Professional Documents

Culture Documents

IMS-EG-002-VER 02 - Guidelines On Provision of Foam Compound and FB 5X in FHCs

Uploaded by

DINESH KUMAROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IMS-EG-002-VER 02 - Guidelines On Provision of Foam Compound and FB 5X in FHCs

Uploaded by

DINESH KUMARCopyright:

Available Formats

Engineering Guideline

PROVISION OF APPROPRIATE FOAM COMPOUND

AND FOAM MAKING BRANCH (FB 5X) IN THE FHCS

Prepare & Prevent

Instead of Repair & Repent

Page 1 of 7 Date of Revision: 14.05.22 IMS-EG-002-VER 02

Document Issue Date Complied By Document Approved By

Issue Owner

IMS-EG-002-1 19.11.2013 Members of Chairman of Chairman of

Rules & Rules & Rules &

Procedure Procedure Procedure

Sub- Sub- Sub-

Committee Committee Committee

Document Version No Revision Date Standard Document No.

01 17.12.18 IMS-EG-002-VER 01

02 14.05.22 IMS-EG-002-VER 02

Table of Content

Sr. Page

Content

No No.

1 Purpose 3

2 Scope 3

3 Definition & Abbreviations 3

4 Implementation Responsibility 3

5 Record 3

6 EG Renewable Process 3

7 Engineering Guidelines 4

Page 2 of 7 Date of Revision: 14.05.22 IMS-EG-002-VER 02

1.0 Purpose

The purpose of this Engineering Guidelines (EG) is to ensure that Fire Hose Cabinets (FHCs)

near Food courts, Liquor stores, DG Rooms & appropriate locations in the building basements

are equipped with foam making branch (FB 5X) & appropriate Foam compound to deal with oil /

alcohol fires (Class B Fires).

2.0 Scope

This guideline is applicable to all Buildings/Units/Malls under DLF -RENTCO.

3.0 Definitions/ Abbreviations

Definition – Nil

Abbreviations

AFFF- Aqueous Film Forming Foam

4.0 Implementation Responsibility

Facility Management team shall be responsible to ensure implementation of this EG.

5.0 Record

The various records shall be maintained at site as explained in this EG.

6.0 EG Renewal Process

The EG shall be reviewed and revised by the rules & Procedure Sub-committee as necessary

and at a minimum, not later than 3 years from the date of the last revision based on the feedback

from various sources.

Page 3 of 7 Date of Revision: 14.05.22 IMS-EG-002-VER 02

7.0 Guidelines

7.1 LOCATIONS REQUIRING FOAM FIRE FIGHTING FACILITY :

7.1.1 Food Courts: In case of fires in food courts it may become necessary to control fires in oily

substances for which foam is one of the appropriate extinguishing media. Therefore, it is felt

necessary to provide foam making arrangements in the FHCs near to food court for timely action. The

FHCs near to food court should be provided with 01 can of AFFF foam compound and 01 Foam

making branch FB 5X.( Minimum two FHCs should have provision). These FHCs should be provided

with a signage “EQUIPPED WITH AFFF & FB 5X”. The signage should be on the FHC Glass.

7.1.2 Liquor stores: Liquor stores are available in certain buildings/units/Malls. Since liquor is

flammable and a polar solvent liquid (water miscible liquid), special type of foam compound namely

Alcohol Resistant - AFFF (AR - AFFF) is an effective extinguishing media to deal with such alcohol

fires. The FHC near to liquor store should be provided with 01 can of Alcohol Resistant - AFFF (AR -

AFFF) foam compound and 01 Foam making branch FB 5X. This FHC should be provided with a

signage “EQUIPPED WITH ALCOHOL RESISTANT- AFFF & FB 5X”. The signage should be on the

FHC Glass

7.1.3 DG Room: Diesel being the fuel for DG sets, foam fire fighting arrangement is essential near

DG Rooms. This can be met by providing one Foam Making Branch(FB 5X) &1 Can of AFFF Foam

compound in the FHCs near to the DG Rooms, minimum two nearest FHCs, preferably near the

entrances (if the DG Room has two different entrances & FHCs are available there, both entrances

should have foam fire fighting facilities). This FHC should be provided with a signage “EQUIPPED

WITH AFFF & FB 5X”. The signage should be on the FHC Glass.

7.1.4 Building Basements: Since basements are extensively used for car parking there could be

possibility of fuel related fires. In order to deal with such situations, in the basement each alternate

FHCs in each row should be provided with one Foam making branch (FB 5X) & 1 Can of AFFF foam

Compound. This FHC should be provided with a signage “EQUIPPED WITH AFFF & FB 5X”. The

signage should be on the FHC Glass.

