Tested by

• Secondary pressures < opening

pressure for control valves

• Control valves 0%

(2) Verify operation of reverse power

protection relay

• Reverse power protection relay

operated

• Generator breaker tripped

or

• Reverse power protection relay not

operating (see serious faults 6.2-0410)

Auxiliary oil pump

o Pressure dependent on o Stop and control valves closed

command

o Turbine speed dropping

(1) Verify startup of auxiliary oil pump on

pressure-dependent command

• Auxiliary oil pump on

Jacking oil pump

o Speed dependent on command o Stop and control valves closed

o Turbine speed dropping

(1) Verify startup of jacking oil pump on

speed-dependent command

• Jacking oil pump on

Turning gear oil valve

o Speed-dependent open o Stop and control valves closed

command

o Turbine speed dropping

(1) Verify opening of turning gear oil

valve on speed-dependent command

• Turning gear oil valve open

Condenser Safety devices

o Response of electrical o Turbine generator unit not operating

condenser safety device

o Condenser plant operating

BHEL, Hardwar 6.3-0060-01/3

Equipment tested o Preconditions Date

o Type of test () Test Step Result

• Result Tested by

o Criteria for shut down of condenser

plant fulfilled

o Main trip valves in operating position

o Stop valves closed

(1) Reduce condenser vacuum

(2) Verify operation of electrical condenser

safety device

• Trip initiated

(3) Restore main trip valves to normal

operating position

o Response of hydraulic low o Condenser safety device test

vacuum trip (electrical) performed

o Condenser vacuum > trip vacuum

(hydraulic)

o Main trip valves in operating position

o Stop valves closed

(1) Simulated turbine speed by screwing

in locking bolt on low-vacuum trip

(2) Reduce condenser vacuum

(3) Verify operation of electrical condenser

safety device

• Trip initiated

(4) Restore main trip valves to normal

Operating position

(5) Cancel hydraulic speed simulation

(Unscrew locking bolt on low-vacuum

trip)

(6) Move test valve into operating position

Condenser Safety devices for

bypass operation

o Response of hydraulic low o Condensate extraction pumps

vacuum trip operating

o Condenser pressure Pabs < 0.5 bar

o Criteria for shut down of condenser

plant fulfilled

BHEL, Hardwar 6.3-0060-01/4

Equipment tested o Preconditions Date

o Type of test () Test Step Result

• Result Tested by

o Bypass operation ended

(1) Press push-button of LP bypass

governor

• Signal pressure for bypass control

valves > 1.7 bar < 2.06 bar

• Bypass stop valves

(2) Operate push-button of LP Bypass limit

controller to inhibit response due to

reduction of condenser vacuum

(3) Reduce condenser vacuum

(4) Verify operation of low vacuum trip

• Signal pressure upstream of bypass

control valves reduced

BHEL, Hardwar 6.3-0060-01/5

You might also like

- ATS Testing & Commissioning - Method Statement HQDocument5 pagesATS Testing & Commissioning - Method Statement HQHansika Rajapaksha100% (1)

- Method Statement For Testing & Commissioning of Diesel GeneratorDocument6 pagesMethod Statement For Testing & Commissioning of Diesel Generatorvin ss100% (1)

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsFrom Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsRating: 1 out of 5 stars1/5 (1)

- Hitachi Ex550-5 Section 4 Operational Performance TestDocument45 pagesHitachi Ex550-5 Section 4 Operational Performance Testdatphuong100% (1)

- Procedure de Test BOPDocument12 pagesProcedure de Test BOPkhireddineboulifaNo ratings yet

- Marine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersFrom EverandMarine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersRating: 5 out of 5 stars5/5 (2)

- Chapter-8 Turbine and Governor TestingDocument10 pagesChapter-8 Turbine and Governor Testingafru2000No ratings yet

- Hitachi Zaxis 200 240 270 3 Class Training Text Performance TroubleshootingDocument20 pagesHitachi Zaxis 200 240 270 3 Class Training Text Performance Troubleshootingjohnathan100% (50)

- Fan Motor D155ax-6 Lmf75 Test 50495Document12 pagesFan Motor D155ax-6 Lmf75 Test 50495Interclima SpaNo ratings yet

- Loop Test ProcedureDocument4 pagesLoop Test Procedureviddyadrian100% (2)

- Digital Systems Design and PrototypingDocument633 pagesDigital Systems Design and PrototypingAshish Shrivastava50% (2)

