Professional Documents

Culture Documents

Work Method Statement

Uploaded by

Ivan Ace OseaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Work Method Statement

Uploaded by

Ivan Ace OseaCopyright:

Available Formats

PHILIPPINE GRANITE STONE CORPORATION

4th FLOOR # 65 Olympic Bldg. Sen. Gil Puyat Ave. Makati City

Tel/Fax: 8887-2306

Email Add: sales-pgsc@primegroup.ph

Work Method Statement for Granite Wall Cladding

INTRODUCTION

This Work Method Statement is to ensure the floor and wall covering is carried out in a

controlled and systematic manner that in all respect confirm to the specification.

CONSTRUCTION METHODS AND TECHNOLOGY

A. Handling Material

1. Temporary Storage Area

Upon arrival of the crates at the temporary storage area, check the

quantity of the stone against the purchase order and the delivery order

to ensure that the correct quantity and crate number are delivered to

site.

Unload the crates to the specific area in the temporary storage area.

The crates shall be stored sector by sector for retrieval when they are

required to be transported to the required area.

2. Installation Location

At the respective floor, the crates will be conveyed to the respective

installation location where they are required for installation.

Open the crates and remove the crates for installation.

B. Grouting/ Pointing

1. Internal Dry Areas

Granite joints should be grouted with Fine Grout, colored, water

resistant, cement based suitable for joints up to 3mm wide.

When grouting to internal dry areas, mix grout with clean water only.

Mix until a uniform colored, thin creamy consistency is obtained.

2. Internal Wet Areas

Granite joints should be grouted with Fine Grout, colored, water

resistant, cement based suitable for joints up to 3mm wide.

When grouting to internal dry areas, mix grout with clean water only.

Mix until a uniform colored, thin creamy consistency is obtained.

Grout offers greater resistant to penetration of water, improved

durability, flexural strength, compressive strength and adhesion to side

of granites.

Allocate joints of approximately 2mm wide between granite slabs.

Apply grout with a rubber squeegee/ float and ensure that joints are

fully compacted with grouting material.

Clean excess grout promptly using a damp cloth or sponge.

Allow grout to set for at least 24-48 hours (preferably longer) before

granite slab installation are subjected to normal service condition.

General Consideration

Granite panels shall be installed about 100mm clear of wall.

All fixing accessories such as brackets, extension plate shall be made of

aluminum, washer, bolt nut shall be made of stainless steel.

PHILIPPINE GRANITE STONE CORPORATION

4th FLOOR # 65 Olympic Bldg. Sen. Gil Puyat Ave. Makati City

Tel/Fax: 8887-2306

Email Add: sales-pgsc@primegroup.ph

Where C-lipped channels to be used, it shall be hot-dipped galvanized (for sub-

framing).

All welding works shall be of fillet weld. Welding works done on site will be

dressed off welding spatters and coated over with galvanized paint.

Setting Out

Setting out shall be carried out based on reference points provided by the main

contractor.

Similarly gridlines are set out based on the control points provided by the main

contractor.

After all the levels and grid lines have been marked on each column/wall, the

position of the brackets.

Marked fabricated truss/channel position on column/wall.

Installation for Wall Finishes-Dry Method

1. Drill holes into column/wall to accommodate fixing accessories, using:

Long Plates or L brackets are welded on to the frame exactly marked for

the fixing of the granite panel.

Position of the bolts are marked exactly behind the granite panel to match

the location of the long plates or L brackets welded on the section frame.

Using a special machines holes are drilled behind the granite panes at the

exact position, approximately 20mm in depth.

The back bolt is fixed and tightened with nut and washer with extension

plates. Tis predrill back bolt granite panels will be hoisted to exact

locations of the welded L angle or plate.

During installation, the adjustable bolt slot hole will accommodate any

adjustment required about 20mm to suit site conditions.

2. Using pre-fabricate truss/ C-channel (where the design require sub-framing) -

Only when necessary or site condition confirm.

Insert anchor bolt into holes drilled in column/wall/beam/floor.

Mount prefabricated truss/vertical C-channel and tighten nut.

Check vertically and alignment of truss/channel.

Mount bracket/horizontal channel onto predrilled hole in truss/channel by

means of bolt and nut with washer. To the predrilled hole in the free length

of the bracket is inserted a dowel pin. Align the bracket with dowel pin,

embedded in Epoxy, in the predrilled holes in the granite slabs.

3. Apply approved sealant to the back and sides of the granite. Allow to dry.

4. Each piece of stone is supported at the back by four brackets bolted to plates or

L angle welded to the hollow section frame.