7.1.5 Fire Control Room: One Foam Branch(FB 5X) & one 20 litre Can of AFFF Foam Compound

should be kept in the Fire Control room so that in case of fire at any location, the foam branch& foam

compound would be readily available.

7.2 AFFF FOAM COMPOUND

7.2.1 The Aqueous Film Forming Foam (AFFF) shall be of 3% Concentration and shall have BIS

Certification (ISI Marking for the Product). The foam compound shall have minimum 5 years shelf life.

The foam compound shall be supplied in 20 litres ISI Marked jerry can.

Page 4 of 7 Date of Revision: 14.05.22 IMS-EG-002-VER 02

7.2.2 For proper identification, a label should be provided on the jerry can of foam compound. In the

case of AFFF foam compound, the label should be “AFFF Foam Compound” and in the case of

alcohol resistant foam compound the label should be “ALCOHOL RESISTANT-AFFF”. In both the

cases, the date of manufacture of the foam compound should be marked on the jerry Can.

7.3 RESERVE STORAGE OF AFFF & FOAM MAKING BRANCH

7.3.1 Commercial buildings, Energy Centres & Malls AFFF

Foam compound 4 x 20 litres = 80 litres

Buildings having liquor store should maintain alcohol resistant foam compound 2 X 20

Litres = 40 litres

FB 5X foam making branch = 3 Nos.

7.4 INSPECTION, MAINTENANCE & TRAINING : The foam making branch should be physically

inspected along with FHC inspection/ maintenance schedule. However, quarterly testing of foam

making branch should be carried-out. During the quarterly testing the Fire team should be given

training on proper operation of foam making branch by using foam compound.

7.4 OPERATION/USAGE OF FB 5X FOAM BRANCH WITH FOAM COMPOUND:

The general guidance for the usage of Foam making branch FB 5X along with foam compound from

Can, using direct foam induction method is given below: -

1. Lay the fire hose from the source of water i.e. landing valve.

Page 5 of 7 Date of Revision: 14.05.22 IMS-EG-002-VER 02

2. Connect the pick-up tube with the Foam making branch 5X and ensure that the connection of pick up

tube with branch is air tight through washer.

3. Connect the foam making branch with female instantaneous coupling of the delivery hose.

4. Set the lever of the branch on water ON mode.

Page 6 of 7 Date of Revision: 14.05.22 IMS-EG-002-VER 02

5. Open the water and ensure that the requisite pressure and water is maintained.

6. Throw initially the water away from the oil fire.

7. Insert the pick-up tube in the foam container/Can and regulate the foam setting of branch. When it

produces foam then aim it for extinguishing the fire in such a way that foam blanket is formed on

the burning oil surface. The foam should be applied on the inner side wall of the burning liquid

container or in such way that foam falls generally on the surface.

Page 7 of 7 Date of Revision: 14.05.22 IMS-EG-002-VER 02

You might also like

- The Manufacture of Sterile Pharmaceuticals and Liquid Medical Devices Using Blow-Fill-Seal Technology: Points to ConsiderFrom EverandThe Manufacture of Sterile Pharmaceuticals and Liquid Medical Devices Using Blow-Fill-Seal Technology: Points to ConsiderNo ratings yet

- IMS-EG-006-VER 02 - Providing Fall Arrest SystemworkingDocument4 pagesIMS-EG-006-VER 02 - Providing Fall Arrest SystemworkingDINESH KUMARNo ratings yet

- IMS-EG-004-VER 02 - Fittings in STPDocument4 pagesIMS-EG-004-VER 02 - Fittings in STPDINESH KUMARNo ratings yet

- Supplementary Specification For StationkeepingDocument15 pagesSupplementary Specification For StationkeepingaseNo ratings yet

- Performance Standard for Cargo Tank CoatingsDocument2 pagesPerformance Standard for Cargo Tank CoatingsBouzid OussamaNo ratings yet

- No. 116 Performance Standard For Protective Coatings For Cargo Oil Tanks of Crude Oil Tankers No. 116Document2 pagesNo. 116 Performance Standard For Protective Coatings For Cargo Oil Tanks of Crude Oil Tankers No. 116aakhyar_2No ratings yet

- PR-DIV02-BTM-0001 Bolt Torquing Procedure SADARADocument10 pagesPR-DIV02-BTM-0001 Bolt Torquing Procedure SADARAvinothkumarNo ratings yet