- Types of Malware and Importance of Malware AnalysisDocument10 pagesTypes of Malware and Importance of Malware AnalysisshaletNo ratings yet

- Gov1 Sim 23.12.06Document25 pagesGov1 Sim 23.12.06SamNo ratings yet

- Testing Method StatementDocument9 pagesTesting Method StatementsardarmkhanNo ratings yet

- PC210-10M0 3 Maintenance and Inspection (Final) - EDocument14 pagesPC210-10M0 3 Maintenance and Inspection (Final) - EReza Syailendra100% (1)

- The Best of Bruce's Postgres Slides: Ruce OmjianDocument26 pagesThe Best of Bruce's Postgres Slides: Ruce OmjianPhotoHawkNo ratings yet

- Qualititative Test of Lipids and Preparation of Carboxylic Acid Salt From LipidsDocument6 pagesQualititative Test of Lipids and Preparation of Carboxylic Acid Salt From LipidsNurul Farhana NasirNo ratings yet

- Vikash Kumar: Career ObjectiveDocument2 pagesVikash Kumar: Career ObjectiveAnikesh SinghNo ratings yet

- Performance CheckDocument603 pagesPerformance CheckSergio Muñoz Barrios100% (1)

- T&C Plan and ChecklistDocument5 pagesT&C Plan and ChecklistAku MattNo ratings yet

- OM Best Practices Guidelines V3.0Document98 pagesOM Best Practices Guidelines V3.0Enrique Balan RomeroNo ratings yet

- Induction Motor Testing at FactoryDocument7 pagesInduction Motor Testing at FactorysrinivasgillalaNo ratings yet

- Automatic Turbine Testing (Att) : PMI-Noida 1Document12 pagesAutomatic Turbine Testing (Att) : PMI-Noida 1rajan_me083100% (1)

- Troubleshooting EngineDocument27 pagesTroubleshooting EngineDani Setiawan100% (1)

- Quy Trinh T&C BMS Cho MVAC - Tham KhaoDocument79 pagesQuy Trinh T&C BMS Cho MVAC - Tham Khaovin ssNo ratings yet

- Reading A02wout AnsDocument4 pagesReading A02wout AnsTavi Nicolae67% (3)

- Seam 325 Prelim Exam ReviewerDocument6 pagesSeam 325 Prelim Exam ReviewerKyle Steven CaymeNo ratings yet

- Soalan Biologi Kertas 2 Tingkatan 4Document14 pagesSoalan Biologi Kertas 2 Tingkatan 4azszah100% (17)

- Control Valve Calibration Procedure Fisher HC6010 PDFDocument14 pagesControl Valve Calibration Procedure Fisher HC6010 PDFAnonymous JwOs90v6TUNo ratings yet

- Angeles, Rea P - Unit 1 - Methods in Teaching Industrial ArtsDocument2 pagesAngeles, Rea P - Unit 1 - Methods in Teaching Industrial ArtsEthel Rose SorianoNo ratings yet

- Steam Turbine Testing During Standstill MaintenanceDocument6 pagesSteam Turbine Testing During Standstill Maintenancedreamboy87No ratings yet

- On-Site Acceptance Test ProgramDocument7 pagesOn-Site Acceptance Test ProgramDaniel CorreaNo ratings yet

- HKC Elect Ric Quart Er T Urn Act Uat or 'HQ' Series Inst Ruct Ion and Maint Enance ManualDocument32 pagesHKC Elect Ric Quart Er T Urn Act Uat or 'HQ' Series Inst Ruct Ion and Maint Enance ManualFlo MarineNo ratings yet

- Lab ManualDocument9 pagesLab Manualnanda_kavalaNo ratings yet

- 730C Articulated Truck TFF0000sss1-UP (MACHINE) POWERED BY C13 Engine (SEBP5991 - 38) - Sistemas y ComponentesDocument4 pages730C Articulated Truck TFF0000sss1-UP (MACHINE) POWERED BY C13 Engine (SEBP5991 - 38) - Sistemas y ComponentesFabrizio JesúsNo ratings yet

- Load Rejection TestDocument3 pagesLoad Rejection TestRaju SkNo ratings yet

- Primus Workbook: Primus Family Quick GuideDocument28 pagesPrimus Workbook: Primus Family Quick Guidecevdet limanNo ratings yet

- Caterpillar Ep20tDocument66 pagesCaterpillar Ep20tCoque de LunaNo ratings yet

- Jaso C712 1982 (En)Document13 pagesJaso C712 1982 (En)m.srinivasanNo ratings yet