5. Ensure that the first (bottom) row of granite is aligned, leveled and properly fixed

on the hollow section frame.

6. The next row will be installed on top of the first row of slabs.

7. Check vertically and alignment of each slab.

8. Leave finished work square, regular, true to line, level and plane with satisfactory

at all junctions.

9. Tape a sheet of 1000g polystyrene over granite for protection of the installed

granite.

You might also like

- Acacia Senegal: Herbal Plants (Halamang Gamot)Document24 pagesAcacia Senegal: Herbal Plants (Halamang Gamot)SORENI SORENINo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- General Construction NotesDocument5 pagesGeneral Construction NotesPatricia Nicole ElediaNo ratings yet

- Final Friends Book 2 - The Dance - Christopher PikeDocument282 pagesFinal Friends Book 2 - The Dance - Christopher PikeNikie5100% (4)

- Contractors HandbookDocument43 pagesContractors HandbookVincent Mutambirwa100% (1)

- General SpecsDocument12 pagesGeneral SpecsKelvene Boy Bravo Silva100% (2)

- Wall and Floor Tiles Method Statment PDFDocument4 pagesWall and Floor Tiles Method Statment PDFAli SaifNo ratings yet

- Multiple Myeloma Case Studies (Tandem 2017) (Final)Document52 pagesMultiple Myeloma Case Studies (Tandem 2017) (Final)Syed Ali Akbar100% (2)

- How to Build a Simple Three Bedroom Shipping Container HouseFrom EverandHow to Build a Simple Three Bedroom Shipping Container HouseRating: 4 out of 5 stars4/5 (2)

- Brick Veneer WallDocument16 pagesBrick Veneer Wallpilapil_jNo ratings yet

- Specifications - Proposed Four Storey Apartment BuildingDocument6 pagesSpecifications - Proposed Four Storey Apartment BuildingEpp0% (1)

- Block Works & Plastering DraftDocument4 pagesBlock Works & Plastering DraftEljo AndsNo ratings yet

- General Specifications Allanalbano (2524)Document7 pagesGeneral Specifications Allanalbano (2524)Allan AlbanoNo ratings yet

- SpecificationsDocument20 pagesSpecificationsJohn Dominic Delos ReyesNo ratings yet

- Scope of Work DuplexDocument7 pagesScope of Work Duplexjet toledo100% (1)

- Building SpecificationsDocument7 pagesBuilding SpecificationsElvin PrestoNo ratings yet

- Anite WorkDocument4 pagesAnite WorkShenbagaraja PandianNo ratings yet

- How to Build a Global Model Earthship Operation II: Concrete WorkFrom EverandHow to Build a Global Model Earthship Operation II: Concrete WorkNo ratings yet

- BrickworksDocument17 pagesBrickworksSyerifaizal Hj. MustaphaNo ratings yet

- Transfusion Reaction - DRGSPDocument42 pagesTransfusion Reaction - DRGSPGaurav PawarNo ratings yet

- Method Statement For Tiling WorkDocument4 pagesMethod Statement For Tiling WorkMaca100% (1)

- Method Statement For: Tiling WorkDocument5 pagesMethod Statement For: Tiling WorkHussam Waleed100% (2)

- Inspection and Test Plan For Pressure VesselDocument2 pagesInspection and Test Plan For Pressure Vesselalokbdas50% (2)

- Masonry & PlasteringDocument18 pagesMasonry & PlasteringlavekushNo ratings yet

- Work InstructionsDocument9 pagesWork InstructionsHariom GuptaNo ratings yet

- Needle Point Tracing Centric RelationDocument12 pagesNeedle Point Tracing Centric RelationAmar BhochhibhoyaNo ratings yet

- Construction SpecificationDocument9 pagesConstruction SpecificationYeth SantosNo ratings yet

- Wall Tiles MethodologyDocument5 pagesWall Tiles MethodologyASHOKKUMARNo ratings yet

- Method Statement - Plastering, Dated. Jan. 03. 2007Document5 pagesMethod Statement - Plastering, Dated. Jan. 03. 2007mohamed4879No ratings yet

- Is 777 For Glazed TilesDocument15 pagesIs 777 For Glazed TilesMadhu BabuNo ratings yet

- XB-1000 Service Manual New PDFDocument21 pagesXB-1000 Service Manual New PDFMuhammad KhizarNo ratings yet

- Specifications: Project: Owner:: LocationDocument6 pagesSpecifications: Project: Owner:: LocationMaria Theresa AlarconNo ratings yet