- NDS-SOP-002 - Storage of AutoStem CartridgesDocument4 pagesNDS-SOP-002 - Storage of AutoStem CartridgesDiego VilaNo ratings yet

- Procedure For Surface Preparation and PaintingDocument11 pagesProcedure For Surface Preparation and Paintingtulasirao.nammiNo ratings yet

- 4251-RA-00379913 - D - 01 - Regulatory Compliance PlanDocument42 pages4251-RA-00379913 - D - 01 - Regulatory Compliance Plansivaguruswamy thangaraj100% (1)

- Reactor Boron System Operating ManualDocument51 pagesReactor Boron System Operating ManualvrajakisoriDasiNo ratings yet

- Asphalting Tank Foundation ProceduresDocument6 pagesAsphalting Tank Foundation ProceduresTim JalurNo ratings yet

- SEL-TBD-O-CA-001 R0 Process Simulation Report SignedDocument12 pagesSEL-TBD-O-CA-001 R0 Process Simulation Report Signedahmad santosoNo ratings yet

- rev01-METHOD STATEMENT FOR INSTALLATION OF LINER TANK FOUNDATIONDocument7 pagesrev01-METHOD STATEMENT FOR INSTALLATION OF LINER TANK FOUNDATIONMahaboob PashaNo ratings yet

- Procedure for Fireproofing InstallationDocument13 pagesProcedure for Fireproofing InstallationRodelio RemoNo ratings yet

- PR 1754Document42 pagesPR 1754Anjani PrabhakarNo ratings yet

- S-726 2021 Recommended Practice for Application of Subsea FastenersDocument13 pagesS-726 2021 Recommended Practice for Application of Subsea FastenersnickchoNo ratings yet

- NTF - Addendum To SP-1126Document6 pagesNTF - Addendum To SP-1126Deepak DubeyNo ratings yet

- Supplementary Specification For General Requirements For Offshore StructuresDocument8 pagesSupplementary Specification For General Requirements For Offshore StructuresaseNo ratings yet

- Ground Treatment SpecificationDocument11 pagesGround Treatment SpecificationaminNo ratings yet

- P05 - ProductionDocument14 pagesP05 - ProductionEDWARD ACHEAMPONGNo ratings yet

- PR-1948 - Electrical Safety Operating ProceduresDocument117 pagesPR-1948 - Electrical Safety Operating ProceduresSamsung JosephNo ratings yet

- Jms Site Preparation - RGTP p20220019 Esb Con Jms 9243 0001 - 1 Code 3Document11 pagesJms Site Preparation - RGTP p20220019 Esb Con Jms 9243 0001 - 1 Code 3amir hakim100% (1)

- Supplementary Specification For Concrete Offshore StructuresDocument13 pagesSupplementary Specification For Concrete Offshore StructuresaseNo ratings yet

- RDSO 2008 CG 06 Rev-1Document15 pagesRDSO 2008 CG 06 Rev-1Shiv PandeyNo ratings yet

- Drilling Program AZSE-4 v.1.1 SIGNEDDocument118 pagesDrilling Program AZSE-4 v.1.1 SIGNEDAli Boubenia100% (6)

- Cylinder With Piston Rod Round Cylinder, Corrosion-Resistant CRDG/CRDSWDocument15 pagesCylinder With Piston Rod Round Cylinder, Corrosion-Resistant CRDG/CRDSWpayaso1234No ratings yet

- Method Statement For Waterproofing InstallationDocument4 pagesMethod Statement For Waterproofing InstallationYurizal firmansyahNo ratings yet

- Ed Well ControlDocument18 pagesEd Well ControlAmeer BabylonianNo ratings yet

- SP 1101Document49 pagesSP 1101Allocation ResourceNo ratings yet

- Coating Performance Standard (CPS) : Guide For The Class NotationDocument11 pagesCoating Performance Standard (CPS) : Guide For The Class NotationGilberto Zamudio100% (1)

- Storage, Handling & Refueling OF LPG For Automotive UseDocument41 pagesStorage, Handling & Refueling OF LPG For Automotive UseNaresh DharmaNo ratings yet

- SP-2034 Ver 1 Specification For Internal FBE Coating of Line Pipe (Amendment - Suppliment To API RP 5L7) (Sep 05)Document21 pagesSP-2034 Ver 1 Specification For Internal FBE Coating of Line Pipe (Amendment - Suppliment To API RP 5L7) (Sep 05)Devam RajNo ratings yet