- Index:: This Performance Test Procedure Contains The Following ElementsDocument6 pagesIndex:: This Performance Test Procedure Contains The Following ElementsAnwarNo ratings yet

- "Wba Units": JCM Products Quick Reference GuideDocument16 pages"Wba Units": JCM Products Quick Reference GuideDan KollanderNo ratings yet

- Over Speed TestDocument8 pagesOver Speed TestsaitamaopmofficialNo ratings yet

- Actuator Calibration GEN IV - en-GBDocument5 pagesActuator Calibration GEN IV - en-GBIsos CellNo ratings yet

- Eep-Commissioning of HV Panel Operational and Functional CheckupDocument3 pagesEep-Commissioning of HV Panel Operational and Functional Checkupabdulyunus_amirNo ratings yet

- Fat 2Document3 pagesFat 2ALI BEN AMORNo ratings yet

- E405-04 (2012) Standard Test Methods For Wear Testing Rotary Operators For WindowsDocument4 pagesE405-04 (2012) Standard Test Methods For Wear Testing Rotary Operators For WindowsMuhammad SalmanNo ratings yet

- 03 Ts 51Document4 pages03 Ts 51giovanni ampueroNo ratings yet

- Aim of The ExperimentDocument10 pagesAim of The Experimentadssf fdgddNo ratings yet

- Pressure TestDocument41 pagesPressure TestJoshua WeeNo ratings yet

- Sy Sl120 EnglishDocument18 pagesSy Sl120 Englishkeerthick vaasanNo ratings yet

- Cirus Controls Valve Assy Install and Commissioning Procedure 8.09Document2 pagesCirus Controls Valve Assy Install and Commissioning Procedure 8.09ohbabyohbabyNo ratings yet

- SK330 Trouble Shoot (By Trouble)Document36 pagesSK330 Trouble Shoot (By Trouble)ferdyak1No ratings yet

- ATT Stop and Control Valves-WriteupDocument3 pagesATT Stop and Control Valves-WriteupVijay MahantNo ratings yet

- MCSI - UHGB - N6-3.43 Operation Manual - Eng PDFDocument7 pagesMCSI - UHGB - N6-3.43 Operation Manual - Eng PDFBatbayar NyandagjidNo ratings yet

- 4200 Performance Verification Manual 2020.2.0Document14 pages4200 Performance Verification Manual 2020.2.0Ana Gabriela OjedaNo ratings yet

- Routine Tests and Type Tests of Transformers - Electrical4uDocument18 pagesRoutine Tests and Type Tests of Transformers - Electrical4u2251 EE MANMAT BIRADARNo ratings yet

- CA BA BS 120&200&200E Application GuideDocument53 pagesCA BA BS 120&200&200E Application Guidevikasverma90No ratings yet

- Astm E405Document4 pagesAstm E405Lupita Ramirez100% (1)

- Operational Performance Test: Section 4Document64 pagesOperational Performance Test: Section 4cunNo ratings yet

- SOP WI Pneumatic On-Off Valves - Calibrating Stroke CheckDocument1 pageSOP WI Pneumatic On-Off Valves - Calibrating Stroke CheckJarrodNo ratings yet

- Testing & Maintenance of Rotating Machines Type Tests, Routine Tests & Special Tests of 1 & 3 Phase Induction MotorsDocument12 pagesTesting & Maintenance of Rotating Machines Type Tests, Routine Tests & Special Tests of 1 & 3 Phase Induction MotorsPKNo ratings yet

- Ohmega 402 OmicronDocument27 pagesOhmega 402 OmicronhossamNo ratings yet

- General Maintenance RevisedDocument80 pagesGeneral Maintenance RevisedseanaluderNo ratings yet

- Process Control Lab ManualDocument95 pagesProcess Control Lab ManualMangaiyarakarasi VenkatachalamNo ratings yet

- Electrical Weights PercentageDocument6 pagesElectrical Weights PercentageHoooda AsdNo ratings yet

- JhonDocument3 pagesJhonlennon rNo ratings yet

- Operational Performance Test: Section 4Document66 pagesOperational Performance Test: Section 4Tú Xuân Lương100% (1)

- Generator Online Test ProcedureDocument6 pagesGenerator Online Test ProcedureantodamanikNo ratings yet

- Edoc-What Is Automatic Transfer Switch Testing and How Is It DoneDocument9 pagesEdoc-What Is Automatic Transfer Switch Testing and How Is It DoneEl Comedor Benedict100% (1)