- Work Method Statement For PlasterDocument8 pagesWork Method Statement For Plasterronaldo aguirreNo ratings yet

- b405 Manual SM - BvU3 2021Document886 pagesb405 Manual SM - BvU3 2021Andres PerezNo ratings yet

- Method Statement For Cement PlasteringDocument6 pagesMethod Statement For Cement PlasteringYazhisai SelviNo ratings yet

- Succession Definition To Codicils (Follow The Outline)Document7 pagesSuccession Definition To Codicils (Follow The Outline)Thalia SalvadorNo ratings yet

- Becca SpecsDocument11 pagesBecca SpecsAlyanna Panganiban100% (1)

- C. 7.4 - Construction MethodsDocument4 pagesC. 7.4 - Construction MethodsJhoycee MiclatNo ratings yet

- 6.gypsum WorkDocument7 pages6.gypsum WorkShenbagaraja PandianNo ratings yet

- Method StatementDocument7 pagesMethod StatementTenuki JapanNo ratings yet

- MOS (Installation of Ceramic Tile) REV2Document3 pagesMOS (Installation of Ceramic Tile) REV2Don Roseller DumayaNo ratings yet

- Method of Statement For PlasteringDocument6 pagesMethod of Statement For PlasteringScott Campbell100% (3)

- Fresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoFrom EverandFresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoNo ratings yet

- Method of Statement For Granite LayingDocument4 pagesMethod of Statement For Granite Layingjohn paulNo ratings yet

- Technical Specifications MidsayapDocument9 pagesTechnical Specifications MidsayapDAP Ysabelle Marie FuentesNo ratings yet

- Technical Specifications: Project: Location: OwnerDocument7 pagesTechnical Specifications: Project: Location: Ownerjay vasquezNo ratings yet

- General Specifications: 1. EarthworksDocument7 pagesGeneral Specifications: 1. Earthworksenvironmental100% (1)

- Project 02 SpecificationDocument16 pagesProject 02 SpecificationDUMLAO, ANGELIE M.No ratings yet

- SPECS2020Document3 pagesSPECS2020nadzimar maquilingNo ratings yet

- MOS (Installation of Ceramic Tile) REV2Document3 pagesMOS (Installation of Ceramic Tile) REV2Eva MarquezNo ratings yet

- Method of Statement: Project Comprehensive MaintenanceDocument32 pagesMethod of Statement: Project Comprehensive MaintenanceShahd JaberNo ratings yet

- Technical SpecificationsDocument3 pagesTechnical SpecificationsJohnNo ratings yet

- Used Water SES 6 Building Works 2012Document29 pagesUsed Water SES 6 Building Works 2012Mark BenjieNo ratings yet

- Material and Finishes SpecificationsDocument8 pagesMaterial and Finishes SpecificationsAldrin Ron MamarilNo ratings yet

- Construction Specifications Sample TemplateDocument7 pagesConstruction Specifications Sample TemplateSheila Marie DomalantaNo ratings yet

- Chapter I. A: Rchitecture Wooden WorkDocument17 pagesChapter I. A: Rchitecture Wooden WorkFengwei ShihNo ratings yet

- Material SpecsDocument4 pagesMaterial SpecsSharon AtanacioNo ratings yet

- Specifications - BUILDING PERMIT - LANIE SISTERWAYDocument4 pagesSpecifications - BUILDING PERMIT - LANIE SISTERWAYCivil EngineerNo ratings yet

- Mathodologies of Various ActivityDocument17 pagesMathodologies of Various Activitynikunj patelNo ratings yet

- Method Statement CMC HotakenaDocument7 pagesMethod Statement CMC HotakenaroshanNo ratings yet

- Construction MethodologyDocument6 pagesConstruction Methodologyadrianalbacete75No ratings yet

- PlasterDocument2 pagesPlastermrameshceNo ratings yet

- Architectural Treatment For Joint GapsDocument25 pagesArchitectural Treatment For Joint GapsRoze-Anne JopsonNo ratings yet

- Method Statement For Drywall Work: Installation GuideDocument2 pagesMethod Statement For Drywall Work: Installation GuideMacaNo ratings yet

- 050920221630-Technical SpeC For Interior Civil2 ND FlCCGRO EastDocument17 pages050920221630-Technical SpeC For Interior Civil2 ND FlCCGRO EastSherif El-SabbahyNo ratings yet

- I. Sitework A. Work IncludedDocument6 pagesI. Sitework A. Work IncludedLouie Jay PoligratesNo ratings yet