- DG Pse 0104 PDFDocument24 pagesDG Pse 0104 PDFErika Caicedo100% (1)

- Indian Railways: Ref: CG-WI-4.2.1-1 Ver.-1.0 Page 1 of 14 Date of Issue October 2018 Spec. NoDocument14 pagesIndian Railways: Ref: CG-WI-4.2.1-1 Ver.-1.0 Page 1 of 14 Date of Issue October 2018 Spec. NoMohitrajranikashyapNo ratings yet

- Super Duplex Valve PDFDocument87 pagesSuper Duplex Valve PDFMohamed YousufNo ratings yet

- SP-2047 - Preparation & Content of Engineering DrawingsDocument56 pagesSP-2047 - Preparation & Content of Engineering Drawingsarjunprasannan7No ratings yet

- SP-1012 Health Safety Environment & Sustainable Development - Specification for Land ManagementDocument21 pagesSP-1012 Health Safety Environment & Sustainable Development - Specification for Land ManagementnickchoNo ratings yet

- Specification For Land Management: Petroleum Development Oman L.L.C. Health Safety Environment & Sustainable DevelopmentDocument21 pagesSpecification For Land Management: Petroleum Development Oman L.L.C. Health Safety Environment & Sustainable DevelopmentHari Prakash GrandheyNo ratings yet

- Supplementary Specification To API 17D Subsea Trees: DecemberDocument42 pagesSupplementary Specification To API 17D Subsea Trees: DecemberAlejandro Sánchez LópezNo ratings yet

- Supplementary Spec To API Specification 17D Subsea Wellhead and Tree Equipment With Justifications S 561Jv2022 11Document81 pagesSupplementary Spec To API Specification 17D Subsea Wellhead and Tree Equipment With Justifications S 561Jv2022 11maximusala83No ratings yet

- Jms Site Preparation - RGTP p20220019 Esb Con Jms 9243 0013Document11 pagesJms Site Preparation - RGTP p20220019 Esb Con Jms 9243 0013amir hakimNo ratings yet

- Laboratory Procedure CHAPELDocument7 pagesLaboratory Procedure CHAPELRapha MarxNo ratings yet

- SP-1121 - Specification For Low Voltage Switchgear and Control AssemblieDocument22 pagesSP-1121 - Specification For Low Voltage Switchgear and Control AssemblieSALAM JAIGADKAR100% (1)

- OmanDocument20 pagesOmanvdhivyaprabaNo ratings yet

- Method Statement: Underground Waterproofing Using Hdpe Waterproofing System From FosrocDocument10 pagesMethod Statement: Underground Waterproofing Using Hdpe Waterproofing System From Fosrocdindo lauronNo ratings yet

- Apcs-113a Method StatmentDocument7 pagesApcs-113a Method StatmentNoman AhmedNo ratings yet

- Well Maintenance ProceduresDocument17 pagesWell Maintenance ProceduresDanian Primasatrya100% (1)

- Flange Management ProcedureDocument22 pagesFlange Management ProcedureDarrel Espino AranasNo ratings yet

- S-562Qv19-01 Quality Requirements For Ball ValvesDocument13 pagesS-562Qv19-01 Quality Requirements For Ball ValvesDANIEL PEREZ100% (1)

- Wbs Handbook v1Document14 pagesWbs Handbook v1Sobe ThapaNo ratings yet

- Proposal For Facade Repair Work, Mill Building Phase.1Document1 pageProposal For Facade Repair Work, Mill Building Phase.1fernando gultomNo ratings yet

- Material Submittal For WPCDocument92 pagesMaterial Submittal For WPCdocument PlasmaNo ratings yet

- Gen Spec For D Design and Engineering Erd-10-04Document85 pagesGen Spec For D Design and Engineering Erd-10-04kattabommanNo ratings yet

- Area Classification - DeP 80.00.10.10-GenDocument12 pagesArea Classification - DeP 80.00.10.10-GenShanying Peng100% (1)

- Explanatory Notes For Industry On The Preparation of A Site Master FileDocument22 pagesExplanatory Notes For Industry On The Preparation of A Site Master FilehuykhiemNo ratings yet

- Exon Mobile Drilling Guide PDFDocument318 pagesExon Mobile Drilling Guide PDFPwint Phoo100% (3)

- Gas and LFF Ready Guide Mar22Document14 pagesGas and LFF Ready Guide Mar22Elmer MissiorNo ratings yet