- T200A Single Phase Universal Test SetDocument8 pagesT200A Single Phase Universal Test SetpiticelNo ratings yet

- Mill Cag PassingDocument2 pagesMill Cag PassingMELCO JITPLNo ratings yet

- BTG AlarmDocument7 pagesBTG AlarmMELCO JITPLNo ratings yet

- WBDocument2 pagesWBMELCO JITPLNo ratings yet

- Bik VaccumDocument2 pagesBik VaccumMELCO JITPLNo ratings yet

- Description Electr. Drawing 5800029 - BHELDocument2 pagesDescription Electr. Drawing 5800029 - BHELMELCO JITPLNo ratings yet

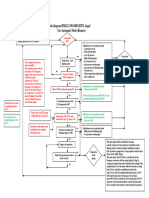

- Block Diagram Automatic Remote Mode - BHELDocument1 pageBlock Diagram Automatic Remote Mode - BHELMELCO JITPLNo ratings yet

- Block Diagram Local Mode HMQ-F - 250-2000 5800029 - BHELDocument1 pageBlock Diagram Local Mode HMQ-F - 250-2000 5800029 - BHELMELCO JITPLNo ratings yet

- Signal List 5800029 Doc.005 2revDocument1 pageSignal List 5800029 Doc.005 2revMELCO JITPLNo ratings yet

- S7-5800029-02 - Doku - en - BHEL BoilerDocument54 pagesS7-5800029-02 - Doku - en - BHEL BoilerMELCO JITPLNo ratings yet

- Vitamins and Minerals Lecture NotesDocument9 pagesVitamins and Minerals Lecture NotesJoymae Olivares Tamayo100% (1)

- Mitsubishi Electric MSZ-FH VE Remote Controller Eng PDFDocument1 pageMitsubishi Electric MSZ-FH VE Remote Controller Eng PDFShadi MattarNo ratings yet

- An Introduction To Mount EverestDocument4 pagesAn Introduction To Mount EverestJihad HasanNo ratings yet

- Recognia Intraday Trader InfosheetDocument2 pagesRecognia Intraday Trader InfosheetDipesh PawaiyaNo ratings yet

- Corporate Governor in Banking SectorDocument4 pagesCorporate Governor in Banking SectorAcousticParesh PatelNo ratings yet

- Ebook PDF Consumer Behaviour Asia Pacific Edition by Wayne D Hoyer PDFDocument41 pagesEbook PDF Consumer Behaviour Asia Pacific Edition by Wayne D Hoyer PDFmarvin.tappen826100% (35)

- Experiment No.1. (Monograph)Document3 pagesExperiment No.1. (Monograph)ayeza.sarwar2021No ratings yet

- BMI Middle East and Africa Oil and Gas Insight March 2016Document10 pagesBMI Middle East and Africa Oil and Gas Insight March 2016Anonymous pPpTQrpvbrNo ratings yet

- Unit 7 Legal EthicalDocument22 pagesUnit 7 Legal Ethicalapi-462777064No ratings yet

- Multi Car ParkingDocument33 pagesMulti Car ParkingTanvi KhuranaNo ratings yet

- WPI PharmaceuticalsDocument23 pagesWPI PharmaceuticalsKyle Millar-CorlissNo ratings yet

- 01-PPS SMOI User Manual BodyDocument93 pages01-PPS SMOI User Manual BodyGuelahourou Joel SossieNo ratings yet

- Sky SurfingDocument10 pagesSky SurfingCamila Soledad Aguilera PizarroNo ratings yet

- Mid Term Asssignment - The Five Senses - PrimaryDocument5 pagesMid Term Asssignment - The Five Senses - PrimaryPrajna MoodabidriNo ratings yet

- Carob (Ceratonia Siliqua) : Synonyms / Common Names / Related TermsDocument7 pagesCarob (Ceratonia Siliqua) : Synonyms / Common Names / Related TermsMonica BotaNo ratings yet

- DLL English 8 q4 w5Document6 pagesDLL English 8 q4 w5Rovie SaladoNo ratings yet

- Roxas Claire B. Science Technology and Society 09 Activity 1Document1 pageRoxas Claire B. Science Technology and Society 09 Activity 1Eldrick Neil Reyes100% (1)

- AkbarDocument13 pagesAkbarNihar HarinkhedeNo ratings yet

- Chapter 4 IR ModelsDocument34 pagesChapter 4 IR ModelsYohannes KefaleNo ratings yet

- Progress Audio Script 2Document1 pageProgress Audio Script 2groniganNo ratings yet