- Squash Court Finish PDFDocument5 pagesSquash Court Finish PDFFrancis T. TolibasNo ratings yet

- Item Particular Dedailed Specification 1 Site Clearing: MortarDocument11 pagesItem Particular Dedailed Specification 1 Site Clearing: MortarcantybuoyNo ratings yet

- Foundation & Construction EngineeringDocument20 pagesFoundation & Construction Engineeringamitkap00rNo ratings yet

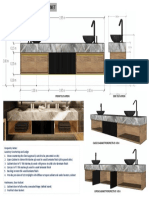

- For Supplier Reference (Countertop) - 5Document1 pageFor Supplier Reference (Countertop) - 5Ivan Ace OseaNo ratings yet

- For Supplier Reference (Countertop) - 4Document1 pageFor Supplier Reference (Countertop) - 4Ivan Ace OseaNo ratings yet

- For Supplier Reference (Countertop) - 7Document1 pageFor Supplier Reference (Countertop) - 7Ivan Ace OseaNo ratings yet

- Dirty Kitchen - Arch - Coscolluella-Layout1Document1 pageDirty Kitchen - Arch - Coscolluella-Layout1Ivan Ace OseaNo ratings yet

- Chapter 9: Managing Crises and National EmergenciesDocument3 pagesChapter 9: Managing Crises and National EmergenciesJayson TasarraNo ratings yet

- E.coli Validation 3m AoacDocument26 pagesE.coli Validation 3m AoacAbdulrahmanNo ratings yet

- GASBRAYTONDocument16 pagesGASBRAYTONJohnCris B. FornilosNo ratings yet

- Employment Contract (Repaired)Document4 pagesEmployment Contract (Repaired)dagz10131979No ratings yet

- Safety Data Sheet: Valvoline Valplex EP GreaseDocument7 pagesSafety Data Sheet: Valvoline Valplex EP Greasediah ayuNo ratings yet

- Third Conditional Gap Filling - 50140Document1 pageThird Conditional Gap Filling - 50140Jose santiago Bernal foreroNo ratings yet

- Hodgkin-Huxley Model and Fitzhugh-Nagumo ModelDocument15 pagesHodgkin-Huxley Model and Fitzhugh-Nagumo ModelGobiNo ratings yet

- Soal - Orthopedi No No 1Document3 pagesSoal - Orthopedi No No 1Harry CenNo ratings yet

- Translation and Cultural Adaptation of The States of Consciousness Questionnaire (SOCQ) and Statistical Validation of The Mystical Experience Questionnaire (MEQ30)Document5 pagesTranslation and Cultural Adaptation of The States of Consciousness Questionnaire (SOCQ) and Statistical Validation of The Mystical Experience Questionnaire (MEQ30)Douglas SouzaNo ratings yet

- DCF Report January 1, 2018Document2 pagesDCF Report January 1, 2018Julia JenaeNo ratings yet

- Sysmex MDADocument10 pagesSysmex MDAAahsan Iqbal احسن اقبالNo ratings yet

- LG Microwave Manual (MS-2348BS - & - MS-2349EB)Document32 pagesLG Microwave Manual (MS-2348BS - & - MS-2349EB)nitinpariharNo ratings yet

- Drug Calculation - IV Fluids CalculationDocument3 pagesDrug Calculation - IV Fluids Calculationchristy INo ratings yet

- Alfa Laval Shell-And-tube Water Cooled CondensersDocument20 pagesAlfa Laval Shell-And-tube Water Cooled CondensersKarthik HegdeNo ratings yet

- Sistem Terpadu Akademik Reguler UMSDocument1 pageSistem Terpadu Akademik Reguler UMSMuhammad WilliNo ratings yet

- Tucson Emission Control System 2.0Document19 pagesTucson Emission Control System 2.0wilder0l0pezNo ratings yet

- Service Manual Dptv305 Dptv310 Dptv315 Dptv330 Dptv335 Dptv340 Dptv345 51mp392h-17 Chassis Mag01 7Document1,848 pagesService Manual Dptv305 Dptv310 Dptv315 Dptv330 Dptv335 Dptv340 Dptv345 51mp392h-17 Chassis Mag01 7brianatwoodNo ratings yet

- Resolution PDFDocument5 pagesResolution PDFRaj BishtNo ratings yet

- SF9 CardDocument2 pagesSF9 CardJohn Marion CapunitanNo ratings yet

- LMENIM1401Document106 pagesLMENIM1401Parameswararao BillaNo ratings yet

- End PointsDocument22 pagesEnd Pointsnikhil1802No ratings yet