- HSE Specification - Land ManagementDocument21 pagesHSE Specification - Land ManagementAshraf MohammedNo ratings yet

- Illuminism - The Occult Force Behind Globalization - by Wes PenreDocument98 pagesIlluminism - The Occult Force Behind Globalization - by Wes Penrebreiard100% (1)

- Rethinking Classroom Assessment With Purpose in MindDocument112 pagesRethinking Classroom Assessment With Purpose in MindlykkhaiNo ratings yet

- Invoice Being Charged Sued If or Violation Has This in Wrongful - RightfulDocument67 pagesInvoice Being Charged Sued If or Violation Has This in Wrongful - RightfulSteven SchoferNo ratings yet

- 2009 - Mazars Insight Ifrs 5 enDocument36 pages2009 - Mazars Insight Ifrs 5 enSahar FekihNo ratings yet

- Jerome KaganDocument5 pagesJerome KaganMandeep morNo ratings yet

- Class Record (Science 9) S.Y. 2020-2021Document8 pagesClass Record (Science 9) S.Y. 2020-2021Wilmar EspinosaNo ratings yet

- Thesis FormatDocument10 pagesThesis FormatMin Costillas ZamoraNo ratings yet

- Kawai MP7 Owner's ManualDocument148 pagesKawai MP7 Owner's ManualMiloNo ratings yet

- Generator Honda EP2500CX1Document50 pagesGenerator Honda EP2500CX1Syamsul Bahry HarahapNo ratings yet

- Coding and Decoding Practice TestDocument13 pagesCoding and Decoding Practice TestRaja SubramanianNo ratings yet

- Lecture 4 - Animated Data VisualizationDocument35 pagesLecture 4 - Animated Data VisualizationAnurag LaddhaNo ratings yet

- IBM Global Business ServicesDocument16 pagesIBM Global Business Servicesamitjain310No ratings yet

- Landmark Church School WBSDocument4 pagesLandmark Church School WBSbayoNo ratings yet

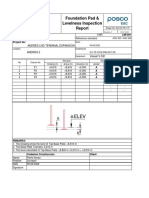

- SG CD FR 175 Levelness V 531 Lmi 001 Firmar SellarDocument1 pageSG CD FR 175 Levelness V 531 Lmi 001 Firmar SellarLuis VelazcogarciaNo ratings yet

- Final MTech ProjectDocument30 pagesFinal MTech ProjectArunSharmaNo ratings yet

- The Effect of Online Game Addiction To TheDocument5 pagesThe Effect of Online Game Addiction To TheRafuell Amper CablasNo ratings yet

- Creutzfeldt JakobDocument6 pagesCreutzfeldt JakobErnesto Ochoa MonroyNo ratings yet

- Excel Case Study 1 - DA - Questions With Key AnswersDocument56 pagesExcel Case Study 1 - DA - Questions With Key AnswersVipin AntilNo ratings yet

- Department of Education: Republic of The PhilippinesDocument51 pagesDepartment of Education: Republic of The PhilippinesChrystal Khey MendozaNo ratings yet

- Philippine Poetry:: It's Form, Language, and SpeechDocument12 pagesPhilippine Poetry:: It's Form, Language, and SpeechRis AsibronNo ratings yet

- Verification and Validation in Computational SimulationDocument42 pagesVerification and Validation in Computational SimulationazminalNo ratings yet

- Developmental AssessmentDocument15 pagesDevelopmental AssessmentShailesh MehtaNo ratings yet

- PDFDocument478 pagesPDFPriyaranjan PradhanNo ratings yet

- ACCA107 Strategic Cost Management Quiz #2Document3 pagesACCA107 Strategic Cost Management Quiz #2Nicole Anne Santiago SibuloNo ratings yet

- Why I Am Not A Primitivist - Jason McQuinnDocument9 pagesWhy I Am Not A Primitivist - Jason McQuinnfabio.coltroNo ratings yet

- Bachelor Thesis MaritimeDocument43 pagesBachelor Thesis MaritimeMiriam PedersenNo ratings yet

- ROM Laboratory v1.00Document548 pagesROM Laboratory v1.00Carlos Reaper Jaque OlivaresNo ratings yet

- Cook's Illustrated 090Document36 pagesCook's Illustrated 090vicky610100% (3)

- How to introduce yourself in 60 secondsDocument15 pagesHow to introduce yourself in 60 secondsJaneGuinumtadNo ratings yet

- Centrifuge PDFDocument11 pagesCentrifuge PDFسراء حيدر كاظمNo ratings yet